- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1172-01 – L12 EX, L12 i EX Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 25.9MB

- Number of Pages: 213

Category: Linde Operator Manual PDF

-

Model List:

- L12 EX

- L12 i EX

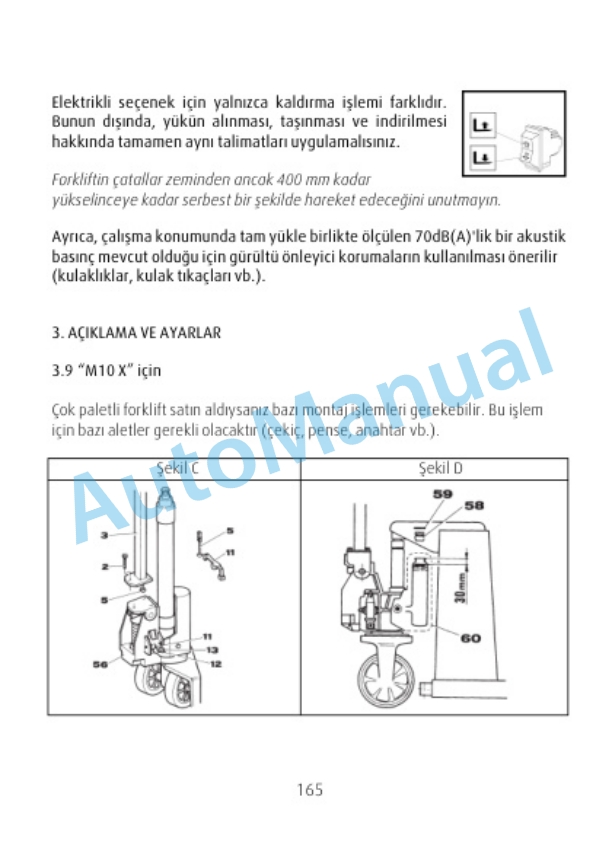

- 1. Pallet stackerL12 EX L12i EX

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your industrial truck

- 1.2.2. Intended use

- 1.2.3. Impermissible use

- 1.2.4. Basic information on explosion protection

- 1.2.5. Description of use and climatic conditions

- 1.2.6. Symbols used

- 1.2.7. Drive

- 1.2.8. Steering

- 1.2.9. Hydraulic system

- 1.2.10. Operation

- 1.2.11. Braking system

- 1.2.12. Load lift system

- 1.2.13. Chassis frame

- 1.2.14. Electrical system

- 1.2.15. Temperature monitoring

- 1.2.16. Receiving the industrial truck

- 1.2.17. Legal requirements for marketing

- 1.2.18. Disposing of components and batteries

- 1.3. Safety

- 1.3.1. Explosion protection safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. Handling consumables

- 1.3.5. Competent person

- 1.3.6. Regular testing

- 1.4. Overview

- 1.4.1. Labels

- 1.4.2. Nameplate

- 1.4.3. Truck overview

- 1.4.4. Motor compartment

- 1.4.5. Tiller head

- 1.4.6. Charging indicator

- 1.4.7. Digicode option (LFM Go)

- 1.4.8. LFM AccessLFM Basic option

- 1.5. Operation

- 1.5.1. Service plan before initial commissioning

- 1.5.2. Instructions for runningin

- 1.5.3. Preshift checks

- 1.5.4. Switching the industrial truck on and off

- 1.5.5. Driving

- 1.5.6. Forward travel

- 1.5.7. Reverse travel

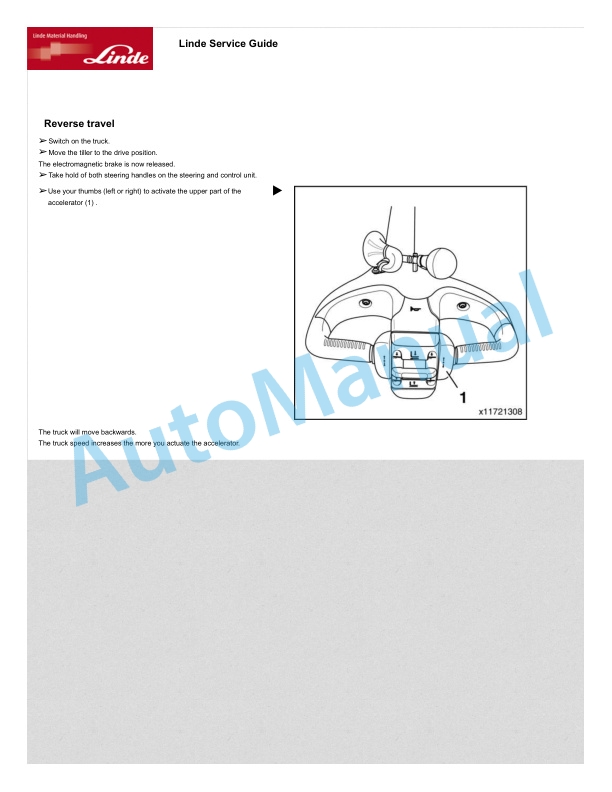

- 1.5.8. Changing the drive direction

- 1.5.9. Creep speed

- 1.5.10. Proportional Speed function

- 1.5.11. Steering

- 1.5.12. Belly switch

- 1.5.13. Brake system

- 1.5.14. Horn

- 1.5.15. Emergency off switch

- 1.5.16. Working with a load

- 1.5.16.1. Picking up a load

- 1.5.16.2. Driving with load

- 1.5.16.3. Use of the truck on a slope

- 1.5.16.4. Emergency lowering

- 1.5.17. Loading.transporting

- 1.5.17.1. Slinging, lifting

- 1.5.17.2. Transport

- 1.6. Servicing

- 1.6.1. Safety information regarding servicing work

- 1.6.2. Inspection and maintenance data

- 1.6.3. Recommendations for consumables

- 1.6.4. Inspection and maintenance overview

- 1.6.4.1. Maintenance plans

- 1.6.4.2. Additional service plan for explosion protection

- 1.6.5. Preparatory tasks

- 1.6.5.1. Cleaning the industrial truck

- 1.6.5.2. Reading out the error memory

- 1.6.6. Chassis, bodywork and fittings

- 1.6.6.1. Checking and lubricating the bearing points and joints

- 1.6.6.2. Other cleaning and greasing

- 1.6.7. Chassis frame

- 1.6.7.1. Tightening the wheel fastenings

- 1.6.7.2. Checking the wheels for wear and damage

- 1.6.7.3. Adjusting the support rollers

- 1.6.7.4. Checking the brake system

- 1.6.8. Operating devices

- 1.6.8.1. Checking the horn for correct function

- 1.6.9. Electrical enclosure

- 1.6.9.1. Checking the battery charge status

- 1.6.9.2. Charging the battery

- 1.6.9.3. Replacing the battery

- 1.6.9.4. Checking the condition and secure attachment of the electric cables, cable connectors, cable connections andexplosionproof screw joints

- 1.6.10. Hydraulics

- 1.6.10.1. Servicing the hydraulic system

- 1.6.11. Load lift system

- 1.6.11.1. Checking the antispark protection on the fork arms and push rods for wear

- 1.6.12. Troubleshooting

- 1.6.12.1. Checking the Proplan safety unit (PSU)

- 1.6.12.2. Fuse

- 1.6.12.3. Diagnostic connector

- 1.6.12.4. Decommissioning the industrial truck

- 1.6.12.5. Disposal of old trucks

- 1.7. Technical data

- 1.7.1. Technical data

- 1.7.2. Noise emission values

- 2. Pallet stackerL12 EX L12i EX

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Your industrial truck

- 2.2.2. Conformity marking

- 2.2.3. Declaration that reflects the content of the declaration of conformity

- 2.2.4. Intended use

- 2.2.5. Impermissible use

- 2.2.6. Basic information on explosion protection

- 2.2.7. Symbols used

- 2.2.8. Taking delivery of the industrial truck

- 2.2.9. Documentation

- 2.2.10. Disposing of gel and lead batteries

- 2.3. Safety

- 2.3.1. Explosion protection safety guidelines

- 2.3.2. Protective equipment for explosion protection

- 2.3.3. Residual risks

- 2.3.4. Stability

- 2.3.5. Competent person

- 2.4. Overview

- 2.4.1. Nameplate

- 2.4.2. Truck overview

- 2.4.3. Display elements

- 2.4.4. Operating devices tiller head

- 2.5. Operating

- 2.5.1. Technical description

- 2.5.2. Drive

- 2.5.3. Steering

- 2.5.4. Hydraulic system

- 2.5.5. Operation

- 2.5.6. Braking system

- 2.5.7. Load lift system

- 2.5.8. Industrial trucks with explosion protection

- 2.5.8.1. Description of use and climatic conditions

- 2.5.8.2. Technical description of explosion protection

- 2.5.8.3. Regular testing

- 2.5.8.4. Batteries for explosion protection

- 2.5.8.5. Wheels and tyres for explosion protection

- 2.5.8.6. Checking the tyres

- 2.5.8.7. Checking the leak resistance

- 2.5.8.8. Handling consumables

- 2.5.8.9. Towing

- 2.5.9. Service plan before initial commissioning

- 2.5.10. Instructions for runningin

- 2.5.11. Preshift checks

- 2.5.11.1. Overview

- 2.5.12. Switching the truck on and off

- 2.5.13. Driving

- 2.5.14. Forward travel

- 2.5.15. Reverse travel

- 2.5.16. Changing the drive direction

- 2.5.17. Steering

- 2.5.18. Belly switch

- 2.5.19. Brake system

- 2.5.20. Horn

- 2.5.21. Emergency off switch

- 2.5.22. Working with a load

- 2.5.22.1. Driving with load

- 2.5.22.2. Handling loads

- 2.5.22.3. Use of the truck on a slope

- 2.5.22.4. Emergency lowering

- 2.5.23. Parking the industrial truck securely

- 2.5.24. Loading.transporting

- 2.5.24.1. Crane loading

- 2.5.24.2. Transport

- 2.6. Service and maintenance

- 2.6.1. Safety information regarding servicing work

- 2.6.2. Inspection and maintenance data

- 2.6.3. Recommendations for consumables

- 2.6.4. Regular maintenance

- 2.6.5. Inspection and maintenance overview

- 2.6.5.1. Maintenance plans

- 2.6.5.2. Additional service plan for explosion protection

- 2.6.6. Preparatory tasks

- 2.6.6.1. Cleaning the industrial truck

- 2.6.6.2. Reading out the error memory

- 2.6.7. Chassis, bodywork and fittings

- 2.6.7.1. Checking the pressuretight housing

- 2.6.7.2. Lifting device

- 2.6.8. Chassis frame

- 2.6.8.1. Tightening the wheel fastenings

- 2.6.8.2. Servicing the wheels and rollers

- 2.6.8.3. Checking the brake system

- 2.6.9. Operating devices

- 2.6.9.1. Checking that the horn is working correctly

- 2.6.10. Electrics.electronics

- 2.6.10.1. Checking the battery charge status

- 2.6.10.2. Connecting the battery to an external battery charger

- 2.6.10.3. Battery replacement

- 2.6.10.4. Checking the condition and secure attachment of the electric cables, cable connectors, cable connections andexplosionproof screw joints

- 2.6.11. Hydraulics

- 2.6.11.1. Servicing the hydraulic system

- 2.6.12. Load lift system

- 2.6.12.1. Checking the antispark protection on the fork arms for wear

- 2.6.12.2. Servicing the lift mast

- 2.6.13. Troubleshooting

- 2.6.13.1. Fuses

- 2.6.13.2. Diagnostic connector

- 2.6.13.3. Decommissioning the industrial truck

- 2.6.13.4. Disposal of old trucks

- 2.6.13.5. Malfunctions during operation

- 2.7. Technical data

- 2.7.1. Technical data

- 2.7.2. Ecodesign requirements for electric motors and variable speed drives

- 2.7.3. Noise emission values

Rate this product

You may also like

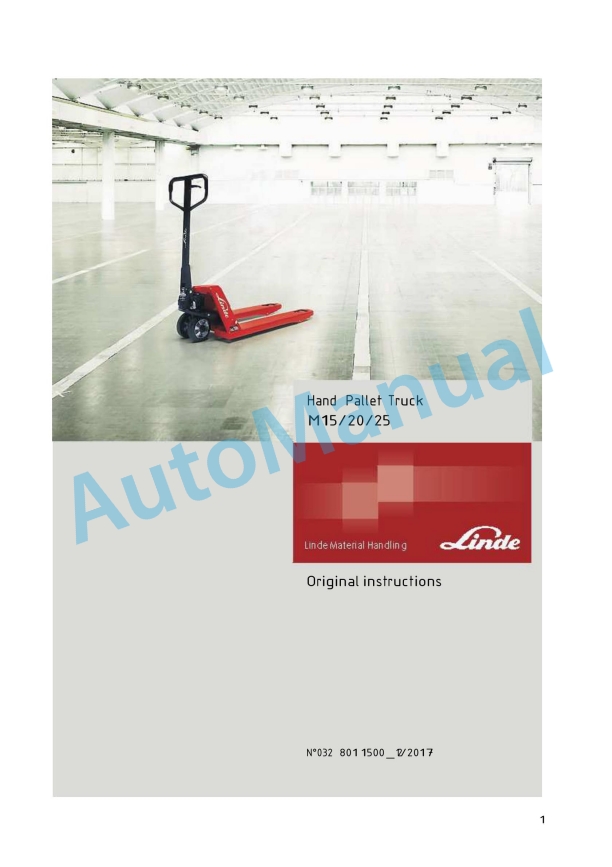

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

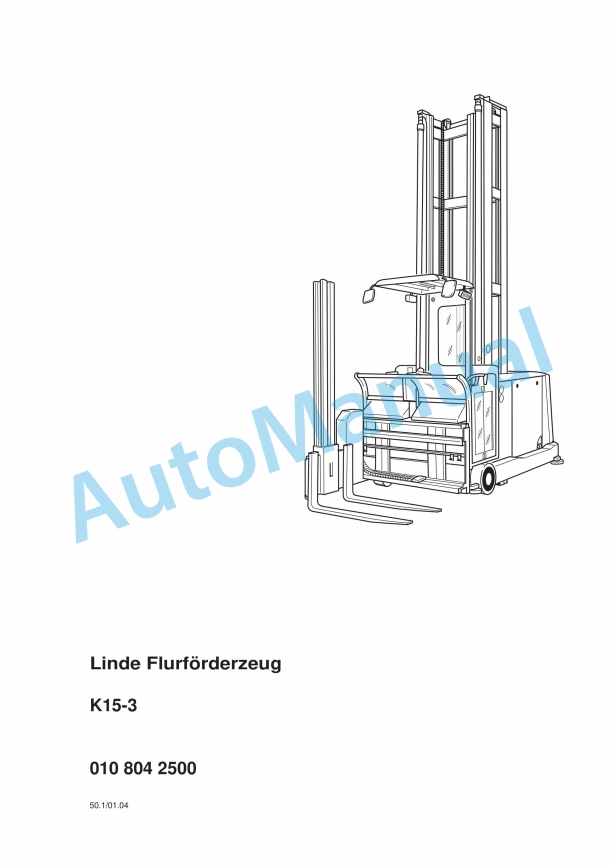

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF