- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WB140PS-2N, WB150PS-2N Backhoe Loader Shop Manual CEBM011100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM011100

- Format: PDF

- Size: 101.6MB

- Number of Pages: 498

Category: Komatsu Shop Manual PDF

-

Model List:

- WB140PS-2N Backhoe Loader

- WB150PS-2N Backhoe Loader

- 0.1. GENERAL

- 0.2. HOW TO READ THE SHOP MANUAL

- 0.2.1. VOLUMES

- 0.2.2. DISTRIBUTION AND UPDATING

- 0.2.3. FILING METHOD

- 0.2.4. REVISED EDITION MARK

- 0.2.5. REVISIONS

- 0.2.6. SYMBOLS

- 0.3. HOISTING INSTRUCTIONS

- 0.3.1. HOISTING

- 0.3.2. WIRE ROPES

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.5.1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

- 0.5.2. TIGHTENING TORQUE OF HOSE NUTS

- 0.5.3. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 0.5.4. TIGHTENING TORQUE FOR FLARED NUTS

- 0.6. ELECTRIC WIRE CODE

- 0.6.1. CLASSIFICATION BY THICKNESS

- 0.6.2. CLASSIFICATION BY COLOR AND CODE

- 0.7. CONVERSION TABLES

- 0.7.1. METHOD OF USING THE CONVERSION TABLE

- 1. STRUCTURE AND FUNCTION

- 1.1. POWER TRAIN

- 1.2. TRANSMISSION

- 1.2.1. DIAGRAM OF THE POWER TRAIN

- 1.2.2. HYDRAULIC CONVERTERTRANSMISSION CIRCUIT DIAGRAM

- 1.3. TRANSMISSION

- 1.4. DRIVE SHAFTS

- 1.4.1. DRIVE SHAFT FOR FORWARD AND REVERSE MOVEMENT

- 1.4.2. DRIVE SHAFT

- 1.4.3. DRIVEN GEAR SHAFT

- 1.4.4. DRIVEN SHAFT 4WD

- 1.5. CONTROL VALVE BLOCK

- 1.5.1. FRONT AXLE

- 1.5.2. FINALREDUCTIONJOINT

- 1.5.3. STEERING CYLINDER

- 1.6. REAR AXLE

- 1.6.1. DIFFERENTIAL

- 1.6.2. FINAL REDUCTION

- 1.6.3. BRAKES

- 1.6.4. DIFFERENTIAL LOCKING

- 1.6.5. PC VALVE, LS VALVE, SERVO PISTON

- 1.6.6. WORKING MODE SOLENOID VALVE

- 1.7. STEERING UNIT

- 1.7.1. TECHNICAL DATA

- 1.7.2. OPERATION

- 1.8. HYDRAULIC CIRCUIT

- 1.9. SHOVEL CONTROL VALVE

- 1.9.1. SPOOL

- 1.9.2. SPOOL

- 1.10. BACKHOE CONTROL VALVE

- 1.10.1. SPOOL

- 1.10.2. SPOOL

- 1.10.3. SPOOL

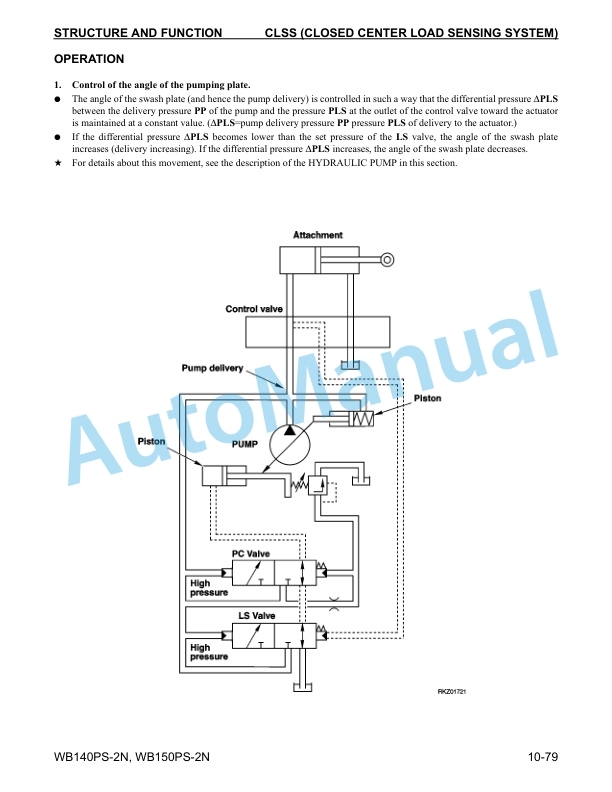

- 1.11. CLSS (CLOSED CENTER LOAD SENSING SYSTEM)

- 1.11.1. DESCRIPTION

- 1.11.2. UNLOADING VALVE

- 1.11.3. INTRODUCTION OF THE LS PRESSURE

- 1.11.4. DELIVERY COMPENSATION

- 1.11.5. LIFD CONTROL SYSTEM

- 1.11.6. LS DECOMPRESSION VALVE

- 1.11.7. PRESSURE CUTOFF VALVE

- 1.11.8. PRIORITY VALVE (ONLY FOR THE 23SPOOL CONTROL VALVE)

- 1.12. SOLENOID VALVE

- 1.12.1. SOLENOID VALVE BLOCK ST1 DIFFERENTIAL LOCKING BACKHOE BOOM LOCKING.

- 1.13. SAFETY VALVE

- 1.14. BRAKE PUMP

- 1.15. SHOVEL CYLINDERS

- 1.15.1. RAISING CYLINDER

- 1.15.2. DUMPING CYLINDER

- 1.15.3. DUMP CYLINDER

- 1.15.4. RAISE CYLINDER

- 1.16. BACKHOE CYLINDERS

- 1.17. BACKHOE CYLINDER MAINTENANCE STANDARD

- 1.18. FRONT WORKING EQUIPMENT

- 1.19. SWING BRACKET

- 1.20. BACKHOE WORK EQUIPMENT

- 1.21. AIRCONDITIONING UNIT

- 1.21.1. AIRCONDITIONING UNIT FUNCTION

- 2. TESTING, ADJUSTING AND TROUBLESHOOTING

- 2.1. NORMAL OR STANDARD TECHNICAL DATA

- 2.1.1. FOR ENGINE

- 2.1.2. FOR MACHINE

- 2.2. SPECIAL TOOLS

- 2.3. MEASURING ENGINE SPEED

- 2.4. ADJUSTING VALVE CLEARANCE

- 2.5. MEASURING COMPRESSION PRESSURE

- 2.6. FUEL INJECTION TIMING

- 2.7. FAN BELT

- 2.7.1. TENSION CHECK

- 2.7.2. FAN BELT TENSION

- 2.8. COMPRESSOR BELT

- 2.8.1. CHECKING TENSION

- 2.8.2. FAN BELT TENSION

- 2.9. ACCELERATOR PEDAL AND LEVER

- 2.9.1. OPERATING TRAVEL

- 2.10. BRAKE PEDAL AND ALIGNMENT

- 2.10.1. TRAVEL AND MICRO SWITCHES

- 2.11. AIR BLEEDING

- 2.11.1. RELEASING RESIDUAL PRESSURE

- 2.12. ATTACHMENTS HYDRAULIC CIRCUIT

- 2.12.1. CHECKING AND SETTING PRESSURE

- 2.13. SENSING SIGNAL (LS VALVE)

- 2.14. UNLOADING VALVE

- 2.14.1. ADJUSTING THE UNLOADING VALVE

- 2.14.2. UNLOADING VALVE FUNCTIONALITY

- 2.15. PRIORITY VALVE

- 2.15.1. TESTING PRIORITY VALVE OPERATION

- 2.15.2. CLEANING PRIORITY VALVE

- 2.16. STEERING CONTROL SYSTEM PRESSURE

- 2.16.1. TESTING

- 2.16.2. SETTING

- 2.17. BRAKE SYSTEM

- 2.17.1. TESTING CIRCUIT AND BRAKE TIGHTNESS

- 2.17.2. TESTING BRAKING GROUP LEAK TIGHTNESS

- 2.18. ENGINE SPEED CONTROL

- 2.18.1. UNDER LOAD

- 2.18.2. PREPARING THE MACHINE

- 2.18.3. TESTING WITH THE TORQUE CONVERTER UNDER STRESS

- 2.18.4. TESTING THE TORQUE CONVERTER AND HYDRAULIC SYSTEM UNDER STRESS

- 2.19. POWER TRAIN PRESSURES

- 2.19.1. PREPARING THE MACHINE

- 2.19.2. CONVERTER OIL PRESSURE

- 2.19.3. CLUTCH ENGAGEMENT PRESSURE

- 2.20. POWER TRAIN CLUTCHES FUNCTION

- 2.20.1. PREPARATION OF THE MACHINE

- 2.20.2. TESTING

- 2.20.3. RETURN TO DIG DEVICE SENSOR

- 2.21. ANALYSIS OF HYDRAULIC DRIFT

- 2.21.1. FRONT EQUIPMENT

- 2.21.2. TESTING FRONT BUCKET DUMPING

- 2.21.3. BACKHOE

- 2.22. AIRCONDITIONING UNIT

- 2.22.1. TESTING THE WORKING TEMPERATURE

- 2.22.2. CHECKING THE UNIT

- 2.22.3. EMPTYING THE AIR CONDITIONING UNIT

- 2.23. FRONT AXLE TROUBLESHOOTING

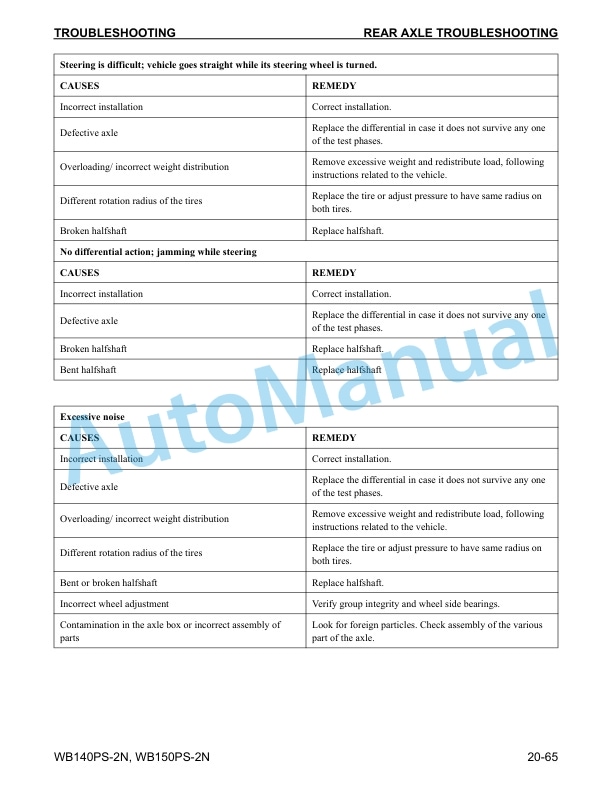

- 2.24. REAR AXLE TROUBLESHOOTING

- 2.25. TRANSMISSION TROUBLESHOOTING

- 2.26. ELECTRONIC CONTROL UNIT INSPECTION

- 2.26.1. FAILURE

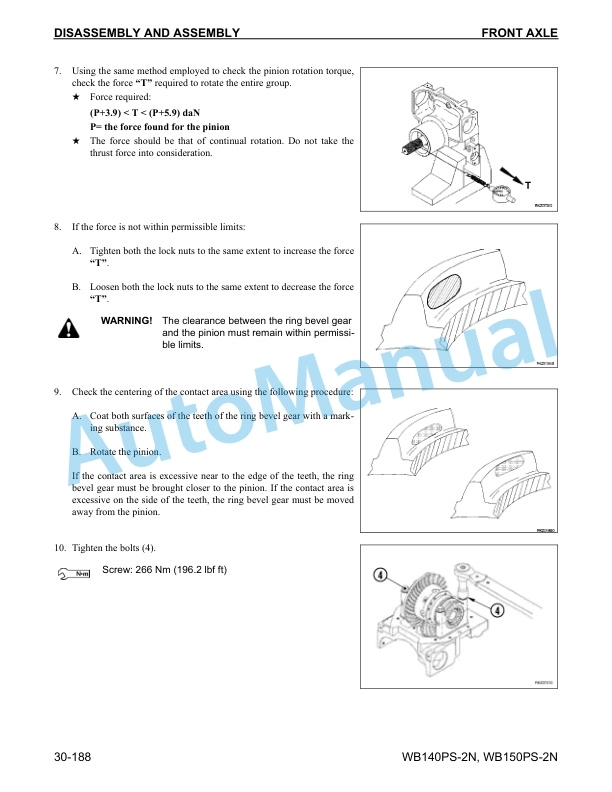

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECAUTIONS DURING OPERATION

- 3.3. AIR CONDITIONING COMPRESSOR

- 3.4. INJECTION NOZZLES

- 3.5. COOLING LIQUID PUMP

- 3.6. ACCUMULATOR DISCONNECT SWITCH

- 3.6.1. REMOVAL

- 3.6.2. INSTALLATION

- 3.7. FRONT COUNTERWEIGHT

- 3.7.1. REMOVAL

- 3.7.2. INSTALLATION

- 3.8. RADIATOR OIL COOLER UNIT

- 3.9. HEAT AND AIR CONDITIONING GROUP

- 3.10. HYDRAULIC OIL TANK

- 3.10.1. REMOVAL

- 3.10.2. INSTALLATION

- 3.11. ENGINEGEARBOXPUMP GROUP

- 3.11.1. DISASSEMBLY CONVERTER

- 3.11.2. ASSEMBLY CONVERTER

- 3.11.3. DISASSEMBLY PLUGS AND FILTERS

- 3.11.4. ASSEMBLY PLUGS AND FILTERS

- 3.11.5. DISASSEMBLY OIL PUMP

- 3.11.6. ASSEMBLY OIL PUMP

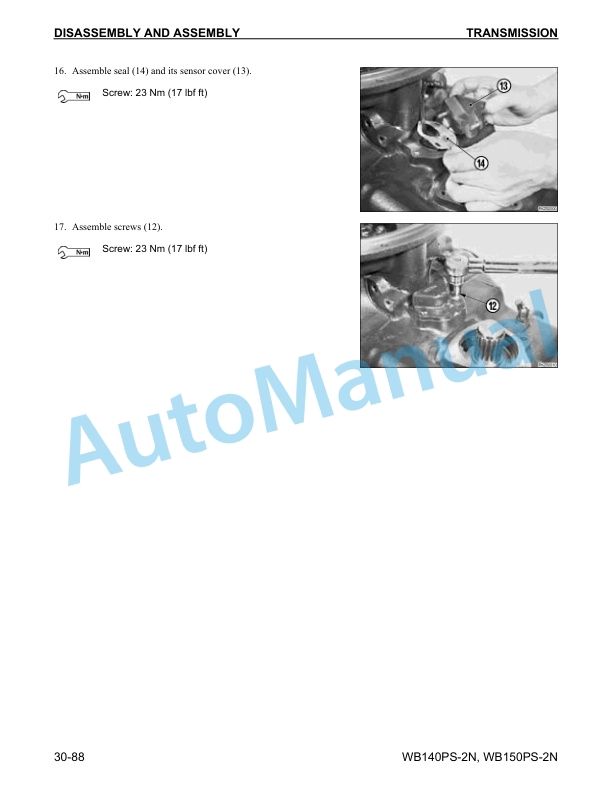

- 3.11.7. DISASSEMBLY PIPES AND SENSORS

- 3.11.8. ASSEMBLY PIPES AND SENSORS

- 3.11.9. DISASSEMBLY HYDRAULIC CONTROL VALVE

- 3.11.10. ASSEMBLY HYDRAULIC CONTROL VALVE

- 3.11.11. DISASSEMBLY TRANSMISSION HOUSING

- 3.11.12. ASSEMBLY TRANSMISSION HOUSING

- 3.11.13. DISASSEMBLY SHAFT A

- 3.11.14. ASSEMBLY SHAFT A

- 3.11.15. DISASSEMBLY SHAFT B

- 3.11.16. ASSEMBLY SHAFT B

- 3.11.17. DISASSEMBLY SHAFT C

- 3.11.18. ASSEMBLY SHAFT C

- 3.11.19. DISASSEMBLY SHAFT E

- 3.11.20. ASSEMBLY SHAFT E

- 3.12. CONVERTER

- 3.12.1. REMOVAL

- 3.12.2. INSTALLATION

- 3.13. HEADLIGHT CONTROL GROUP

- 3.13.1. REMOVAL OF THE TRANSMISSION INDICATOR AND HEADLIGHT DIMMER

- 3.13.2. INSTALLATION OF THE TRANSMISSION INDICATOR AND HEADLIGHT DIMMER

- 3.14. STEERING UNIT

- 3.14.1. REMOVAL

- 3.14.2. INSTALLATION

- 3.15. WORKING BRAKE PUMP GROUP

- 3.15.1. REMOVAL

- 3.15.2. INSTALLATION

- 3.16. FRONT WORK EQUIPMENT CONTROL VALVE

- 3.17. REAR AXLE

- 3.17.1. REMOVAL

- 3.17.2. INSTALLATION

- 3.17.3. DISASSEMBLY

- 3.17.4. ASSEMBLY

- 3.18. WORK EQUIPMENT

- 3.18.1. FRONT BUCKET BOOMRAISING CYLINDER

- 3.18.2. FRONT BUCKET TILT CYLINDERS

- 3.18.3. FRONT BUCKET

- 3.18.4. FRONT WORK EQUIPMENT

- 3.18.5. BACKHOE CONTROL VALVE

- 3.18.6. BACKHOE BOOM CYLINDER

- 3.18.7. BACKHOE ARM CYLINDER

- 3.18.8. TELESCOPIC ARM CYLINDER

- 3.18.9. BACKHOE BUCKET CYLINDER

- 3.18.10. OUTRIGGER CYLINDERS

- 3.18.11. BACKHOE SWING CYLINDERS

- 3.19. CYLINDERS

- 3.19.1. DISASSEMBLY

- 3.19.2. ASSEMBLY

- 3.20. BOOM SWING CYLINDER

- 3.20.1. DISASSEMBLY

- 3.20.2. ASSEMBLY

- 3.21. BOOM SAFETY CYLINDER

- 3.21.1. REMOVAL

- 3.21.2. INSTALLATION

- 3.22. BACKHOE WORKING EQUIPMENT

- 3.23. TELESCOPIC ARM, COMPLETE

- 3.24. BACKHOE SWING BRACKET

- 3.24.1. REMOVAL

- 3.24.2. INSTALLATION

- 3.25. BACKHOE OUTRIGGERS

- 3.25.1. REMOVAL

- 3.25.2. INSTALLATION

- 4. OTHERS

- 4.1. HYDRAULIC CIRCUIT (CONTROL VALVE)

- 4.2. HYDRAULIC CIRCUIT (PUMP AND TANK)

- 4.3. ELECTRICAL SCHEMATIC (Sheet 1 of 3)

- 4.4. ELECTRICAL SCHEMATIC (Sheet 2 of 3)

- 4.5. ELECTRICAL SCHEMATIC (Sheet 3 of 3)

- 4.6. AIR CONDITIONER CIRCUIT

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF