- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 115-03 – R14G, R16G, R20G Operating Instructions SN 10.07 and up SN up to 12.09

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 10.07 and up SN up to 12.09

- Format: PDF

- Size: 23.8MB

- Number of Pages: 185

- Serial Number:

SN 10.07 and up SN up to 12.09

Category: Linde Operator Manual PDF

-

Model List:

- R14G

- R16G

- R20G

- 1. Electric reach truckR14G03, R16G03, R20G03

- 1.1. Table of content

- 1.2. Introduction and general description

- 1.2.1. Introduction

- 1.2.2. Legal requirements for marketing

- 1.2.3. General description

- 1.3. Safety

- 1.3.1. Operator safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the event of tipover

- 1.3.5. Noise emission levels

- 1.3.6. Frequency characteristic for human body vibrations

- 1.4. Getting to know the truck

- 1.4.1. Location of identification plates and labels

- 1.4.2. Truck type.capacity plate

- 1.4.3. General view of truck

- 1.4.4. Operating controls and indicators

- 1.4.5. Operators display

- 1.4.6. Definition of direction of travel

- 1.5. Operation

- 1.5.1. Runningin instructions

- 1.5.2. Preshift checks

- 1.5.2.1. Preshift

- 1.5.2.2. Check the battery state of charge

- 1.5.2.3. Check all controls and their operation

- 1.5.2.4. Check all Interlock switches

- 1.5.2.5. Check general condition of truck

- 1.5.3. The battery

- 1.5.4. Operator adjustments

- 1.5.5. Braking twin pedal

- 1.5.6. Braking single pedal

- 1.5.7. Driving twin pedal

- 1.5.8. Driving single pedal

- 1.5.9. Travelling on an incline

- 1.5.10. Operating the mast and attachments (with two joystick control)

- 1.5.11. Operating the mast and attachments (with four joystick control)

- 1.5.12. Handling loads

- 1.5.13. Before leaving the truck

- 1.5.14. Opposite direction steering (Option)

- 1.5.15. Operator code entry (Option)

- 1.5.16. Data Logger (Option)

- 1.5.17. Truck data management LFM (Option)

- 1.5.18. Ambient temperature cabin

- 1.6. Maintenance

- 1.6.1. Maintenance safety guidelines

- 1.6.2. Report of Thorough Examination

- 1.6.3. Covers and cowlings

- 1.6.4. Fuses

- 1.6.5. Emergency lower

- 1.6.6. Emergency steering and parking brake release

- 1.6.7. Slinging the truck

- 1.6.8. Securing for transportation

- 1.6.9. Jacking the truck

- 1.6.10. Towing procedure

- 1.6.11. Mast unit

- 1.6.12. Recommended lubricants

- 1.6.13. Inspection and maintenance data

- 1.6.14. Routine inspection and maintenance

- 1.6.15. Service plans

- 1.6.15.1. As required

- 1.6.15.2. h Service plan

- 1.6.15.3. h Service plan

- 1.6.15.4. h Service plan

- 1.6.15.5. h Service plan

- 1.6.15.6. h Service plan

- 1.6.16. Motor

- 1.6.16.1. Check the parking brake gap

- 1.6.17. Axles

- 1.6.17.1. Check the drive unit suspension system

- 1.6.18. Chassis, bodywork and fittings

- 1.6.18.1. Clean the truck

- 1.6.18.2. Check and lubricate the battery trolley slides and associated mechanism

- 1.6.19. Undercarriage

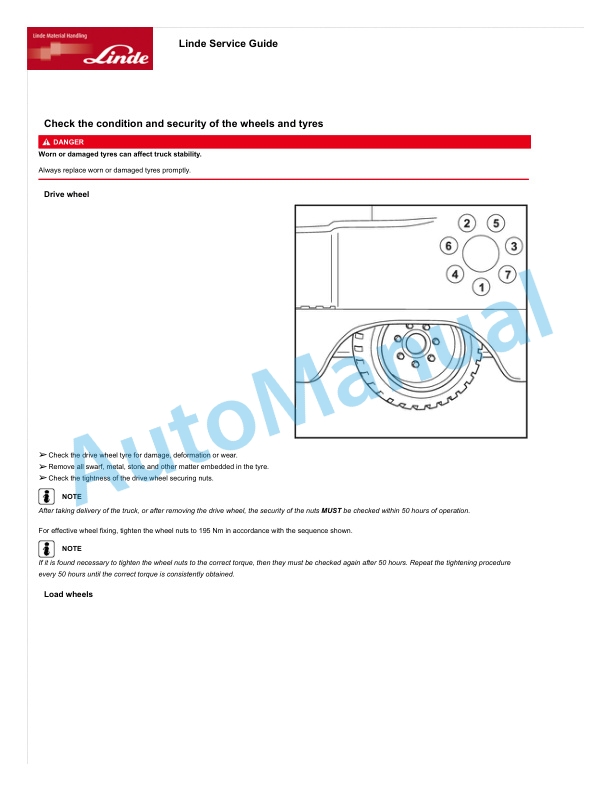

- 1.6.19.1. Check the condition and security of the wheels and tyres

- 1.6.19.2. Check the brake fluid level

- 1.6.19.3. Check the load wheel brake shoes for wear

- 1.6.19.4. Grease the load wheel bearings

- 1.6.19.5. Change the brake fluid

- 1.6.19.6. Check condition of brake pipes

- 1.6.20. Controls

- 1.6.20.1. Check all controls and their operation

- 1.6.21. Electrical . Electronic

- 1.6.21.1. Check the condition of the battery and battery cables

- 1.6.21.2. Check the battery electrolyte level and specific gravity

- 1.6.21.3. Check the condition and security of electrical connections and cables

- 1.6.22. Hydraulic installation

- 1.6.22.1. Check the hydraulic hoses and pipes for damage

- 1.6.22.2. Check the hydraulic oil level

- 1.6.22.3. Replace the hydraulic tank breather filter

- 1.6.22.4. Change the hydraulic fluid

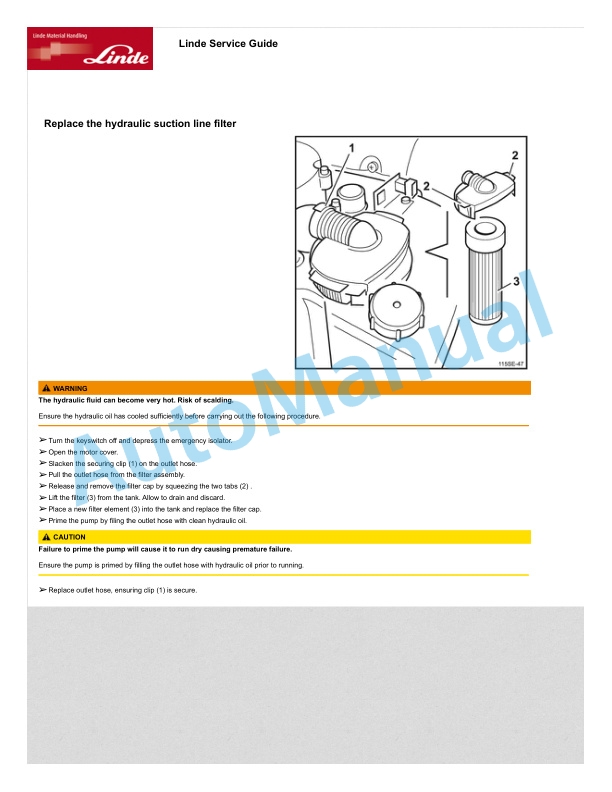

- 1.6.22.5. Replace the hydraulic suction line filter

- 1.6.23. Load lift system

- 1.6.23.1. Adjust the lift chains

- 1.6.23.2. Check the lift chains for condition and security

- 1.6.23.3. Lubricate the mast, lift chains and chain pulleys

- 1.6.23.4. Lubricate the reach channels and rollers

- 1.6.23.5. Check the reach carriage rollers, adjust if required

- 1.6.23.6. Check and lubricate the fork carriage

- 1.6.23.7. Check and lubricate the sideshift mechanism

- 1.6.23.8. Lubricate the mast pivots

- 1.6.24. Special equipment and accessories

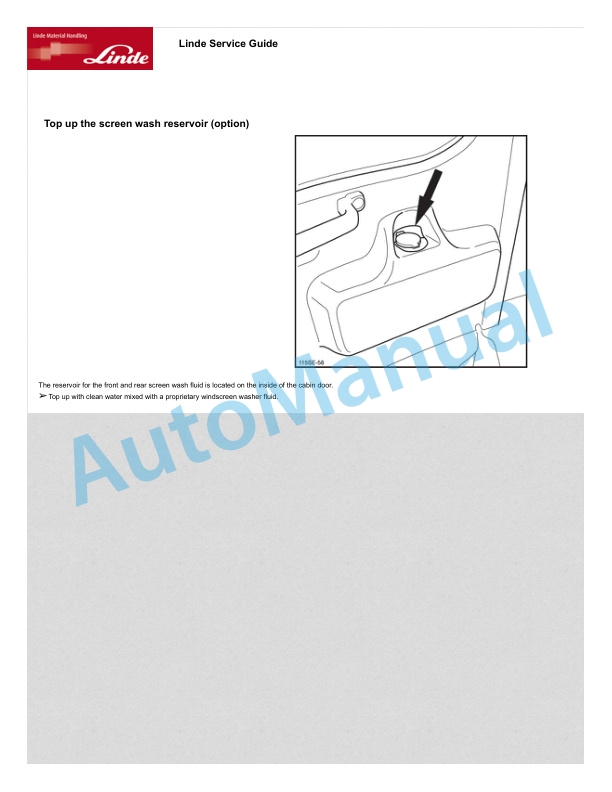

- 1.6.24.1. Top up the screen wash reservoir (option)

- 1.6.24.2. Lubricate the cabin hinges and door latch (option)

- 1.6.25. Taking the truck out of operation

- 1.6.26. Decommissioning the truck

- 1.7. Technical data

- 1.7.1. Battery data

- 1.7.2. Dimensions

- 1.7.3. Technical data 1.4 tonne capacity

- 1.7.4. Technical data 1.6 tonne capacity

- 1.7.5. Technical data 2.0 tonne capacity

- 1.7.6. Mast variations

- 1.8. Circuit diagrams

- 1.8.1. Circuit Diagram (1 of 4)

- 1.8.2. Circuit Diagram (2 of 4)

- 1.8.3. Circuit Diagram (3 of 4)

- 1.8.4. Circuit Diagram (4 of 4)

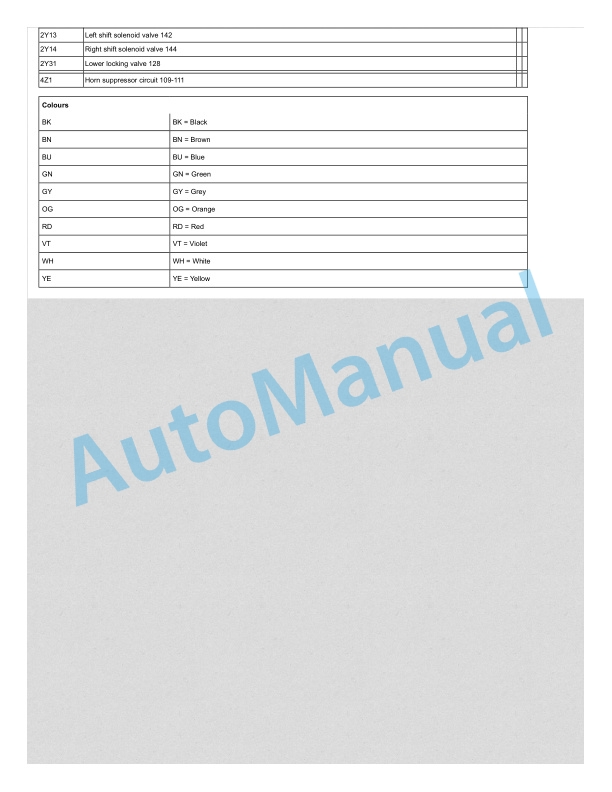

- 1.8.5. Circuit diagram (Standard) keycode

- 1.8.6. Circuit Diagram variable electric brake (1 of 4)

- 1.8.7. Circuit Diagram variable electric brake (2 of 4)

- 1.8.8. Circuit Diagram variable electric brake (3 of 4)

- 1.8.9. Circuit Diagram variable electric brake (4 of 4)

- 1.8.10. Circuit diagram (Variable electric brake) keycode

- 1.8.11. Hydraulic circuit

- 1.8.12. Hydraulic circuit keycode

Rate this product

You may also like

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

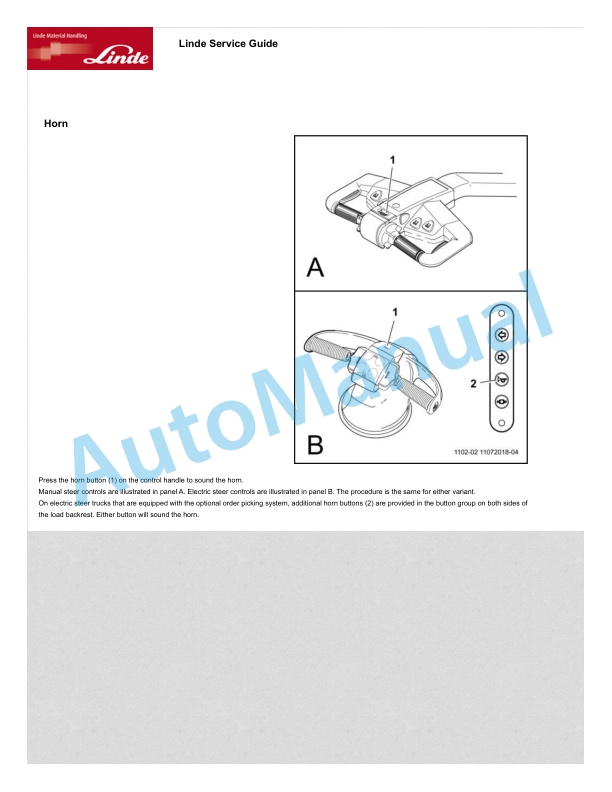

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF