- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1172-01 – BW22, L10, L10AS, L10B, L12, L12AS, L12I Production site CTT Operating Instructions SN 11.08 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 11.08 and up

- Format: PDF

- Size: 51.8MB

- Number of Pages: 499

- Serial Number:

SN 11.08 and up

Category: Linde Operator Manual PDF

-

Model List:

- BW22

- L10

- L10AS

- L10B

- L12

- L12AS

- L12I

- 1. V lithiumion batteries

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Important information about the compatibility of the lithiumion battery and truck

- 1.2.2. Before using the truck

- 1.2.3. Important information about this manual

- 1.2.4. Identification label on the lithiumion battery

- 1.2.5. Correct use

- 1.2.6. Dangerous misuse

- 1.2.7. Productspecific risks

- 1.2.8. Information on the conformity of lithiumion batteries

- 1.2.9. Explanations of terms and symbols

- 1.2.10. Qualification of the user

- 1.2.11. Description of use and climatic conditions

- 1.3. Safety

- 1.3.1. Battery management system and safety

- 1.3.2. What to do in an emergency

- 1.3.3. Firstaid measures

- 1.4. General views

- 1.4.1. General view of 24V LiB batteries from 1.7 to 3.5

- 1.4.2. General view of the 24V LiB 7.1 battery

- 1.4.3. General view of the 24V LiB battery from 10.6 to 14.2

- 1.5.1. Description of the battery

- 1.5.2. Safety guidelines

- 1.5.3. Status of the battery on delivery

- 1.5.4. Transport mode

- 1.5.5. Connecting the battery to the truck

- 1.5.6. Switching on the battery

- 1.5.7. Modes of operation

- 1.5.8. Temperature conditions for operating . charging

- 1.5.9. Charging the battery

- 1.5.10. Changing the lithiumion battery

- 1.5.11. Switching off the battery

- 1.5.12. Resolving battery faults

- 1.5.13. Transporting lithiumion batteries

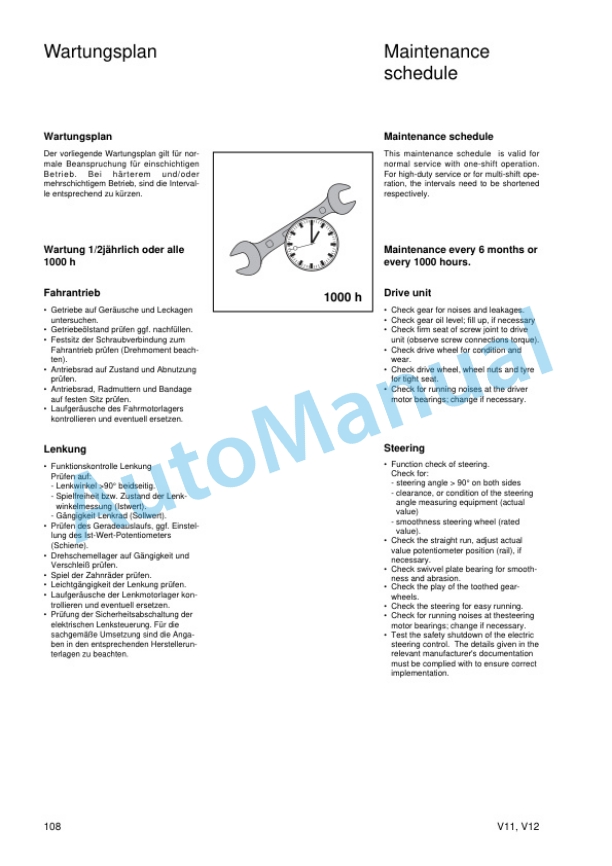

- 1.6. Maintenance

- 1.6.1. Regular maintenance

- 1.6.2. Service plan

- 1.6.3. Cleaning the battery

- 1.6.4. Transporting and storing within the company

- 1.6.5. Disposing of batteries

- 1.7. Technical specifications

- 1.7.1. Lithiumion battery datasheet

- 2. Electric pallet stacker1172_L10, 1172_L10B, 1172_L12, 1172_L12i

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Your truck

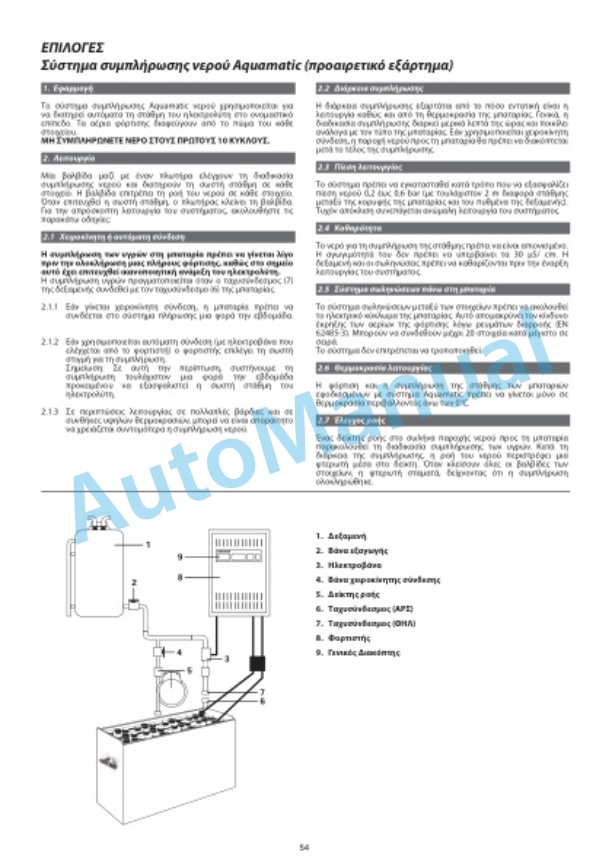

- 2.2.2. Impermissible use

- 2.2.3. Description of use and climatic conditions

- 2.2.4. Specific use of the equipment

- 2.2.5. Symbols used

- 2.2.6. Legal requirements for placing on the market

- 2.2.7. Technical description

- 2.3. Safety

- 2.3.1. Residual risks

- 2.3.2. Stability

- 2.3.3. Operation of industrial trucks in plant area

- 2.3.4. Competent person

- 2.3.5. Safety regulations

- 2.3.6. Driving regulations

- 2.3.7. Handling consumables

- 2.3.8. Periodic general checks on the trucks

- 2.4. General views

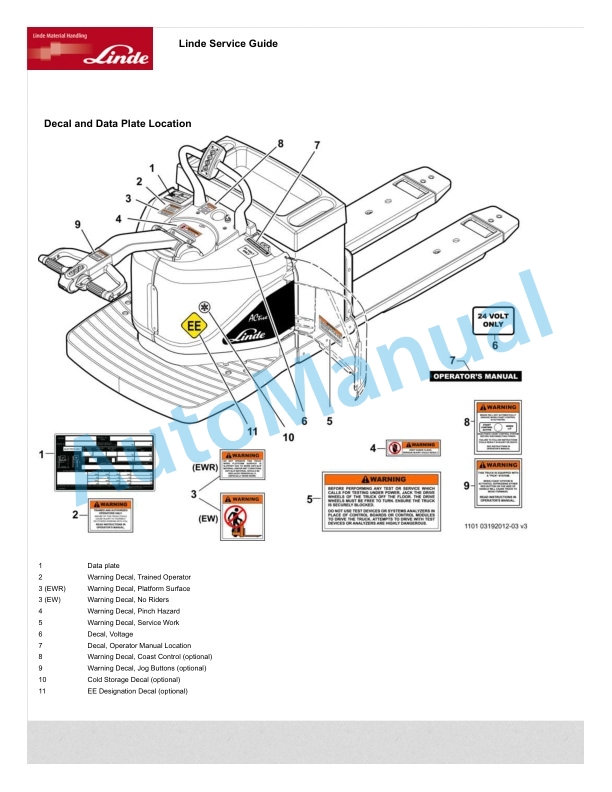

- 2.4.1. Labels

- 2.4.2. Identification label

- 2.4.3. General view

- 2.4.4. Actuation controls

- 2.4.5. Battery charge indicator

- 2.4.6. Digicode option (LFM Go)

- 2.4.7. LFM AccessLFM Basic option

- 2.5.1. Commissioning

- 2.5.2. Checks before first use

- 2.5.3. Daily checks before use

- 2.5.4. Checking the working environment

- 2.5.5. General information on batteries

- 2.5.6. Using the onboard charger

- 2.5.7. Adjusting the onboard charger

- 2.5.8. Operating instructions for 1172

- 2.5.9. Driving the 1172

- 2.5.10. Cold store usage (optional)

- 2.5.11. Creep Speed function

- 2.5.12. Proportional Speed Function (Proportional Speed)

- 2.5.13. Use of the truck on a slope

- 2.5.14. Braking, lifting, lowering, horn

- 2.5.15. Initial lift function (only on the L12i model)

- 2.5.16. Load handling

- 2.5.17. Reading the capacity rating plate

- 2.5.18. Emergency mast lowering

- 2.5.19. Slinging, lifting

- 2.5.20. Truck towing procedure

- 2.5.21. Transporting the machine

- 2.5.22. Storage of truck

- 2.6. Maintenance

- 2.6.1. General information

- 2.6.2. Calendar of testing and maintenance operations

- 2.6.3. Recommended lubricants

- 2.6.4. Technical data for inspection and maintenance

- 2.6.5. Daily checks before starting work

- 2.6.6. Maintenance schedule as required

- 2.6.7. Battery

- 2.6.8. Inspection and maintenance overview

- 2.6.9. Forks

- 2.6.10. Transmission

- 2.6.11. Steering.Wheels.Braking

- 2.6.12. Electrical equipment

- 2.6.13. Hydraulic systems

- 2.6.14. Lift mast

- 2.7. Technical datasheet

- 2.7.1. Technical specification

- 2.7.2. Noise emission values

- 2.8. Diagrams

- 2.8.1. Electric diagrams

- 2.8.2. Hydraulic diagrams

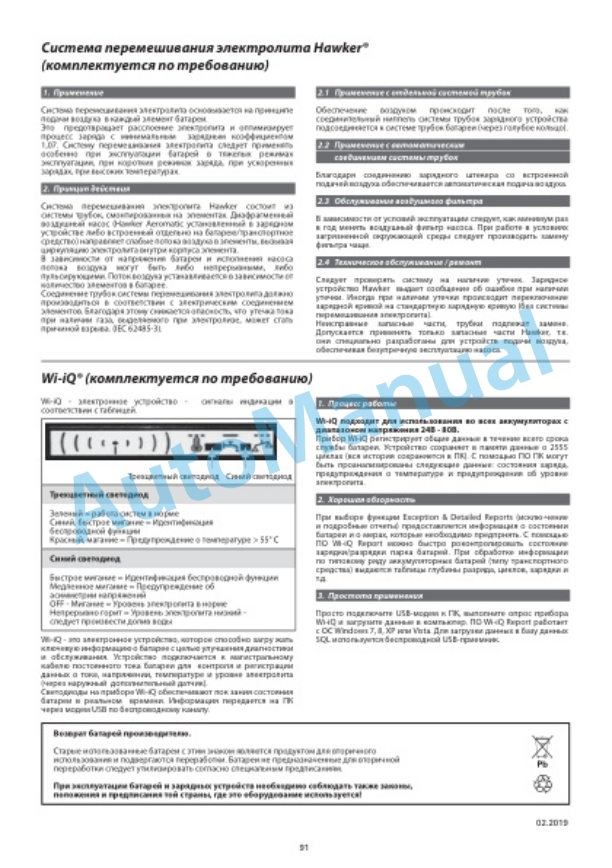

- 3. EnerSys.Hawker Batteries

- 4. Industrial truck for battery replacement

- 4.1. Table of content

- 4.2. Introduction

- 4.2.1. Your battery replacement truck

- 4.2.2. Conformity marking

- 4.2.3. Declaration that reflects the content of the declaration of conformity

- 4.2.4. Intended use

- 4.2.5. Impermissible use

- 4.2.6. Description of use and climatic conditions

- 4.2.7. Symbols used

- 4.2.8. Taking delivery of the industrial truck

- 4.2.9. Documentation

- 4.2.10. Disposing of gel and lead batteries

- 4.3. Safety

- 4.3.1. Residual risks

- 4.3.2. Stability

- 4.3.3. Safety regulations

- 4.3.4. Use of lubricants

- 4.3.5. Periodic safety inspection

- 4.4. General views

- 4.4.1. Data plates and adhesive labels

- 4.4.2. Nameplate

- 4.4.3. Overview

- 4.4.4. Operating devices

- 4.4.5. Battery charge indicator

- 4.4.6. Digicode option (LFM Go)

- 4.5. Operation

- 4.5.1. Technical description

- 4.5.2. Instructions for runningin

- 4.5.3. Preshift checks

- 4.5.4. Commissioning and driving

- 4.5.5. Handling loads

- 4.5.6. Error codes

- 4.5.7. Handling the industrial truck in special operating situations

- 4.5.8. Handling the battery

- 4.5.9. Decommissioning

- 4.5.10. Storage

- 4.6. Maintenance

- 4.6.1. Summary of checks and maintenance work

- 4.6.2. Safety regulations for maintenance

- 4.6.3. Preparatory procedures for maintenance

- 4.6.4. Cleaning

- 4.6.5. Maintenance as required

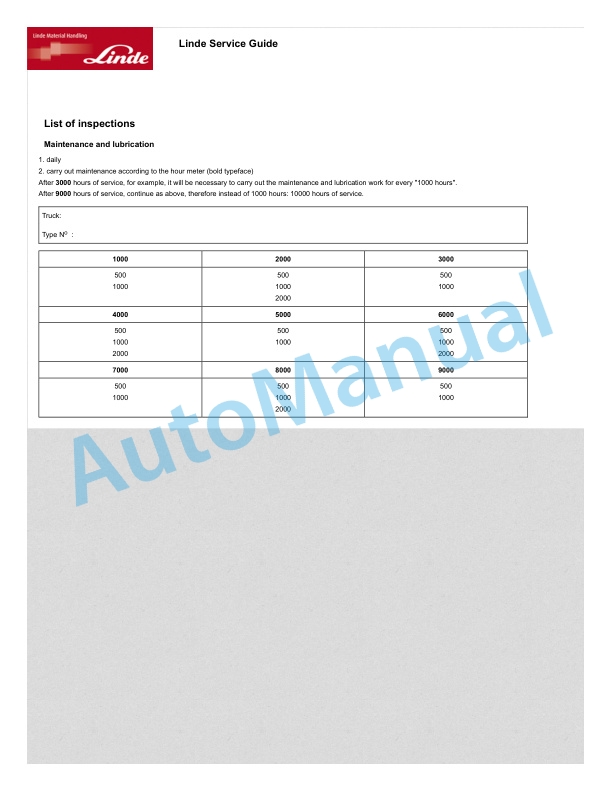

- 4.6.6. hour maintenance schedule

- 4.6.7. hour maintenance schedule

- 4.6.8. hour maintenance schedule

- 4.7. Technical data

- 4.7.1. Technical data

- 4.7.2. Ecodesign requirements for electric motors and variable speed drives

- 4.7.3. Noise emission values

- 5. Lithiumion batteries

- 5.1. Table of content

- 5.2. Introduction

- 5.2.1. Introduction

- 5.2.2. Information on the conformity of lithiumion batteries

- 5.3. Safety

- 5.3.1. Special lithiumion safety rules

- 5.3.2. What to do in the event of incorrect use

- 5.3.3. Personal protective measures following an incident

- 5.3.4. What to do in the event of an accidental spillage

- 5.3.5. Transporting a lithiumion battery

- 5.3.6. Scrapping lithiumion batteries

- 5.4. Labels

- 5.4.1. Identification label for lithiumion batteries

- 5.4.2. Labels on the top of lithiumion batteries

- 5.4.3. Labels on the sides of lithiumion batteries

- 5.5.1. Installing the external charger

- 5.5.2. Charging lithiumion batteries

- 5.5.3. Battery charging times

- 5.5.4. Recharging lithiumion batteries using the onboard charger(se presente)

- 5.5.5. Commissioning a truck equipped with a lithiumion battery

- 5.5.6. Replacing the lithiumion battery

- 5.5.7. Malfunctions

- 5.5.8. Lithiumion batteries longterm storage

- 5.6. Maintenance

- 5.6.1. General Information

- 5.6.2. Maintenance as required

- 5.6.3. Scheduled maintenance

- 6. MIDAC Batteries

- 7. TAB Batteries

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF