- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1166-01 – MR12AP, MR15AP Production site Xiamen Workshop Manuals SN CT1166J00001 and up

$50.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN CT1166J00001 and up

- Format: PDF

- Size: 35.1MB

- Number of Pages: 276

- Serial Number:

SN CT1166J00001 and up

Category: Linde Workshop Manual PDF

-

Model List:

- MR12AP

- MR15AP

- 1. Service case Release tools for contacts

- 1.1. Table of content

- 1.2. Safety information

- 1.2.1. Safety information for repair and maintenance work

- 1.3. Information

- 1.3.1. Information

- 1.4. Overview

- 1.4.1. Overview of service cases

- 1.5. Plug systems

- 1.5.1. ATS 2.8 plug connector

- 1.5.2. CMC plug connector

- 1.5.3. DCS 9.5 plug connector

- 1.5.4. DIN 1.5mm circular connector

- 1.5.5. DIN 2.5mm circular connector

- 1.5.6. Deutsch DTM plug connector

- 1.5.7. ECU appliance plug

- 1.5.8. MCON appliance plug

- 1.5.9. Appliance plug with JPT and MQS contacts

- 1.5.10. Appliance plug with MT2 and JPT contacts

- 1.5.11. SICMA appliance plug

- 1.5.12. Econoseal JMark 2 plug connector

- 1.5.13. Elobau 11pin receptacle housing

- 1.5.14. E5931 plug connector

- 1.5.15. FASTINFASTON 6.3mm plug connector

- 1.5.16. GT150 plug connector

- 1.5.17. HDSCS plug connector

- 1.5.18. JPT plug connector

- 1.5.19. JPT SLD plug connector

- 1.5.20. JPT plug connector Saab

- 1.5.21. JPT plug connector VW

- 1.5.22. Kompakt 1.1 plug connector

- 1.5.23. Bosch Kompakt 4 plug connector

- 1.5.24. Leavyseal plug connector

- 1.5.25. MCON 1.2mm LL plug connector

- 1.5.26. MCON 1.2mm CB plug connector

- 1.5.27. MCP plug connector

- 1.5.28. MetriPack 150 plug connector

- 1.5.29. MiniFit plug connector

- 1.5.30. Mini Universal MATENLOK plug connector

- 1.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 1.5.32. MKR Plus plug connector

- 1.5.33. MQS plug connector

- 1.5.34. MR plug connector

- 1.5.35. MTA plug housing and fuse housing

- 1.5.36. MT2 plug connector

- 1.5.37. MT2 1.5mm plug connector VW

- 1.5.38. Multilock plug connector

- 1.5.39. MX150 plug connector

- 1.5.40. NG1 plug connector

- 1.5.41. Phönix Contact HC plug connector

- 1.5.42. PT 3F plug connector

- 1.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 1.5.44. Relay socket with SPT and MPT contacts

- 1.5.45. Fuse holder with SPT contacts

- 1.5.46. Sicma plug connector

- 1.5.47. SLK 2.8 plug connector

- 1.5.48. Souriau UTL7 plug connector

- 1.5.49. Superseal 1.5mm plug connector

- 1.5.50. Trident Neptune plug connector

- 1.5.51. Universal MATENLOK plug connector

- 1.5.52. VW 9.5mm plug connector

- 2. Electric Reach TruckMR12AP, MR15AP

- 2.1. Table of content

- 2.2. Product Information

- 2.2.1. Overview and Specifications

- 2.2.1.1. SAFETY WARNING

- 2.2.1.2. Common Tools

- 2.2.1.3. General Tightening Torques

- 2.2.2. Troubleshooting

- 2.2.2.1. Preparation Before Troubleshooting

- 2.2.2.2. Troubleshooting Solutions of Common Faults

- 2.3. Drive System

- 2.3.1. Drive Unit

- 2.3.1.1. Drive System

- 2.3.1.2. Electromagnetic Brakes

- 2.3.1.3. Drive Wheel

- 2.3.1.4. Drive Motor

- 2.3.1.5. Gearbox

- 2.3.1.6. Proximity Switch

- 2.3.1.7. Steering Motor

- 2.3.1.8. Speed Encoder

- 2.4. Truck Structure

- 2.4.1. Views

- 2.4.1.1. General view

- 2.4.2. Main Components Position

- 2.4.2.1. Travel Switch

- 2.4.2.2. Proportional Lifting and Lowering Switch . Horn Button

- 2.4.2.3. Emergency Reverse Switch

- 2.4.2.4. Forward and Backward Switch . Tilt Switch

- 2.4.2.5. Emergency Stop Switch

- 2.4.2.6. Key Switch . Charge Gauge

- 2.4.2.7. Traction Controller.Fuse

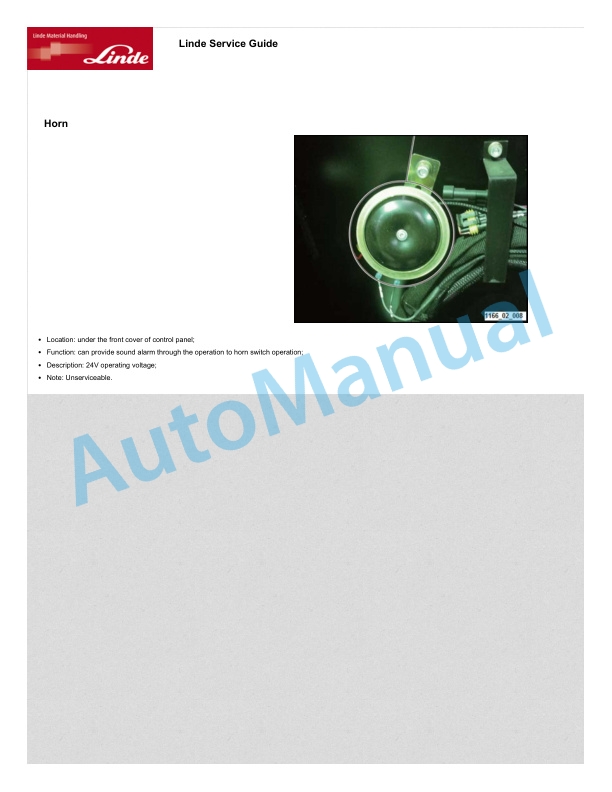

- 2.4.2.8. Horn

- 2.4.2.9. Main Contactor

- 2.4.2.10. EPSDC0 Controller

- 2.4.2.11. Lifting Limit Switch

- 2.4.2.12. Interlock Switch

- 2.4.2.13. MotorPump

- 2.4.2.14. Potentiometer

- 2.4.2.15. Multiway Solenoid Valve

- 2.4.3. Truck Body Parts

- 2.4.3.1. Removal and Installation

- 2.4.3.2. Removal and Installation

- 2.4.4. Lubrication

- 2.4.4.1. Application Amount of Hydraulic Oil

- 2.4.4.2. Sliding Surface

- 2.5. Steering and Wheels

- 2.5.1. Load Wheels

- 2.5.1.1. Removal and Installation

- 2.5.1.2. Load Wheels Faults and Causes

- 2.5.2. Castor Wheels

- 2.5.2.1. View

- 2.5.2.2. Caster removal and installation

- 2.6. Operating device

- 2.6.1. Control Head

- 2.6.1.1. Control Head Removal

- 2.6.1.2. Cap Assembly Removal

- 2.6.2. Button Switch

- 2.6.2.1. Button Switch

- 2.6.2.2. Removal and Installation

- 2.6.2.3. Faults and Causes

- 2.6.2.4. Checking and Testing

- 2.6.2.5. Control Circuit Troubleshooting

- 2.6.3. Travel Switch

- 2.6.3.1. Removal and Installation

- 2.6.3.2. Faults and Causes

- 2.6.3.3. Checking and Testing

- 2.6.3.4. Control Circuit Troubleshooting

- 2.6.4. Potentiometer

- 2.6.4.1. Removal and Installation

- 2.6.4.2. Faults and Causes

- 2.6.4.3. Checking and Testing

- 2.6.4.4. Control Circuit Troubleshooting

- 2.7. Electrical Equipment

- 2.7.1. Controller

- 2.7.1.1. Controller Interface Function

- 2.7.1.2. Controller Functions

- 2.7.2. Electrical Components

- 2.7.2.1. Fuse

- 2.7.2.2. Key Switch

- 2.7.2.3. Main Contactor

- 2.7.2.4. Lifting Limit Switch

- 2.7.2.5. Sidegate Switch

- 2.7.2.6. Cooling Fan

- 2.7.2.7. Deadman Switch

- 2.7.2.8. Proximity Switch

- 2.7.2.9. Interlock Switch

- 2.7.2.10. Charge Gauge

- 2.7.3. Hand Diagnostic Instrument

- 2.7.3.1. Zapi Handheld Unit (Optional)

- 2.7.3.2. Fault Detection

- 2.7.3.3. Testing Truck Operation

- 2.7.3.4. Set Options

- 2.7.3.5. Instruction of Set Options

- 2.7.3.6. Adjustments

- 2.7.3.7. Instruction of Adjustments

- 2.7.3.8. Parameter Change

- 2.7.3.9. Instruction of Parameter Change

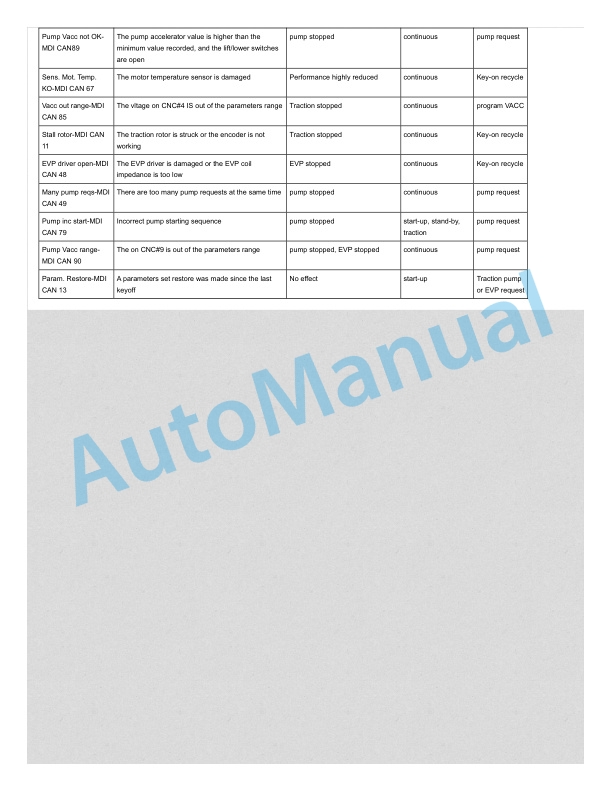

- 2.7.3.10. Controller Error Message

- 2.7.3.11. Traction.Pump Controller

- 2.7.3.12. Steering Controller (EPSACO) Error codes

- 2.8. Hydraulic System

- 2.8.1. Summary

- 2.8.1.1. Hydraulic Overview

- 2.8.1.2. Hydraulic Troubleshooting

- 2.8.1.3. Pump and Motor Assembly

- 2.8.2. Hydraulic Parts

- 2.8.2.1. Pump Motor

- 2.8.2.2. Multiway Reversing Solenoid Valve

- 2.8.2.3. Solenoid Valve

- 2.8.2.4. Gear Pump

- 2.8.2.5. Reach Cylinder

- 2.9. Mast

- 2.9.1. Twostage Mast

- 2.9.1.1. Twostage Mast Removal and Installation

- 2.9.1.2. Tilt Cylinde

- 2.9.1.3. Lift Cylinder

- 2.9.1.4. Lifting Chains

- 2.9.1.5. Mast Tubing

- 2.9.2. Therestage Mast

- 2.9.2.1. Lift Cylinder

- 2.9.2.2. Lifting Chains

- 2.9.2.3. Mast Removal and Installation

- 2.9.2.4. Mast Tubing

- 2.10. Special Equipment

- 2.10.1. Leadacid Battery

- 2.10.1.1. Maintenance and Care

- 2.10.1.2. Use of Battery

- 2.10.1.3. Storage

- 2.10.1.4. Troubleshooting

- 2.10.1.5. Safety and Warnings

- 2.10.2. Maintenancefree Battery

- 2.10.2.1. Safety and Warnings

- 2.11. Schematic Diagram

- 2.11.1. Wire Diagram

- 2.11.1.1. Electrical diagram

- 2.11.2. Hydraulic Diagram

- 2.11.2.1. Hydraulic diagram

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Workshop Manuals SN A11102V00001 and up

$50.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF