Linde 131-01 – T20 EX AP, T20 EX SP, T24 EX AP, T24 EX SP Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 28.1MB

- Number of Pages: 232

Category: Linde Operator Manual PDF

-

Model List:

- T20 EX AP

- T20 EX SP

- T24 EX AP

- T24 EX SP

- 1. Pallet truckT20.24 AP.SP EX3G

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your industrial truck

- 1.2.2. Conformity marking

- 1.2.3. Declaration that reflects the content of the declaration of conformity

- 1.2.4. Intended use

- 1.2.5. Impermissible use

- 1.2.6. Basic information on explosion protection

- 1.2.7. Symbols used

- 1.2.8. Taking delivery of the industrial truck

- 1.2.9. Documentation

- 1.2.10. Disposing of components and batteries

- 1.3. Safety

- 1.3.1. Explosion protection safety guidelines

- 1.3.2. Protective equipment for explosion protection

- 1.3.3. Residual risks

- 1.3.4. Stability

- 1.3.5. Handling consumables

- 1.3.6. Competent person

- 1.4. Overview

- 1.4.1. Labels

- 1.4.2. Identification plate.adhesive label

- 1.4.3. Truck overview

- 1.4.4. Display elements

- 1.4.5. Operating devices

- 1.4.6. Display unit

- 1.5. Operation

- 1.5.1. Technical description

- 1.5.2. Industrial trucks with explosion protection

- 1.5.2.1. Description of use and climatic conditions

- 1.5.2.2. Technical description of explosion protection

- 1.5.2.3. Regular testing

- 1.5.2.4. Batteries for explosion protection

- 1.5.2.5. Wheels and tyres for explosion protection

- 1.5.2.6. Checking the tyres

- 1.5.2.7. Checking the leak resistance

- 1.5.2.8. Handling consumables

- 1.5.2.9. Towing

- 1.5.3. Service plan before initial commissioning

- 1.5.4. Instructions for runningin

- 1.5.5. Preshift checks

- 1.5.6. Switching the truck on and off

- 1.5.7. Driving the T20 SP

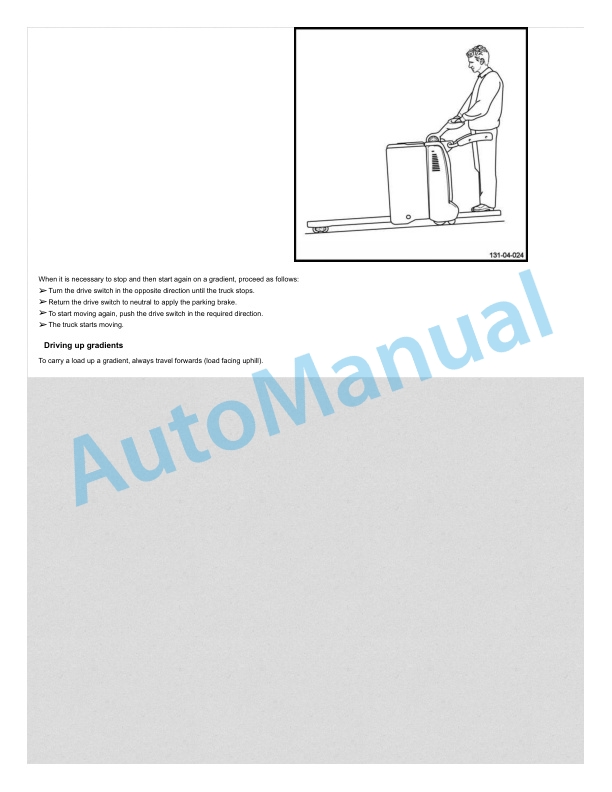

- 1.5.8. Driving on gradients with the T20 SP

- 1.5.9. Driving the T20 AP

- 1.5.10. Driving on gradients

- 1.5.11. Forward travel

- 1.5.12. Reverse travel

- 1.5.13. Steering

- 1.5.14. Decelerating when cornering

- 1.5.15. Impact button Safety switchover

- 1.5.16. Brakes

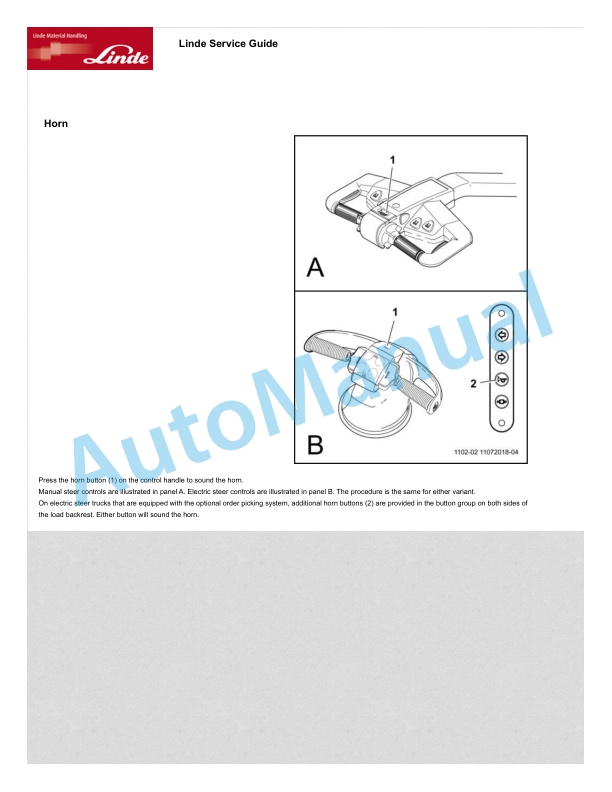

- 1.5.17. Horn

- 1.5.18. Emergency off switch

- 1.5.19. Working with a load

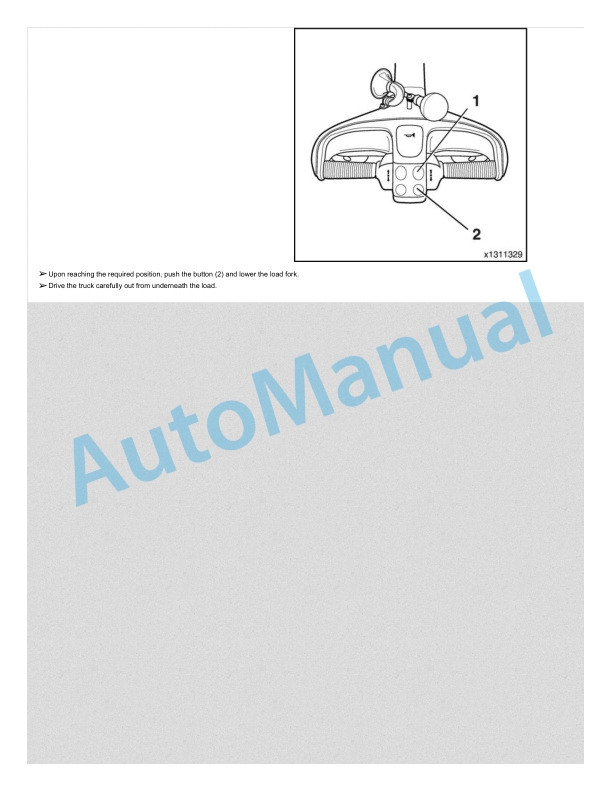

- 1.5.19.1. Picking up a load

- 1.5.19.2. Driving with load

- 1.5.20. Loading.transporting

- 1.5.20.1. Crane loading

- 1.5.20.2. Transport

- 1.5.21. Leaving the truck

- 1.5.21.1. Parking the industrial truck securely

- 1.6. Servicing

- 1.6.1. Safety information regarding servicing work

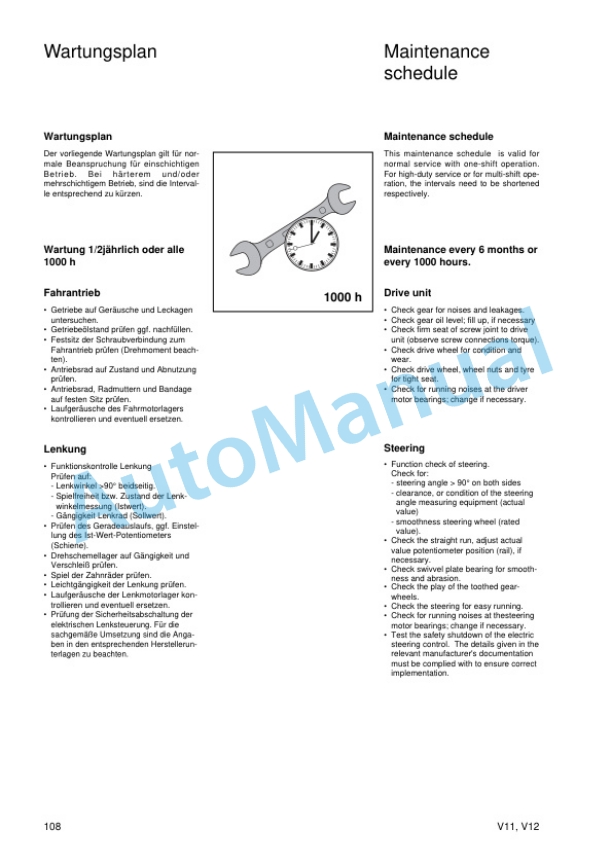

- 1.6.2. Inspection and maintenance data

- 1.6.3. Recommendations for consumables

- 1.6.4. Inspection and maintenance overview

- 1.6.4.1. Service plan after 50 hours after 3 months at the latest

- 1.6.4.2. Service plan every 500 hours after 6 months at the latest

- 1.6.4.3. Service plan every 1000 hours after a year at the latest

- 1.6.4.4. Service plan every 2000 hours after 2 years at the latest

- 1.6.5. Preparatory tasks

- 1.6.5.1. Cleaning the industrial truck

- 1.6.5.2. Reading out the error memory

- 1.6.6. Gearbox

- 1.6.6.1. Wheel gear

- 1.6.7. Chassis, bodywork and fittings

- 1.6.7.1. Checking the pressuretight housings

- 1.6.7.2. Checking and lubricating the bearing points and joints

- 1.6.7.3. Other cleaning and greasing

- 1.6.8. Chassis frame

- 1.6.8.1. Tightening the wheel fastenings

- 1.6.8.2. Checking the wheels for wear and damage

- 1.6.8.3. Lubricating the drive unit steering ring

- 1.6.8.4. Checking the brake system

- 1.6.8.5. Checking the stabilisers

- 1.6.9. Operating devices

- 1.6.9.1. Checking that the horn is working correctly

- 1.6.10. Electrics.electronics

- 1.6.10.1. Checking the battery charge status

- 1.6.10.2. Connecting the battery to an external battery charger

- 1.6.10.3. Replacing the battery

- 1.6.10.4. Checking the electric cables, cable connectors, cable connections and screw joints

- 1.6.11. Hydraulics

- 1.6.11.1. Servicing the hydraulic systems

- 1.6.12. Load lift system

- 1.6.12.1. Checking the antispark protection on the fork arms for wear

- 1.6.13. Troubleshooting

- 1.6.13.1. Fuses

- 1.6.13.2. Diagnostic connector

- 1.6.13.3. Decommissioning the industrial truck

- 1.6.13.4. Disposal of industrial trucks

- 1.6.13.5. Malfunctions during operation

- 1.7. Technical data

- 1.7.1. T20.T24 AP.SP Ex type sheet

- 1.7.2. Ecodesign requirements for electric motors and variable speed drives

- 2. Pallet truckT20.24 EX AP.SP

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Your industrial truck

- 2.2.2. Intended use

- 2.2.3. Impermissible use

- 2.2.4. Description of use and climatic conditions

- 2.2.5. Symbols used

- 2.2.6. Technical description

- 2.2.7. Insulation monitoring

- 2.2.8. Insulation monitoring warning

- 2.2.9. Insulation monitoring fault

- 2.2.10. Receiving the industrial truck

- 2.2.11. Legal requirements for placing on the market

- 2.2.12. Service plan before initial commissioning

- 2.3. Safety

- 2.3.1. Safety regulations

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. Handling consumables

- 2.3.5. Person qualified in exploseion protection

- 2.3.6. Operation of industrial trucks in plant area

- 2.3.7. Regulations

- 2.4. Overview

- 2.4.1. Labels

- 2.4.2. Identification plate.adhesive label

- 2.4.3. Truck overview

- 2.4.4. Display elements

- 2.4.5. Operating devices

- 2.4.6. Display unit

- 2.5. Operation

- 2.5.1. Instructions for runningin

- 2.5.2. Preshift checks

- 2.5.3. Switching the truck on and off

- 2.5.4. Driving the T20 SP

- 2.5.5. Driving on gradients with the T20 SP

- 2.5.6. Driving the T20 AP

- 2.5.7. Driving on gradients

- 2.5.8. Forward travel

- 2.5.9. Reverse travel

- 2.5.10. Steering

- 2.5.11. Decelerating when cornering

- 2.5.12. Safety switchover impact button

- 2.5.13. Brakes

- 2.5.14. Horn

- 2.5.15. Emergency off switch

- 2.5.16. Working with a load

- 2.5.16.1. Picking up a load

- 2.5.16.2. Driving with load

- 2.5.17. Loading.transporting

- 2.5.17.1. Crane loading

- 2.5.17.2. Transport

- 2.5.18. Leaving the truck

- 2.5.18.1. Parking the industrial truck securely

- 2.6. Maintenance

- 2.6.1. General information

- 2.6.2. Inspection and maintenance data

- 2.6.3. Recommendations for consumables

- 2.6.4. Inspection and maintenance overview

- 2.6.4.1. Service plan after 50 hours after 3 months at the latest

- 2.6.4.2. Service plan every 500 hours after 6 months at the latest

- 2.6.4.3. Service plan every 1000 hours after a year at the latest

- 2.6.4.4. Service plan every 2000 hours after 2 years at the latest

- 2.6.5. Preparatory tasks

- 2.6.5.1. Cleaning the industrial truck

- 2.6.5.2. Reading out the error memory

- 2.6.6. Gearbox

- 2.6.6.1. Wheel gear

- 2.6.7. Chassis, bodywork and fittings

- 2.6.7.1. Checking the pressuretight housings

- 2.6.7.2. Checking and lubricating the bearing points and joints

- 2.6.7.3. Other cleaning and greasing

- 2.6.8. Chassis frame

- 2.6.8.1. Tightening the wheel fastenings

- 2.6.8.2. Checking the wheels for wear and damage

- 2.6.8.3. Lubricating the drive unit steering ring

- 2.6.8.4. Checking the brake system

- 2.6.8.5. Checking the stabilisers

- 2.6.9. Operating devices

- 2.6.9.1. Checking that the horn is working correctly

- 2.6.10. Electrics.electronics

- 2.6.10.1. Checking the battery charge status

- 2.6.10.2. Connecting the battery to an external battery charger

- 2.6.10.3. Replacing the battery

- 2.6.10.4. Checking the condition and secure attachment of electric cables, cable connectors, cable connections and explosionprotected screw joints

- 2.6.11. Hydraulics

- 2.6.11.1. Servicing the hydraulic systems

- 2.6.12. Load lift system

- 2.6.12.1. Checking the antispark protection of the fork arms for wear

- 2.6.13. Troubleshooting

- 2.6.13.1. Fuses

- 2.6.13.2. Diagnostic connector

- 2.6.13.3. Shutting down

- 2.6.13.4. Disposal of old trucks

- 2.6.13.5. Malfunctions during operation

- 2.7. Technical data

- 2.7.1. T20.T24 AP.SP Ex type sheet

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00