- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1151-01 – T16, T16P, T20, T20P Production site Xiamen Operating Instructions SN 07.11 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 07.11 and up

- Format: PDF

- Size: 41.4MB

- Number of Pages: 330

- Serial Number:

SN 07.11 and up

Category: Linde Operator Manual PDF

-

Model List:

- T16

- T16P

- T20

- T20P

- 1. series Electric Pallet TruckModel T20

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Scope

- 1.2.2. Obligations of the Equipment Owner

- 1.2.3. Operator Responsibilities

- 1.2.4. Proper use

- 1.2.5. Hazard messages

- 1.3. Safety

- 1.3.1. Before Operation

- 1.3.2. Operator daily checklist

- 1.3.3. Operating Position

- 1.3.4. Travel

- 1.3.5. Inclines, Ramps, Docks, Elevators

- 1.3.6. Parking

- 1.3.7. Battery Safety

- 1.3.8. Safety During Maintenance

- 1.3.8.1. Personnel Qualifications

- 1.3.8.2. Hazardous Substances

- 1.3.9. Operator Warning Decals

- 1.3.9.1. Data plate

- 1.3.9.2. No riding decal

- 1.3.9.3. Trained operator warning decal

- 1.3.9.4. Test or service warning decal

- 1.3.9.5. Crushed fingers warning decal

- 1.3.9.6. No step warning decal

- 1.3.9.7. Voltage decal

- 1.4. Overview

- 1.4.1. Technical Description

- 1.4.2. Truck Components

- 1.4.3. Controls

- 1.4.4. Indicator Unit

- 1.4.5. Decal and Data Plate Location

- 1.4.6. Data Plate

- 1.4.7. Definition of directions

- 1.4.8. Options

- 1.5. Operation

- 1.5.1. Unloading and Preparing a New Truck for Operation

- 1.5.2. Turning the Truck On and Off

- 1.5.3. Keyless Access (Optional equipment)

- 1.5.4. Keyless Access Summary

- 1.5.5. Driving

- 1.5.6. Steering

- 1.5.7. Horn

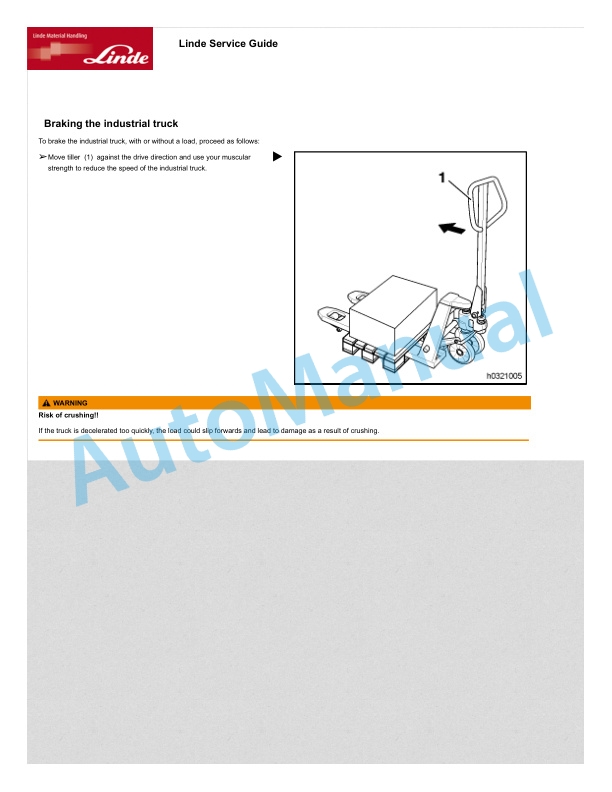

- 1.5.8. Braking

- 1.5.9. Emergency Stop Handle

- 1.5.10. Raising and Lowering the Forks

- 1.5.11. Connecting and Disconnecting the Battery

- 1.5.12. Changing the Battery

- 1.5.13. Connecting the Battery to an External Charger

- 1.5.14. Hoisting the Truck

- 1.5.15. Towing the Truck

- 1.6. Maintenance

- 1.6.1. Personnel Qualifications

- 1.6.2. Cleaning the Truck

- 1.6.3. Daily Inspection

- 1.6.3.1. Daily Inspection Overview

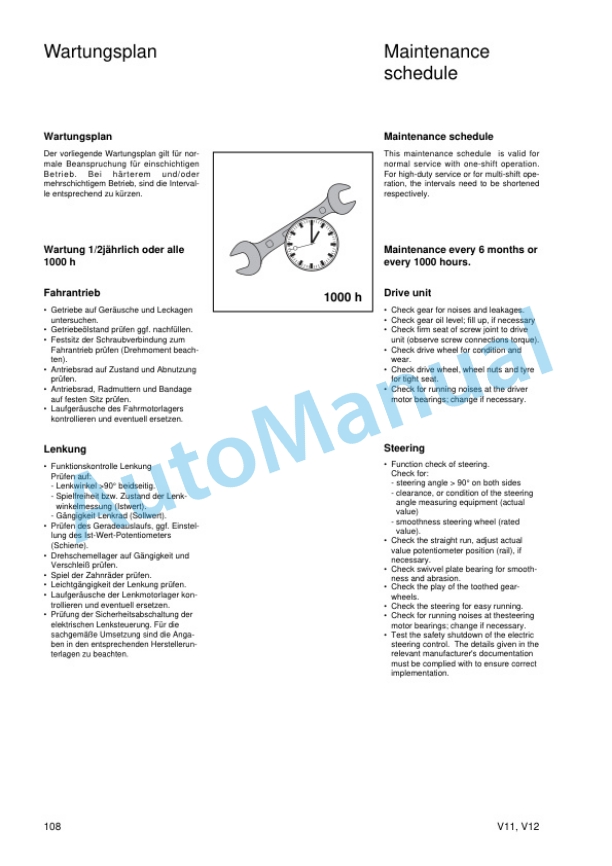

- 1.6.4. Scheduled Maintenance

- 1.6.4.1. General Maintenance Information

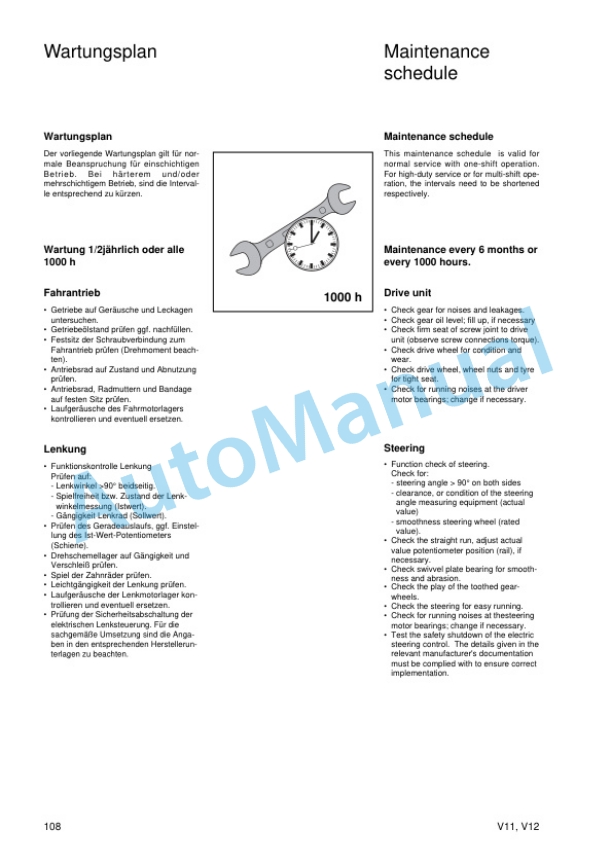

- 1.6.4.2. Maintenance at 1000 Hours

- 1.6.4.3. Maintenance at 2000 Hours

- 1.6.4.4. Maintenance at 5000 Hours

- 1.6.4.5. Maintenance at 10,000 Hours

- 1.6.4.6. Scheduled Maintenance Summary

- 1.6.5. Fluids and Lubricants

- 1.6.5.1. Fluid and Lubricant Specifications

- 1.6.5.2. Capacities

- 1.6.6. Troubleshooting

- 1.6.6.1. Removing Chassis Covers

- 1.6.6.2. Fuses

- 1.6.6.3. Diagnostic Connector

- 1.7. Technical Data

- 1.7.1. Specifications

- 2. Electric Pallet Forklift TruckT16, T20Zapi controller

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Legal requirements for marketing

- 2.2.2. Introduction

- 2.2.3. Intended use

- 2.2.4. Improper use

- 2.2.5. Additional information

- 2.2.6. Description of use and climatic conditions

- 2.2.7. Symbols used

- 2.2.8. Electric Pallet Truck 1151

- 2.3. Safety

- 2.3.1. Safety guidelines

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. EMC Electromagnetic compatibility

- 2.3.5. Handling consumables

- 2.3.6. Regulations

- 2.3.7. Competent person

- 2.4. General layout

- 2.4.1. Labels

- 2.4.2. Identification plates

- 2.4.3. T16 T20 Model General View

- 2.4.4. control unit

- 2.4.5. Battery Charging Indicator

- 2.4.6. Digicode option (LFM Go)

- 2.4.7. LFM Connect option

- 2.5.1. Settings

- 2.5.2. Checks before first commissioning

- 2.5.3. Preshift checks before starting work

- 2.5.4. Operating Instructions

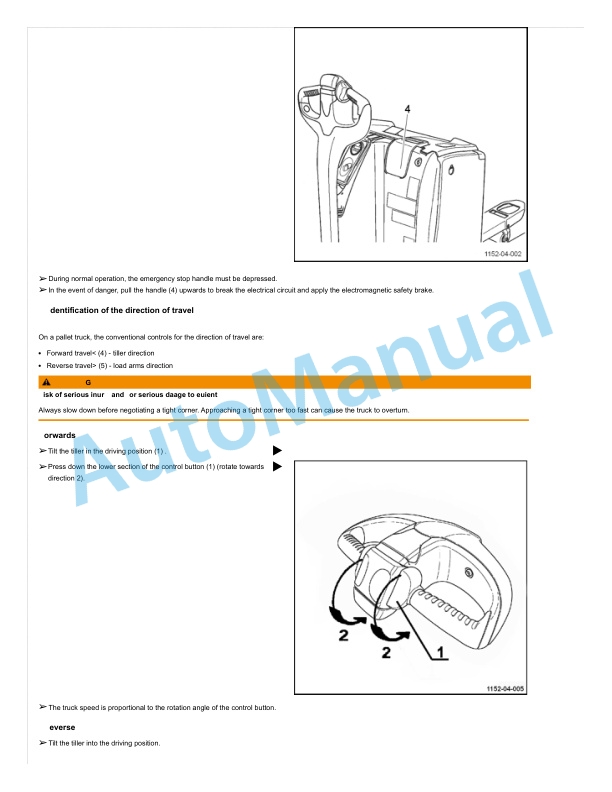

- 2.5.5. Driving 1151

- 2.5.6. Using the truck on ramps

- 2.5.7. Creep Speed Function

- 2.5.8. Braking, lifting, lowering, horn

- 2.5.9. Working with loads

- 2.5.10. Lifting and towing

- 2.5.11. Cold store usage (optional)

- 2.6. Maintenance

- 2.6.1. Inspection and maintenance work tables

- 2.6.2. hour maintenance plan

- 2.6.3. hour maintenance plan

- 2.6.4. hour maintenance plan

- 2.6.5. Technical inspection and maintenance characteristics

- 2.6.6. Recommended lubricants

- 2.6.7. Preshift checks

- 2.6.8. Checking the brakes

- 2.6.9. Testing the safety devices

- 2.6.10. Checking the battery charging status

- 2.6.11. Connecting.disconnecting the battery plug connector

- 2.6.12. Opening the battery cover

- 2.6.13. Charging the battery with the builtin charger

- 2.6.14. Battery charging with an external charger

- 2.6.15. Essential maintenance

- 2.6.15.1. Cleaning the Pallet Truck

- 2.6.15.2. Cleaning the battery and its compartment

- 2.6.15.3. Accessing the electrical control compartment

- 2.6.15.4. Checking the condition of cables, terminals and the battery connector

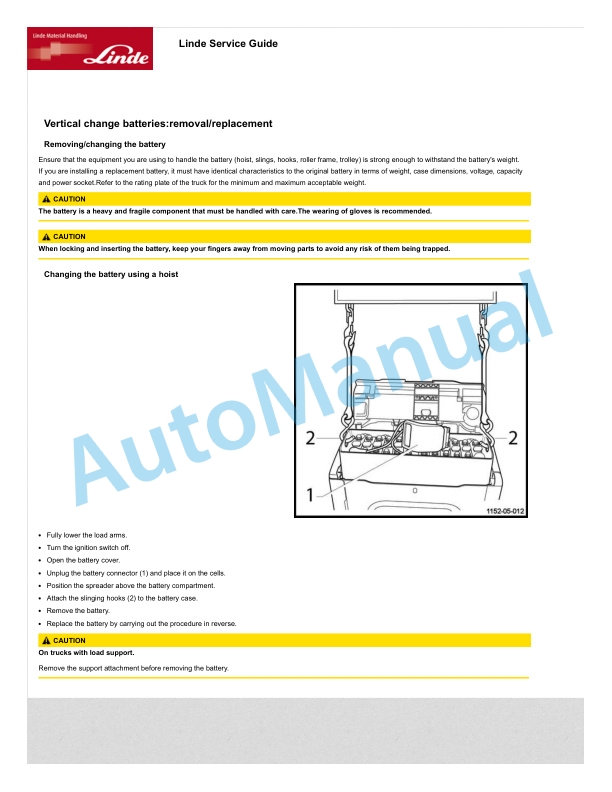

- 2.6.15.5. Vertical change batteriesremoval.replacement

- 2.6.15.6. Lateral change batterychanging the battery using a trolley

- 2.6.15.7. Lateral change batterychanging the battery using a mobile support

- 2.6.16. hour maintenance plan

- 2.6.16.1. Checking the brake air gap

- 2.6.16.2. Adjusting the height of the stabilisers

- 2.6.16.3. Oil level check

- 2.6.16.4. Battery maintenance

- 2.6.16.5. Checking the wear on collars and hinge pins

- 2.6.16.6. Greasing the rings and articulations (greased option)

- 2.6.17. hour maintenance plan

- 2.6.17.1. Hydraulic circuit, draining the circuit

- 2.6.18. hour maintenance plan

- 2.6.18.1. Servicing the reducer

- 2.7. Datasheet

- 2.7.1. T16 . T20 Datasheet

- 2.7.2. Technical datasheet T16 . T20

- 3. Electric pallet truck1151_T16, 1151_T16P, 1151_T20, 1151_T20P

- 3.1. Table of content

- 3.2. Introduction

- 3.2.1. Introduction

- 3.2.2. Impermissible use

- 3.2.3. Description of use and climatic conditions

- 3.2.4. Symbols used

- 3.2.5. Legal requirements for marketing

- 3.2.6. Electric pallet trucks 1151

- 3.3. Safety

- 3.3.1. Residual risks

- 3.3.2. Stability

- 3.3.3. Safety regulations

- 3.3.4. Use of lubricants

- 3.3.5. Periodic general checks on trucks

- 3.4. General views

- 3.4.1. Labels

- 3.4.2. Identification plates

- 3.4.3. General view T16 T20 type 1151

- 3.4.4. General view T16P T20P type 1151

- 3.4.5. Controls for 1151

- 3.4.6. Battery charge indicator

- 3.4.7. Digicode option (LFM Go)

- 3.4.8. LFM AccessLFM Basic option

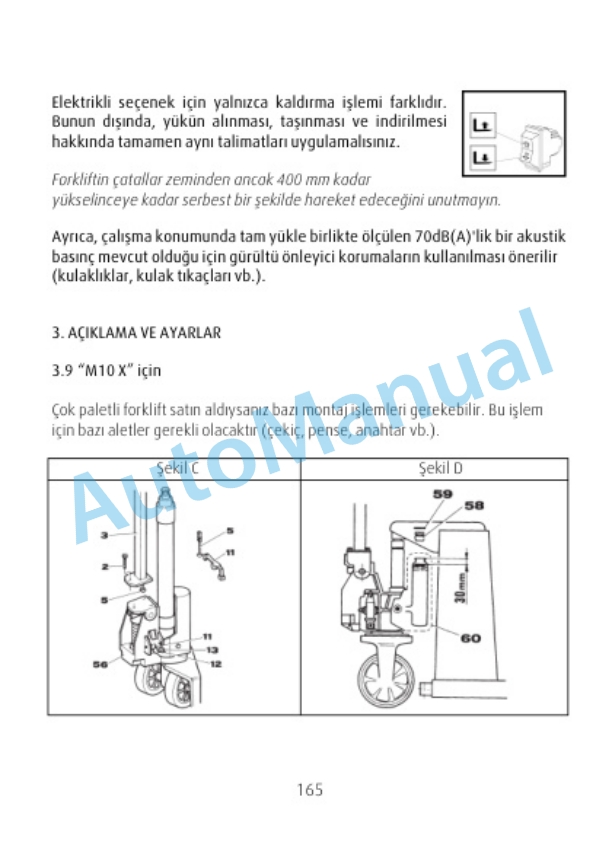

- 3.5.1. Setup

- 3.5.2. Checks before first commissioning

- 3.5.3. Preshift checks before starting work

- 3.5.4. Adjusting the onboard charger

- 3.5.5. Operating instructions for 1151

- 3.5.6. Driving the 1151

- 3.5.7. Use of the truck on a slope

- 3.5.8. Braking

- 3.5.9. Designation

- 3.6. Maintenance

- 3.6.1. General information

- 3.6.2. Daily checks before starting work

- 3.6.2.1. Checking the direction of travel controls

- 3.6.2.2. Checking the lifting.lowering controls

- 3.6.2.3. Checking the battery charging status

- 3.6.2.4. Battery charging using an external charger

- 3.6.3. Maintenance plan as required

- 3.6.3.1. Cleaning the battery and its compartment

- 3.6.3.2. Access to the technical compartment

- 3.6.3.3. Accessing the reducer and the brake

- 3.6.3.4. Checking the fuses

- 3.6.3.5. Opening the battery cover

- 3.6.3.6. Disconnecting.connecting the battery connector

- 3.6.4. Inspection and maintenance overview

- 3.6.5. Gearbox

- 3.6.6. Steering . braking . wheels

- 3.6.6.1. Adjusting the height of the stabilisers

- 3.6.7. Electrical equipment

- 3.6.7.1. Battery maintenance

- 3.6.7.2. Checking the onboard charger

- 3.6.8. Hydraulic circuits

- 3.6.8.1. Oil level check

- 3.6.8.2. Hydraulic circuit, draining the circuit

- 3.6.9. Lifting system

- 3.6.9.1. Checking the wear on collars and hinge pins

- 3.6.9.2. Greasing the rings and articulations (greased option)

- 3.7. Datasheet

- 3.7.1. Datasheet T16 . T20

- 3.7.2. Datasheet T16P . T20P

- 3.7.3. Noise emission values

- 4. Leadacid battery charger 24V

- 5. Leadacid battery charger 24V . 48V

- 6. Leadacid battery charger 24V . 48V . 80V

Rate this product

You may also like

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

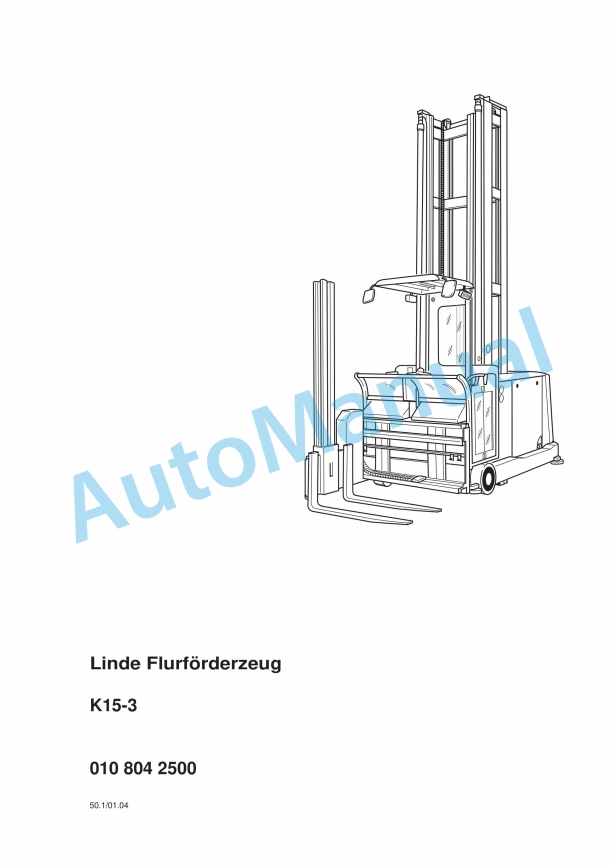

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF