- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA95-3 Wheel Loader Operation and Maintenance Manual VEAM980200

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: VEAM980200

- Format: PDF

- Size: 8.5MB

- Number of Pages: 198

-

Model List:

- WA95-3 Wheel Loader

- 1. MAIN MENU

- 2. COVER

- 3. Table of Contents

- 4. Introduction

- 4.1. Forword

- 4.2. Safety Information

- 4.3. Introduction

- 4.3.1. Features

- 4.3.2. Breaking in a New Machine

- 4.4. Location of Plates, Table to Enter Serial No. and Distributor

- 4.4.1. Machine Serial No. Plate position

- 4.4.2. Engine Serial No. Plate Position

- 4.4.3. Table to Enter Serial No. and Distributor

- 4.5. Why You Should Read these Operating Instructions

- 4.6. Notes on Safety Regulations

- 4.6.1. Correct Use

- 4.6.2. Safety Notes in the Operating Instructions

- 4.7. Equipment

- 5. Loading and Transporting the Machine

- 5.1. Loading and Transporting the Machine

- 5.1.1. Securing the Articulated Steering

- 5.1.2. Lifting the Machine

- 5.1.3. Driving Machine Onto Loading Area of Transport Vehicle

- 5.1.4. Securing the Machine During Transport

- 5.1.5. After Transport

- 6. Safety

- 6.1. General Safety Measures

- 6.1.1. Safety Instructions

- 6.1.2. Safety Devices

- 6.1.3. Emergency Exit

- 6.1.4. Clothing and Personal Protection

- 6.1.5. Machine Modifications

- 6.1.6. Before You Leave the Drivers Seat

- 6.1.7. Mounting and Dismounting

- 6.1.8. Fire Prevention and Fire Fighting

- 6.1.9. Protection Against Asbestos Dust

- 6.1.10. Protection Against Injuries

- 6.1.11. Working at High Temperatures

- 6.1.12. RollOver Protection System (ROPS)

- 6.1.13. Attachment for Protection Against Falling Objects (FOPS)

- 6.1.14. Attachments

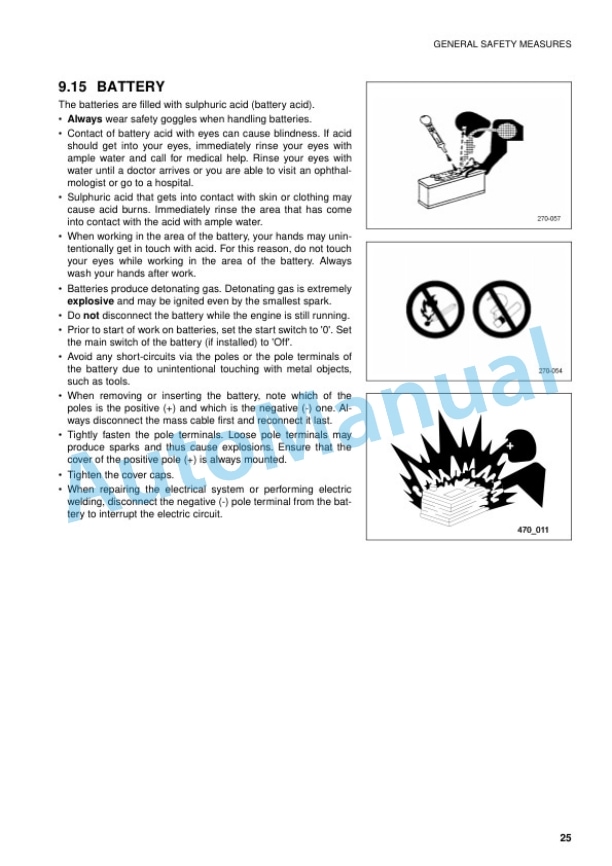

- 6.1.15. Battery

- 6.2. Safety Measures during Operation

- 6.2.1. Before You Start the Engine

- 6.2.2. Machine Operation

- 6.2.3. Transport

- 6.3. Safety Measures During Maintenance

- 6.3.1. Personnel

- 6.3.2. Prior to Start of Maintenance Measures

- 6.3.3. During Maintenance

- 6.3.4. Tires

- 6.4. Labeling

- 6.4.1. Position of Safety Labels

- 6.4.2. Position of Standard Labels

- 7. Controls and Indicators

- 7.1. General View of the Machine

- 7.2. Controls and Indicators

- 7.2.1. General View

- 7.2.2. Instrument Panel

- 7.2.3. Warning Lights

- 7.2.4. Control Lamps

- 7.2.5. Measuring Indicators

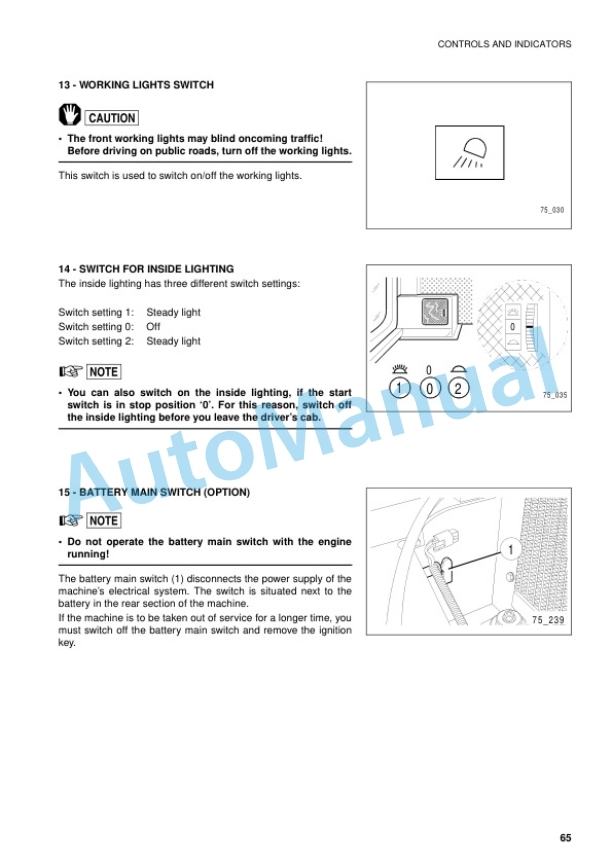

- 7.2.6. Switches

- 7.2.7. Control Levers, Pedals

- 7.2.8. Articulated Steering Catch

- 7.2.9. Traction Device

- 7.2.10. Socket

- 7.2.11. Door Unlocking System

- 7.2.12. Alarm Horn for Reverse Driving

- 8. Operation

- 8.1. Running in the Machine

- 8.2. Preparing the Machine Start

- 8.2.1. Visual Checks

- 8.3. Adjustments Prior to Machine Start

- 8.3.1. Adjusting the Drivers Seat

- 8.3.2. Adjusting the Steering Column

- 8.3.3. Adjusting the Armrest

- 8.3.4. Adjusting the RearView Mirrors

- 8.3.5. Adjusting the Heating and Ventilation System

- 8.3.6. Putting on the Safety Belt

- 8.4. Starting and Switching Off the Engine

- 8.4.1. Starting the Engine

- 8.4.2. Switching Off the Engine

- 8.5. Driving

- 8.5.1. StartUp

- 8.5.2. Changing the Driving Direction

- 8.5.3. Reverse Driving

- 8.5.4. Turning

- 8.5.5. Braking

- 8.5.6. Stopping

- 8.5.7. LongerDistance Driving

- 8.6. Operating the Machine

- 8.6.1. Preparing the Work Equipment

- 8.6.2. Tire Service Life

- 8.6.3. Loading

- 8.6.4. Transporting

- 8.6.5. Dumping / Unloading

- 8.6.6. Planing

- 8.6.7. Working With the Forklift Truck Attachment

- 8.6.8. Precautions For Special Operations

- 8.6.9. After the work is finished

- 8.6.10. Instructions for Winter Operation

- 8.6.11. Longer Standstill Periods of the Machine

- 9. Troubleshooting

- 9.1. Troubleshooting

- 9.1.1. Warning Lights and Indicators

- 9.1.2. Electrical System

- 9.1.3. Engine

- 9.1.4. Hydraulic system

- 9.1.5. Brakes

- 9.1.6. Axles

- 9.1.7. Emergency Steering Characteristics

- 9.1.8. Emergency Lowering System

- 9.1.9. Starting the Engine with a Battery Jumper Cable

- 9.1.10. Starting the Engine

- 9.1.11. Towing the Machine

- 9.1.12. Towing a Machine with Defective Brakes

- 10. Maintenance

- 10.1. Maintenance Basics

- 10.1.1. Preparing the Machine for Maintenance

- 10.1.2. Cleaning the Machine

- 10.1.3. WorkingAreaDependent Maintenance

- 10.1.4. Lubricants and Operating Agents

- 10.1.5. Replacing SafetyRelated Parts

- 10.1.6. Spare Parts and Consumable Components

- 10.1.7. Electrical System

- 10.1.8. Tires

- 10.1.9. Tools

- 10.1.10. Torque for Standard Nuts and Bolts

- 10.2. Maintenance Schedule

- 10.3. Maintenance Prior to Start

- 10.3.1. Visual Checks

- 10.3.2. Cooling System, Checking the Coolant Level, Topping off Coolant

- 10.3.3. Engine, Checking the Oil Level, Topping off Oil

- 10.3.4. Engine, Draining Off Oil

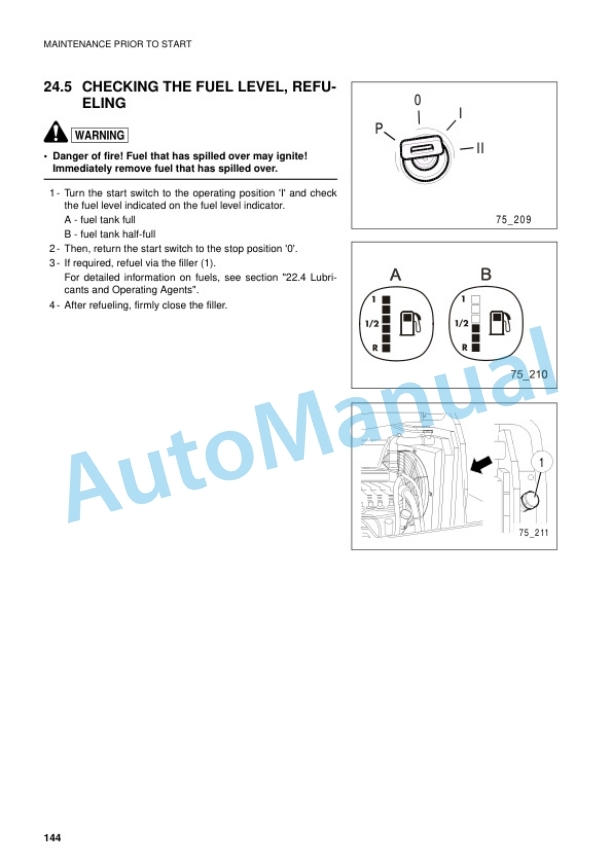

- 10.3.5. Checking the Fuel Level, Refueling

- 10.3.6. Checking the Controls

- 10.3.7. Checking the Parking Brake

- 10.3.8. Checking the Service Brake

- 10.3.9. Checking the Electrical Connections

- 10.3.10. Other Maintenance Measures Prior to Start

- 10.4. Maintenance Every 10 Operating Hours

- 10.4.1. Lubrication

- 10.5. Maintenance After the First 50 Operating Hours

- 10.5.1. Engine, Changing Oil and Replacing the Oil Filter Cartridge

- 10.5.2. VBelt, Checking the Condition

- 10.5.3. VBelt, Checking and Adjusting the Tension

- 10.5.4. Hydraulic System, Replacing the Filter Insert

- 10.5.5. Checking and Tightening the Wheel Nuts

- 10.5.6. Front and Rear Axle, Changing Oil

- 10.5.7. Transfer Gear Changing Oil

- 10.6. Maintenance Every 50 Operating Hours

- 10.6.1. Checking the cooling System, coolant level in the radiator and expansion tank

- 10.6.2. Draining Off Water and Dirt Deposits From the Fuel Tank

- 10.6.3. Checking the Service Brake and Oil Level, Refilling Oil

- 10.6.4. Checking the Battery and Acid Level

- 10.6.5. Lubrication

- 10.7. Maintenance Every 100 Operating Hours

- 10.7.1. Draining the Water Separator, Removing Water and Dirt Deposits

- 10.8. Maintenance Every 250 Operating Hours

- 10.8.1. Changing the Engine Oil and Oil Filter Cartridge

- 10.8.2. Checking the VBelt Condition

- 10.8.3. Checking and Adjusting the Vbelt Tension

- 10.8.4. Lubrication

- 10.8.5. Front and Rear Axle, Checking the Oil Level

- 10.8.6. Air Filter, Removing and ReInstalling the Filter Insert, Checking and Cleaning the Filter I…

- 10.8.7. Cleaning the Radiator Segments

- 10.9. Maintenance Every 500 Operating Hours

- 10.9.1. Changing the Fuel Filter and Filter Element

- 10.9.2. Changing the Filter Cartridge of the Hydraulic System

- 10.9.3. Cleaning the Water Separator

- 10.9.4. Lubrication

- 10.9.5. Transfer Gear, Checking the Oil Level and Refilling Oil

- 10.9.6. Air Filter, Replacing the Filter Insert, Replacing the Safety Filter

- 10.10. Maintenance Every 1000 Operating Hours

- 10.10.1. Cooling System, Exchanging Coolant and Cleaning the System

- 10.10.2. Front Axle, Oil Change

- 10.10.3. Rear Axle, Oil Change

- 10.10.4. Transfer Gear, Oil Change

- 10.10.5. Service Brake

- 10.10.6. Checking and Adjusting System Pressures

- 10.10.7. Checking and Adjusting the Valve clearance

- 10.10.8. Checking and Adjusting the Injection Nozzles, Nozzle Pressure and FuelJet Pattern

- 10.11. Maintenance Every 2000 Operating Hours

- 10.11.1. Hydraulic System, Oil Change

- 10.11.2. Bleeding the Hydraulic Oil Tank

- 10.11.3. Cooling System, Checking the Antifreeze Content of the Coolant

- 10.11.4. Checking the Cooling System

- 10.11.5. Checking the Fuel Pump

- 10.11.6. Checking the Fuel and Coolant Tubes, Replacing the Tubes (if required)

- 10.11.7. Checking the Water Pump

- 10.11.8. Checking and Adjusting the Fuel Injection and Injection time

- 10.11.9. Engine, Intake Valves and Outlet Valves Grinding In the Valve Bases

- 11. Technical Data

- 11.1. Technical Data

- 11.1.1. Noise Emission Levels

- 11.1.2. Vibration Level

- 11.1.3. Limit Values for Slopes

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF