- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 1196-01 – LT06, LT08, LT10, LT12, LT16, LT20 Production site Aschaffenburg Workshop Manuals SN H21196F00001 and up

$50.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN H21196F00001 and up

- Format: PDF

- Size: 18.4MB

- Number of Pages: 177

- Serial Number:

SN H21196F00001 and up

Category: Linde Workshop Manual PDF

-

Model List:

- LT06

- LT08

- LT10

- LT12

- LT16

- LT20

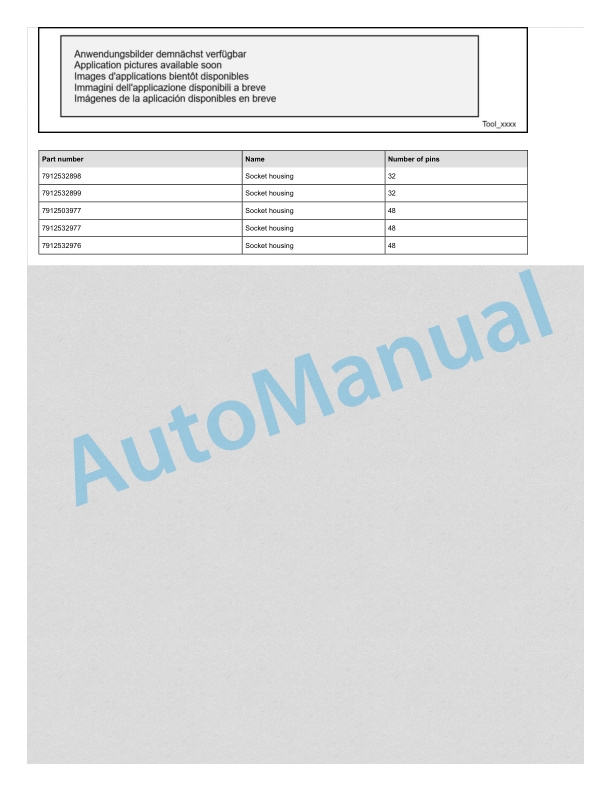

- 1. Service case Release tools for contacts

- 1.1. Table of content

- 1.2. Safety information

- 1.2.1. Safety information for repair and maintenance work

- 1.3. Information

- 1.3.1. Information

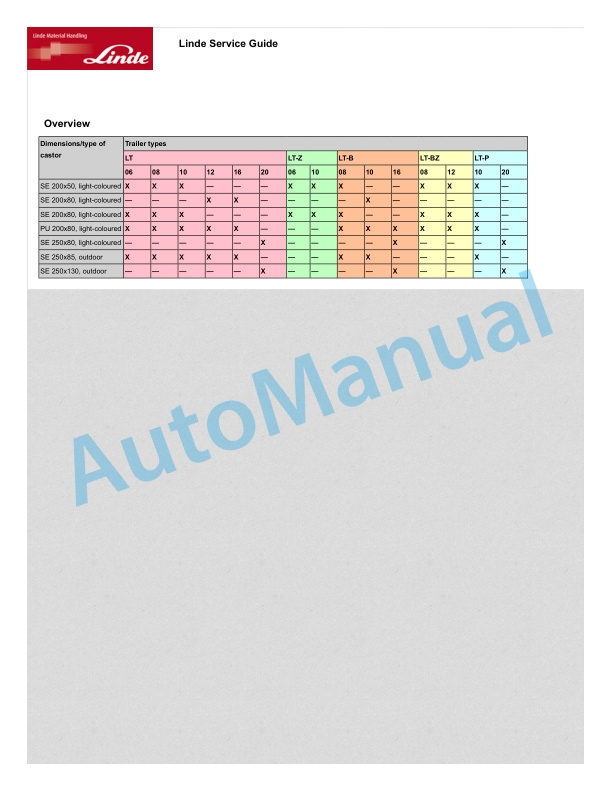

- 1.4. Overview

- 1.4.1. Overview of service cases

- 1.5. Plug systems

- 1.5.1. ATS 2.8 plug connector

- 1.5.2. CMC plug connector

- 1.5.3. DCS 9.5 plug connector

- 1.5.4. DIN 1.5mm circular connector

- 1.5.5. DIN 2.5mm circular connector

- 1.5.6. Deutsch DTM plug connector

- 1.5.7. ECU appliance plug

- 1.5.8. MCON appliance plug

- 1.5.9. Appliance plug with JPT and MQS contacts

- 1.5.10. Appliance plug with MT2 and JPT contacts

- 1.5.11. SICMA appliance plug

- 1.5.12. Econoseal JMark 2 plug connector

- 1.5.13. Elobau 11pin receptacle housing

- 1.5.14. E5931 plug connector

- 1.5.15. FASTINFASTON 6.3mm plug connector

- 1.5.16. GT150 plug connector

- 1.5.17. HDSCS plug connector

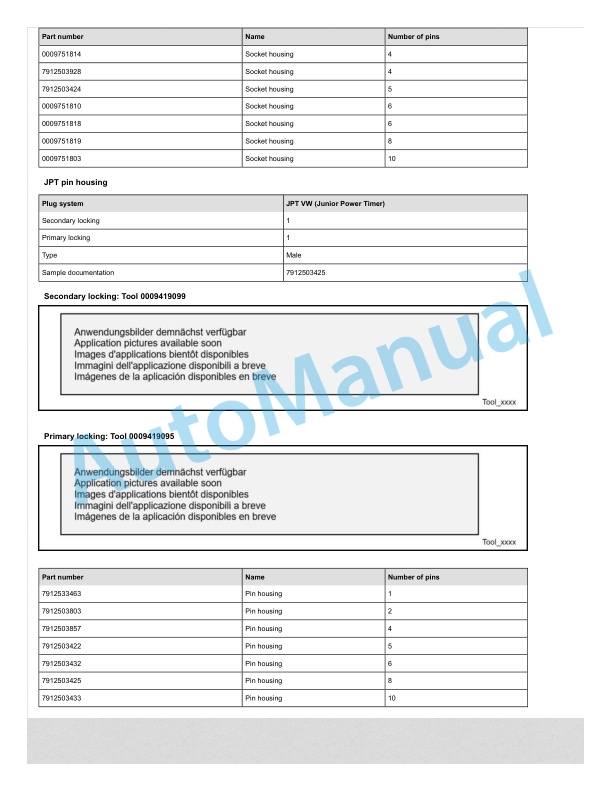

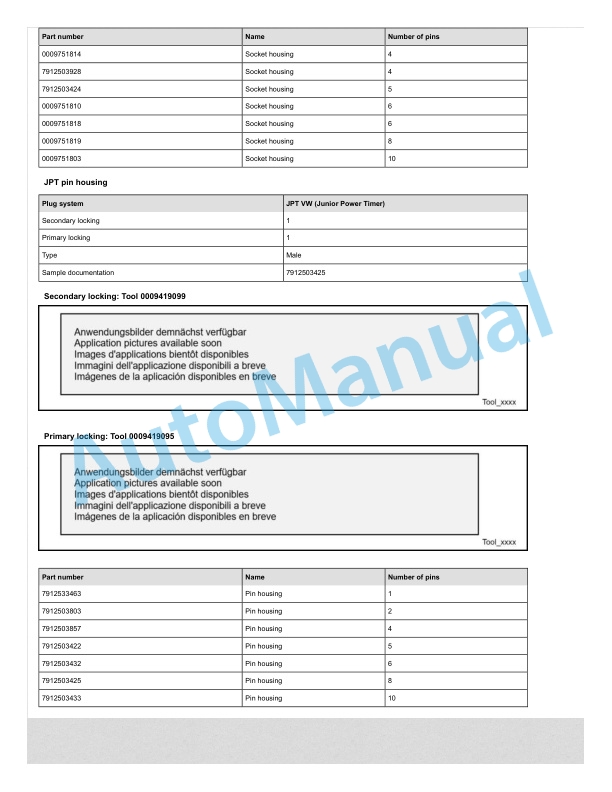

- 1.5.18. JPT plug connector

- 1.5.19. JPT SLD plug connector

- 1.5.20. JPT plug connector Saab

- 1.5.21. JPT plug connector VW

- 1.5.22. Kompakt 1.1 plug connector

- 1.5.23. Bosch Kompakt 4 plug connector

- 1.5.24. Leavyseal plug connector

- 1.5.25. MCON 1.2mm LL plug connector

- 1.5.26. MCON 1.2mm CB plug connector

- 1.5.27. MCP plug connector

- 1.5.28. MetriPack 150 plug connector

- 1.5.29. MiniFit plug connector

- 1.5.30. Mini Universal MATENLOK plug connector

- 1.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 1.5.32. MKR Plus plug connector

- 1.5.33. MQS plug connector

- 1.5.34. MR plug connector

- 1.5.35. MTA plug housing and fuse housing

- 1.5.36. MT2 plug connector

- 1.5.37. MT2 1.5mm plug connector VW

- 1.5.38. Multilock plug connector

- 1.5.39. MX150 plug connector

- 1.5.40. NG1 plug connector

- 1.5.41. Phönix Contact HC plug connector

- 1.5.42. PT 3F plug connector

- 1.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 1.5.44. Relay socket with SPT and MPT contacts

- 1.5.45. Fuse holder with SPT contacts

- 1.5.46. Sicma plug connector

- 1.5.47. SLK 2.8 plug connector

- 1.5.48. Souriau UTL7 plug connector

- 1.5.49. Superseal 1.5mm plug connector

- 1.5.50. Trident Neptune plug connector

- 1.5.51. Universal MATENLOK plug connector

- 1.5.52. VW 9.5mm plug connector

- 2. TrailerLT, LTB, LTBZ, LTP, LTZ

- 2.1. Table of content

- 2.2. Product information

- 2.2.1. General

- 2.2.1.1. Technical description

- 2.2.1.2. Inspection and maintenance overview

- 2.2.1.3. Tightening torques for standard pitch threads

- 2.3. Diagnostics

- 2.3.1. Diagnostic equipment

- 2.3.1.1. Measurement box

- 2.3.2. Error codes

- 2.3.2.1. Overview

- 2.4. Electric motor

- 2.4.1. Lift motors

- 2.4.1.1. Description

- 2.4.1.2. Technical data and connections

- 2.5. Chassis, bodywork and fittings, general

- 2.5.1. Trailer types

- 2.5.1.1. LT with lifting device and load pickup device

- 2.5.1.2. LTZ for inline trolleys

- 2.5.1.3. LTB with lifting device and load pickup device

- 2.5.1.4. LTBZ for inline trolleys

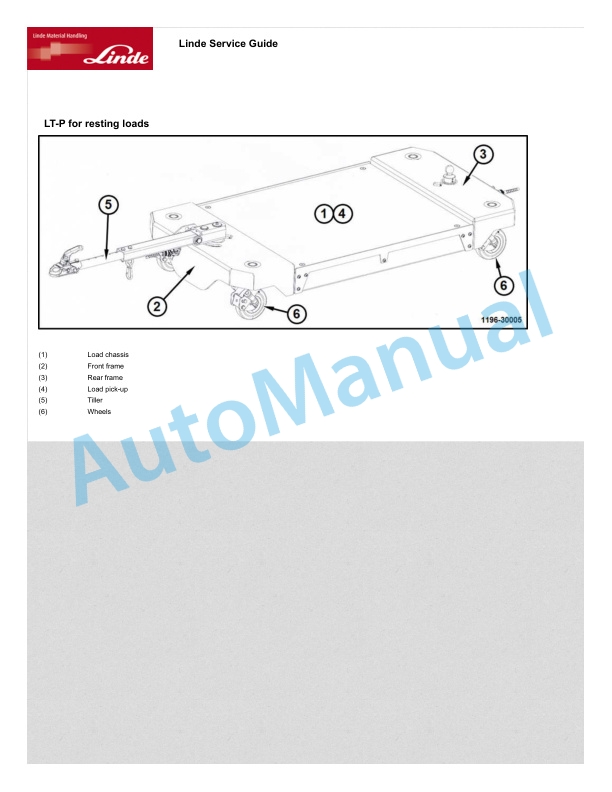

- 2.5.1.5. LTP for resting loads

- 2.5.1.6. Units

- 2.6. Chassis frame, general

- 2.6.1. Steering system

- 2.6.1.1. Electric fourwheel steering

- 2.6.1.1.1. Functionality

- 2.6.1.1.2. Design

- 2.6.1.1.3. Connections for the steering controller

- 2.6.1.1.4. Tiller position sensor 3R1

- 2.6.1.1.5. Rearaxle position sensor 3R2

- 2.6.1.2. Mechanical fourwheel steering

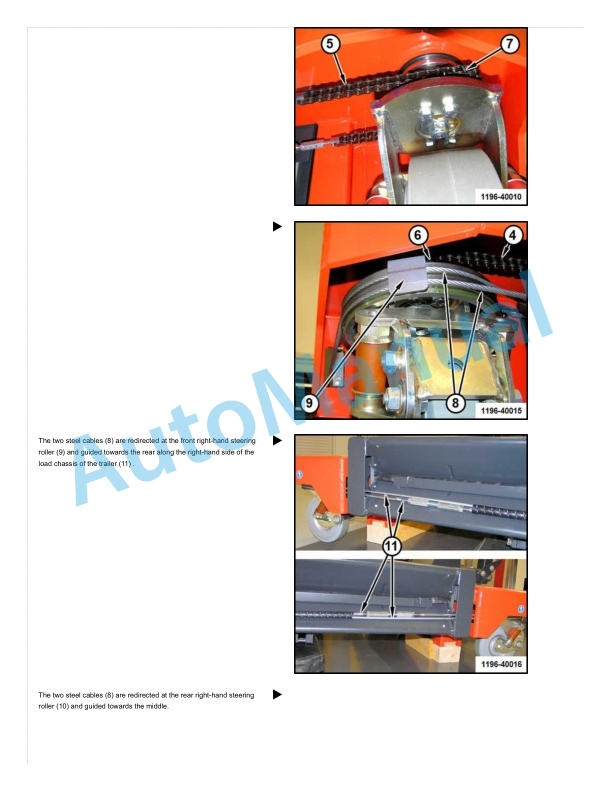

- 2.6.1.2.1. Cable transmission for LT and LTZ

- 2.6.1.2.2. Chain transmission for LT and LTZ

- 2.6.1.2.3. Cable transmission for LTP

- 2.6.1.3. Mechanical twowheel steering

- 2.6.1.3.1. Functionality

- 2.6.2. Load rollers

- 2.6.2.1. Overview

- 2.7. Electrics.electronics, general

- 2.7.1. Teach function configuring the logistic train

- 2.7.1.1. Description

- 2.8. Load lift system

- 2.8.1. Load pick up

- 2.8.1.1. Rigid fork arms

- 2.8.1.2. Heightadjustable fork arms

- 2.8.1.3. Replacing the fork arms

- 2.8.1.4. Load pickup bracket

- 2.8.1.5. Adjustable central post

- 2.8.2. Locking mechanisms

- 2.8.2.1. Fork arms

- 2.8.2.2. Load pickup bracket

- 2.8.2.3. Adjustable central post

- 3. Circuit diagramsTrailersLT, LTB

- 3.1. Table of content

- 3.2. Circuit diagrams from 06.2014 onwards

- 3.2.1. Wiring diagrams

- 3.2.1.1. Controller for 2 motors, type LT

- 3.2.1.2. Controller for 2 motors, type LTB

- 3.2.1.3. Controller for 4 motors, type LT

- 3.2.1.4. Controller for 4 motors, type LTB

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Workshop Manuals

$50.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF