- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Workshop Manuals

$50.00

- Type Of Manual: Workshop Manuals

- Format: PDF

- Size: 1217.1MB

- Number of Pages: 10248

Category: Linde Workshop Manual PDF

-

Model List:

- K Generation 1 2

- K Generation 3

- K Generation 4

- 1. Operating Instructions

- 1.1. Abseiling system

- 1.2. Aisle Safety Assistant (GSA)011_K

- 1.3. Battery frames011_K, 5212_V10, 5213_V, 5222_A

- 1.4. Cold Store Cab011_K(48V), 011_K(80V), 5231_K

- 1.5. Emergency operating panel

- 1.6. Extension deviceK

- 1.7. Extension device2301

- 1.8. Fallprotection device011_K, 011_K(48V), 011_K(80V), 5021_V10, 5213_OPM, 5213_V

- 1.9. Fallprotection deviceV, K

- 1.10. Linde forklift data management (LFM)011_K, 5213_V, 5222_A

- 1.11. Operating Instruction

- 1.12. Operating Instruction

- 1.13. Operating Instruction

- 1.14. Order picker truckK

- 1.15. Order picker truckK

- 1.16. Order picking truckK

- 1.17. Skylotec emergency abseil system

- 1.18. Trucks operating in Cold Storage Warehouse

- 1.19. VNA Navigation

- 1.20. Visual warning unit

- 2. Fault descriptionsInformation on the displayK generation 4

- 2.1. Table of content

- 2.2. Foreword

- 2.3. Fault descriptions

- 3. Regular testing

- 3.1. Table of content

- 3.2. Regular testing

- 3.3. Electric motor

- 3.4. Chassis drivers compartment

- 3.5. Steering system

- 3.6. Guidance

- 3.7. Wheels and tyres

- 3.8. Brake system

- 3.9. Operating devices

- 3.10. Electrical enclosure

- 3.11. Hydraulics

- 3.12. Lift mast

- 3.13. Load support

- 3.14. Attachment

- 3.15. Special equipment.accessories

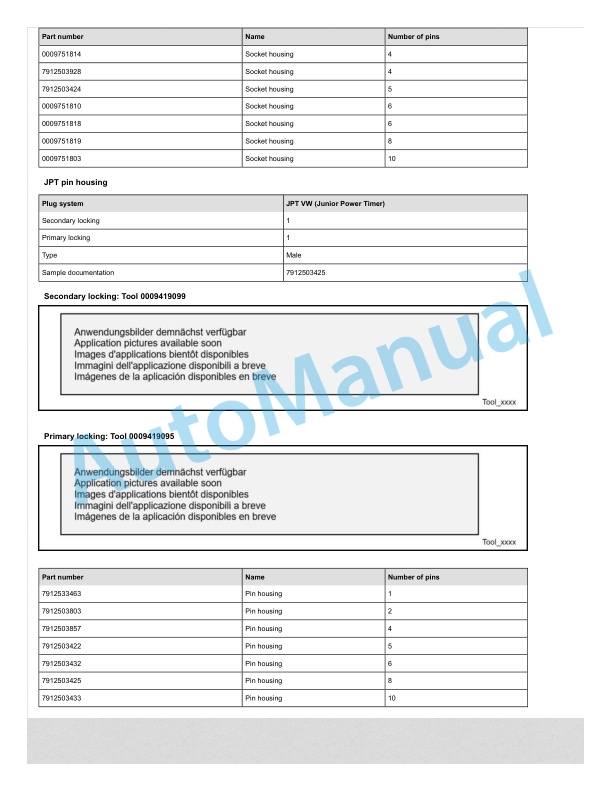

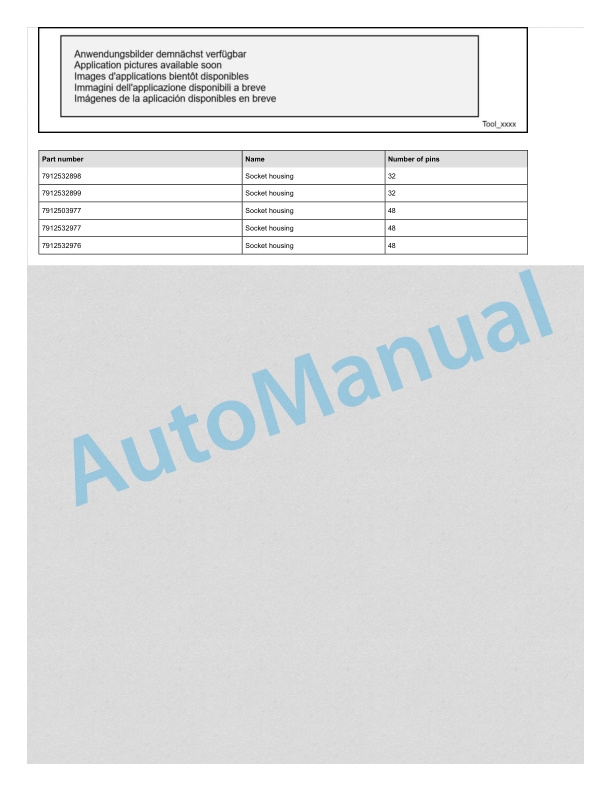

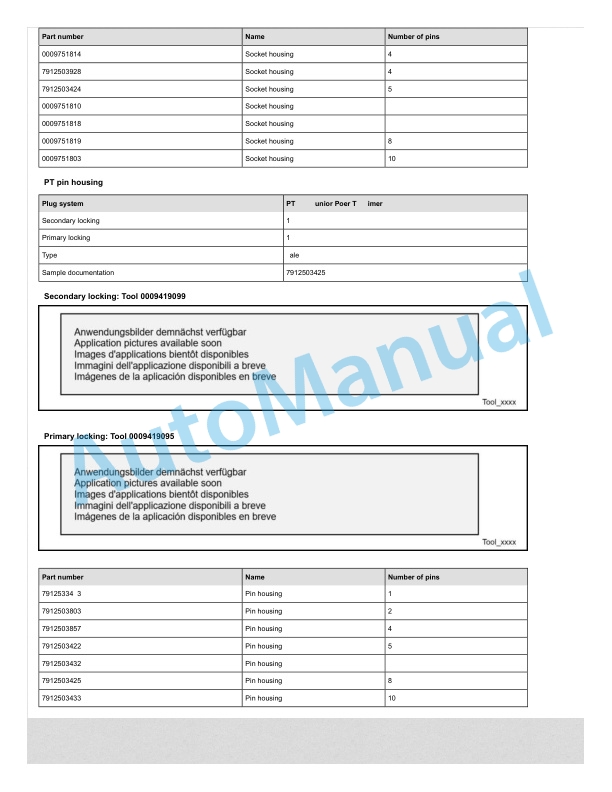

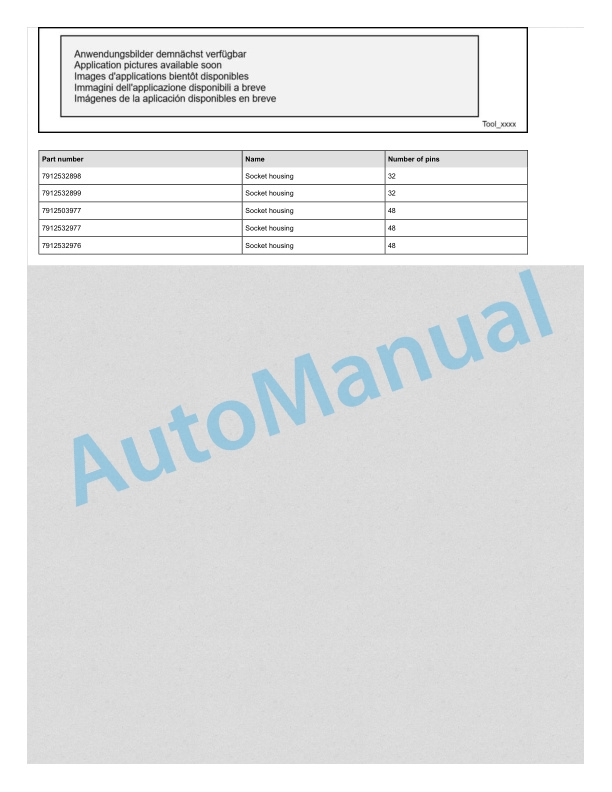

- 4. Service case Release tools for contacts

- 4.1. Table of content

- 4.2. Safety information

- 4.3. Information

- 4.4. Overview

- 4.5. Plug systems

- 5. Manual for qualified personsV10, V11, V12, K

- 5.1. Table of content

- 5.2. Description

- 5.3. Application

- 5.4. Maintenance and testing

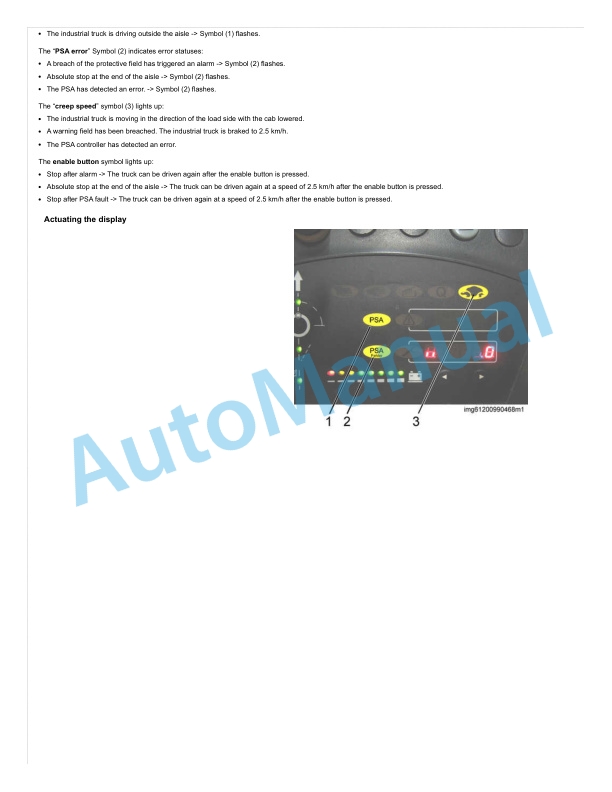

- 6. Mobile personal protection system

- 6.1. Table of content

- 6.2. Mobile personal protection system

- 6.3. System description

- 6.4. Commissioning

- 6.5. Component descriptions

- 6.6. Detectors

- 6.7. Maintenance

- 6.8. Diagnostics system

- 7. Mobile personal protection system

- 7.1. Table of content

- 7.2. Mobile personal protection system

- 7.3. Commissioning

- 7.4. Component descriptions

- 7.5. Maintenance

- 7.6. Diagnostics

- 8. Order picking truckK generation 4, 48 V

- 8.1. Table of content

- 8.2. Product information

- 8.3. Diagnostics

- 8.4. Electric motor

- 8.5. Mechanical drive axle

- 8.6. Drivers compartment

- 8.7. Steering

- 8.8. Mechanical guidance

- 8.9. Inductive guidance

- 8.10. Wheels and tyres

- 8.11. Brake system

- 8.12. Operating devices

- 8.13. Display elements

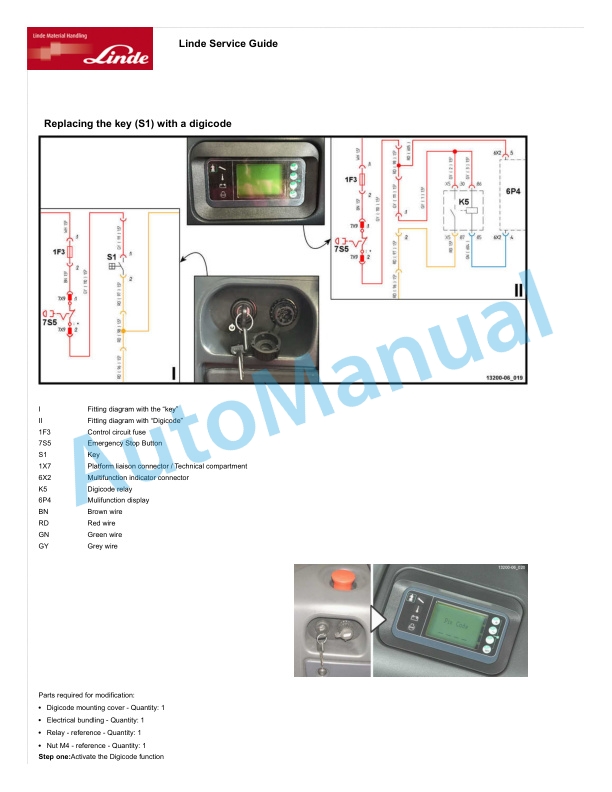

- 8.14. Electrics . electronics

- 8.15. Electronic controls

- 8.16. Hydraulics, general

- 8.17. Working hydraulics

- 8.18. Valves

- 8.19. Load lift system

- 8.20. Lift mast

- 8.21. Attachments

- 8.22. Special equipment.accessories

- 9. Order picking truckK generation 4, 80V

- 9.1. Table of content

- 9.2. Product information

- 9.3. Diagnostics

- 9.4. Electric motor

- 9.5. Mechanical drive axle

- 9.6. Drivers compartment

- 9.7. Steering

- 9.8. Mechanical guidance

- 9.9. Inductive guidance

- 9.10. Wheels and tyres

- 9.11. Brake system

- 9.12. Operating devices

- 9.13. Display elements

- 9.14. Electrics . electronics

- 9.15. Electronic controls

- 9.16. Hydraulics, general

- 9.17. Working hydraulics

- 9.18. Valves

- 9.19. Load lift system

- 9.20. Lift mast

- 9.21. Attachments

- 9.22. Special equipment . accessories

- 10. Service trainingK generation 1, 2 80 V

- 10.1. Table of content

- 10.2. Product information

- 10.3. Diagnostics

- 10.4. Electric motor

- 10.5. Mechanical drive axle

- 10.6. Steering

- 10.7. Mechanical guidance

- 10.8. Inductive guidance

- 10.9. Wheels and tyres

- 10.10. Brake system

- 10.11. Operating devices

- 10.12. Electrics.electronics

- 10.13. Electronic controls

- 10.14. Hydraulics, general

- 10.15. Working hydraulics

- 10.16. Valves

- 10.17. Lift mast

- 10.18. Attachments

- 10.19. Special equipment.accessories

- 11. Service trainingK generation 3, 80 V

- 11.1. Table of content

- 11.2. Product information

- 11.3. Diagnostics

- 11.4. Electric motor

- 11.5. Mechanical drive axle

- 11.6. Steering

- 11.7. Mechanical guidance

- 11.8. Inductive guidance

- 11.9. Wheels and tyres

- 11.10. Brake system

- 11.11. Operating devices

- 11.12. Electrics.electronics

- 11.13. Electronic controls

- 11.14. Hydraulics, general

- 11.15. Working hydraulics

- 11.16. Valves

- 11.17. Lift mast

- 11.18. Attachments

- 11.19. Special equipment.accessories

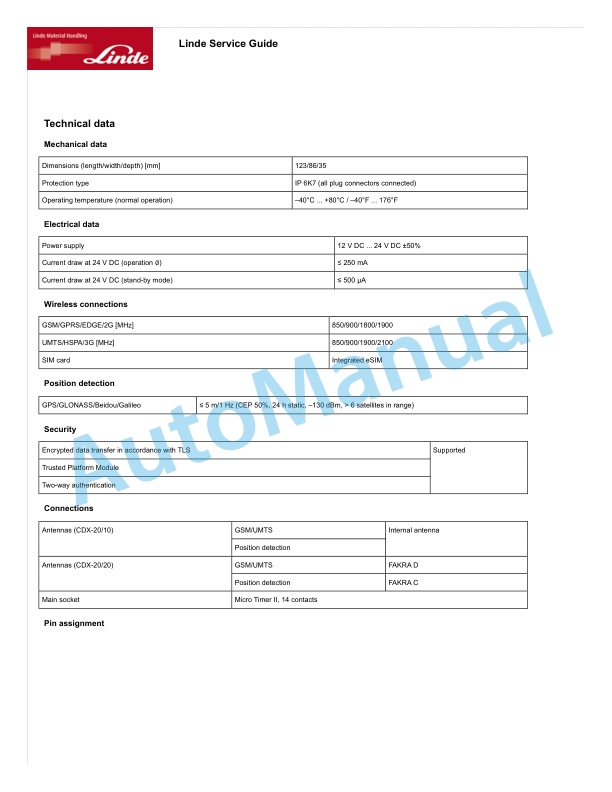

- 12. VNA Navigation011_K

- 12.1. Table of content

- 12.2. General

- 12.3. Hardware

- 12.4. Truck software

- 12.5. Diagnostics

- 12.6. Software for the warehouse configuration VNAP LCF

- 12.7. Commissioning

- 13. Workshop manualK Generation 3 48V

- 13.1. Table of content

- 13.2. Product information

- 13.3. Diagnostics

- 13.4. Electric motor

- 13.5. Mechanical drive axle

- 13.6. Steering

- 13.7. Mechanical rail guidance

- 13.8. Inductive guidance

- 13.9. Wheels and tyres

- 13.10. Brake system

- 13.11. Controls

- 13.12. Electrics . Electronics

- 13.13. Electronic controllers

- 13.14. Hydraulics, general

- 13.15. Working hydraulics

- 13.16. Valves

- 13.17. Lift mast

- 13.18. Attachments

- 13.19. Special equipment . Accessories

- 14. Workshop Manuals

- 14.1. Fault descriptionsInformation on the displayK generation 4

- 14.2. Regular testing

- 14.3. Service case Release tools for contacts

- 14.4. Manual for qualified personsV10, V11, V12, K

- 14.5. Mobile personal protection system

- 14.6. Mobile personal protection system

- 14.7. Order picking truckK generation 4, 48 V

- 14.8. Order picking truckK generation 4, 80V

- 14.9. Service trainingK generation 1, 2 80 V

- 14.10. Service trainingK generation 3, 80 V

- 14.11. VNA Navigation011_K

- 14.12. Workshop manualK Generation 3 48V

- 15. Spis treci

- 16. Opis

- 16.1. System opuszczania Skylotec

- 17. Zastosowanie

- 17.1. Przygotowanie

- 17.2. Mocowanie wizki przewodów

- 17.3. Wychodzenie z kabiny operatora

- 17.4. Dziaanie

- 17.5. Czynnoci nastpcze

- 17.6. Szok zawieszenia

- 18. Konserwacja i kontrola

- 18.1. Konserwacja

- 18.2. Okresowa kontrola bezpieczestwa

- 19. System opuszczania Skylotec

- 19.1. Spis treci

- 19.2. Opis

- 19.3. Zastosowanie

- 19.4. Konserwacja i kontrola

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Workshop Manuals

$50.00

Linde Workshop Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Workshop Manuals SN W41110V00529 and up

$50.00

Linde Workshop Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Workshop Manuals

$50.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF