Linde 1286-01 – E30SL, E35SL Production site Xiamen Workshop Manuals SN C11286H00001 and up

$40.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN C11286H00001 and up

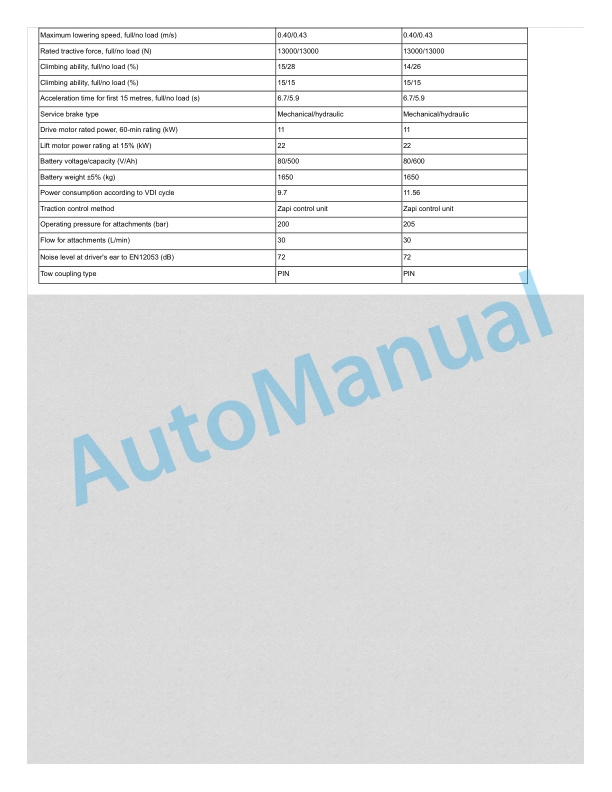

- Format: PDF

- Size: 141.0MB

- Number of Pages: 1101

- Serial Number:

SN C11286H00001 and up

Category: Linde Workshop Manual PDF

-

Model List:

- E30SL

- E35SL

- 1. Operating Instructions

- 1.1. Electric Forklift TruckE30SL, E35SL

- 1.1.1. Table of content

- 1.1.2. Introduction

- 1.1.3. Safety

- 1.1.4. Overview

- 1.1.5. Operation

- 1.1.6. Maintenance

- 1.1.7. Technical datasheet

- 1.2. Leadacid battery charger 24V . 48V . 80V

- 1.3. Lithiumion batteryWNE, WEB Lithium BatteryWNE lithiumion battery

- 1.3.1. Table of content

- 1.3.2. Overview

- 1.3.3. Safety

- 1.3.4. General view

- 1.3.5. Operating instructions

- 1.3.6. Maintenance

- 1.3.7. Warranty description

- 2. Regular testing

- 2.1. Table of content

- 2.2. Regular testing

- 2.2.1. Principles for testing industrial trucks

- 2.2.2. Test log

- 2.2.3. Testing instruments, measuring devices, tools and devices

- 2.3. Electric motor

- 2.3.1. Test steps for the electric traction motor

- 2.4. Internal combustion engine

- 2.4.1. Test steps for the exhaust system

- 2.4.2. Diesel internal combustion engine

- 2.4.3. LPG internal combustion engine

- 2.5. Drive axle

- 2.5.1. Drive axle test steps

- 2.6. Chassis

- 2.6.1. Test steps for chassis

- 2.7. Drivers compartment

- 2.7.1. Test steps for drivers compartment

- 2.8. Steering systems

- 2.8.1. Test steps for the steering

- 2.9. Wheels and tyres

- 2.9.1. Test steps for wheels

- 2.9.2. Tyre test steps

- 2.10. Brake system

- 2.10.1. Definition and description of the industrial truck groups

- 2.10.2. Permissible braking distances for unladen industrial trucks

- 2.10.3. Service brake

- 2.10.4. Parking brake

- 2.11. Operating devices

- 2.11.1. Test steps for operating devices

- 2.12. Electrics.electronics

- 2.12.1. Test steps for electrical equipment

- 2.12.2. Notes regarding insulation testing

- 2.12.3. Insulation testing

- 2.12.4. Test steps for the battery and battery connection assemblies

- 2.13. Hydraulics

- 2.13.1. Test steps for hydraulic system

- 2.13.2. Safety regulations for hydraulic hose lines

- 2.14. Lift mast

- 2.14.1. Test steps for lift mast

- 2.14.2. Test steps for load chains

- 2.15. Load support

- 2.15.1. Test steps for fork arms

- 2.15.2. Combined testing device for testing fork arms, lifting chains and lifting hydraulics

- 2.16. Attachments

- 2.16.1. Test steps for attachments and other lifting accessories

- 2.17. Special equipment.accessories

- 2.17.1. LPG tanks on trucks

- 2.17.2. Test steps for other accessories

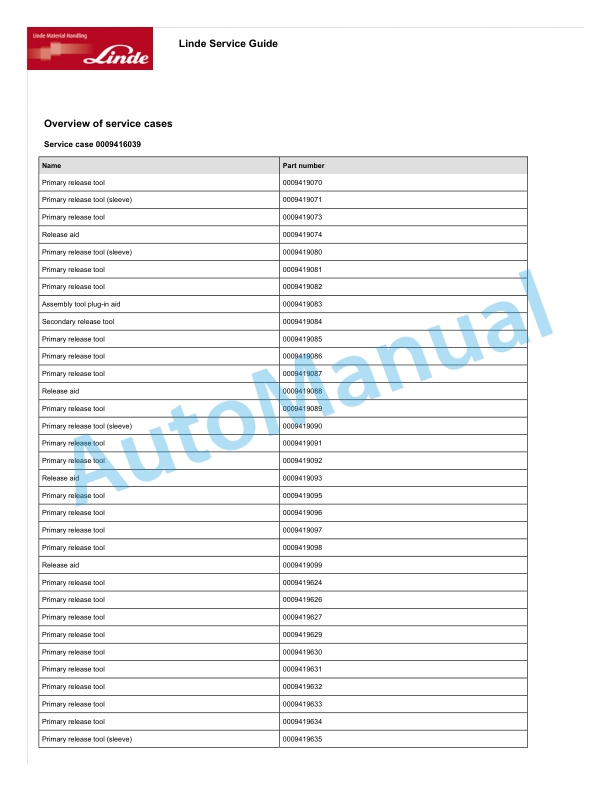

- 3. Service case Release tools for contacts

- 3.1. Table of content

- 3.2. Safety information

- 3.2.1. Safety information for repair and maintenance work

- 3.3. Information

- 3.3.1. Information

- 3.4. Overview

- 3.4.1. Overview of service cases

- 3.5. Plug systems

- 3.5.1. ATS 2.8 plug connector

- 3.5.2. CMC plug connector

- 3.5.3. DCS 9.5 plug connector

- 3.5.4. DIN 1.5mm circular connector

- 3.5.5. DIN 2.5mm circular connector

- 3.5.6. Deutsch DTM plug connector

- 3.5.7. ECU appliance plug

- 3.5.8. MCON appliance plug

- 3.5.9. Appliance plug with JPT and MQS contacts

- 3.5.10. Appliance plug with MT2 and JPT contacts

- 3.5.11. SICMA appliance plug

- 3.5.12. Econoseal JMark 2 plug connector

- 3.5.13. Elobau 11pin receptacle housing

- 3.5.14. E5931 plug connector

- 3.5.15. FASTINFASTON 6.3mm plug connector

- 3.5.16. GT150 plug connector

- 3.5.17. HDSCS plug connector

- 3.5.18. JPT plug connector

- 3.5.19. JPT SLD plug connector

- 3.5.20. JPT plug connector Saab

- 3.5.21. JPT plug connector VW

- 3.5.22. Kompakt 1.1 plug connector

- 3.5.23. Bosch Kompakt 4 plug connector

- 3.5.24. Leavyseal plug connector

- 3.5.25. MCON 1.2mm LL plug connector

- 3.5.26. MCON 1.2mm CB plug connector

- 3.5.27. MCP plug connector

- 3.5.28. MetriPack 150 plug connector

- 3.5.29. MiniFit plug connector

- 3.5.30. Mini Universal MATENLOK plug connector

- 3.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 3.5.32. MKR Plus plug connector

- 3.5.33. MQS plug connector

- 3.5.34. MR plug connector

- 3.5.35. MTA plug housing and fuse housing

- 3.5.36. MT2 plug connector

- 3.5.37. MT2 1.5mm plug connector VW

- 3.5.38. Multilock plug connector

- 3.5.39. MX150 plug connector

- 3.5.40. NG1 plug connector

- 3.5.41. Phönix Contact HC plug connector

- 3.5.42. PT 3F plug connector

- 3.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 3.5.44. Relay socket with SPT and MPT contacts

- 3.5.45. Fuse holder with SPT contacts

- 3.5.46. Sicma plug connector

- 3.5.47. SLK 2.8 plug connector

- 3.5.48. Souriau UTL7 plug connector

- 3.5.49. Superseal 1.5mm plug connector

- 3.5.50. Trident Neptune plug connector

- 3.5.51. Universal MATENLOK plug connector

- 3.5.52. VW 9.5mm plug connector

- 4. Electric Counterbalance ForkliftE30SL, E35SL

- 4.1. Table of content

- 4.2. Product information

- 4.2.1. Technical data

- 4.2.2. Diagnostic software

- 4.3. Drive motor

- 4.3.1. Drive motor

- 4.3.2. Sensors

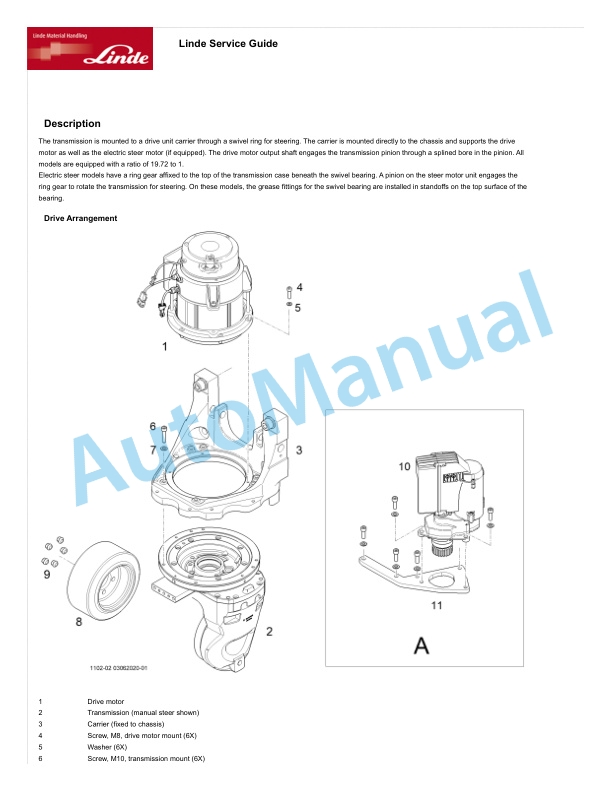

- 4.4. Transmission system

- 4.4.1. Retarder

- 4.4.2. Drive axle

- 4.5. Chassis

- 4.5.1. Chassis

- 4.6. Steering system

- 4.6.1. Steering system

- 4.6.2. Steering axle

- 4.7. Operating equipment

- 4.7.1. Brake system

- 4.7.2. Accelerator system

- 4.7.3. Operating handle

- 4.8. Electrical system

- 4.8.1. General

- 4.8.2. Control unit

- 4.8.3. Electrical components

- 4.8.4. Display unit

- 4.9. Hydraulics

- 4.9.1. General

- 4.9.2. Hydraulic pump unit

- 4.9.3. Control valve unit

- 4.9.4. Hydraulic components

- 4.10. Load lifting system

- 4.10.1. Lift mast

- 4.11. Special equipment

- 4.11.1. Battery

- 4.11.2. Special tools list

- 5. Lithiumion batteryWNE, WEB series

- 5.1. Table of content

- 5.2. Product information

- 5.2.1. Series no

- 5.3. Error diagnosis

- 5.3.1. Error diagnosis

- 5.4. Schematic diagrams

- 5.4.1. Electrical diagrams

- 6. Maintenance of charger ADY 6117

- 7. Workshop Manuals

- 7.1. Regular testing

- 7.1.1. Table of content

- 7.1.2. Regular testing

- 7.1.3. Electric motor

- 7.1.4. Internal combustion engine

- 7.1.5. Drive axle

- 7.1.6. Chassis

- 7.1.7. Drivers compartment

- 7.1.8. Steering systems

- 7.1.9. Wheels and tyres

- 7.1.10. Brake system

- 7.1.11. Operating devices

- 7.1.12. Electrics.electronics

- 7.1.13. Hydraulics

- 7.1.14. Lift mast

- 7.1.15. Load support

- 7.1.16. Attachments

- 7.1.17. Special equipment.accessories

- 7.2. Service case Release tools for contacts

- 7.2.1. Table of content

- 7.2.2. Safety information

- 7.2.3. Information

- 7.2.4. Overview

- 7.2.5. Plug systems

- 7.3. Electric Counterbalance ForkliftE30SL, E35SL

- 7.3.1. Table of content

- 7.3.2. Product information

- 7.3.3. Drive motor

- 7.3.4. Transmission system

- 7.3.5. Chassis

- 7.3.6. Steering system

- 7.3.7. Operating equipment

- 7.3.8. Electrical system

- 7.3.9. Hydraulics

- 7.3.10. Load lifting system

- 7.3.11. Special equipment

- 7.4. Lithiumion batteryWNE, WEB series

- 7.4.1. Table of content

- 7.4.2. Product information

- 7.4.3. Error diagnosis

- 7.4.4. Schematic diagrams

- 7.5. Maintenance of charger ADY 6117

- 8. Table of content

- 9. Schematic diagrams

- 9.1. Electrical diagram up to 30.10.2022

- 9.1.1. Electrical diagram 1

- 9.1.2. Electrical diagram 2

- 9.1.3. Electrical diagram 3

- 9.1.4. Electrical diagram 4 (fully enclosed drivers cab)

- 9.2. Electrical diagram 31.10.2022 and up

- 9.2.1. Electrical diagram 1

- 9.2.2. Electrical diagram 1 (without ISO)

- 9.2.3. Electrical diagram 2

- 9.2.4. Electrical diagram 2 (without ISO)

- 9.2.5. Electrical diagram 3

- 9.2.6. Electrical diagram 4 (fully enclosed drivers cab)

- 9.2.7. Circuit diagram 5 (lithiumion battery)

- 9.3. Hydraulic diagram

- 9.3.1. Hydraulic diagram

- 9.4. Braking diagram

- 9.4.1. Braking diagram

- 10. Schematic diagramsElectric forklift truck1286_E30SL, 1286_E35SL

- 10.1. Table of content

- 10.2. Schematic diagrams

- 10.2.1. Electrical diagram up to 30.10.2022

- 10.2.2. Electrical diagram 31.10.2022 and up

- 10.2.3. Hydraulic diagram

- 10.2.4. Braking diagram

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Workshop Manuals SN A11103V00001 and up

$40.00

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Workshop Manuals SN A11102V00001 and up

$40.00

Linde Workshop Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Workshop Manuals

$40.00