Linde 1301-01 – T33 Workshop Manuals

$40.00

- Type Of Manual: Workshop Manuals

- Format: PDF

- Size: 29.3MB

- Number of Pages: 351

Category: Linde Workshop Manual PDF

-

Model List:

- T33

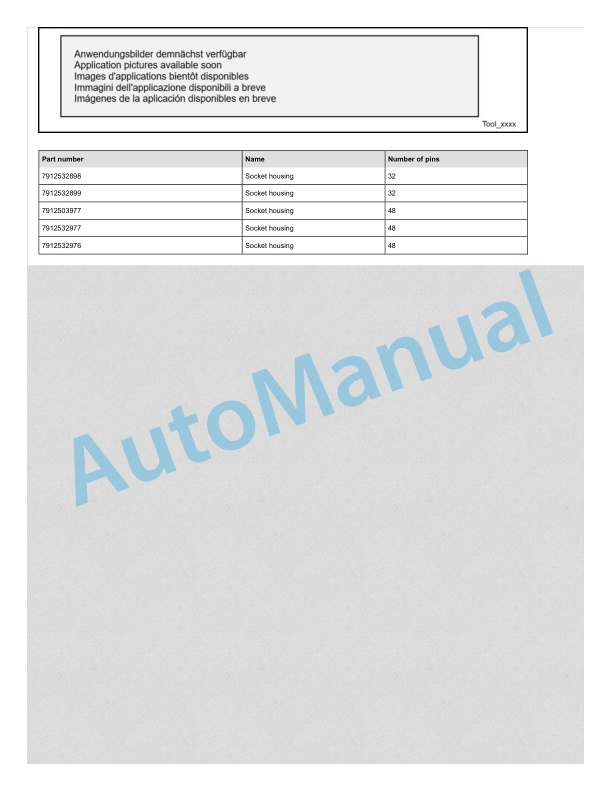

- 1. Service case Release tools for contacts

- 1.1. Table of content

- 1.2. Safety information

- 1.2.1. Safety information for repair and maintenance work

- 1.3. Information

- 1.3.1. Information

- 1.4. Overview

- 1.4.1. Overview of service cases

- 1.5. Plug systems

- 1.5.1. ATS 2.8 plug connector

- 1.5.2. CMC plug connector

- 1.5.3. DCS 9.5 plug connector

- 1.5.4. DIN 1.5mm circular connector

- 1.5.5. DIN 2.5mm circular connector

- 1.5.6. Deutsch DTM plug connector

- 1.5.7. ECU appliance plug

- 1.5.8. MCON appliance plug

- 1.5.9. Appliance plug with JPT and MQS contacts

- 1.5.10. Appliance plug with MT2 and JPT contacts

- 1.5.11. SICMA appliance plug

- 1.5.12. Econoseal JMark 2 plug connector

- 1.5.13. Elobau 11pin receptacle housing

- 1.5.14. E5931 plug connector

- 1.5.15. FASTINFASTON 6.3mm plug connector

- 1.5.16. GT150 plug connector

- 1.5.17. HDSCS plug connector

- 1.5.18. JPT plug connector

- 1.5.19. JPT SLD plug connector

- 1.5.20. JPT plug connector Saab

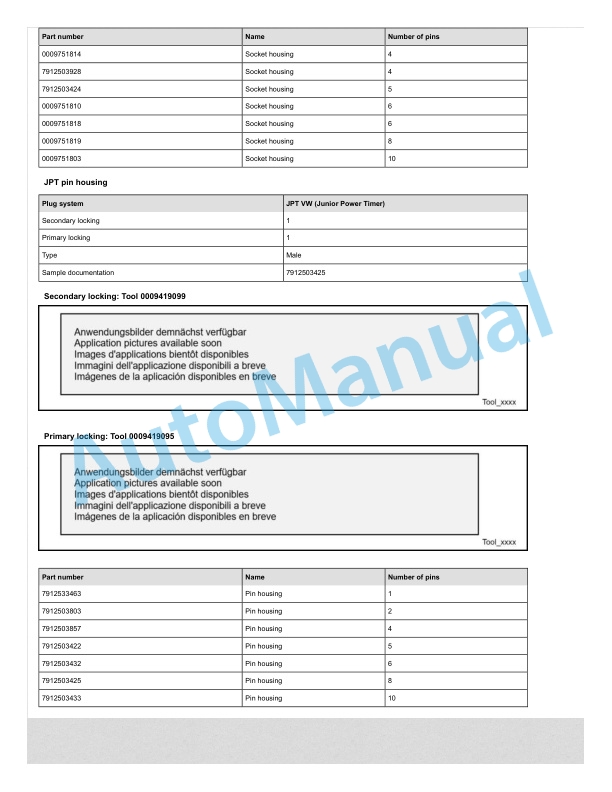

- 1.5.21. JPT plug connector VW

- 1.5.22. Kompakt 1.1 plug connector

- 1.5.23. Bosch Kompakt 4 plug connector

- 1.5.24. Leavyseal plug connector

- 1.5.25. MCON 1.2mm LL plug connector

- 1.5.26. MCON 1.2mm CB plug connector

- 1.5.27. MCP plug connector

- 1.5.28. MetriPack 150 plug connector

- 1.5.29. MiniFit plug connector

- 1.5.30. Mini Universal MATENLOK plug connector

- 1.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 1.5.32. MKR Plus plug connector

- 1.5.33. MQS plug connector

- 1.5.34. MR plug connector

- 1.5.35. MTA plug housing and fuse housing

- 1.5.36. MT2 plug connector

- 1.5.37. MT2 1.5mm plug connector VW

- 1.5.38. Multilock plug connector

- 1.5.39. MX150 plug connector

- 1.5.40. NG1 plug connector

- 1.5.41. Phönix Contact HC plug connector

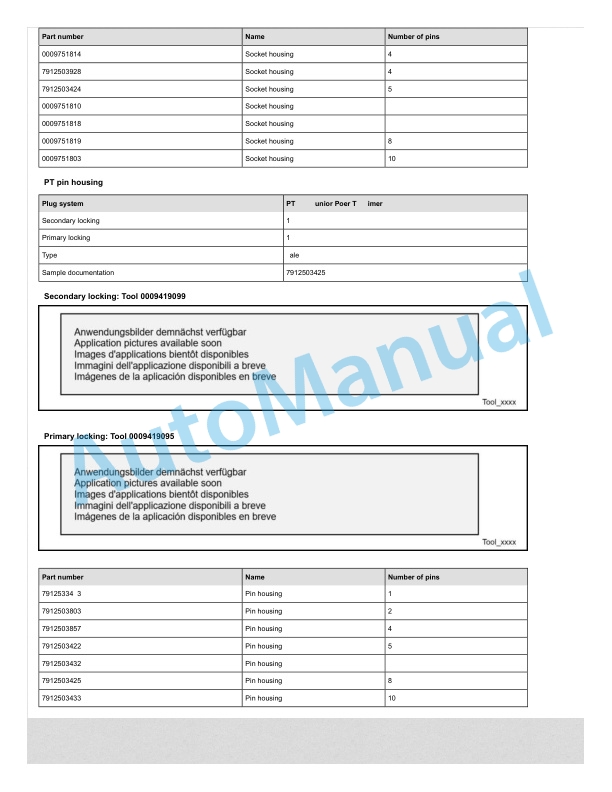

- 1.5.42. PT 3F plug connector

- 1.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 1.5.44. Relay socket with SPT and MPT contacts

- 1.5.45. Fuse holder with SPT contacts

- 1.5.46. Sicma plug connector

- 1.5.47. SLK 2.8 plug connector

- 1.5.48. Souriau UTL7 plug connector

- 1.5.49. Superseal 1.5mm plug connector

- 1.5.50. Trident Neptune plug connector

- 1.5.51. Universal MATENLOK plug connector

- 1.5.52. VW 9.5mm plug connector

- 2. Rider seated pallet truck5132_T33

- 2.1. Table of content

- 2.2. Product information

- 2.2.1. General product information

- 2.2.1.1. Control design

- 2.2.1.2. Technical data

- 2.3. Diagnostics

- 2.3.1. Onboard diagnostics

- 2.3.1.1. General

- 2.3.1.2. Parameter menu item

- 2.3.1.3. Information menu item

- 2.3.1.4. Diagnostic menu item

- 2.3.2. Software

- 2.3.2.1. ParaDig

- 2.3.2.1.1. General

- 2.3.3. Error list

- 2.3.3.1. General

- 2.3.3.2. Truck central control (FZS) fault list

- 2.3.3.3. Right brake control (BRS RE) fault list

- 2.3.3.4. Left brake controller (BRS LI) fault list

- 2.3.3.5. Traction controller (FS) fault list

- 2.3.3.6. Left electrical steering unit (ELK LI) fault list

- 2.3.3.7. Right electrical steering unit (ELK RE) fault list

- 2.3.4. Teachin

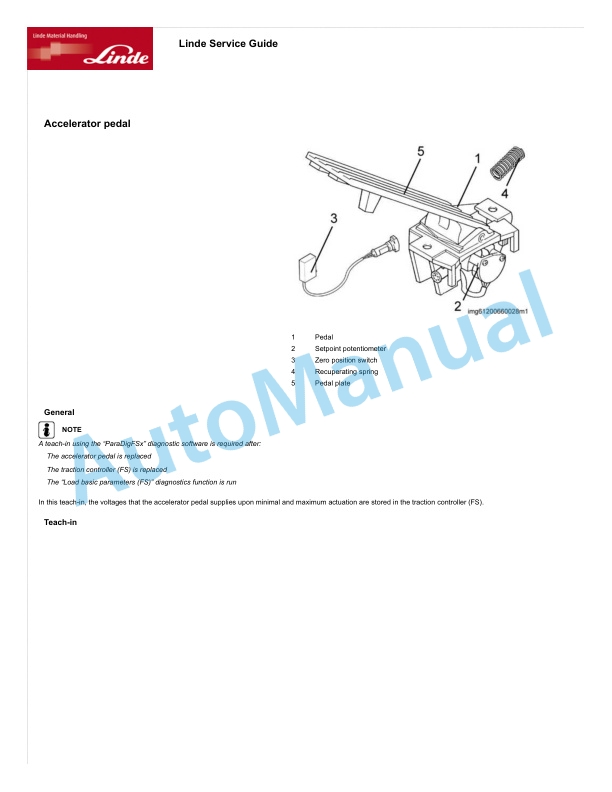

- 2.3.4.1. Accelerator pedal

- 2.3.4.2. Brake pedal

- 2.4. Electric motor

- 2.4.1. Traction motor

- 2.4.1.1. General

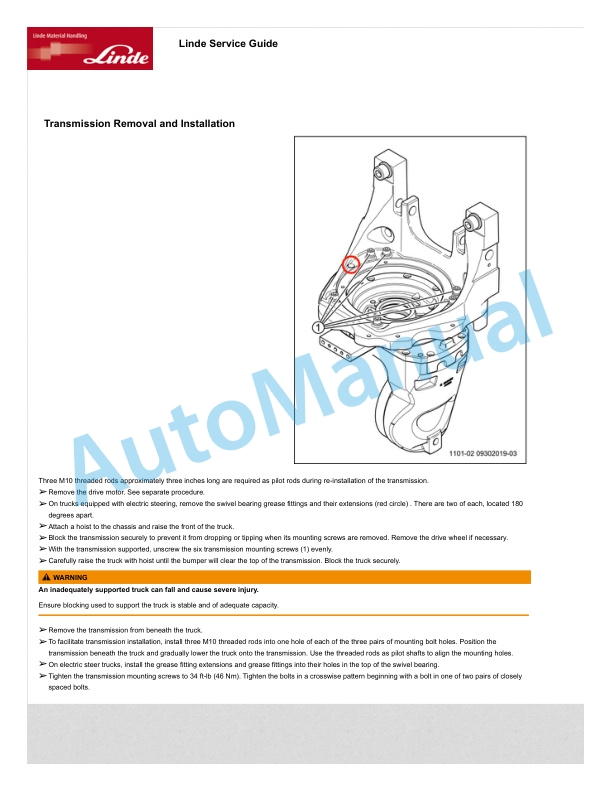

- 2.5. Mechanical drive axle

- 2.5.1. Front bevel gears

- 2.5.1.1. General

- 2.6. Steering system

- 2.6.1. Electric steering

- 2.6.1.1. General

- 2.6.1.2. Electric steering unit

- 2.6.1.2.1. General

- 2.6.1.2.2. Test

- 2.6.1.2.3. Repair

- 2.6.1.2.4. Maintenance

- 2.6.1.3. Setpoint potentiometer

- 2.6.1.3.1. General

- 2.6.1.3.2. Test

- 2.6.1.3.3. Repair

- 2.6.1.4. Actual value potentiometer

- 2.6.1.4.1. General

- 2.6.1.4.2. Test

- 2.6.1.4.3. Repair

- 2.6.1.5. Reference switch

- 2.6.1.5.1. General

- 2.6.1.5.2. Testing

- 2.6.1.5.3. Repair

- 2.7. Wheels and tyres

- 2.7.1. Wheels

- 2.7.1.1. Drive wheel

- 2.7.1.1.1. General

- 2.7.1.1.2. Repair

- 2.7.1.2. Load wheels

- 2.7.1.2.1. General

- 2.7.1.2.2. Repair

- 2.8. Brake system

- 2.8.1. Electric service brake

- 2.8.1.1. General

- 2.8.2. Parking brake

- 2.8.2.1. General

- 2.8.2.2. Testing

- 2.8.2.3. Repair

- 2.8.2.4. Maintenance

- 2.9. Operating devices, general

- 2.9.1. Drive and brake actuation

- 2.9.1.1. Accelerator pedal

- 2.9.1.1.1. General

- 2.9.1.1.2. Testing

- 2.9.1.1.3. Repair

- 2.9.1.2. Brake pedal

- 2.9.1.2.1. General

- 2.9.1.2.2. Testing

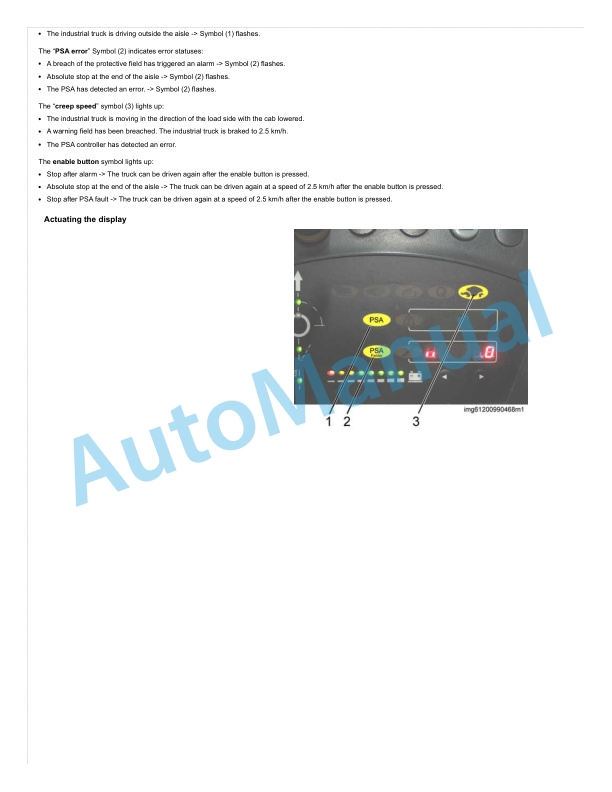

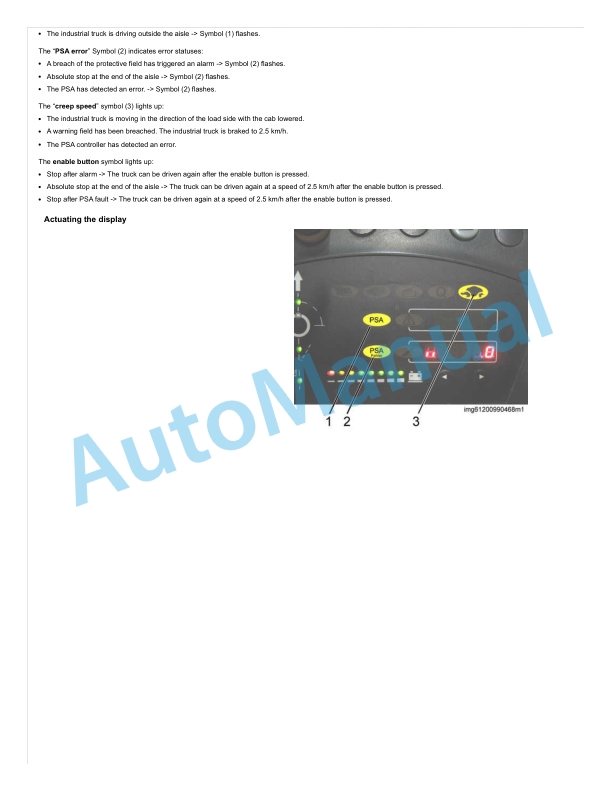

- 2.10. Display elements

- 2.10.1. Display

- 2.10.1.1. Standard display

- 2.10.1.1.1. General

- 2.10.1.1.2. Testing

- 2.10.1.1.3. Repair

- 2.10.1.1.4. Maintenance.

- 2.11. Electrics.electronics

- 2.11.1. Electrical system

- 2.11.1.1. DC.DC converter

- 2.11.1.1.1. General

- 2.11.2. Battery and accessories

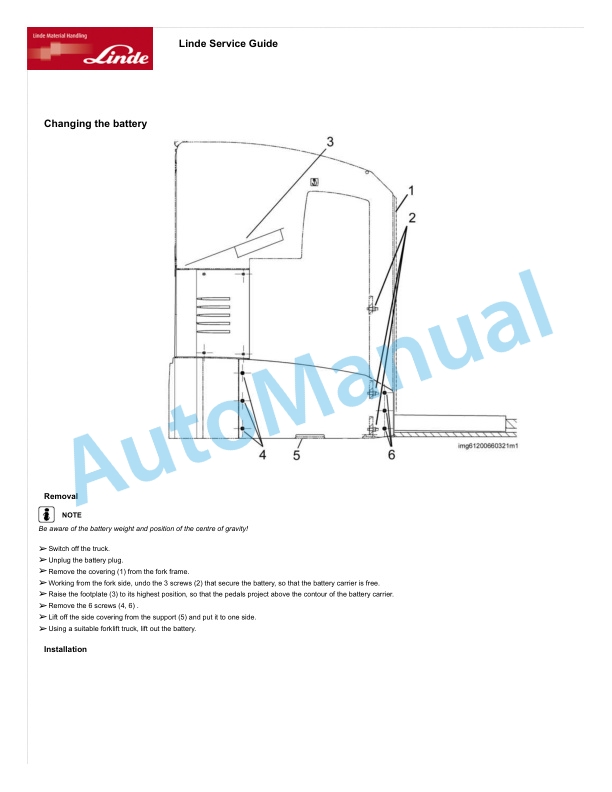

- 2.11.2.1. Changing the battery

- 2.12. Electronic controllers

- 2.12.1. Traction controller (FS)

- 2.12.1.1. General

- 2.12.1.2. Battery discharge indicator

- 2.12.2. Other electronic controls

- 2.12.2.1. Brake control (BRS)

- 2.12.2.1.1. General

- 2.12.2.2. Truck control unit (FZS)

- 2.12.2.2.1. General

- 2.12.2.3. CAN bus

- 2.12.2.3.1. General

- 2.12.2.3.2. Testing

- 2.13. Load lift system

- 2.13.1. Initial lift system

- 2.13.1.1. Angled lever

- 2.13.1.1.1. General

- 2.13.1.1.2. Repair

- 2.13.1.2. Roller fork

- 2.13.1.2.1. Repair

- 2.13.1.3. Insertion wheels for CHEP pallets

- 2.13.1.3.1. Changing the insertion wheels for CHEP pallets

- 2.14. Other accessories

- 2.14.1. Devices

- 2.14.1.1. Dynometer

- 3. Spare parts catalogue

- 3.1. TABLE OF CONTENTS

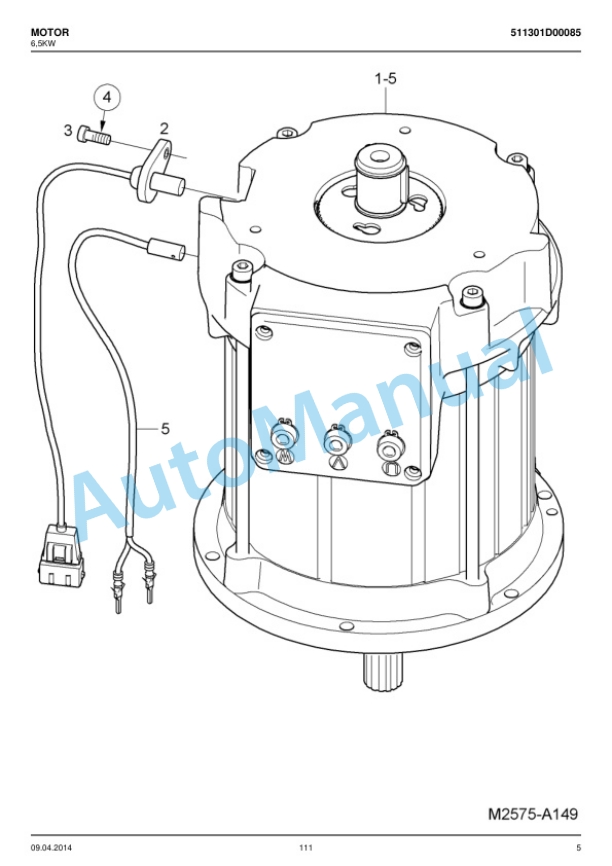

- 3.1.1. ELECTRIC MOTOR

- 3.1.1.1. MOTOR (6,5KW)

- 3.1.2. MECHANICAL DRIVE AXLE

- 3.1.2.1. WHEEL DRIVE

- 3.1.2.1.1. TRANSMISSION (I15,17)

- 3.1.2.1.2. MOTOR (6,5KW)

- 3.1.2.1.3. STEERING UNIT,COMPL

- 3.1.2.1.4. SPRINGOPERATED BRAKE

- 3.1.2.2. TRANSMISSION (I15,17)

- 3.1.3. CHASSIS

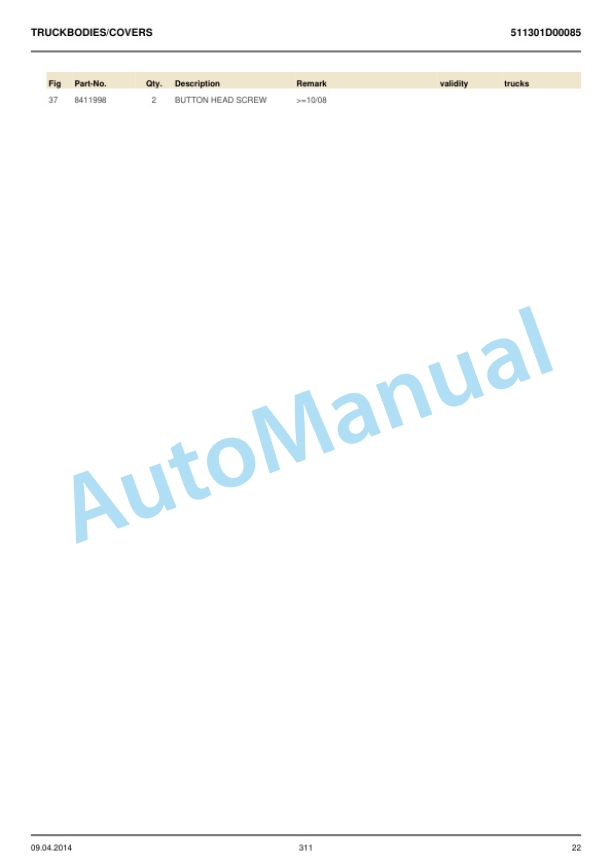

- 3.1.3.1. TRUCKBODIES/COVERS

- 3.1.3.2. FLOOR PLATE

- 3.1.3.2.1. TRAVEL SENDER

- 3.1.3.2.2. BRAKE SENDER

- 3.1.4. DRIVERS POSITION

- 3.1.4.0.1. STEERING

- 3.1.5. STEERING SYSTEM

- 3.1.5.1. STEERING UNIT,COMPL

- 3.1.5.2. STEERING

- 3.1.6. BRAKING SYSTEM

- 3.1.6.1. SPRINGOPERATED BRAKE

- 3.1.7. CONTROLS

- 3.1.7.1. TRAVEL SENDER

- 3.1.7.2. BRAKE SENDER

- 3.1.7.3. INSTRUMENT BOARD

- 3.1.8. ELECTRICS/ELECTRONICS

- 3.1.8.1. CONNECTOR, COMPL. (DIN320A/95)

- 3.1.8.2. ELECTR.INSTALLATIONFRAME

- 3.1.8.2.1. CONTROL BOARD

- 3.1.8.3. CONTROL BOARD

- 3.1.8.3.1. CABLE HARNESS

- 3.1.8.3.2. CABLE KITMAIN CURRENT

- 3.1.8.4. CONTROL BOARD

- 3.1.8.4.1. CABLE HARNESS

- 3.1.8.4.2. CABLE KITMAIN CURRENT (STILL FSX33)

- 3.1.8.5. CABLE HARNESS

- 3.1.8.6. CABLE KITMAIN CURRENT

- 3.1.9. WORKING HYDRAULICS

- 3.1.9.1. MOTORPUMP UNIT (48V/2KW)

- 3.1.10. UPRIGHT

- 3.1.10.1. LIFT CYLINDER (D68mm/H115mm/L233mm)

- 3.1.11. OTHER ACCESSORIES

- 3.1.11.1. PLATE ARRANGEMENT (LINDE)

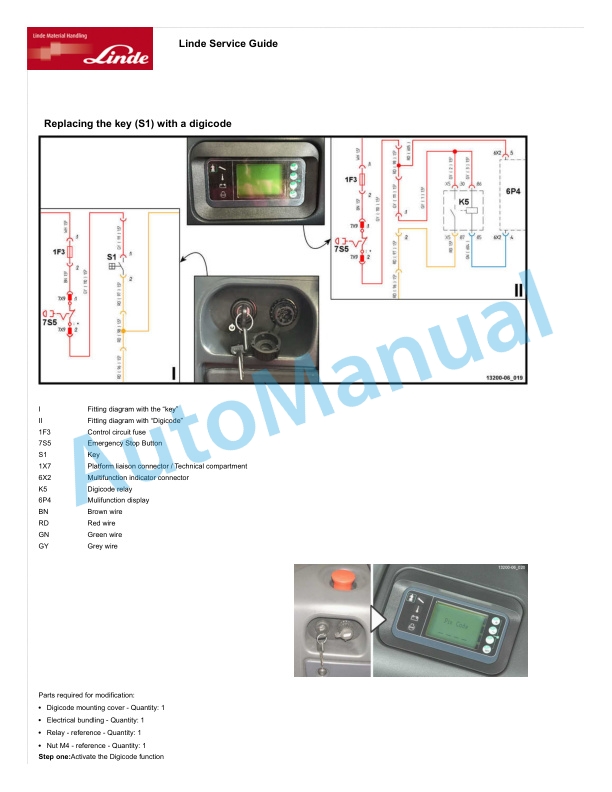

- 3.1.11.2. ELECTRONIC ACCESS CONTROL (PIN CODE)

- 3.2. index parts

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Workshop Manuals SN W41110V00529 and up

$40.00

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

$40.00