Linde 1287-01 – E40 to E50B Production site China, LX Workshop Manuals SN C11287X00009 and up

$40.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN C11287X00009 and up

- Format: PDF

- Size: 43.9MB

- Number of Pages: 373

- Serial Number:

SN C11287X00009 and up

Category: Linde Workshop Manual PDF

-

Model List:

- E40

- E40-20

- E40B

- E45

- E45-20

- E45B

- E50

- E50-20

- E50B

- 1. Service case Release tools for contacts

- 1.1. Table of content

- 1.2. Safety information

- 1.2.1. Safety information for repair and maintenance work

- 1.3. Information

- 1.3.1. Information

- 1.4. Overview

- 1.4.1. Overview of service cases

- 1.5. Plug systems

- 1.5.1. ATS 2.8 plug connector

- 1.5.2. CMC plug connector

- 1.5.3. DCS 9.5 plug connector

- 1.5.4. DIN 1.5mm circular connector

- 1.5.5. DIN 2.5mm circular connector

- 1.5.6. Deutsch DTM plug connector

- 1.5.7. ECU appliance plug

- 1.5.8. MCON appliance plug

- 1.5.9. Appliance plug with JPT and MQS contacts

- 1.5.10. Appliance plug with MT2 and JPT contacts

- 1.5.11. SICMA appliance plug

- 1.5.12. Econoseal JMark 2 plug connector

- 1.5.13. Elobau 11pin receptacle housing

- 1.5.14. E5931 plug connector

- 1.5.15. FASTINFASTON 6.3mm plug connector

- 1.5.16. GT150 plug connector

- 1.5.17. HDSCS plug connector

- 1.5.18. JPT plug connector

- 1.5.19. JPT SLD plug connector

- 1.5.20. JPT plug connector Saab

- 1.5.21. JPT plug connector VW

- 1.5.22. Kompakt 1.1 plug connector

- 1.5.23. Bosch Kompakt 4 plug connector

- 1.5.24. Leavyseal plug connector

- 1.5.25. MCON 1.2mm LL plug connector

- 1.5.26. MCON 1.2mm CB plug connector

- 1.5.27. MCP plug connector

- 1.5.28. MetriPack 150 plug connector

- 1.5.29. MiniFit plug connector

- 1.5.30. Mini Universal MATENLOK plug connector

- 1.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 1.5.32. MKR Plus plug connector

- 1.5.33. MQS plug connector

- 1.5.34. MR plug connector

- 1.5.35. MTA plug housing and fuse housing

- 1.5.36. MT2 plug connector

- 1.5.37. MT2 1.5mm plug connector VW

- 1.5.38. Multilock plug connector

- 1.5.39. MX150 plug connector

- 1.5.40. NG1 plug connector

- 1.5.41. Phönix Contact HC plug connector

- 1.5.42. PT 3F plug connector

- 1.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 1.5.44. Relay socket with SPT and MPT contacts

- 1.5.45. Fuse holder with SPT contacts

- 1.5.46. Sicma plug connector

- 1.5.47. SLK 2.8 plug connector

- 1.5.48. Souriau UTL7 plug connector

- 1.5.49. Superseal 1.5mm plug connector

- 1.5.50. Trident Neptune plug connector

- 1.5.51. Universal MATENLOK plug connector

- 1.5.52. VW 9.5mm plug connector

- 2. Electric forklift truckE40, E45, E50,E40B, E45B, E50B

- 2.1. Table of content

- 2.2. Product information

- 2.2.1. Technical data

- 2.2.1.1. Truck serial number

- 2.2.1.2. Tightening torque requirements for standard bolts

- 2.2.1.3. _Tightening torque requirements for some bolts

- 2.2.2. Diagnostic software

- 2.2.2.1. Calibrating an acceleration potentiometer

- 2.2.2.2. Calibrating the handle

- 2.2.2.3. Steering angle sensor calibration

- 2.2.2.4. Electronic parking brake eFSB calibration

- 2.2.2.5. Setting eFSB parameters

- 2.2.3. CAN box

- 2.2.3.1. Authorisations

- 2.2.3.2. CAN box

- 2.2.3.3. USBCANBox 2 and BluetoothCANBox 3 software update

- 2.2.4. Error code

- 2.2.4.1. Code lists

- 2.2.4.2. Traction

- 2.2.4.3. Working hydraulics

- 2.2.4.4. Single Power unit _ working hydraulic

- 2.2.4.5. Double Power unit _ traction left traction right

- 2.2.4.6. Display unit error codes

- 2.2.5. Aftersales service

- 2.2.5.1. Inspection and maintenance data

- 2.2.5.2. Recommended fuels and oils

- 2.2.5.3. Service plan table

- 2.3. Drive mechanism and transmission system

- 2.3.1. Drive axle

- 2.3.1.1. Overview of drive axle

- 2.3.1.2. Drive axle sensor

- 2.3.1.3. Drive axle filling oil inlet overview

- 2.3.2. Drive axle speed reduction gearbox

- 2.3.2.1. Checking the oil level of the reduction gearbox

- 2.3.2.2. Changing the reduction gearbox oil

- 2.3.3. Drive motor

- 2.3.3.1. Motor terminals

- 2.3.4. Sensors

- 2.3.4.1. Drive axle temperature sensor

- 2.3.5. Brake system

- 2.3.5.1. Manually releasing the electronic parking brake

- 2.3.5.2. Electronic parking brake

- 2.3.5.3. The electronic parking eFSB brake system

- 2.3.5.4. Checking the brake fluid level in the brake fluid reservoir

- 2.3.5.5. Replacing the oil in the brake fluid reservoir

- 2.3.6. Steering system

- 2.3.6.1. Functional description

- 2.3.6.2. Steering column assembly

- 2.3.6.3. Steering system overview

- 2.3.7. Steering axle

- 2.3.7.1. Functional description

- 2.3.7.2. Removing the steering axle

- 2.3.7.3. Changing the steering cylinder seals

- 2.3.7.4. Adjusting the steering lock

- 2.3.7.5. Steering angle sensor 3B1

- 2.3.7.6. Changing the steering angle sensor

- 2.4. Chassis and bodywork

- 2.4.1. Chassis design

- 2.4.1.1. Chassis design

- 2.5. Drivers cab

- 2.5.1. Drivers handhold

- 2.5.1.1. Handhold

- 2.5.2. Drivers seat

- 2.5.2.1. Seat belt monitoring and alarm function

- 2.5.2.2. Seat belt monitoring and alarm

- 2.5.3. Operating handle

- 2.5.3.1. Joystick variants

- 2.5.3.2. Joystick interlock

- 2.5.3.3. Exchange

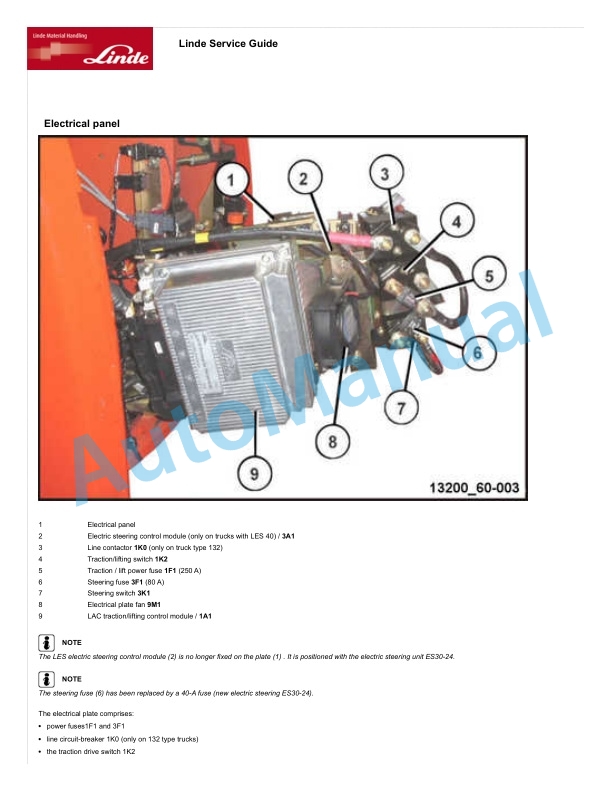

- 2.6. Electrics.electronics

- 2.6.1. Overview

- 2.6.1.1. Electrical equipment safety instructions

- 2.6.1.2. Cleaning the electrical system

- 2.6.1.3. Insulation test

- 2.6.1.4. EMC Electromagnetic compatibility

- 2.6.1.5. CAN bus

- 2.6.1.6. Electrostatic charging

- 2.6.1.7. Power module and motor layout

- 2.6.1.8. Layout of electric components

- 2.6.2. Electrical components

- 2.6.2.1. Emergency stop switch

- 2.6.2.2. Main contactor

- 2.6.2.3. Fan control

- 2.6.2.4. Current sensor version 2

- 2.6.2.5. Operating lever controls

- 2.6.2.6. Horn

- 2.6.3. Power module

- 2.6.3.1. Overview of functional modules

- 2.6.3.2. Power module pins

- 2.6.4. Control module

- 2.6.4.1. Truck control unit overview

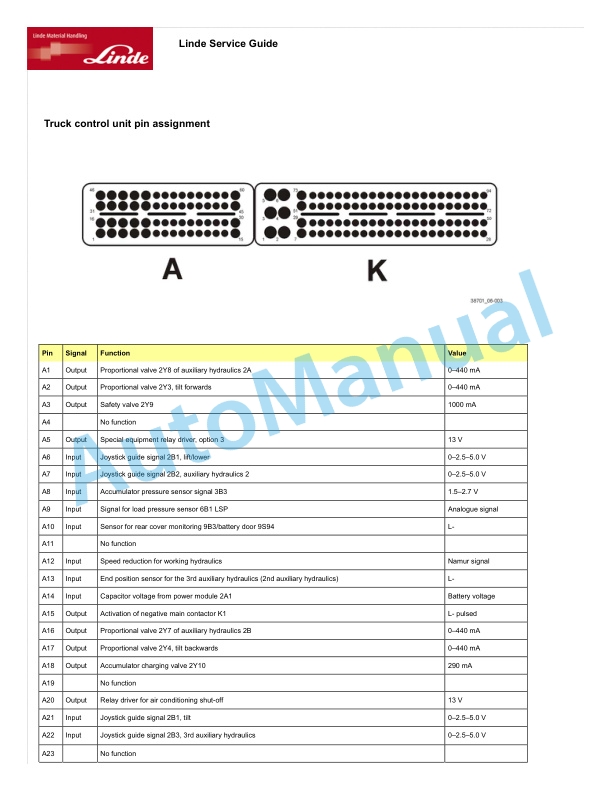

- 2.6.4.2. Pin assignments for truck control unit

- 2.6.4.3. Truck control unit pin assignment

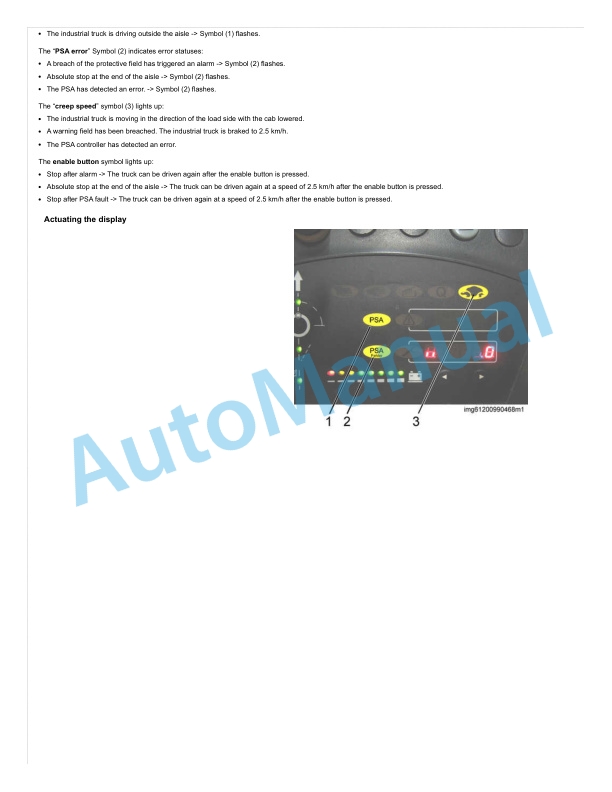

- 2.6.5. Display unit

- 2.6.5.1. Display unit

- 2.6.5.2. Display unit overview

- 2.6.5.3. Original pin definition

- 2.7. Hydraulic system

- 2.7.1. Overview

- 2.7.1.1. Hydraulic system contamination

- 2.7.2. Basic hydraulics

- 2.7.2.1. Gear pump

- 2.7.2.2. Priority valve

- 2.7.2.3. Steering control valve

- 2.7.2.4. Control valve

- 2.7.2.5. Filter and oil tank accessories

- 2.7.2.6. Tilt cylinder

- 2.7.2.7. Changing the hydraulic oil

- 2.7.2.8. Replacing the filter

- 2.8. Lifting system

- 2.8.1. Lift mast

- 2.8.1.1. Safety information for lift mast operations

- 2.8.1.2. Lift mast chains

- 2.8.1.3. Adjusting the lift mast chain

- 2.8.1.4. Rupture valve

- 2.8.1.5. Adjusting the tilt angle of the mast

- 2.9. Special equipment

- 2.9.1. Battery

- 2.9.1.1. Lead acid battery introduction

- 2.9.2. Other devices

- 2.9.2.1. Electrostatic belt

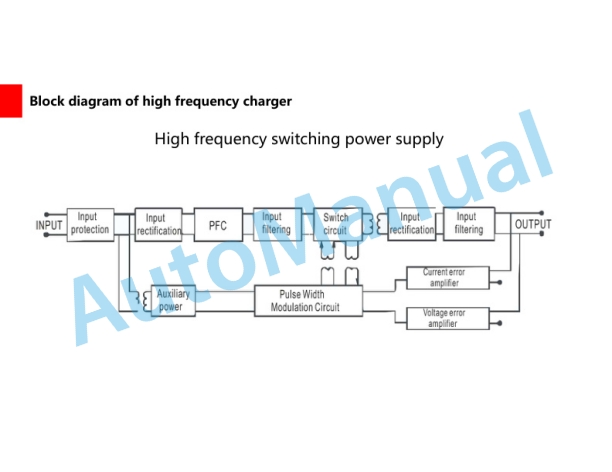

- 3. Maintenance of charger ADY 6117

- 4. Schematic diagramsBattery Counterbalanced Forklift TruckE40, E45, E50E4020, E4520, E5020

- 4.1. Table of content

- 4.2. Electrical diagrams

- 4.2.1. Electrical diagrams_E40.45.50

- 4.2.1.1. Electrical diagrams15.9.2021 after 30.6.2022

- 4.2.1.1.1. Electrical diagram_1

- 4.2.1.1.2. Electrical diagram_2

- 4.2.1.1.3. Electrical diagram_3

- 4.2.1.1.4. Electrical diagram_4

- 4.2.1.1.5. Electrical diagram_5

- 4.2.1.1.6. Electrical diagram_6

- 4.2.1.1.7. Electrical diagram_7

- 4.2.1.2. Electrical diagram 14.9.2021

- 4.2.1.2.1. Electrical diagram_1

- 4.2.1.2.2. Electrical diagram_5

- 4.2.2. Electrical diagrams_E40.45.5020

- 4.2.2.1. Electrical diagrams 30.6.2022

- 4.2.2.1.1. Electrical diagrams_1

- 4.2.2.1.2. Electrical diagrams_2

- 4.2.2.1.3. Electrical diagrams_3

- 4.2.2.1.4. Electrical diagrams_4

- 4.2.2.1.5. Electrical diagrams_5

- 4.2.2.1.6. Electrical diagrams_6

- 4.2.2.1.7. Electrical diagrams_7

- 4.2.3. Electrical diagrams_work lights, fully enclosed cab option

- 4.2.3.1. Electrical diagram_1

- 4.2.3.2. Electrical diagram_2

- 4.3. Hydraulics diagrams

- 4.3.1. Hydraulics diagrams

- 4.3.2. Hydraulic pressure diagrams_E40.45.5020

- 4.4. Brake schematic diagrams

- 4.4.1. Brake schematic diagram

- 4.5. Diagram of major stressed structural parts

- 4.5.1. Diagram of major stressed structural parts

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1110-01 – V08-01, V08-02 Workshop Manuals SN 11.09 and up SN up to W41110V00528

$40.00

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Workshop Manuals SN A11102V00001 and up

$40.00

Linde Workshop Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Workshop Manuals SN W41110V00529 and up

$40.00