Linde 1275-02 – EG16, EG16H, EG16P, EG16PH, EG20PH Production site Kolbaskowo Operating Instructions SN 11.22 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 11.22 and up

- Format: PDF

- Size: 29.5MB

- Number of Pages: 222

- Serial Number:

SN 11.22 and up

Category: Linde Operator Manual PDF

-

Model List:

- EG16

- EG16H

- EG16P

- EG16PH

- EG20PH

- 1. Electric truckEG1602, EG16H02, EG16P02, EG16PH02, EG20PH02

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. The truck

- 1.2.1.1. General information

- 1.2.1.2. Conformity marking

- 1.2.1.3. Declaration that reflects the content of the declaration of conformity

- 1.2.1.4. Declarations of conformity in accordance with directive RED 2014.53.EU

- 1.2.1.5. Nameplate

- 1.2.1.6. Serial number and identification plates of the components

- 1.2.1.7. Truck configuration

- 1.2.1.8. Nameplate of a lithiumion battery

- 1.2.1.9. Reception of truck

- 1.2.2. Application conditions

- 1.2.2.1. Intended use

- 1.2.2.2. Improper use

- 1.2.2.3. Hazard assessment

- 1.2.3. Information about the operating instructions

- 1.2.3.1. Documentation

- 1.2.3.2. Symbols used

- 1.2.4. Disposing of components and batteries

- 1.3. Safety

- 1.3.1. Responsible persons

- 1.3.1.1. Operating company

- 1.3.1.2. Drivers

- 1.3.1.3. Competent person

- 1.3.2. Operating safely

- 1.3.2.1. Requirements

- 1.3.2.2. Accidents involving lithiumion batteries

- 1.3.2.3. Stability

- 1.3.2.4. Data security

- 1.3.2.5. Residual risks

- 1.3.2.6. Wheelslide protection chains in winter operation

- 1.3.3. Emissions

- 1.3.3.1. Electromagnetic compatibility

- 1.3.4. Working on the truck

- 1.3.4.1. Handling the lithiumion battery

- 1.3.4.2. Handling consumables

- 1.3.4.3. Fitting attachments

- 1.3.5. Periodic safety inspection

- 1.4. Overview

- 1.4.1. Truck overview

- 1.4.2. Operating devices

- 1.4.3. Display unit

- 1.4.4. Switch panel

- 1.5. Operation

- 1.5.1. Initial commissioning

- 1.5.1.1. Checks before initial commissioning

- 1.5.1.2. Instructions for runningin

- 1.5.2. Preshift checks

- 1.5.3. Drivers compartment

- 1.5.3.1. Entering and exiting the truck

- 1.5.3.2. Minimum distance between head and overhead guard

- 1.5.3.3. Adjusting the drivers seat (standard) and seat belt

- 1.5.3.4. Adjusting the drivers seat (comfort) and seat belt

- 1.5.3.5. Adjusting the drivers seat (luxury drivers seat)

- 1.5.3.6. Seat belt monitoring and alarm function

- 1.5.3.7. Drivers cab

- 1.5.3.8. Lighting

- 1.5.3.9. BlueSpot

- 1.5.3.10. Windscreen wiper functions

- 1.5.3.11. Rear window heating

- 1.5.3.12. Heating system

- 1.5.4. Display unit

- 1.5.4.1. Starting up the system

- 1.5.4.2. Control buttons

- 1.5.4.3. Status display menu

- 1.5.4.4. Speed indicator menu

- 1.5.4.5. Settings menu

- 1.5.4.6. Malfunctions menu

- 1.5.5. Operation

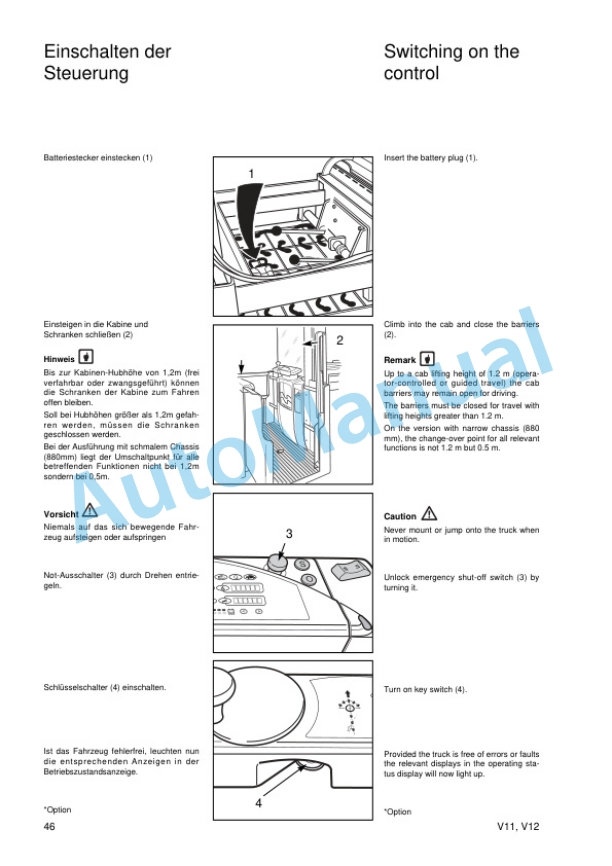

- 1.5.5.1. Switching the truck on and off Single pedal operation

- 1.5.5.2. Switching the truck on and off Dual pedal operation

- 1.5.5.3. Access system connect

- 1.5.5.4. Emergency off switches

- 1.5.5.5. Driving Dualpedal operation

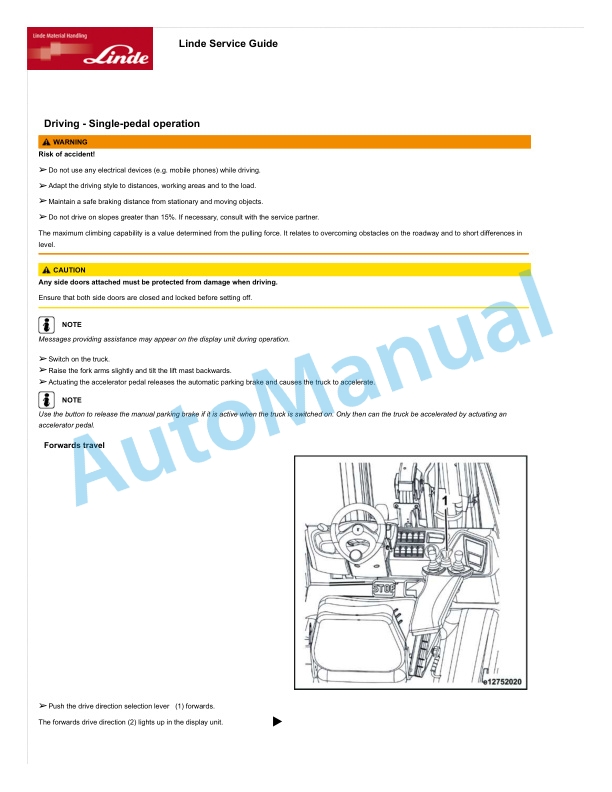

- 1.5.5.6. Driving Singlepedal operation

- 1.5.5.7. Briefly leaving the truck

- 1.5.5.8. Steering system

- 1.5.5.9. Brake system

- 1.5.5.10. Joystick Central lever operation

- 1.5.5.11. Joystick Single lever operation

- 1.5.5.12. Reducing the driving speed using a radar sensor (SpeedAssist)

- 1.5.6. Working with a load

- 1.5.6.1. Capacity rating plate

- 1.5.6.2. Additional capacity rating plate for attachments

- 1.5.6.3. Adjusting the fork arm distance

- 1.5.6.4. Determining visibility conditions when driving with a load

- 1.5.6.5. Driving with a load

- 1.5.6.6. Transporting suspended loads

- 1.5.6.7. Setting down a load

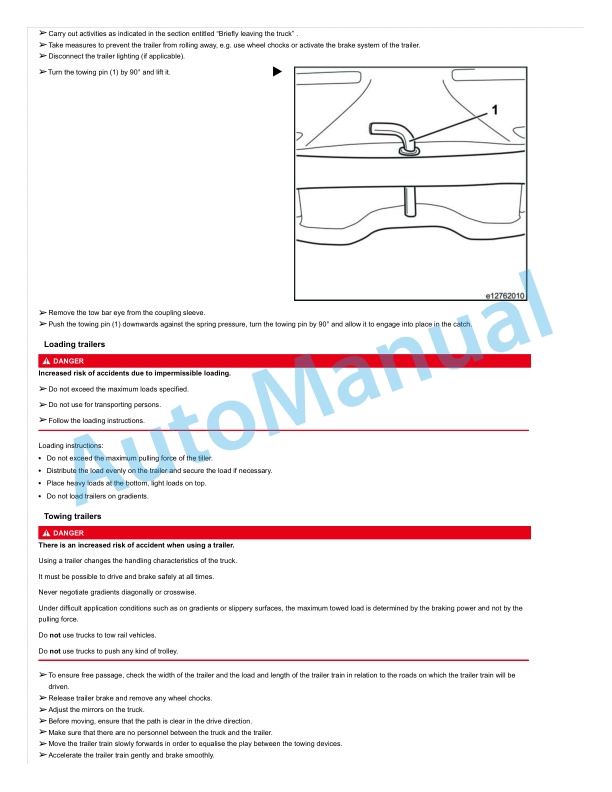

- 1.5.6.8. Towing device

- 1.5.6.9. Mast positioning

- 1.5.7. Leaving the truck

- 1.5.8. Drive batteries

- 1.5.8.1. Special instructions and course of action for BSeries lithiumion batteries

- 1.5.8.2. Checking the battery charge state

- 1.5.8.3. Opening and closing the battery hood

- 1.5.8.4. Charging the lithiumion battery

- 1.5.8.5. Charging the leadacid battery

- 1.5.8.6. Replacing the lithiumion battery (B series)

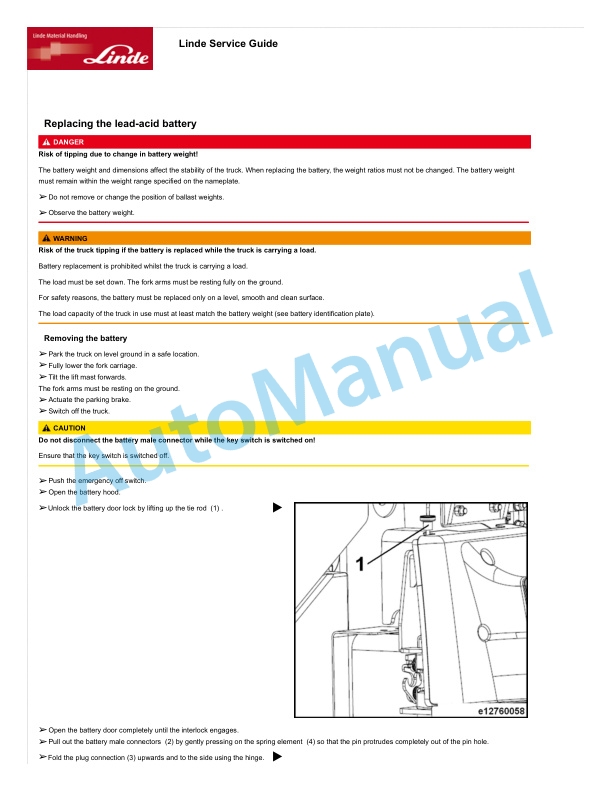

- 1.5.8.7. Replacing the leadacid battery

- 1.5.8.8. Replacing the leadacid battery using a hand pallet truck and battery support (optional)

- 1.5.8.9. Replacing the leadacid battery using a truck and battery support (optional)

- 1.5.8.10. Replacing the leadacid battery using a truck and battery pallet (optional)

- 1.5.9. Emergency operation

- 1.5.9.1. Emergency lowering

- 1.5.9.2. Towing

- 1.5.10. Loading.transporting

- 1.5.10.1. Removing.attaching the lift mast

- 1.5.10.2. Transporting the truck using a lorry or flat bed trailer

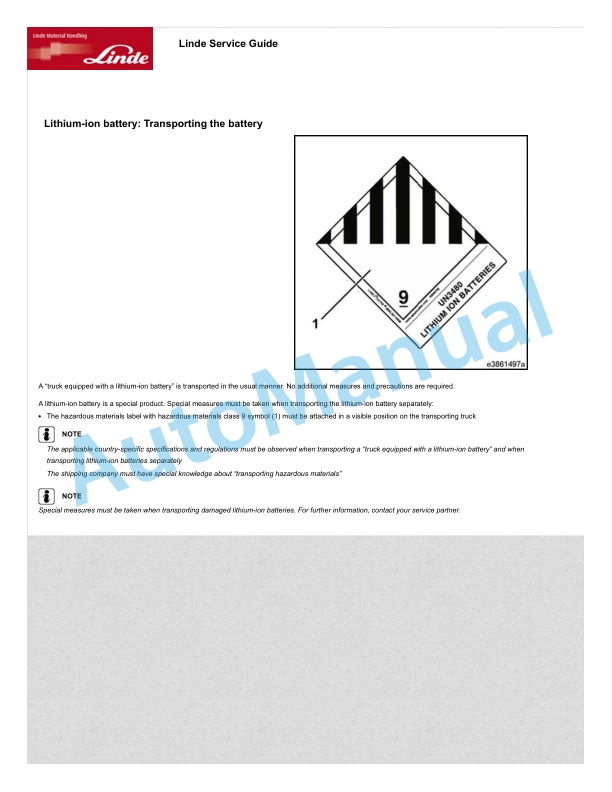

- 1.5.10.3. Lithiumion battery Transporting the battery

- 1.6. Service and maintenance

- 1.6.1. Safety information regarding servicing work

- 1.6.2. Overview of filling quantities and set values

- 1.6.3. Recommendation for consumables

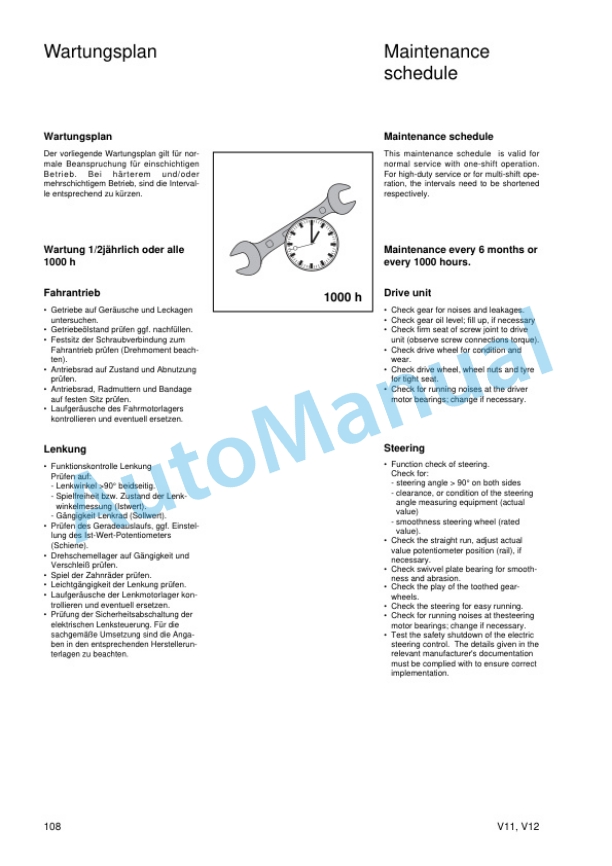

- 1.6.4. Regular maintenance

- 1.6.5. Cleaning the truck

- 1.6.6. Running gear and drive train

- 1.6.6.1. Changing wheels

- 1.6.6.2. Tightening the wheel fastenings

- 1.6.6.3. Checking the condition of the antistatic belt

- 1.6.6.4. Lubricating the swing steering axle

- 1.6.7. Electrics.electronics

- 1.6.7.1. Checking the condition of the electric cables and connections

- 1.6.8. Hydraulics

- 1.6.8.1. Checking that the bleeder valve on the hydraulic tank is working correctly

- 1.6.8.2. Hydraulic systemChecking for leak tightness

- 1.6.8.3. Checking the preload of the hose lines

- 1.6.9. Lifting system

- 1.6.9.1. Working on the lift mast and at the front of the truck

- 1.6.9.2. Checking the condition of the lift mast

- 1.6.9.3. Cleaning and spraying the lift mast chain

- 1.6.9.4. Checking the fork arms and arm safety devices

- 1.6.9.5. Checking and lubricating the sideshift (special equipment)

- 1.6.10. Selfhelp

- 1.6.10.1. Opening and closing the fuse box

- 1.6.10.2. Fuses for basic equipment and for special equipment

- 1.6.10.3. Diagnostic connector

- 1.6.10.4. Lithiumion battery Diagnostic connector

- 1.6.10.5. Lithiumion battery Power reduction due to vibration

- 1.6.10.6. Malfunctions on the lithiumion battery

- 1.6.10.7. Malfunctions in the electric parking brake

- 1.6.10.8. Malfunctions, causes and remedies Hydraulic system

- 1.6.11. Decommissioning

- 1.6.11.1. Parking for an extended period Decommissioning the truck

- 1.6.11.2. Leadacid battery Storage

- 1.6.11.3. Disposal of industrial trucks

- 1.7. Technical datasheet

- 1.7.1. Overview of dimensions

- 1.7.2. EG16.EG16H Technical datasheet

- 1.7.3. EG16P.EG16PH Technical datasheet

- 1.7.4. EG20PH Technical datasheet

- 1.7.5. Ecodesign requirements for electric motors and variable speed drives

- 1.7.6. Lift mast data for model 1511

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00