- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1153-01 – T20AP Ex3G, T25 Ex3G, T25AP Ex3G, T30 Ex3G Workshop Manuals

$50.00

- Type Of Manual: Workshop Manuals

- Format: PDF

- Size: 115.8MB

- Number of Pages: 920

Category: Linde Workshop Manual PDF

-

Model List:

- T20AP Ex3G

- T25 Ex3G

- T25AP Ex3G

- T30 Ex3G

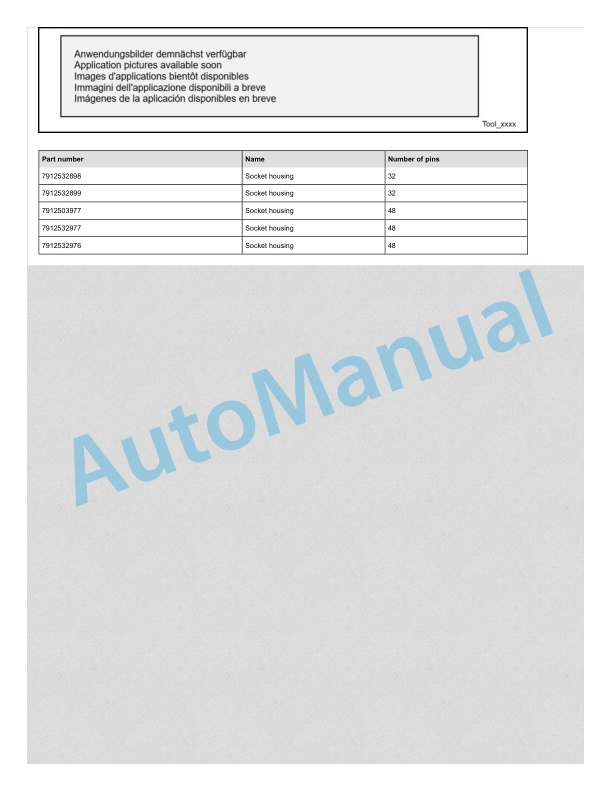

- 1. Service case Release tools for contacts

- 1.1. Table of content

- 1.2. Safety information

- 1.2.1. Safety information for repair and maintenance work

- 1.3. Information

- 1.3.1. Information

- 1.4. Overview

- 1.4.1. Overview of service cases

- 1.5. Plug systems

- 1.5.1. ATS 2.8 plug connector

- 1.5.2. CMC plug connector

- 1.5.3. DCS 9.5 plug connector

- 1.5.4. DIN 1.5mm circular connector

- 1.5.5. DIN 2.5mm circular connector

- 1.5.6. Deutsch DTM plug connector

- 1.5.7. ECU appliance plug

- 1.5.8. MCON appliance plug

- 1.5.9. Appliance plug with JPT and MQS contacts

- 1.5.10. Appliance plug with MT2 and JPT contacts

- 1.5.11. SICMA appliance plug

- 1.5.12. Econoseal JMark 2 plug connector

- 1.5.13. Elobau 11pin receptacle housing

- 1.5.14. E5931 plug connector

- 1.5.15. FASTINFASTON 6.3mm plug connector

- 1.5.16. GT150 plug connector

- 1.5.17. HDSCS plug connector

- 1.5.18. JPT plug connector

- 1.5.19. JPT SLD plug connector

- 1.5.20. JPT plug connector Saab

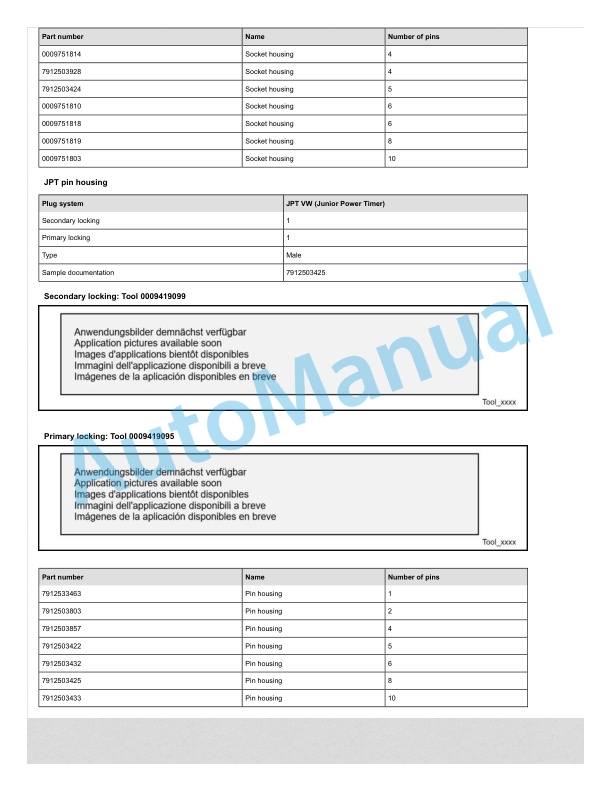

- 1.5.21. JPT plug connector VW

- 1.5.22. Kompakt 1.1 plug connector

- 1.5.23. Bosch Kompakt 4 plug connector

- 1.5.24. Leavyseal plug connector

- 1.5.25. MCON 1.2mm LL plug connector

- 1.5.26. MCON 1.2mm CB plug connector

- 1.5.27. MCP plug connector

- 1.5.28. MetriPack 150 plug connector

- 1.5.29. MiniFit plug connector

- 1.5.30. Mini Universal MATENLOK plug connector

- 1.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 1.5.32. MKR Plus plug connector

- 1.5.33. MQS plug connector

- 1.5.34. MR plug connector

- 1.5.35. MTA plug housing and fuse housing

- 1.5.36. MT2 plug connector

- 1.5.37. MT2 1.5mm plug connector VW

- 1.5.38. Multilock plug connector

- 1.5.39. MX150 plug connector

- 1.5.40. NG1 plug connector

- 1.5.41. Phönix Contact HC plug connector

- 1.5.42. PT 3F plug connector

- 1.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 1.5.44. Relay socket with SPT and MPT contacts

- 1.5.45. Fuse holder with SPT contacts

- 1.5.46. Sicma plug connector

- 1.5.47. SLK 2.8 plug connector

- 1.5.48. Souriau UTL7 plug connector

- 1.5.49. Superseal 1.5mm plug connector

- 1.5.50. Trident Neptune plug connector

- 1.5.51. Universal MATENLOK plug connector

- 1.5.52. VW 9.5mm plug connector

- 2. Extest recording for ignition protection types

- 3. Explosion protection

- 3.1. Table of content

- 3.2. Basic principles

- 3.2.1. ATEX

- 3.2.2. Implementing the directives into national law

- 3.2.3. Conformity assessment procedures

- 3.2.4. EU type approval

- 3.2.5. Notified bodies

- 3.2.6. Explosion protection measures

- 3.2.7. Fires and explosion conditions

- 3.2.8. Potential sources of ignition

- 3.2.9. Potentially explosive area

- 3.2.10. Hazardous quantities

- 3.2.11. Explosion limits

- 3.2.12. Zones for potentially explosive areas

- 3.2.13. Classification as equipment for potentially explosive atmospheres

- 3.2.14. Classification as electrical equipment for potentially explosive atmospheres

- 3.2.15. Equipment categories

- 3.2.16. Equipment Protection Level (EPL)

- 3.2.17. Identification

- 3.2.18. Assignment of zones, equipment category and protection level

- 3.2.19. Protection types provided by housings with an IP code

- 3.2.20. Significant temperatures

- 3.3. Spark protection

- 3.3.1. Overview

- 3.3.2. Flameproof enclosure Ex d

- 3.3.3. Increased safety Ex e

- 3.3.4. Intrinsic safety Ex i

- 3.3.5. Type of spark protection Ex n

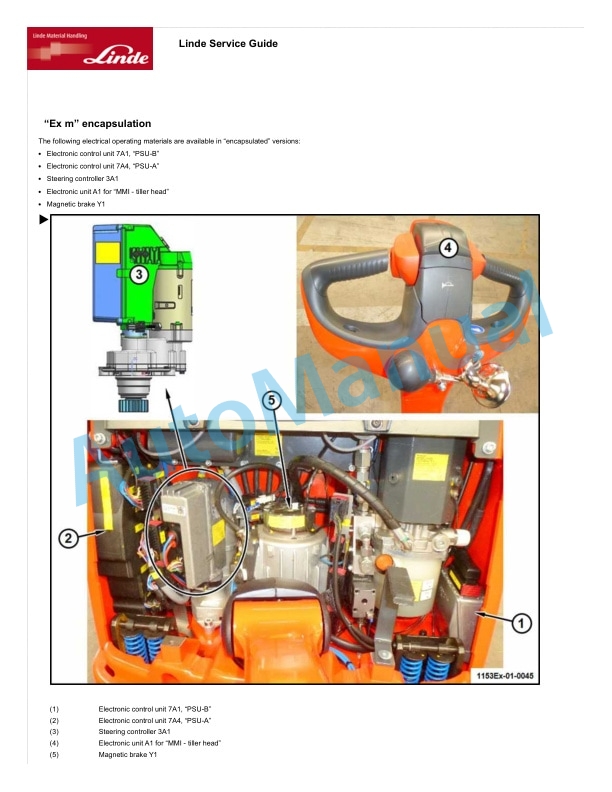

- 3.3.6. Encapsulation Ex m

- 3.3.7. Equipment dust explosion protection by enclosures Ex t

- 3.3.8. Constructional safety Ex c

- 3.3.9. Protection against static electricity

- 3.4. Safety electronics

- 3.4.1. Receiver

- 3.4.2. Horn control

- 3.4.3. Interface

- 3.4.4. Insulation monitoring

- 3.4.5. Fan thermostat

- 3.4.6. Proplan safety unit

- 3.4.7. REG 16 temperature control

- 3.4.8. Relay box

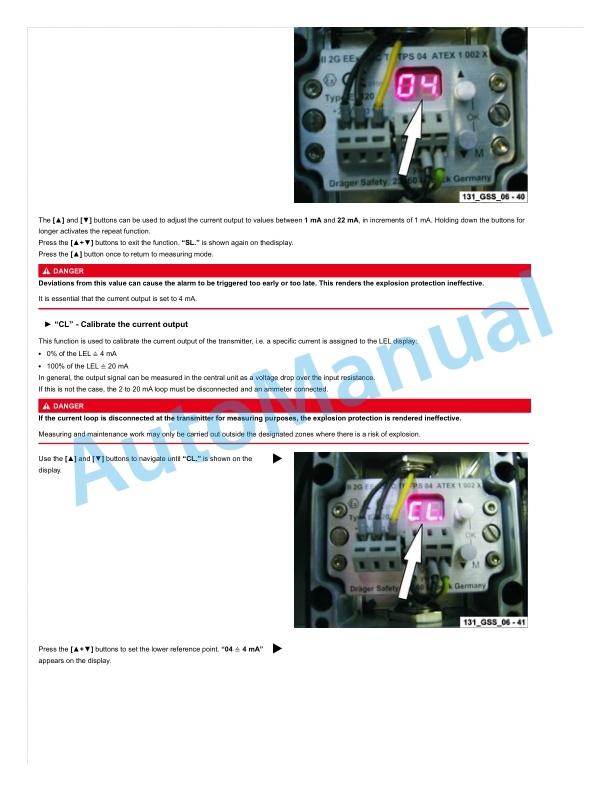

- 3.4.9. Transmitter

- 3.4.10. PWM monitoring system electronic control unit

- 3.4.11. THERMO 16 electronic control unit

- 3.4.12. Converter

- 3.5. Gas safety systems

- 3.5.1. Gas explosion conditions

- 3.5.2. Explosion limits

- 3.5.3. Preventing a gas explosion

- 3.5.4. Using gas safety systems

- 3.5.5. Gas safety systems on industrial trucks

- 3.5.6. Gas measurement

- 3.5.7. Gas safety systems in use

- 4. Lithiumion 24V warehouse batteries

- 4.1. Table of content

- 4.2. Product information

- 4.2.1. Foreword

- 4.2.2. Safety information

- 4.3. Service

- 4.3.1. Operating materials

- 4.4. Diagnostics

- 4.4.1. Diagnostics

- 4.5. Battery status

- 4.5.1. Status of the battery

- 4.5.2. Transport function

- 4.5.3. Under voltage protection

- 4.5.4. Waking up the battery

- 4.5.5. Heating functions

- 4.6. Deenergised system

- 4.6.1. BG 20

- 4.6.2. BG 21, BG 22

- 4.7. Design and function

- 4.7.1. Structural principle of the battery

- 4.7.2. Structural principle of the battery module

- 4.7.3. Structural principle of the technology compartment

- 4.7.4. CAN bus connections

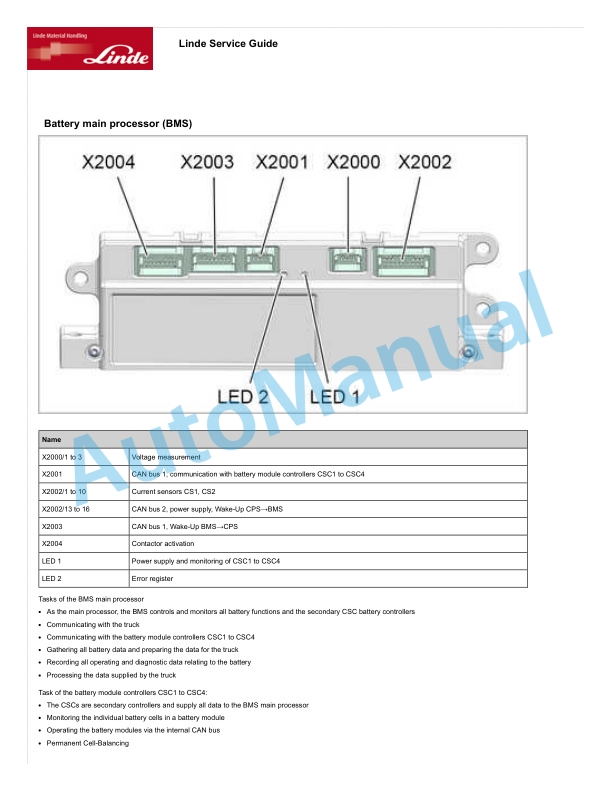

- 4.7.5. Battery main processor (BMS)

- 4.7.6. Constant power supply (CPS)

- 4.7.7. Current.voltage sensors (CVS)

- 4.7.8. Battery isolating contactor (BSD)

- 4.7.9. Electrical fuses

- 4.7.10. Pressure compensation element

- 4.8. Battery tray

- 4.8.1. Warehouse technology 1

- 4.9. Wiring

- 4.9.1. Warehouse technology

- 4.10. Technology compartment

- 4.10.1. BG 20

- 4.10.2. BG 21, BG 22

- 4.11. Battery

- 4.11.1. BG 20

- 4.11.2. BG 21, BG 22

- 5. Lithiumion 24 V warehouse batteries

- 5.1. Table of content

- 5.2. Product information

- 5.2.1. Description of lithiumion battery

- 5.2.2. Emergency procedures

- 5.2.3. Functional description

- 5.3. Service

- 5.3.1. Maintenance and repair

- 5.4. Diagnostics

- 5.4.1. Diagnostics

- 5.5. Wiring

- 5.5.1. Power cables and communication cables

- 5.5.2. Removing.installing the power cable

- 5.6. Battery access

- 5.6.1. Battery trays, warehouse technology

- 5.6.2. Removing.installing the battery

- 5.7. Compact D1.D3

- 5.7.1. Deenergised system

- 5.7.2. Structure Components

- 5.7.3. Technology compartment Components

- 5.8. NextGen F6

- 5.8.1. Deenergised system

- 5.8.2. Structure Components

- 5.8.3. Technology compartment Components

- 5.9. NextGen H9.H12

- 5.9.1. Deenergised system

- 5.9.2. Structure Components

- 5.9.3. Technology compartment Components

- 6. Pallet truckT20AP, T20APB, T25, T25AP, T30 Ex3G

- 6.1. Table of content

- 6.2. Product information

- 6.2.1. Truck information

- 6.2.2. Service

- 6.3. Running gear and drive train

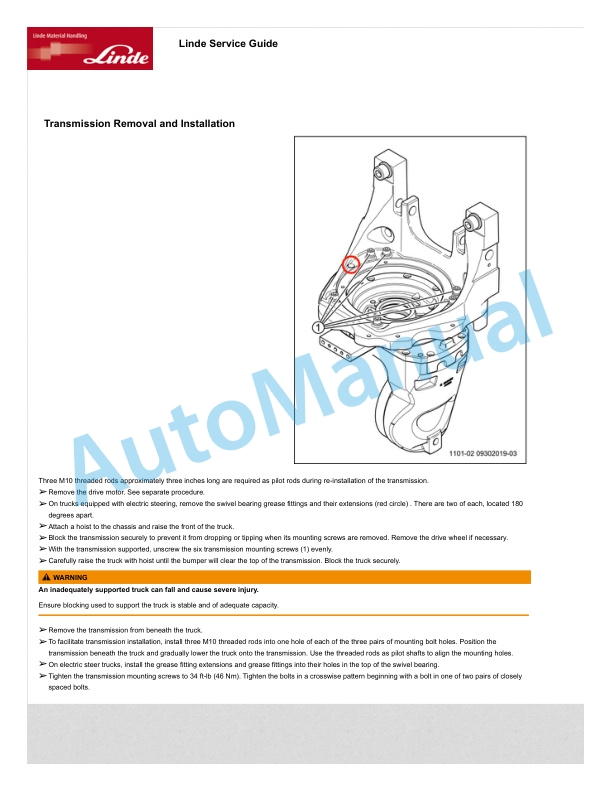

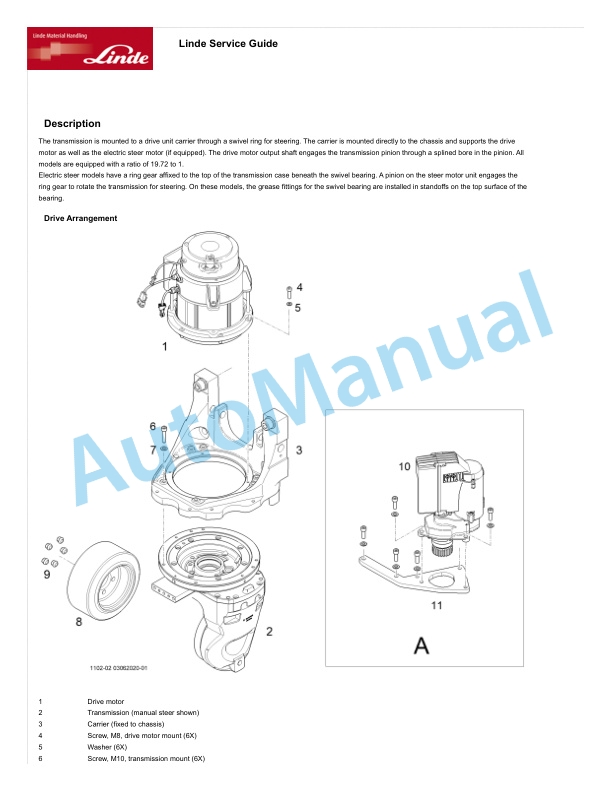

- 6.3.1. Drive components

- 6.3.2. Steering system

- 6.3.3. Brake system

- 6.4. Drivers compartment

- 6.4.1. Overview of operating units and display elements

- 6.4.2. Operating units

- 6.4.3. Display elements

- 6.5. Electrics.electronics

- 6.5.1. Wiring

- 6.5.2. Electrics.electronics components

- 6.5.3. Control units

- 6.6. Hydraulics

- 6.6.1. Basic and working hydraulics

- 7. Pallet truckT20AP, T20APB, T25, T25AP, T30 Ex3G

- 7.1. Table of content

- 7.2. Product information

- 7.2.1. Truck information

- 7.2.2. Service

- 7.3. Running gear and drive train

- 7.3.1. Drive components

- 7.3.2. Steering system

- 7.4. Drivers compartment

- 7.4.1. Overview of operating units and display elements

- 7.4.2. Operating units

- 7.4.3. Display elements

- 7.5. Electrics.electronics

- 7.5.1. Wiring

- 7.5.2. Control units

- 7.6. hydraulics

- 7.6.1. Basic and working hydraulics

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Workshop Manuals

$50.00

Linde Workshop Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Workshop Manuals SN A11102V00001 and up

$50.00

Linde Workshop Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Workshop Manuals

$50.00

Linde Workshop Manual PDF

$50.00

Linde Workshop Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Workshop Manuals SN A11103V00001 and up

$50.00

Linde Workshop Manual PDF

$50.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF