- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WF550-3, WF550T-3 Trash Compactor Shop Manual VEBM090100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM090100

- Format: PDF

- Size: 17.1MB

- Number of Pages: 394

Category: Komatsu Shop Manual PDF

-

Model List:

- WF550-3 Trash Compactor

- WF550T-3 Trash Compactor

- 1. WF5503 / WF550T3

- 2. CONTENTS

- 3. SAFETY

- 3.1. Safety notice

- 3.2. Foreword

- 3.3. How to read the shop manual

- 3.4. Hoisting instructions

- 4. STRUCTURE AND FUNCTION

- 4.1. General

- 4.2. Drive unit cooling fan

- 4.3. Transmission

- 4.4. Main relief, torque converter relief valve

- 4.5. Axle

- 4.6. Differential

- 4.7. Limited slip differential

- 4.8. Final drive

- 4.9. Axle mount, center hinge pin

- 4.10. Steering piping

- 4.11. Brake piping

- 4.12. Brake

- 4.13. Parking brake emergency release solenoid valve

- 4.14. Hydraulic piping

- 4.15. Work equipment lever linkage

- 4.16. Hydraulic tank

- 4.17. PPC valve

- 4.18. Cutoff valve

- 4.19. Main control valve

- 4.20. Main relief valve

- 4.21. Suction valve

- 4.22. Float selector valve and unload valve

- 4.23. Operation (WF550T3)

- 4.24. Operation (WF5503)

- 4.25. Bucket positioner and boom kickout (WF5503)

- 4.26. Air conditioner

- 4.27. Machine monitor system

- 4.28. Main monitor

- 4.29. Maintenance monitor

- 4.30. Transmission controller

- 4.31. Electric transmission control

- 5. TESTING AND ADJUSTING

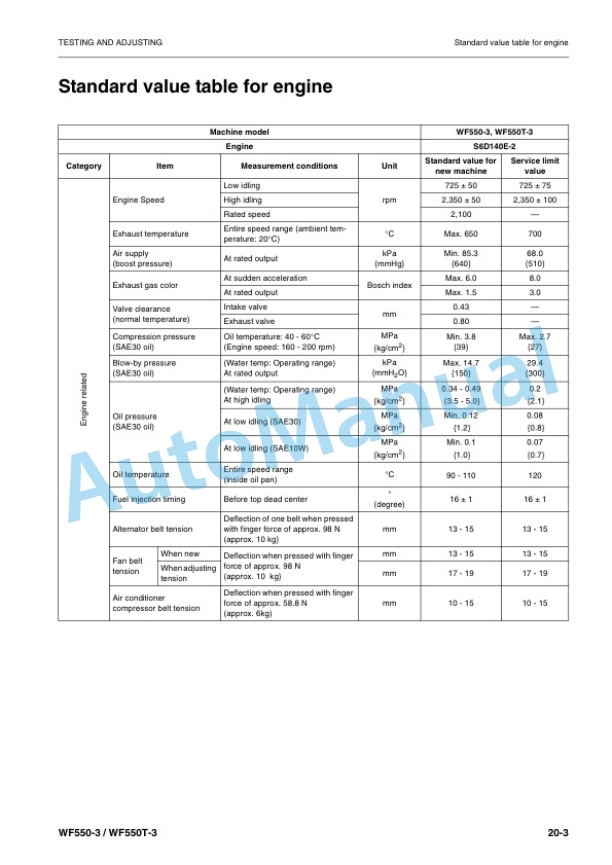

- 5.1. Standard value table for engine

- 5.2. Standard value table for chassis

- 5.3. Standard value table for electrical parts

- 5.4. Table of required tools

- 5.5. Sketch of special tools

- 5.6. Measuring blowby pressure

- 5.7. Measuring engine oil pressure

- 5.8. Adjusting speed sensor

- 5.9. Adjusting of engine stop motor cable

- 5.10. Torque converter and transmission oil pressure

- 5.11. Steering oil pressure

- 5.12. Measuring parking brake oil pressure

- 5.13. Testing and adjusting PPC oil pressure

- 5.14. Adjusting PPC valve linkage

- 5.15. Work equipment hydraulic pressure

- 5.16. Adjusting work equipment lever linkage

- 5.17. Adjusting main monitor (speedometer module)

- 6. TROUBLESHOOTING

- 6.1. Outline

- 6.2. Connector types and mounting locations

- 6.3. Connector arrangement diagram

- 7. TROUBLESHOOTING FOR RADIATOR COOLING FAN SYSTEM (EC MODE)

- 7.1. Electric circuit diagram of cooling fan system

- 7.2. EC1 Fan does not rotate (selector switch position AUTO)

- 8. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 8.1. H1 Blade does not move

- 8.2. H2 Blade is slow or blade lacks power

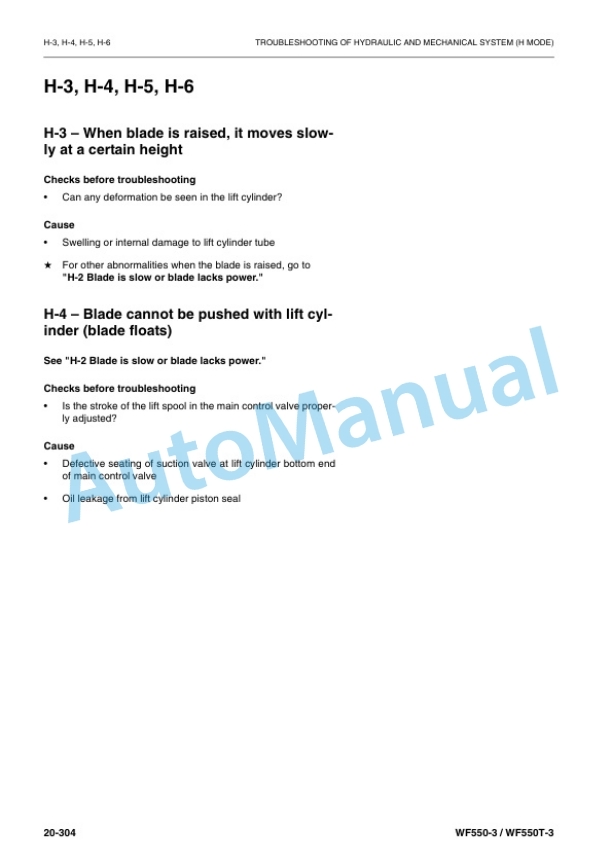

- 8.3. H3, H4, H5, H6

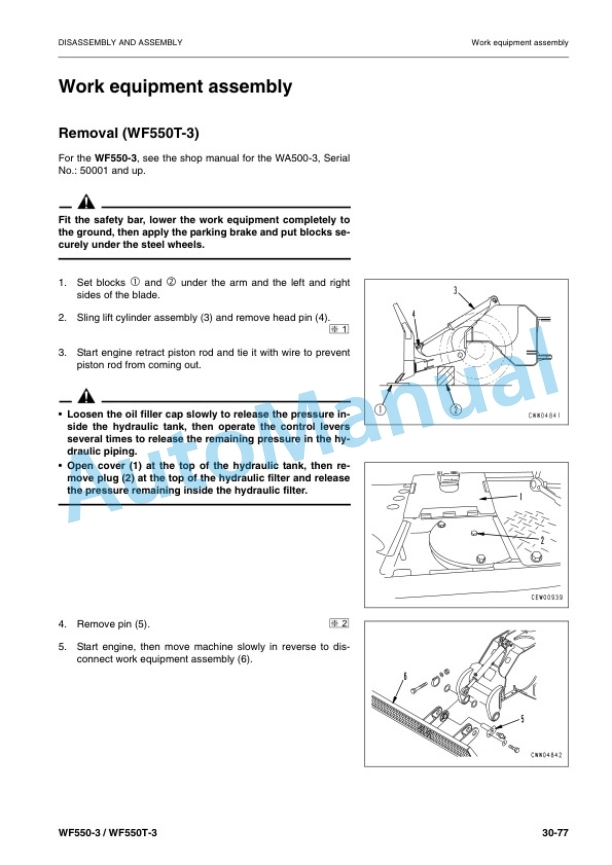

- 9. DISASSEMBLY AND ASSEMBLY

- 9.1. Special tool list

- 9.2. Sketches of special tools

- 9.3. Starting motor assembly

- 9.4. Engine front seal

- 9.5. Radiator assembly

- 9.6. Engine assembly

- 9.7. Front axle assembly

- 9.8. Front differential assembly

- 9.9. Rear axle assembly

- 9.10. Rear differential assembly

- 9.11. Differential gear assembly

- 9.12. Final drive assembly

- 9.13. Steering cylinder assembly

- 9.14. Steering valve assembly

- 9.15. Slack adjuster assembly

- 9.16. Hydraulic tank assembly

- 9.17. PPC valve assembly

- 9.18. Main control valve assembly

- 9.19. Lift cylinder assembly

- 9.20. Boom, bucket and lift cylinders assembly

- 9.21. Work equipment assembly

- 9.22. Engine hood assembly

- 9.23. Floor frame assembly

- 9.24. Fuel tank assembly

- 9.25. Air conditioner condenser assembly

- 9.26. Reciver tank

- 10. MAINTENANCE STANDARD

- 10.1. Engine mount

- 10.2. Transmission mount

- 10.3. Damper

- 10.4. Torque converter charging pump

- 10.5. Torque converter, PTO

- 10.6. Transmission

- 10.7. Transfer

- 10.8. Main relief, torque converter relief valve

- 10.9. Lubrication relief valve

- 10.10. Center hinge pin

- 10.11. Steering column

- 10.12. Steering pump

- 10.13. Steering valve

- 10.14. Steering cylinder mount

- 10.15. Switch, PPC pump

- 10.16. PPC valve

- 10.17. Main control valve

- 10.18. Cutoff valve

- 10.19. Hydraulic cylinders

- 10.20. Work equipment linkage

- 10.21. Bucket positioner and boom kickout

- 10.22. ROPS cab

- 11. OTHERS

- 11.1. Hydraulic circuit diagram for power train

- 11.2. Brake circuit diagram

- 11.3. Electric circuit for cooling fan

- 11.4. Work equipment hydraulic circuit diagram (WF550T3)

- 11.5. Work equipment hydraulic circuit diagram (WF5503)

- 11.6. Electric circuit diagram (1/4)

- 11.7. Electric circuit diagram (2/4)

- 11.8. Electric circuit diagram (3/4)

- 11.9. Electric circuit diagram (4/4)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF