Linde 1220-01 – H25D, H25T, H30D, H30T, H35D, H35T Production site Xiamen Workshop Manuals SN C11220G00001 and up

$40.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN C11220G00001 and up

- Format: PDF

- Size: 149.8MB

- Number of Pages: 907

- Serial Number:

SN C11220G00001 and up

Category: Linde Workshop Manual PDF

-

Model List:

- H25D

- H25T

- H30D

- H30T

- H35D

- H35T

- 1. Regular testing

- 1.1. Table of content

- 1.2. Regular testing

- 1.2.1. Principles for testing industrial trucks

- 1.2.2. Test log

- 1.2.3. Testing instruments, measuring devices, tools and devices

- 1.3. Electric motor

- 1.3.1. Test steps for the electric traction motor

- 1.4. Internal combustion engine

- 1.4.1. Test steps for the exhaust system

- 1.4.2. Diesel internal combustion engine

- 1.4.3. LPG internal combustion engine

- 1.5. Drive axle

- 1.5.1. Drive axle test steps

- 1.6. Chassis

- 1.6.1. Test steps for chassis

- 1.7. Drivers compartment

- 1.7.1. Test steps for drivers compartment

- 1.8. Steering systems

- 1.8.1. Test steps for the steering

- 1.9. Wheels and tyres

- 1.9.1. Test steps for wheels

- 1.9.2. Tyre test steps

- 1.10. Brake system

- 1.10.1. Definition and description of the industrial truck groups

- 1.10.2. Permissible braking distances for unladen industrial trucks

- 1.10.3. Service brake

- 1.10.4. Parking brake

- 1.11. Operating devices

- 1.11.1. Test steps for operating devices

- 1.12. Electrics.electronics

- 1.12.1. Test steps for electrical equipment

- 1.12.2. Notes regarding insulation testing

- 1.12.3. Insulation testing

- 1.12.4. Test steps for the battery and battery connection assemblies

- 1.13. Hydraulics

- 1.13.1. Test steps for hydraulic system

- 1.13.2. Safety regulations for hydraulic hose lines

- 1.14. Lift mast

- 1.14.1. Test steps for lift mast

- 1.14.2. Test steps for load chains

- 1.15. Load support

- 1.15.1. Test steps for fork arms

- 1.15.2. Combined testing device for testing fork arms, lifting chains and lifting hydraulics

- 1.16. Attachments

- 1.16.1. Test steps for attachments and other lifting accessories

- 1.17. Special equipment.accessories

- 1.17.1. LPG tanks on trucks

- 1.17.2. Test steps for other accessories

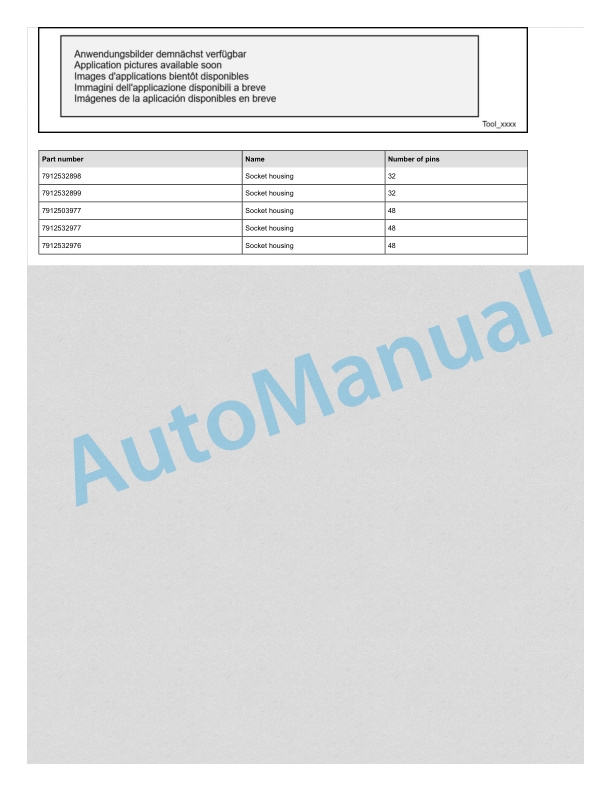

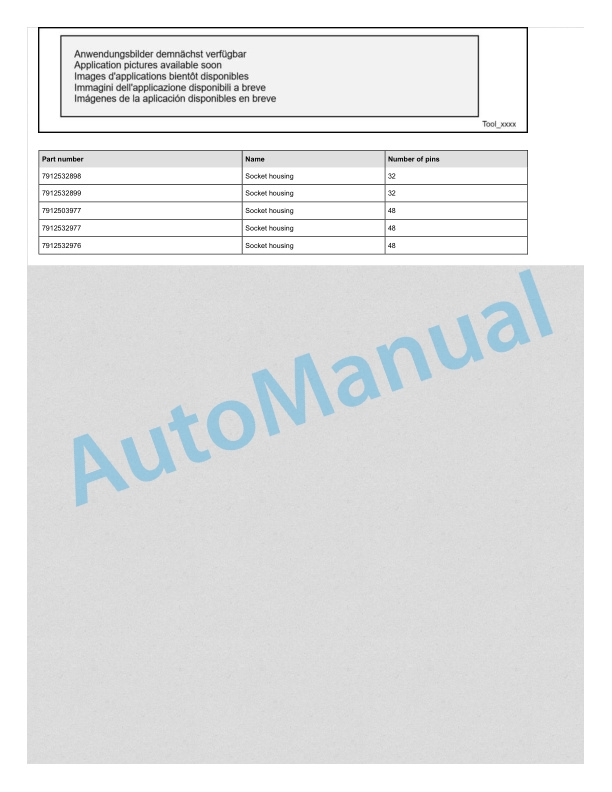

- 2. Service case Release tools for contacts

- 2.1. Table of content

- 2.2. Safety information

- 2.2.1. Safety information for repair and maintenance work

- 2.3. Information

- 2.3.1. Information

- 2.4. Overview

- 2.4.1. Overview of service cases

- 2.5. Plug systems

- 2.5.1. ATS 2.8 plug connector

- 2.5.2. CMC plug connector

- 2.5.3. DCS 9.5 plug connector

- 2.5.4. DIN 1.5mm circular connector

- 2.5.5. DIN 2.5mm circular connector

- 2.5.6. Deutsch DTM plug connector

- 2.5.7. ECU appliance plug

- 2.5.8. MCON appliance plug

- 2.5.9. Appliance plug with JPT and MQS contacts

- 2.5.10. Appliance plug with MT2 and JPT contacts

- 2.5.11. SICMA appliance plug

- 2.5.12. Econoseal JMark 2 plug connector

- 2.5.13. Elobau 11pin receptacle housing

- 2.5.14. E5931 plug connector

- 2.5.15. FASTINFASTON 6.3mm plug connector

- 2.5.16. GT150 plug connector

- 2.5.17. HDSCS plug connector

- 2.5.18. JPT plug connector

- 2.5.19. JPT SLD plug connector

- 2.5.20. JPT plug connector Saab

- 2.5.21. JPT plug connector VW

- 2.5.22. Kompakt 1.1 plug connector

- 2.5.23. Bosch Kompakt 4 plug connector

- 2.5.24. Leavyseal plug connector

- 2.5.25. MCON 1.2mm LL plug connector

- 2.5.26. MCON 1.2mm CB plug connector

- 2.5.27. MCP plug connector

- 2.5.28. MetriPack 150 plug connector

- 2.5.29. MiniFit plug connector

- 2.5.30. Mini Universal MATENLOK plug connector

- 2.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 2.5.32. MKR Plus plug connector

- 2.5.33. MQS plug connector

- 2.5.34. MR plug connector

- 2.5.35. MTA plug housing and fuse housing

- 2.5.36. MT2 plug connector

- 2.5.37. MT2 1.5mm plug connector VW

- 2.5.38. Multilock plug connector

- 2.5.39. MX150 plug connector

- 2.5.40. NG1 plug connector

- 2.5.41. Phönix Contact HC plug connector

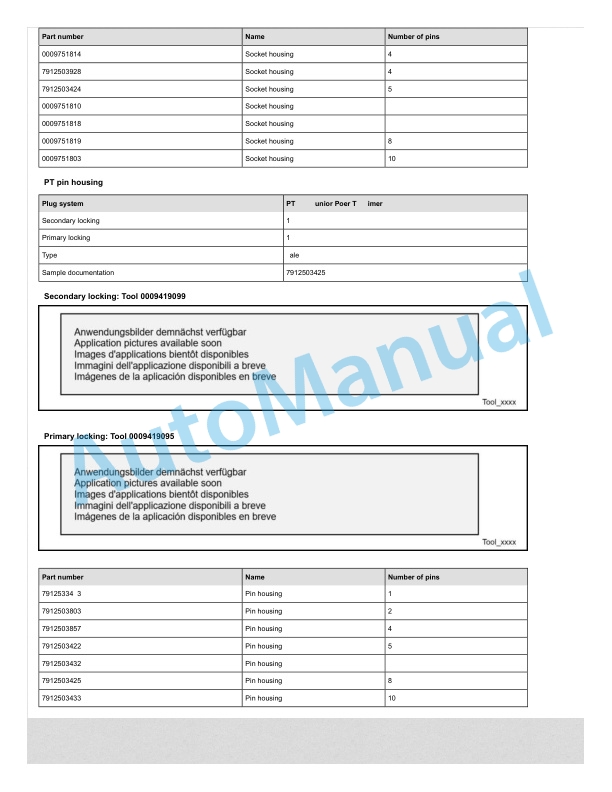

- 2.5.42. PT 3F plug connector

- 2.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 2.5.44. Relay socket with SPT and MPT contacts

- 2.5.45. Fuse holder with SPT contacts

- 2.5.46. Sicma plug connector

- 2.5.47. SLK 2.8 plug connector

- 2.5.48. Souriau UTL7 plug connector

- 2.5.49. Superseal 1.5mm plug connector

- 2.5.50. Trident Neptune plug connector

- 2.5.51. Universal MATENLOK plug connector

- 2.5.52. VW 9.5mm plug connector

- 3. Steering axle crimping tool

- 3.1. Table of content

- 3.2. Crimping tool

- 3.2.1. Press tool Overview of parts

- 3.2.2. Basic device

- 3.2.3. Basic design

- 3.3. Replacement kits

- 3.3.1. Steering axle 301.1601

- 3.3.2. Steering axle 302.303.1602.1603

- 3.4. Steering axle 301.302.303

- 3.4.1. Trackrod pin on the steering cylinder Preparing the press tool

- 3.4.2. Pressing out the trackrod pin on the steering cylinder

- 3.4.3. Trackrod pin on the axle stub Preparing the press tool

- 3.4.4. Pressing out the trackrod pin on the axle stub

- 3.4.5. Pressing in the trackrod pin on the axle stub

- 3.4.6. Pressing in the trackrod pin on the steering cylinder

- 3.5. Steering axle 1601

- 3.5.1. Trackrod pin on the steering cylinder Preparing the press tool

- 3.5.2. Pressing out the trackrod pin on the steering cylinder

- 3.5.3. Trackrod pin for the mudflap on the axle stub Preparing the press tool

- 3.5.4. Pressing out the trackrod pin for the mudflap on the axle stub

- 3.5.5. Pressing in the trackrod pin for the mudflap on the axle stub

- 3.5.6. Pressing in the trackrod pin on the steering cylinder

- 3.6. Steering axle 1602.1603

- 3.6.1. Trackrod pin on the steering cylinder Preparing the press tool

- 3.6.2. Pressing out the trackrod pin on the steering cylinder

- 3.6.3. Trackrod pin for the mud flap on the axle stub Preparing the press tool

- 3.6.4. Pressing out the trackrod pin for the mud flap on the axle stub

- 3.6.5. Pressing in the trackrod pin for the mud flap on the axle stub

- 3.6.6. Pressing in the trackrod pin on the steering cylinder

- 4. IC TruckH25D . H25T . H30D . H30TH35D . H35T

- 4.1. Table of content

- 4.2. Product information

- 4.2.1. Diagnostic software

- 4.2.2. Special torque settings

- 4.3. Engine

- 4.3.1. Kubota diesel engine

- 4.3.2. Deutz diesel engine

- 4.3.3. Kubota LPG engine

- 4.4. Hydrostatic transmission

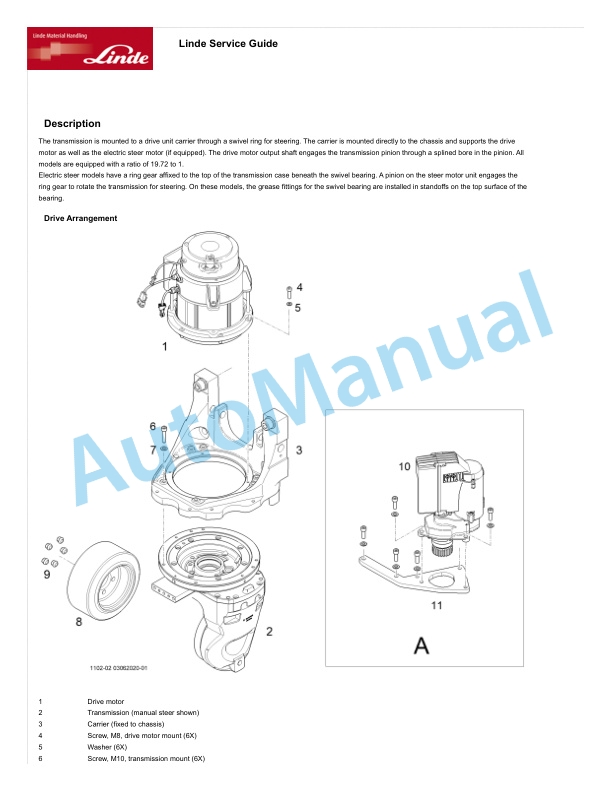

- 4.4.1. Hydrostatic drive unit

- 4.5. Drive axle

- 4.5.1. Introduction

- 4.5.2. Disassembly

- 4.5.3. Error diagnosis

- 4.6. Steering system

- 4.6.1. Hydraulic steering system

- 4.6.2. Steering axle

- 4.7. Operating system

- 4.7.1. Brake system

- 4.7.2. GUIDF296D58294B343539C1B7D00D5AFDF32 Accelerator pedal

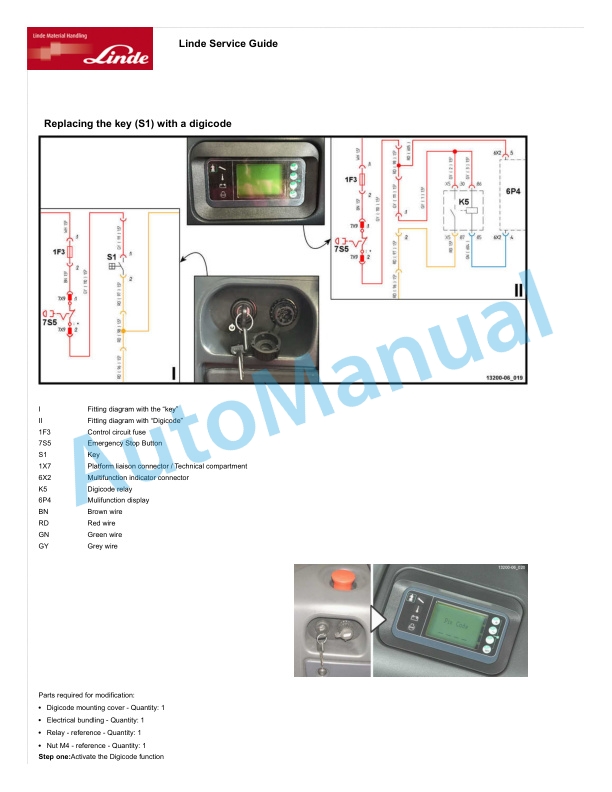

- 4.8. Electrical system

- 4.8.1. Overview

- 4.8.2. Introduction to the main electrical components

- 4.8.3. Display unit Kubota

- 4.8.4. GUIDE1E09C5344F6484AB056883C877AE051 Electrical component testing

- 4.9. Hydraulic system

- 4.9.1. GUID20CF5E6B49894792B1D9FF7E85AD3FF8 Working hydraulic system

- 4.10. Lift mast

- 4.10.1. Lift mast

- 4.11. Special equipment, accessories

- 4.11.1. GUID2BAC82AA76DB483D86E64E1A4B7B1A25 Special tools list

- 5. Circuit diagramsDiesel TruckH25D, H30D, H35D

- 5.1. Table of content

- 5.2. Circuit diagrams

- 5.2.1. Wire diagram Kubota

- 5.2.2. Wire diagram Deutz

- 5.2.3. Hydraulic diagram Kubota

- 5.2.4. Brake diagram

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Workshop Manuals

$40.00

Linde Workshop Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Workshop Manuals SN A11103V00001 and up

$40.00

Linde Workshop Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Workshop Manuals SN W41110V00529 and up

$40.00