- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WF650T-3 Trash Compactor Shop Manual SEBM027401

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM027401

- Format: PDF

- Size: 24.2MB

- Number of Pages: 743

Category: Komatsu Shop Manual PDF

-

Model List:

- WF650T-3 Trash Compactor

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANT AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. COOLING SYSTEM

- 4.2. POWER TRAIN SYSTEM

- 4.3. TORQUE CONVERTER AND TRANSMISSION PIPING

- 4.4. HYDRAULIC CIRCUIT DIAGRAM FOR POWER TRAIN

- 4.5. UBRICATION BYPASS VALVE

- 4.6. TORQUE CONVERTER

- 4.7. TORQUE CONVERTER REGULATOR VALVE

- 4.8. TORQUE CONVERTER RELIEF VALVE

- 4.9. TRANSMISSION

- 4.10. ANSMISSION CONTROL VALVE

- 4.11. ERGENCY MANUAL SPOOL

- 4.12. WHEEL (TRIANGLE FOOT TYPE)

- 4.13. WHEEL (CHPPER TYPE)

- 4.14. AXLE MOUNT, CENTER HINGE PIN

- 4.15. STEERING PIPING

- 4.16. STEERING COLUMN

- 4.17. STEERING UNIT (ORBITROLL VALVE)

- 4.18. STEERING VALVE

- 4.19. TWOWAY RESTRICTION VALVE

- 4.20. STOP VALVE

- 4.21. BRAKE PIPING

- 4.22. BRAKE CIRCUIT DIAGRAM

- 4.23. BRAKE VALVE

- 4.24. CHARGE VALVE

- 4.25. ACCUMULATOR (FOR BRAKE)

- 4.26. SLACK ADJUSTER

- 4.27. BRAKE

- 4.28. PARKING BRAKE

- 4.29. SPRING CYLINDER

- 4.30. PARKING BRAKE SOLENOID VALVE

- 4.31. HYDRAULIC PIPING

- 4.32. HYDRAULIC CIRCUIT DIAGRAM

- 4.33. WORK EQUIPMENT LEVER LINKAGE

- 4.34. HYDRAULIC TANK

- 4.35. ACCUMULATOR (FOR PPC VALVE)

- 4.36. PPC VALVE

- 4.37. PPC RELIEF VALVE

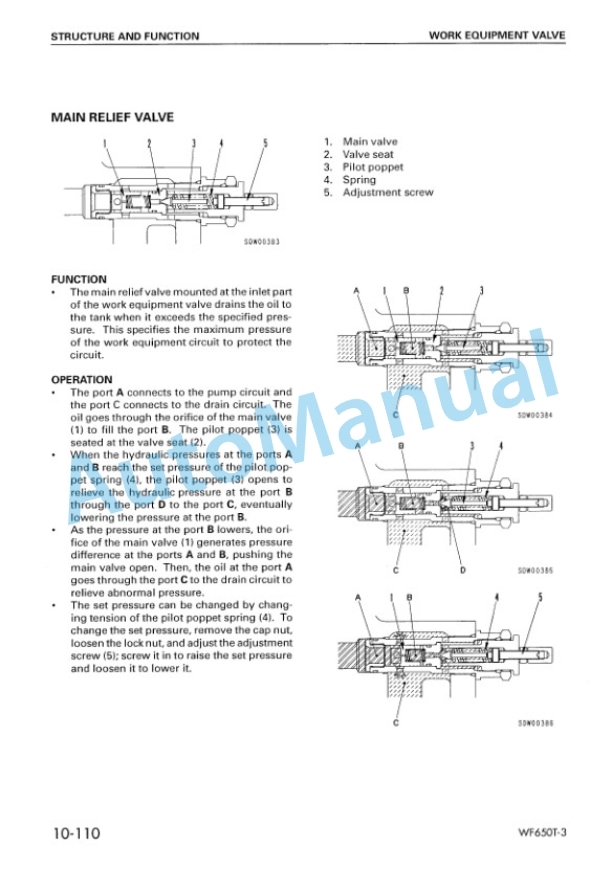

- 4.38. WORK EQUIPMENT VALVE

- 4.39. AIR CONDITIONER

- 4.40. MACHINE MONITOR SYSTEM

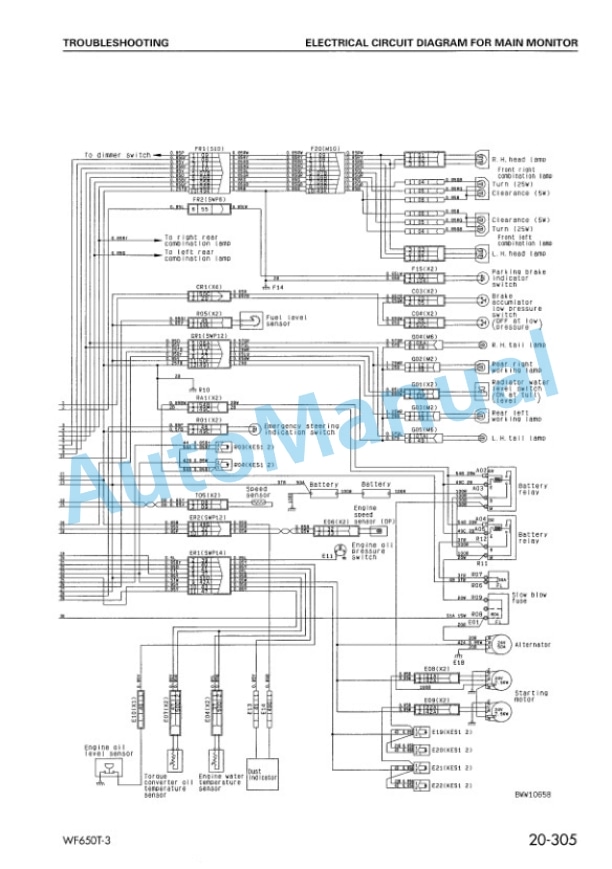

- 4.41. MAIN MONITOR

- 4.42. MAINTENANCE MONITOR

- 4.43. ENGINE STARTING CIRCUIT

- 4.44. ENGINE STOP CIRCUIT

- 4.45. AUTO PRIMING SYSTEM (APS)

- 4.46. ELECTRIC TRANSMISSION CONTROL

- 4.47. KICKDOWN SWITCH

- 4.48. KICKDOWN ELECTRICAL CIRCUIT

- 4.49. ELECTRIC PARKING BRAKE CONTROL

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE

- 5.1.1. STANDARD VALUE TABLE FOR ENGINE

- 5.1.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.1.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TABLE OF TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.2.2. MEASURING ENGINE SPEED

- 5.2.3. MEASURING EXHAUST GAS COLOR

- 5.2.4. ADJUSTING VALVE CLEARANCE

- 5.2.5. MEASURING COMPRESSION PRESSURE

- 5.2.6. MEASURING BLOWBY BRESSURE

- 5.2.7. MEASURING ENGINE OIL PRESSURE

- 5.2.8. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.2.9. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.2.10. TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 5.2.11. REPLACING FAN BELT ADJUSTING AUTOTENSIONER

- 5.2.12. MEASURING EXHAUST TEMPERATURE

- 5.2.13. MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)

- 5.2.14. ADJUSTING SPEED SENSOR

- 5.2.15. ADJUSTING FUEL CONTROL CABLE

- 5.2.16. METHOD FOR ADJUSTING ENGINE STOP MOTOR CABLE

- 5.2.17. TESTING AND ADJUSTING TORQUE CONVERTER, TRANSMISSION OIL PRESSURE

- 5.2.18. PROCEDURE FOR FLUSHING TORQUE CONVERTER, TRANSMISSION HYDRAULIC CIRCUIT

- 5.2.19. PROCEDURE FOR MOVING MACHINE WHEN TRANSMISSION VALVE FAILS

- 5.2.20. TESTING AND ADJUSTING STEERING OIL PRESSURE

- 5.2.21. TESTING AND ADJUSTING STEERING STOP VALVE

- 5.2.22. TESTING BRAKE OIL PRESSURE

- 5.2.23. MEASURING WEAR OF BRAKE DISC

- 5.2.24. MEASURING BRAKE PERFORMANCE

- 5.2.25. TESTING AND ADJUSTING PARKING BRAKE

- 5.2.26. TESTING AND ADJUSTING ACCUMULATOR CHARGE CUTIN AND CUTOUT PRESSURE

- 5.2.27. TESTING AND ADJUSTING PPC OIL PRESSURE

- 5.2.28. TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE

- 5.2.29. AJUSTING WORK EQUIPMENT LEVER LINKAGE

- 5.2.30. ADJUSTING MAIN MONITOR

- 5.2.31. BLEEDING AIR

- 5.2.32. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.3. TROUBLESHOOTING

- 5.3.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.3.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.3.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.3.4. CHECKS BEFORE TROUBLESHOOTING

- 5.3.5. CONNECTOR TYPES AND MOUNTING LOCATION

- 5.3.6. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.3.7. METHOD OF USING MATRIX TROUBLESHOOTHING TABLES

- 5.3.8. TROUBLESHOOTING OF MAIN MONITOR SYSTEM (M MODE)

- 5.3.9. TROUBLESHOOTING OF MAINTENANCE MONITOR SYSTEM (K MODE)

- 5.3.10. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 5.3.11. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

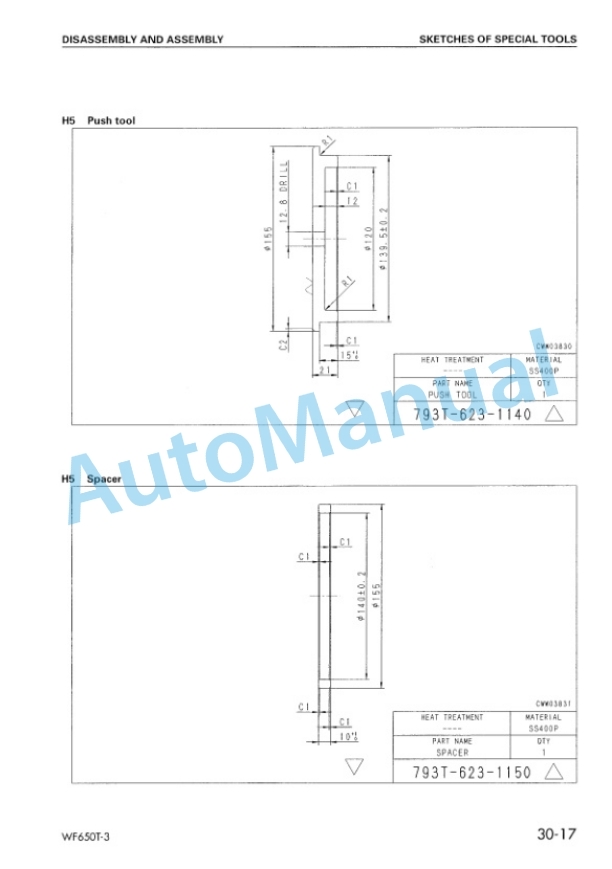

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. STARTING MOTOR

- 6.5.1. Removal and Installation

- 6.6. ALTERNATOR

- 6.6.1. Removal and Installation

- 6.7. ENGINE OIL COOLER

- 6.7.1. Removal and Installation

- 6.8. FUEL INJECTION PUMP

- 6.8.1. Removal and Installation

- 6.9. WATER PUMP

- 6.9.1. Removal and Installation

- 6.10. NOZZLE HOLDER

- 6.10.1. Removal and Installation

- 6.11. TURBOCHARGER

- 6.11.1. Removal

- 6.11.2. Installation

- 6.12. ENGINE FRONT SEAL

- 6.12.1. Replacement

- 6.13. ENGINE REAR SEAL

- 6.13.1. Removal and Installation

- 6.14. AFTERCOOLER CORE

- 6.15. ENGINE AND TORQUE CONVERTER ASSEMBLY

- 6.15.1. Removal

- 6.15.2. Installation

- 6.16. TORQUE CONVERTER ASSEMBLY

- 6.17. TRANSFER ASSEMBLY

- 6.17.1. Disassembly

- 6.17.2. Assembly

- 6.18. CENTER SUPPORT

- 6.18.1. Removal and Installation

- 6.19. FRONT DIFFERENTIAL

- 6.20. REAR DIFFERENTIAL

- 6.20.1. Removal

- 6.20.2. Installation

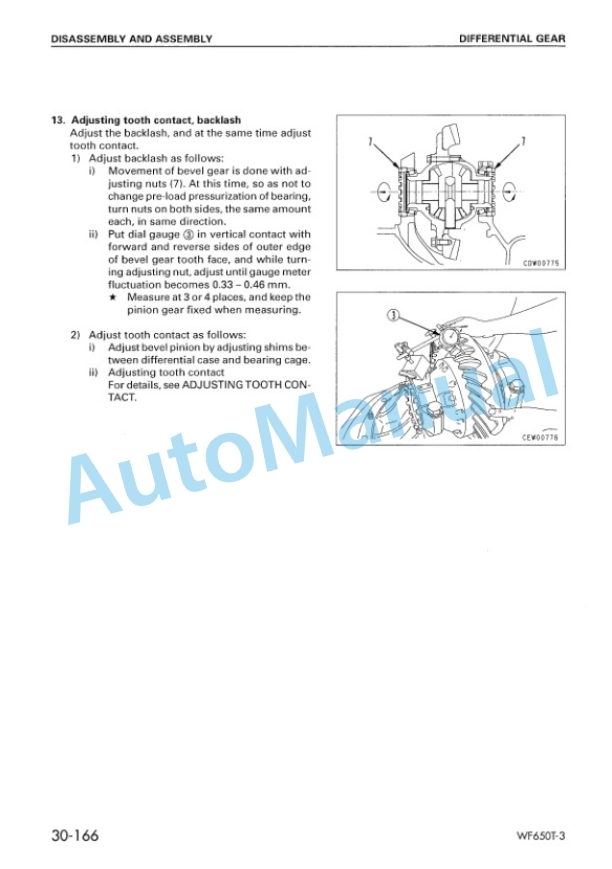

- 6.21. DIFFERENTIAL GEAR ASSEMBLY

- 6.21.1. Disassembly

- 6.21.2. Assembly

- 6.22. NONSPIN DIFFERENTIAL ASSEMBLY

- 6.22.1. Removal and Installation

- 6.23. STEERING CYLINDER

- 6.23.1. Removal and Installation

- 6.24. BRAKE VALVE (R.H.)

- 6.24.1. Disassembly

- 6.24.2. Assembly

- 6.25. BRAKE VALVE (L.H.)

- 6.25.1. Disassembly

- 6.25.2. Assembly

- 6.26. SLACK ADJUSTER

- 6.26.1. Removal and Installation

- 6.26.2. Disassembly

- 6.26.3. Assembly

- 6.27. BRAKE

- 6.27.1. Removal and Installation

- 6.27.2. Disassembly

- 6.27.3. Assembly

- 6.28. HYDRAULIC PUMP ASSEMBLY

- 6.29. HYDRAULIC FILTER

- 6.29.1. Removal and Installation

- 6.30. PCC VALVE

- 6.30.1. Removal and Installation

- 6.30.2. Disassembly and Assembly

- 6.31. WORK EQUIPMENT VALVE

- 6.31.1. Removal

- 6.31.2. Installation

- 6.32. LIFT CYLINDER ASSEMBLY

- 6.32.1. Removal

- 6.32.2. Installation

- 6.33. CENTER HINGE PIN

- 6.33.1. Removal

- 6.33.2. Installation

- 6.34. WORK EQUIPMENT ASSEMBLY

- 6.34.1. Removal and Installation

- 6.34.2. Removal and Installation

- 6.34.3. Removal and Installation

- 6.35. ACCUMULATOR

- 6.35.1. Removal and Installation

- 6.36. ACCUMULATOR CHARGE VALVE

- 6.36.1. Removal and Installation

- 6.37. PARKING BRAKE SOLENOID VALVE

- 6.37.1. Removal and Installation

- 6.38. PARKING BRAKE

- 6.38.1. Removal and Installation

- 6.39. PARKING BRAKE CALIPERS

- 6.39.1. Disassembly

- 6.39.2. Assembly

- 6.40. PARKING BRAKE PAD

- 6.40.1. Removal and Installation

- 6.41. PEAR STEEL WHEELS

- 6.41.1. Removal and Installation

- 6.42. AIR CONDITIONER COMPRESSOR

- 6.42.1. Removal and Installation

- 6.43. AIR CONDITIONER CONDENSER

- 6.43.1. Removal and Installation

- 6.44. RECEIVER TANK

- 6.44.1. Removal and Installation

- 6.45. AIR CONDITIONER UNIT

- 6.45.1. Removal

- 6.45.2. Installation

- 6.46. MONITOR

- 6.46.1. Removal and Installation

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT

- 7.2. TRANSMISSION MOUNT

- 7.3. TORQUE CONVERTER

- 7.4. TORQUE CONVERTER REGULATOR VALVE

- 7.5. TRANSMISSION

- 7.6. TRANSMISSION SOLENOID VALVE

- 7.7. TRANSMISSION CONTROL VALVE

- 7.8. CENTER HINGE PIN

- 7.9. STEERING COLUMN

- 7.10. STEERING VALVE

- 7.11. STEERING CYLINDER MOUNT

- 7.12. WORK EQUIPMENT VALVE

- 7.13. HYDRAULIC CYLINDER

- 7.14. WORK EQUIPMENT LINKAGE

- 7.15. ROPS CANOPY

- 8. OTHERS

- 8.1. ELECTRIC CIRCUIT DIAGRAM

- 8.1.1. Electric circuit diagram (1/5)

- 8.1.2. Electric circuit diagram (2/5)

- 8.1.3. Electric circuit diagram (3/5)

- 8.1.4. Electric circuit diagram (4/5)

- 8.1.5. Electric circuit diagram (5/5)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF