- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1165-01 – ML16P Production site Xiamen Operating Instructions SN CT1165J00001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN CT1165J00001 and up

- Format: PDF

- Size: 14.5MB

- Number of Pages: 101

- Serial Number:

SN CT1165J00001 and up

Category: Linde Operator Manual PDF

-

Model List:

- ML16P

- 1. Electric Pallet StackerML16AP

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. General information

- 1.2.3. Conformity marking

- 1.2.4. Declaration that reflects the content of the declaration of conformity

- 1.2.5. Nameplate (LX)

- 1.2.6. Factory dataplate (for exports)

- 1.2.7. Intended use of the trucks

- 1.2.8. Additional information

- 1.2.9. Hazard assessment

- 1.2.10. Disposing of components and batteries

- 1.2.11. Impermissible use

- 1.2.12. Symbols used

- 1.2.13. Description of use and climatic conditions

- 1.2.14. Technical description

- 1.2.15. Series

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. Operating company

- 1.3.5. Drivers

- 1.3.6. Competent person

- 1.3.7. Regulations

- 1.3.8. Handling consumables

- 1.3.9. Use of lubricants

- 1.3.10. EMC Electromagnetic compatibility

- 1.4. Views

- 1.4.1. Drive directions

- 1.4.2. Overview of main components

- 1.4.3. Tiller

- 1.4.4. Dataplate and safety labels

- 1.4.5. Load label

- 1.5. Operation

- 1.5.1. Intended use of the trucks

- 1.5.2. First use

- 1.5.3. Daily checks before use

- 1.5.4. Checking the working environment

- 1.5.5. General information on batteries

- 1.5.6. Charging and discharging batteries

- 1.5.7. Drive operations

- 1.5.7.1. Description

- 1.5.7.2. Starting

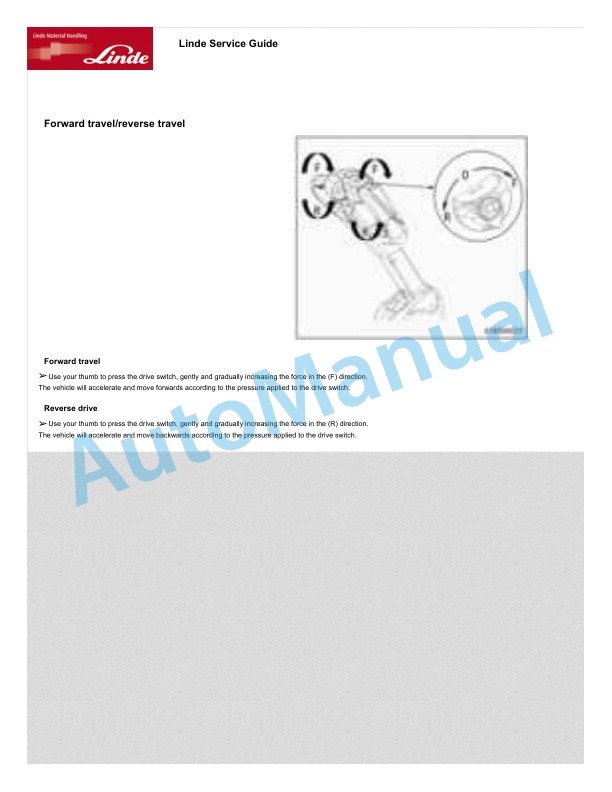

- 1.5.7.3. Forward travel.reverse travel

- 1.5.7.4. Braking

- 1.5.7.5. Safety reverser

- 1.5.7.6. Steering

- 1.5.7.7. Horn

- 1.5.7.8. Use on a slope

- 1.5.8. Hydraulic operations

- 1.5.8.1. Using the mast

- 1.5.8.2. Working with loads

- 1.5.8.3. Emergency lowering

- 1.5.9. Before leaving the equipment

- 1.5.10. Putting the equipment back into operation

- 1.5.11. Slinging

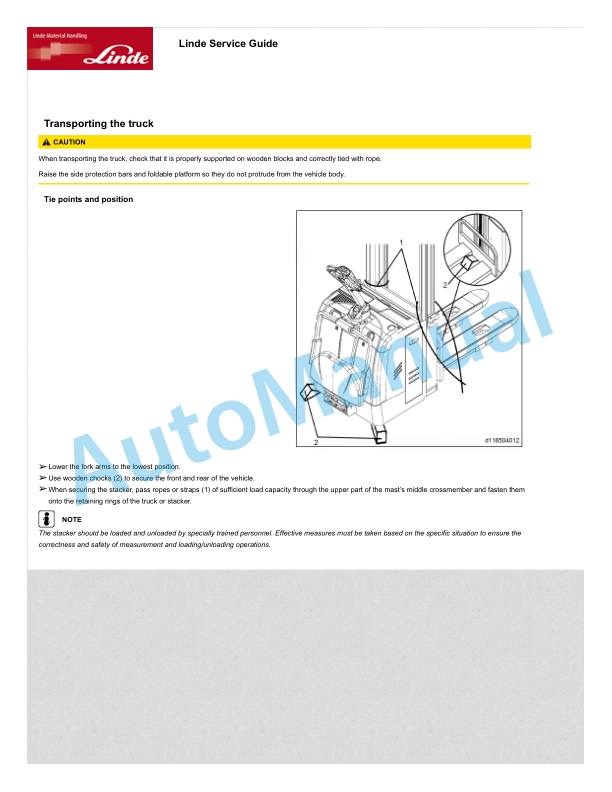

- 1.5.12. Transporting the truck

- 1.6. Maintenance

- 1.6.1. General maintenance information

- 1.6.1.1. General

- 1.6.1.2. Servicing and maintenance personnel training and qualification

- 1.6.1.3. Battery maintenance staff

- 1.6.1.4. Maintenance operations that do not require special training

- 1.6.2. Service plan

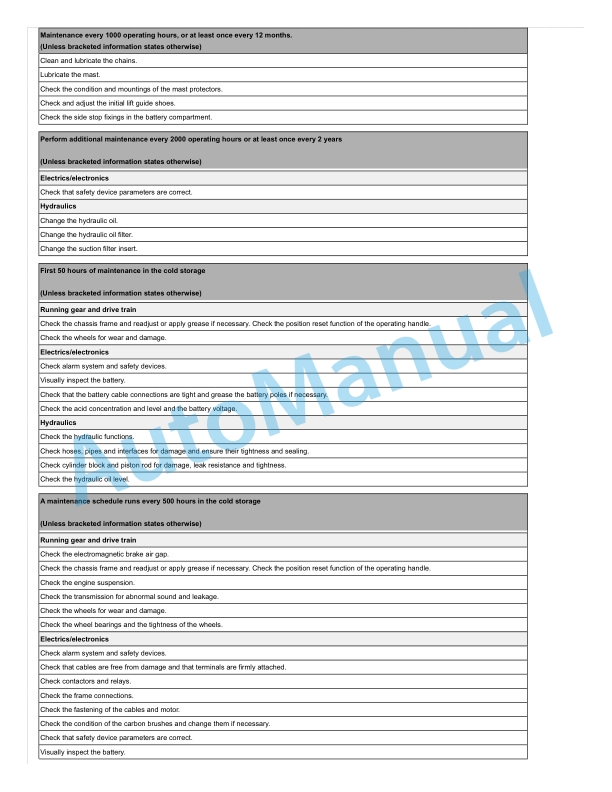

- 1.6.3. Service plan table

- 1.6.4. Maintenance work

- 1.6.4.1. Changing the battery

- 1.6.4.2. Removing the front hood

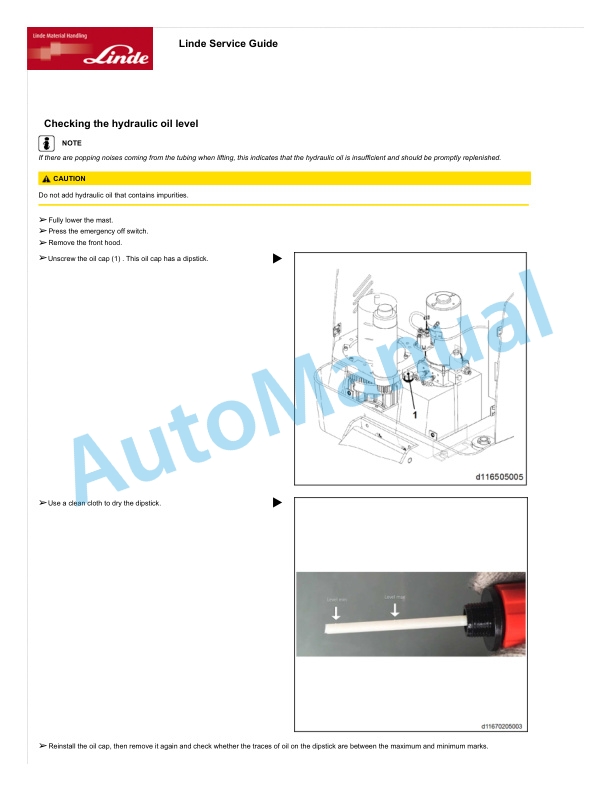

- 1.6.4.3. Checking the hydraulic oil level

- 1.6.4.4. Checking the gear oil level

- 1.6.4.5. Checking fuses

- 1.6.4.6. Lubrication point

- 1.6.4.7. Recommended lubricants for cold store vehicles

- 1.6.5. Tyre operation

- 1.6.5.1. Drive Wheel

- 1.6.5.2. Load wheels removing and installing

- 1.6.5.3. Caster Removal and Installation

- 1.6.6. Malfunction analysis

- 1.7. Technical data

- 1.7.1. Dimensional Illustration

- 1.7.2. ML16AP technical datasheet

- 1.8. Schematic diagrams

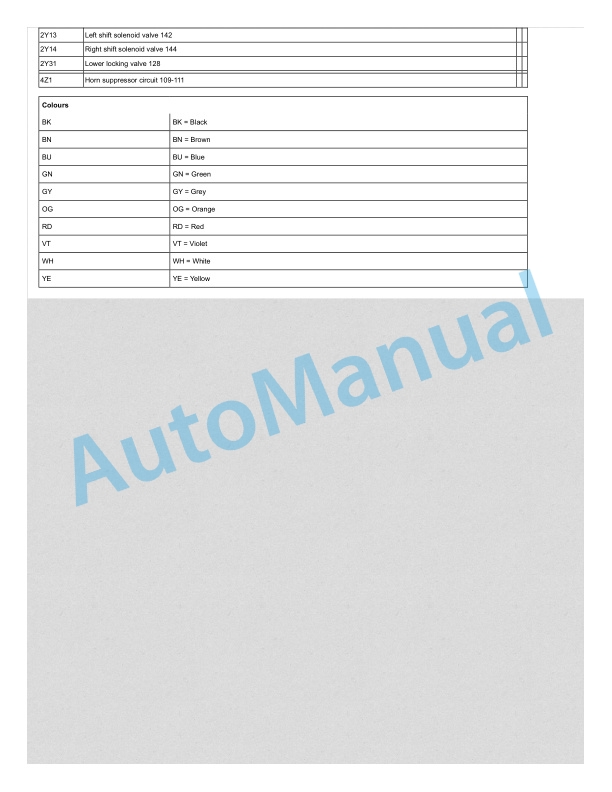

- 1.8.1. Electrical diagrams

- 1.8.2. Hydraulic diagram

- 1.8.3. Brake Principle

- 1.8.4. Diagram of major stressed structural parts

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF