Linde 126-01 – P60Z EX Workshop Manuals

$40.00

- Type Of Manual: Workshop Manuals

- Format: PDF

- Size: 142.1MB

- Number of Pages: 1238

Category: Linde Workshop Manual PDF

-

Model List:

- P60Z EX

- 1. Operating Instructions

- 1.1. Electric tow tractorP60Z

- 1.1.1. Table of content

- 1.1.2. Introduction

- 1.1.3. Safety

- 1.1.4. Overview

- 1.1.5. Operation

- 1.1.6. Maintenance

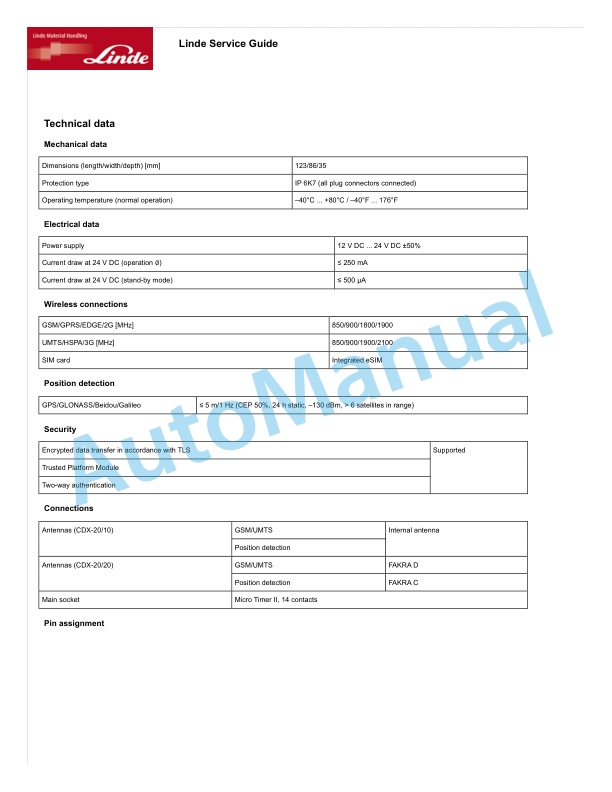

- 1.1.7. Technical data

- 2. Regular testing

- 2.1. Table of content

- 2.2. Regular testing

- 2.2.1. Principles for testing industrial trucks

- 2.2.2. Test log

- 2.2.3. Testing instruments, measuring devices, tools and devices

- 2.3. Electric motor

- 2.3.1. Test steps for the electric traction motor

- 2.4. Internal combustion engine

- 2.4.1. Test steps for the exhaust system

- 2.4.2. Diesel internal combustion engine

- 2.4.3. LPG internal combustion engine

- 2.5. Drive axle

- 2.5.1. Drive axle test steps

- 2.6. Chassis

- 2.6.1. Test steps for chassis

- 2.7. Drivers compartment

- 2.7.1. Test steps for drivers compartment

- 2.8. Steering systems

- 2.8.1. Test steps for the steering

- 2.9. Wheels and tyres

- 2.9.1. Test steps for wheels

- 2.9.2. Tyre test steps

- 2.10. Brake system

- 2.10.1. Definition and description of the industrial truck groups

- 2.10.2. Permissible braking distances for unladen industrial trucks

- 2.10.3. Service brake

- 2.10.4. Parking brake

- 2.11. Operating devices

- 2.11.1. Test steps for operating devices

- 2.12. Electrics.electronics

- 2.12.1. Test steps for electrical equipment

- 2.12.2. Notes regarding insulation testing

- 2.12.3. Insulation testing

- 2.12.4. Test steps for the battery and battery connection assemblies

- 2.13. Hydraulics

- 2.13.1. Test steps for hydraulic system

- 2.13.2. Safety regulations for hydraulic hose lines

- 2.14. Lift mast

- 2.14.1. Test steps for lift mast

- 2.14.2. Test steps for load chains

- 2.15. Load support

- 2.15.1. Test steps for fork arms

- 2.15.2. Combined testing device for testing fork arms, lifting chains and lifting hydraulics

- 2.16. Attachments

- 2.16.1. Test steps for attachments and other lifting accessories

- 2.17. Special equipment.accessories

- 2.17.1. LPG tanks on trucks

- 2.17.2. Test steps for other accessories

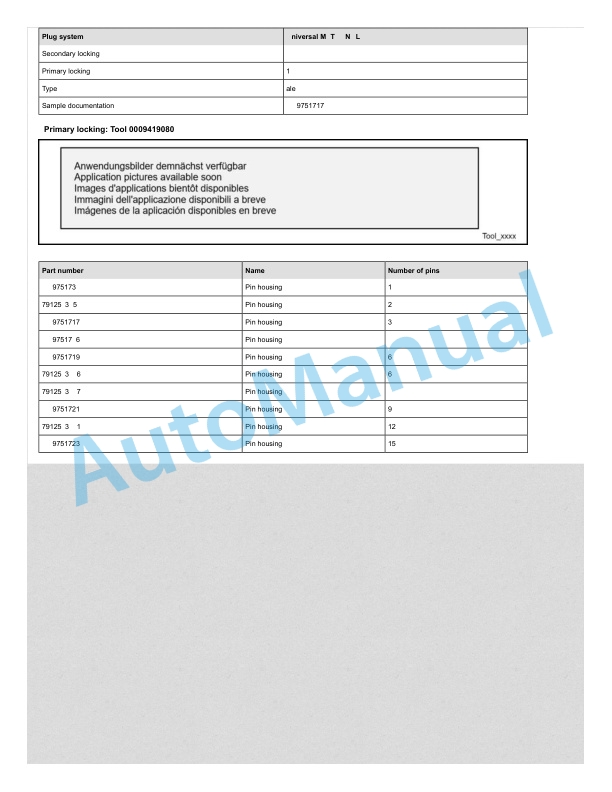

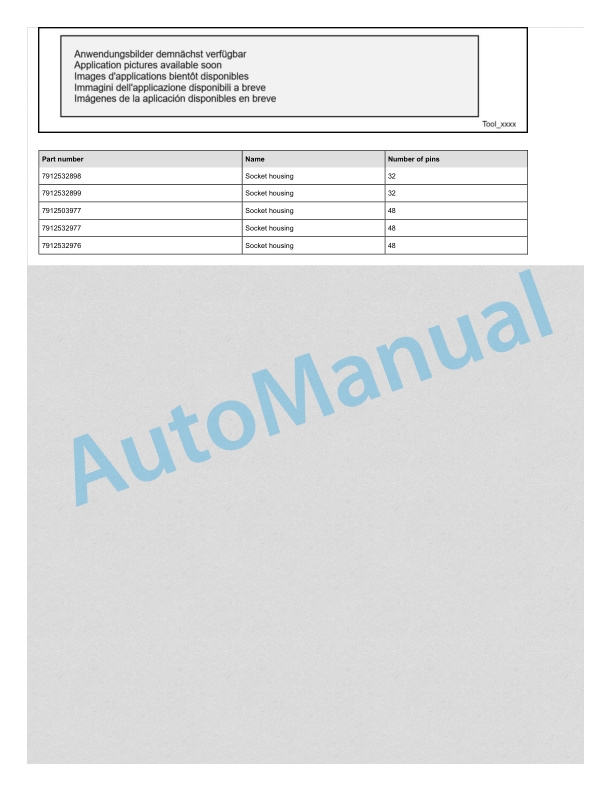

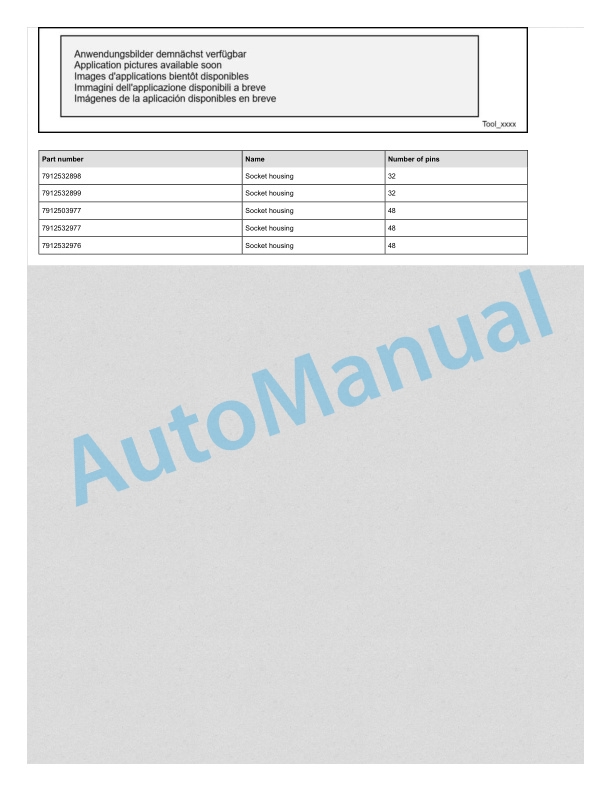

- 3. Service case Release tools for contacts

- 3.1. Table of content

- 3.2. Safety information

- 3.2.1. Safety information for repair and maintenance work

- 3.3. Information

- 3.3.1. Information

- 3.4. Overview

- 3.4.1. Overview of service cases

- 3.5. Plug systems

- 3.5.1. ATS 2.8 plug connector

- 3.5.2. CMC plug connector

- 3.5.3. DCS 9.5 plug connector

- 3.5.4. DIN 1.5mm circular connector

- 3.5.5. DIN 2.5mm circular connector

- 3.5.6. Deutsch DTM plug connector

- 3.5.7. ECU appliance plug

- 3.5.8. MCON appliance plug

- 3.5.9. Appliance plug with JPT and MQS contacts

- 3.5.10. Appliance plug with MT2 and JPT contacts

- 3.5.11. SICMA appliance plug

- 3.5.12. Econoseal JMark 2 plug connector

- 3.5.13. Elobau 11pin receptacle housing

- 3.5.14. E5931 plug connector

- 3.5.15. FASTINFASTON 6.3mm plug connector

- 3.5.16. GT150 plug connector

- 3.5.17. HDSCS plug connector

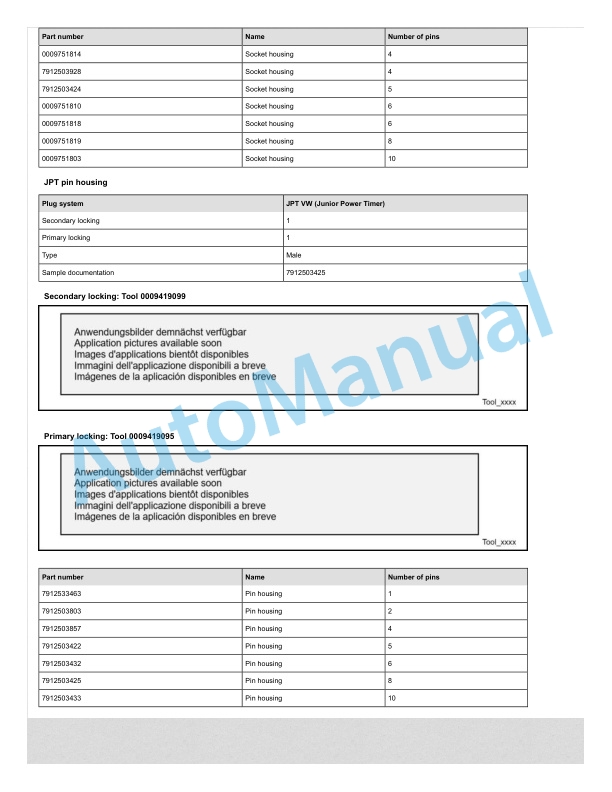

- 3.5.18. JPT plug connector

- 3.5.19. JPT SLD plug connector

- 3.5.20. JPT plug connector Saab

- 3.5.21. JPT plug connector VW

- 3.5.22. Kompakt 1.1 plug connector

- 3.5.23. Bosch Kompakt 4 plug connector

- 3.5.24. Leavyseal plug connector

- 3.5.25. MCON 1.2mm LL plug connector

- 3.5.26. MCON 1.2mm CB plug connector

- 3.5.27. MCP plug connector

- 3.5.28. MetriPack 150 plug connector

- 3.5.29. MiniFit plug connector

- 3.5.30. Mini Universal MATENLOK plug connector

- 3.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 3.5.32. MKR Plus plug connector

- 3.5.33. MQS plug connector

- 3.5.34. MR plug connector

- 3.5.35. MTA plug housing and fuse housing

- 3.5.36. MT2 plug connector

- 3.5.37. MT2 1.5mm plug connector VW

- 3.5.38. Multilock plug connector

- 3.5.39. MX150 plug connector

- 3.5.40. NG1 plug connector

- 3.5.41. Phönix Contact HC plug connector

- 3.5.42. PT 3F plug connector

- 3.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 3.5.44. Relay socket with SPT and MPT contacts

- 3.5.45. Fuse holder with SPT contacts

- 3.5.46. Sicma plug connector

- 3.5.47. SLK 2.8 plug connector

- 3.5.48. Souriau UTL7 plug connector

- 3.5.49. Superseal 1.5mm plug connector

- 3.5.50. Trident Neptune plug connector

- 3.5.51. Universal MATENLOK plug connector

- 3.5.52. VW 9.5mm plug connector

- 4. Explosion Protection Fundamentals

- 5. Explosion protection

- 5.1. Table of content

- 5.2. Basic principles

- 5.2.1. ATEX

- 5.2.2. Implementing the directives into national law

- 5.2.3. Conformity assessment procedures

- 5.2.4. EU type approval

- 5.2.5. Notified bodies

- 5.2.6. Explosion protection measures

- 5.2.7. Fires and explosion conditions

- 5.2.8. Potential sources of ignition

- 5.2.9. Potentially explosive area

- 5.2.10. Hazardous quantities

- 5.2.11. Explosion limits

- 5.2.12. Zones for potentially explosive areas

- 5.2.13. Classification as equipment for potentially explosive atmospheres

- 5.2.14. Classification as electrical equipment for potentially explosive atmospheres

- 5.2.15. Equipment categories

- 5.2.16. Equipment Protection Level (EPL)

- 5.2.17. Identification

- 5.2.18. Assignment of zones, equipment category and protection level

- 5.2.19. Protection types provided by housings with an IP code

- 5.2.20. Significant temperatures

- 5.3. Spark protection

- 5.3.1. Overview

- 5.3.2. Flameproof enclosure Ex d

- 5.3.3. Increased safety Ex e

- 5.3.4. Intrinsic safety Ex i

- 5.3.5. Type of spark protection Ex n

- 5.3.6. Encapsulation Ex m

- 5.3.7. Equipment dust explosion protection by enclosures Ex t

- 5.3.8. Constructional safety Ex c

- 5.3.9. Protection against static electricity

- 5.4. Safety electronics

- 5.4.1. Receiver

- 5.4.2. Horn control

- 5.4.3. Interface

- 5.4.4. Insulation monitoring

- 5.4.5. Fan thermostat

- 5.4.6. Proplan safety unit

- 5.4.7. REG 16 temperature control

- 5.4.8. Relay box

- 5.4.9. Transmitter

- 5.4.10. PWM monitoring system electronic control unit

- 5.4.11. THERMO 16 electronic control unit

- 5.4.12. Converter

- 5.5. Gas safety systems

- 5.5.1. Gas explosion conditions

- 5.5.2. Explosion limits

- 5.5.3. Preventing a gas explosion

- 5.5.4. Using gas safety systems

- 5.5.5. Gas safety systems on industrial trucks

- 5.5.6. Gas measurement

- 5.5.7. Gas safety systems in use

- 6. Workshop Manuals

- 6.1. Regular testing

- 6.1.1. Table of content

- 6.1.2. Regular testing

- 6.1.3. Electric motor

- 6.1.4. Internal combustion engine

- 6.1.5. Drive axle

- 6.1.6. Chassis

- 6.1.7. Drivers compartment

- 6.1.8. Steering systems

- 6.1.9. Wheels and tyres

- 6.1.10. Brake system

- 6.1.11. Operating devices

- 6.1.12. Electrics.electronics

- 6.1.13. Hydraulics

- 6.1.14. Lift mast

- 6.1.15. Load support

- 6.1.16. Attachments

- 6.1.17. Special equipment.accessories

- 6.2. Service case Release tools for contacts

- 6.2.1. Table of content

- 6.2.2. Safety information

- 6.2.3. Information

- 6.2.4. Overview

- 6.2.5. Plug systems

- 6.3. Explosion Protection Fundamentals

- 6.4. Explosion protection

- 6.4.1. Table of content

- 6.4.2. Basic principles

- 6.4.3. Spark protection

- 6.4.4. Safety electronics

- 6.4.5. Gas safety systems

- 7. Circuit diagramsElectric tow tractorP60Z Ex

- 7.1. Table of content

- 7.2. Circuit diagrams from 11.2001

- 7.2.1. Control component sheet 1

- 7.2.2. Control component sheet 2

- 8. Circuit Diagrams

- 8.1. Circuit diagramsElectric tow tractorP60Z Ex

- 8.1.1. Table of content

- 8.1.2. Circuit diagrams from 11.2001

- 9. hour service plan

- 10. hour service plan

- 11. hour service plan

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Workshop Manuals SN W41110V00529 and up

$40.00

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Workshop Manuals

$40.00

Linde Workshop Manual PDF

Linde 1110-01 – V08-01, V08-02 Workshop Manuals SN 11.09 and up SN up to W41110V00528

$40.00

Linde Workshop Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Workshop Manuals SN A11103V00001 and up

$40.00