- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 015-01 – V11-04, V11AC, V11N Workshop Manuals

$50.00

- Type Of Manual: Workshop Manuals

- Format: PDF

- Size: 82.0MB

- Number of Pages: 708

Category: Linde Workshop Manual PDF

-

Model List:

- V11-04

- V11AC

- V11N

- 1. Regular testing

- 1.1. Table of content

- 1.2. Regular testing

- 1.2.1. Basic principles

- 1.3. Electric motor

- 1.3.1. Test steps for the electric traction motor

- 1.4. Chassis drivers compartment

- 1.4.1. Test steps for the chassis

- 1.4.2. Test steps for the raisable drivers compartment

- 1.4.3. Test steps for the nonraisable drivers compartment

- 1.5. Steering system

- 1.5.1. Test steps for the steering

- 1.5.2. Test steps for the steering motor

- 1.6. Guidance

- 1.6.1. Test steps for guidance

- 1.7. Wheels and tyres

- 1.7.1. Test steps for Vulkollan tyres

- 1.8. Brake system

- 1.8.1. Test steps for the brake system

- 1.8.2. Checking the braking power of the service brake

- 1.8.3. Required braking capabilities for group C industrial trucks

- 1.9. Operating devices

- 1.9.1. Test steps for operating devices

- 1.10. Electrical enclosure

- 1.10.1. Test steps for electrical equipment

- 1.10.2. Test steps for the battery and battery connection assemblies

- 1.11. Hydraulics

- 1.11.1. Test steps for the hydraulic system

- 1.11.2. Test steps for the pump motor

- 1.12. Lift mast

- 1.12.1. Test steps for the lift mast

- 1.13. Load support

- 1.13.1. Test steps for load chains

- 1.13.2. Test steps for the fork arms

- 1.14. Attachment

- 1.14.1. Test steps for the standard attachment

- 1.14.2. Test steps for retrofitted attachments and other lifting accessories

- 1.15. Special equipment.accessories

- 1.15.1. Test steps for other accessories

- 1.15.2. Test steps for the onboard charging system

- 1.15.3. Test steps for the cold store cabWind deflector cab

- 1.15.4. Test steps for the abseil system

- 1.15.5. Test steps for the fall protection system

- 1.15.6. Test steps for assistance systems

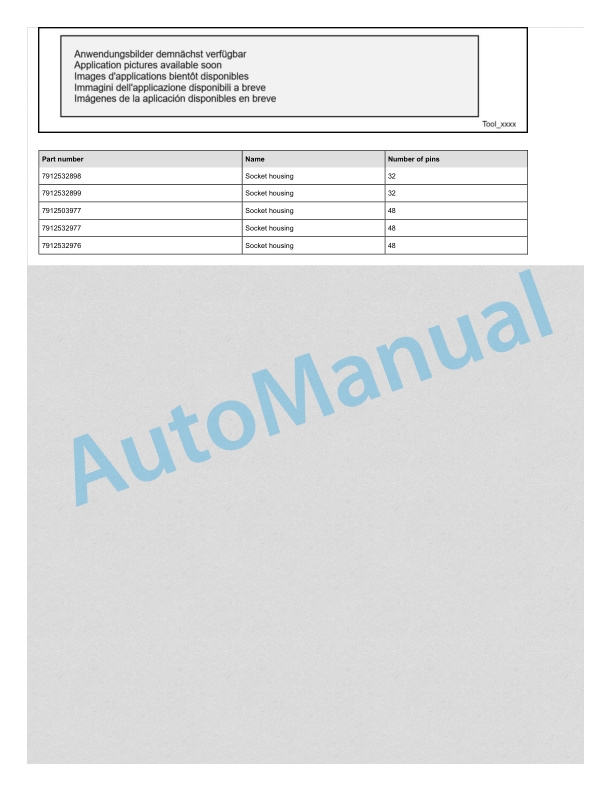

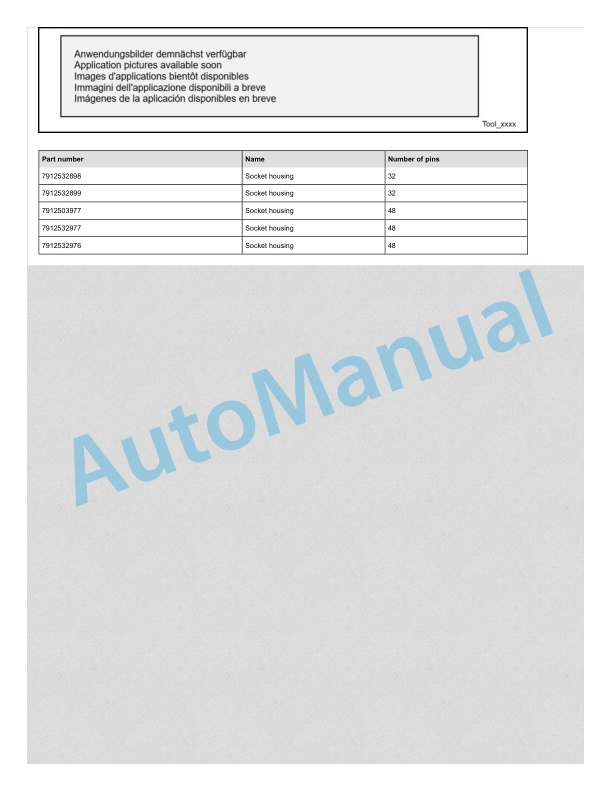

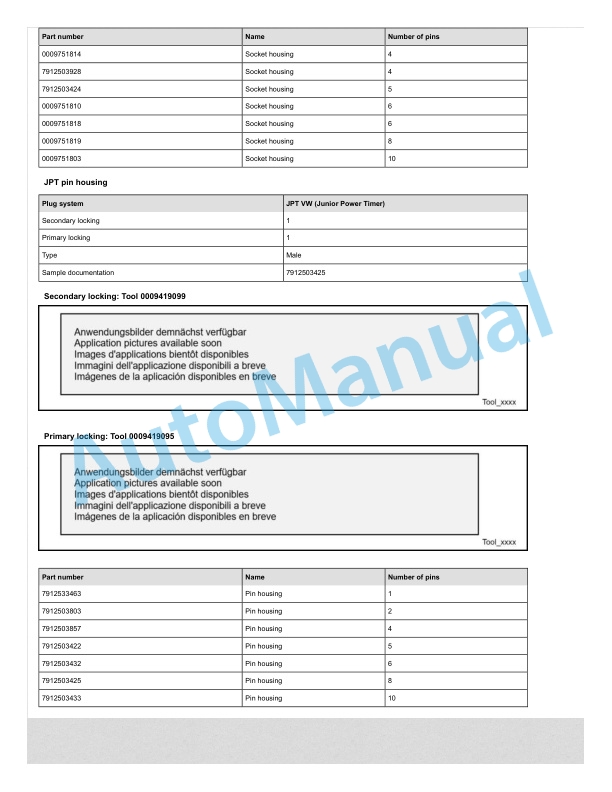

- 2. Service case Release tools for contacts

- 2.1. Table of content

- 2.2. Safety information

- 2.2.1. Safety information for repair and maintenance work

- 2.3. Information

- 2.3.1. Information

- 2.4. Overview

- 2.4.1. Overview of service cases

- 2.5. Plug systems

- 2.5.1. ATS 2.8 plug connector

- 2.5.2. CMC plug connector

- 2.5.3. DCS 9.5 plug connector

- 2.5.4. DIN 1.5mm circular connector

- 2.5.5. DIN 2.5mm circular connector

- 2.5.6. Deutsch DTM plug connector

- 2.5.7. ECU appliance plug

- 2.5.8. MCON appliance plug

- 2.5.9. Appliance plug with JPT and MQS contacts

- 2.5.10. Appliance plug with MT2 and JPT contacts

- 2.5.11. SICMA appliance plug

- 2.5.12. Econoseal JMark 2 plug connector

- 2.5.13. Elobau 11pin receptacle housing

- 2.5.14. E5931 plug connector

- 2.5.15. FASTINFASTON 6.3mm plug connector

- 2.5.16. GT150 plug connector

- 2.5.17. HDSCS plug connector

- 2.5.18. JPT plug connector

- 2.5.19. JPT SLD plug connector

- 2.5.20. JPT plug connector Saab

- 2.5.21. JPT plug connector VW

- 2.5.22. Kompakt 1.1 plug connector

- 2.5.23. Bosch Kompakt 4 plug connector

- 2.5.24. Leavyseal plug connector

- 2.5.25. MCON 1.2mm LL plug connector

- 2.5.26. MCON 1.2mm CB plug connector

- 2.5.27. MCP plug connector

- 2.5.28. MetriPack 150 plug connector

- 2.5.29. MiniFit plug connector

- 2.5.30. Mini Universal MATENLOK plug connector

- 2.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 2.5.32. MKR Plus plug connector

- 2.5.33. MQS plug connector

- 2.5.34. MR plug connector

- 2.5.35. MTA plug housing and fuse housing

- 2.5.36. MT2 plug connector

- 2.5.37. MT2 1.5mm plug connector VW

- 2.5.38. Multilock plug connector

- 2.5.39. MX150 plug connector

- 2.5.40. NG1 plug connector

- 2.5.41. Phönix Contact HC plug connector

- 2.5.42. PT 3F plug connector

- 2.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 2.5.44. Relay socket with SPT and MPT contacts

- 2.5.45. Fuse holder with SPT contacts

- 2.5.46. Sicma plug connector

- 2.5.47. SLK 2.8 plug connector

- 2.5.48. Souriau UTL7 plug connector

- 2.5.49. Superseal 1.5mm plug connector

- 2.5.50. Trident Neptune plug connector

- 2.5.51. Universal MATENLOK plug connector

- 2.5.52. VW 9.5mm plug connector

- 3. High level order pickerV11ac, V12ac

- 3.1. Table of content

- 3.2. Product information

- 3.2.1. General product information

- 3.3. Diagnostics

- 3.3.1. Diagnostics

- 3.3.2. Software

- 3.3.3. Error lists

- 3.3.4. Teachin

- 3.4. Electric motor

- 3.4.1. Traction motor

- 3.4.2. Rev sensor

- 3.4.3. Temperature sensor

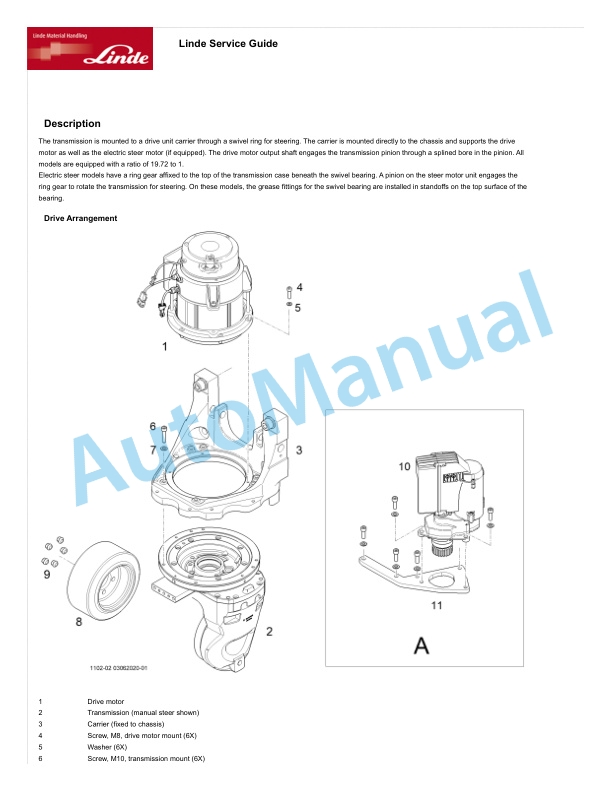

- 3.5. Mechanical drive axle

- 3.5.1. Front bevel gears

- 3.6. Steering

- 3.6.1. Electric steering

- 3.7. Mechanical guidance

- 3.7.1. Guide elements

- 3.7.2. Aisle detection

- 3.8. Inductive guidance

- 3.8.1. Inductive guidance

- 3.8.2. Central unit

- 3.8.3. Peripherals

- 3.8.4. Aisle detection

- 3.8.5. Steering angle limiter (LWB)

- 3.9. Wheels and tyres

- 3.9.1. Wheels

- 3.10. Brake system

- 3.10.1. Brake system

- 3.10.2. Electric service brake

- 3.10.3. Parking brake

- 3.11. Controls

- 3.11.1. Operating panel

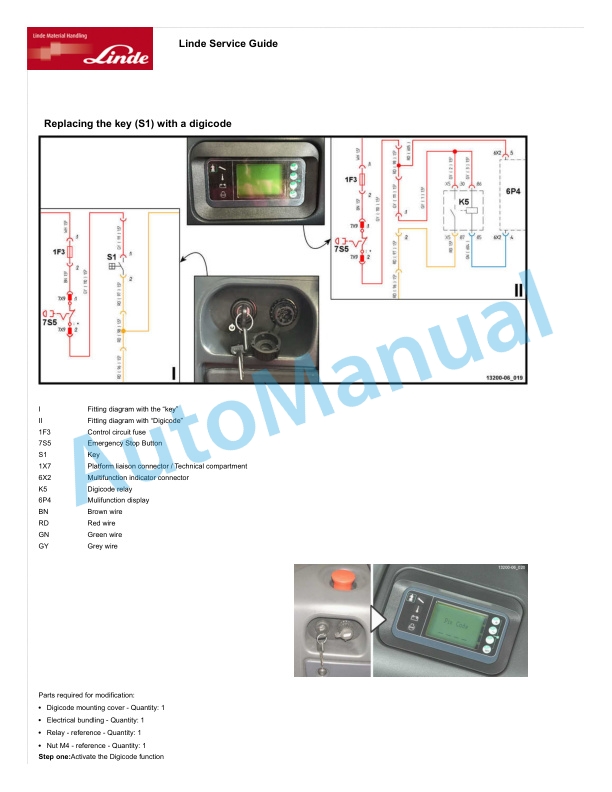

- 3.12. Electrics . Electronics

- 3.12.1. Wiring

- 3.12.2. Electrical system

- 3.12.3. Sensor system

- 3.12.4. Other components

- 3.13. Electronic controllers

- 3.13.1. Drive.pump controller (FPS) A10

- 3.13.2. Other electronic controllers

- 3.14. Hydraulics, general

- 3.14.1. Basic hydraulics

- 3.15. Valves

- 3.15.1. Pressure relief valve

- 3.15.2. Directional control valve

- 3.15.3. Proportional valve

- 3.15.4. Valve elements

- 3.15.5. Valve block

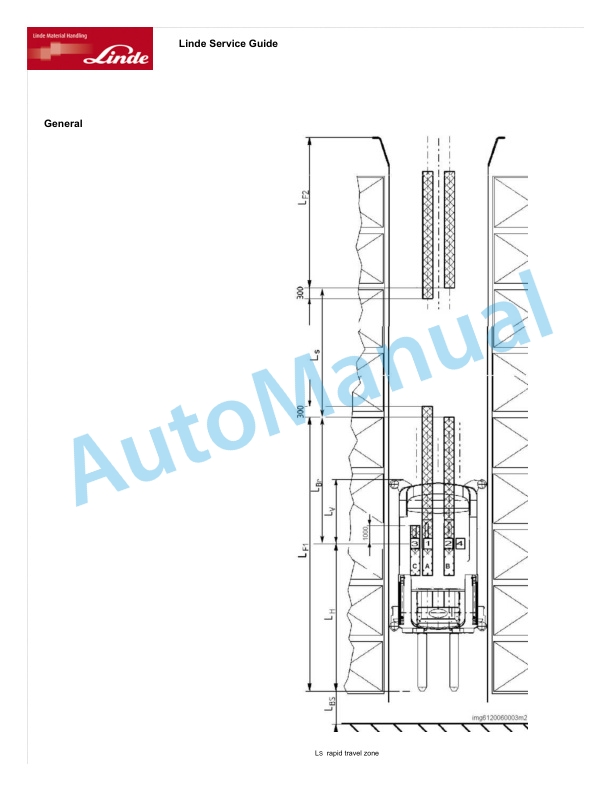

- 3.16. Load lift system

- 3.16.1. Lift mast bracing

- 3.16.2. Lift mast bearing

- 3.17. Lift mast

- 3.17.1. Lift cylinder

- 3.18. Special equipment, very narrow aisle trucks

- 3.18.1. End of aisle slow down and stop (ZAG)

- 3.19. Other accessories

- 3.19.1. Devices

- 4. Manual for qualified personsV10, V11, V12, K

- 4.1. Table of content

- 4.2. Description

- 4.2.1. Skylotec abseil system

- 4.3. Application

- 4.3.1. Preparation

- 4.3.2. Fastening the harness

- 4.3.3. Exiting the drivers cab

- 4.3.4. Operation

- 4.3.5. Followup work

- 4.4. Maintenance and testing

- 4.4.1. Maintenance

- 4.4.2. Regular testing

- 5. Mobile personal protection system

- 5.1. Table of content

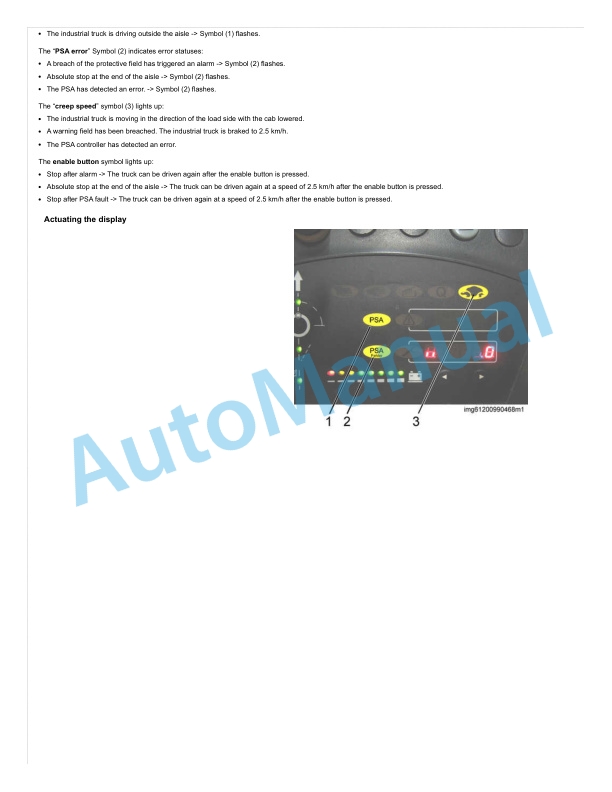

- 5.2. Mobile personal protection system

- 5.2.1. Functionality of an MPSE

- 5.2.2. MPSE operating status

- 5.2.3. Interface for the truck control unit

- 5.3. System description

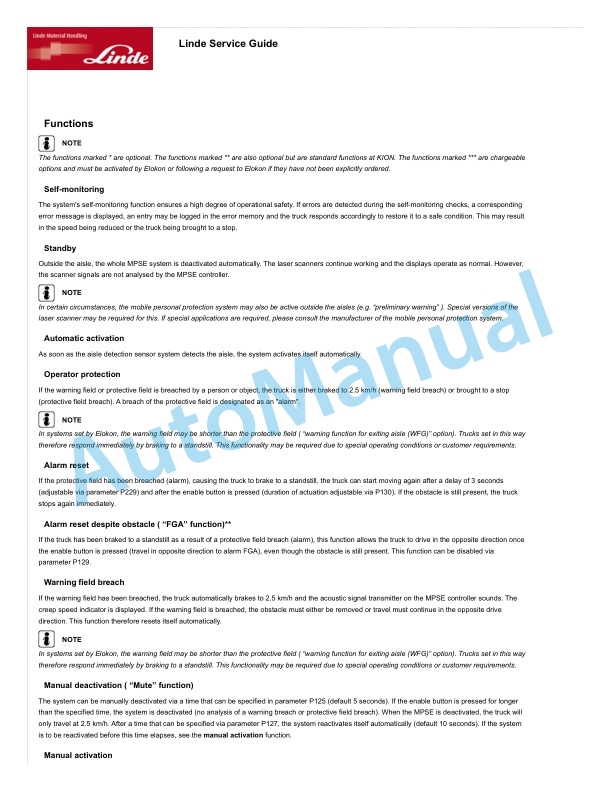

- 5.3.1. Functions

- 5.3.2. Warehouse configuration

- 5.3.3. Block diagram

- 5.4. Commissioning

- 5.4.1. Daily commissioning

- 5.4.2. Initial commissioning

- 5.5. Component descriptions

- 5.5.1. MGAL controller

- 5.5.2. Distance measuring instrument

- 5.5.3. Reflective light switch

- 5.5.4. Magnetoperated switches

- 5.6. Detectors

- 5.6.1. Laser scanner

- 5.7. Maintenance

- 5.7.1. Maintenance and testing

- 5.8. Diagnostics system

- 5.8.1. Diagnostic software

- 5.8.2. Diagnostics

- 5.8.3. Error list

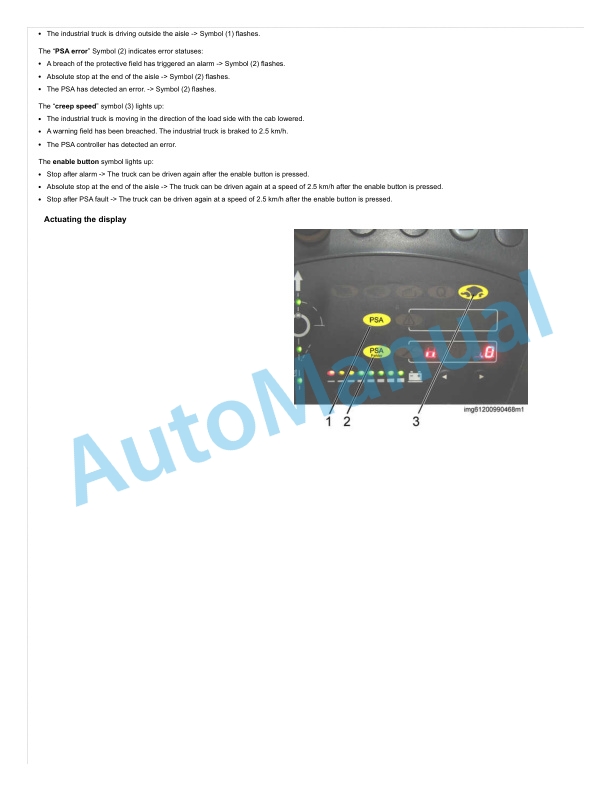

- 6. Mobile personal protection system

- 6.1. Table of content

- 6.2. Mobile personal protection system

- 6.2.1. General

- 6.2.2. Functionality of the personal protection system

- 6.3. Commissioning

- 6.3.1. Daily commissioning tasks

- 6.3.2. Initial commissioning tasks

- 6.4. Component descriptions

- 6.4.1. Block diagram

- 6.4.2. PSA controller

- 6.4.3. Interface to the industrial truck

- 6.4.4. Displacement transducer

- 6.4.5. Reflective light barriers

- 6.4.6. Reflectors

- 6.4.7. Magnetoperated switch

- 6.4.8. Laser scanner

- 6.5. Maintenance

- 6.5.1. Maintenance and testing

- 6.6. Diagnostics

- 6.6.1. Diagnostics

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Workshop Manuals SN W41110V00529 and up

$50.00

Linde Workshop Manual PDF

$50.00

Linde Workshop Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Workshop Manuals SN A11103V00001 and up

$50.00

Linde Workshop Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Workshop Manuals

$50.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF