Linde 1313-01 – H25CT, H27CT, H30CT, H32CT Operating Instructions SN 12.09 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 12.09 and up

- Format: PDF

- Size: 22.3MB

- Number of Pages: 185

- Serial Number:

SN 12.09 and up

Category: Linde Operator Manual PDF

-

Model List:

- H25CT

- H27CT

- H30CT

- H32CT

- 1. CT series LP Gas Forklift TruckModels H25CT, H27CT, H30CT, H32CT

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Scope

- 1.2.2. Obligations of the Equipment Owner

- 1.2.3. Operator Responsibilities

- 1.2.4. Proper use

- 1.2.5. Hazard messages

- 1.3. Safety

- 1.3.1. Before Operation

- 1.3.2. Operator Daily Checklist

- 1.3.3. Operating position

- 1.3.4. Pedestrians

- 1.3.5. Travel

- 1.3.6. Lifting and Lowering

- 1.3.7. Inclines, Ramps, Docks, Elevators

- 1.3.8. Avoiding Falls and Tipovers

- 1.3.9. Suspended Loads

- 1.3.10. Parking

- 1.3.11. Using LP Gas

- 1.3.11.1. Operating LP GasPowered Trucks

- 1.3.11.2. Refilling LP Gas Tanks

- 1.3.12. Safety During Maintenance

- 1.3.12.1. Personnel Qualifications

- 1.3.12.2. Hazardous Substances

- 1.3.12.3. Coolant reservoir or radiator

- 1.3.12.4. Starting Battery

- 1.3.12.5. Vehicle exhaust

- 1.3.12.6. Rotating fan blades

- 1.3.12.7. Wheels and Tires

- 1.3.13. Operator Warning Decals

- 1.3.13.1. Data plate

- 1.3.13.2. Parking brake warning decal

- 1.3.13.3. Operator warning decal

- 1.3.13.4. Trained operator warning decal

- 1.3.13.5. Never stand or walk under forks warning decal

- 1.3.13.6. Do not lift personnel warning decal

- 1.3.13.7. Crushed fingers warning decal

- 1.3.13.8. No step warning decal

- 1.3.13.9. Tipover warning decal

- 1.3.13.10. Disconnect LP hose warning decal

- 1.3.13.11. LP tank specification plate

- 1.3.13.12. Back up alarm warning decal

- 1.3.13.13. Hood latch warning decal

- 1.3.13.14. Hot coolant warning decal

- 1.4. Overview

- 1.4.1. Technical Description

- 1.4.2. Truck Components

- 1.4.3. Controls

- 1.4.4. Indicator Unit

- 1.4.5. Definition of directions

- 1.4.6. Vehicle Marking

- 1.4.6.1. Decal and Data Plate Location

- 1.4.6.2. Data Plate

- 1.4.7. Variants and Options

- 1.4.7.1. Mast variants

- 1.4.7.2. Attachments

- 1.4.7.3. System options

- 1.4.7.4. Chassis options

- 1.4.7.5. Cabin options

- 1.4.7.6. Operating environment options

- 1.5. Operation

- 1.5.1. Unloading and Preparing a New Truck for Operation

- 1.5.2. Setting Up the LP Tank Bracket

- 1.5.3. Reading LP Level

- 1.5.4. Adjusting the Operators Seat

- 1.5.5. Steering column tilt angle adjustment

- 1.5.6. Setting the Clock Display

- 1.5.7. Seat Belt

- 1.5.8. Engine Starting and Shutdown

- 1.5.9. Driving Dual Pedal Version

- 1.5.10. Driving Single Pedal Version (optional equipment)

- 1.5.11. Braking

- 1.5.12. Steering System

- 1.5.13. Horn

- 1.5.14. Fork Position Adjustment

- 1.5.15. Hydraulic Controls Individual Levers

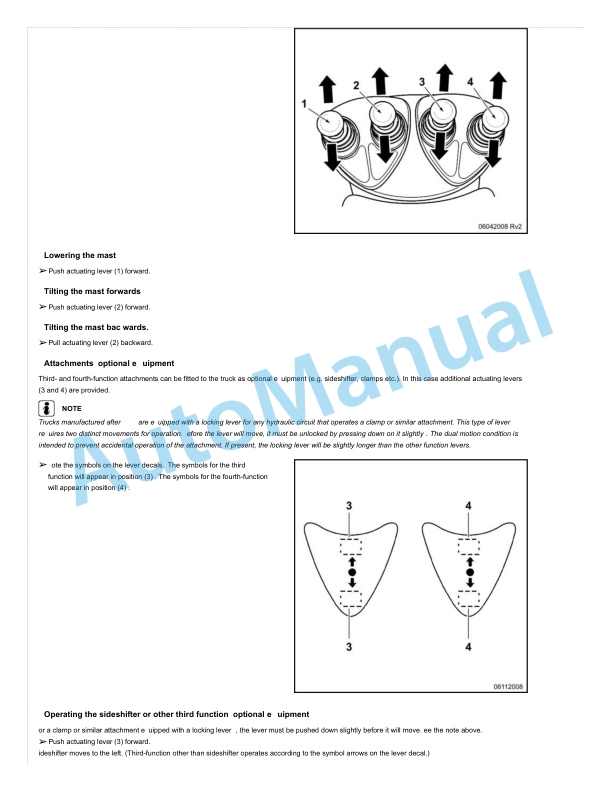

- 1.5.16. Hydraulic Controls MultiFunction Levers

- 1.5.17. Lights and BackUp Alarm

- 1.5.18. Fan (optional equipment)

- 1.5.19. Tilt Memory (optional equipment)

- 1.5.20. Changing the LP Gas Tank

- 1.5.21. Opening the Hood

- 1.5.22. Towing Loads

- 1.5.23. Depressurization System for Auxiliary Hydraulics (optional equipment)

- 1.5.24. Towing the Truck

- 1.5.25. Manual Lowering of Fork Carriage

- 1.5.26. Securing the Truck for Transport

- 1.5.27. Hoisting the Truck

- 1.5.28. LongTerm Storage

- 1.6. Maintenance

- 1.6.1. Personnel Qualifications

- 1.6.2. Cleaning

- 1.6.2.1. Cleaning the Truck

- 1.6.2.2. Cleaning the Lift Chains

- 1.6.3. Operator Inspection and Maintenance

- 1.6.3.1. Daily Inspection Overview

- 1.6.3.2. Daily Inspection Checklist

- 1.6.3.3. Check for fluid leakage

- 1.6.3.4. Check overhead guard

- 1.6.3.5. Check hydraulic cylinders

- 1.6.3.6. Check lift chains

- 1.6.3.7. Check fork carriage

- 1.6.3.8. Check engine fan

- 1.6.3.9. Check engine oil level

- 1.6.3.10. Check the coolant level

- 1.6.3.11. Check fuel line

- 1.6.3.12. Check hydraulic oil level

- 1.6.3.13. Check decal condition

- 1.6.3.14. Check control lever bellows

- 1.6.3.15. Antistatic strap (optional equipment)

- 1.6.3.16. Check wheels and tires

- 1.6.3.17. Check the seat and seat belt

- 1.6.3.18. Check the steering axle

- 1.6.3.19. Check prefilter bowl (optional equipment)

- 1.6.3.20. Operational checks

- 1.6.4. Scheduled Maintenance

- 1.6.4.1. General Maintenance Information

- 1.6.4.2. Sideshifter Maintenance Intervals

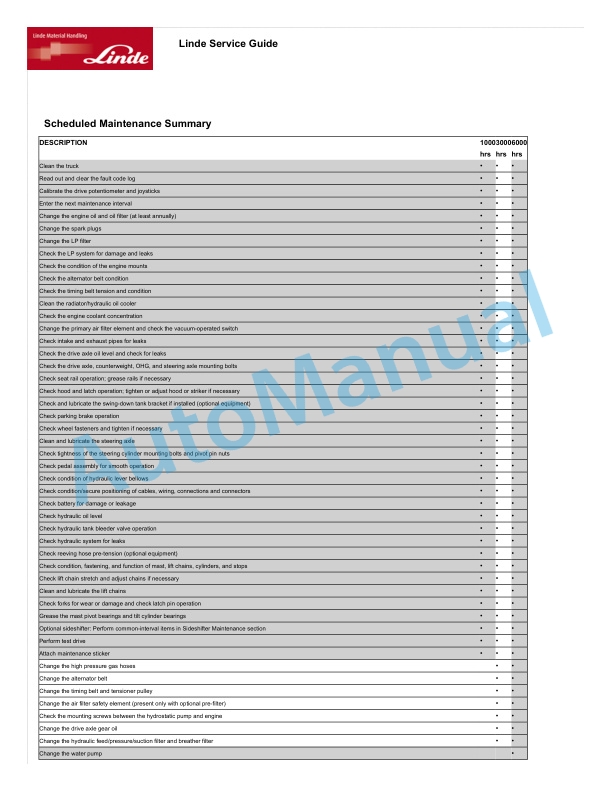

- 1.6.4.3. Scheduled Maintenance Summary

- 1.6.4.4. Maintenance at 1000 hours

- 1.6.4.5. Maintenance at 3000 hours

- 1.6.4.6. Maintenance at 6000 hours

- 1.6.4.7. Sideshifter Maintenance (optional equipment)

- 1.6.5. Fluids and Lubricants

- 1.6.5.1. Capacities

- 1.6.5.2. Fuel

- 1.6.5.3. Fluid and Lubricant Specifications

- 1.6.6. Troubleshooting

- 1.6.6.1. Fuses

- 1.6.6.2. Diagnostic Connector

- 1.6.6.3. Jump Starting

- 1.6.6.4. Fault Indicator Explanations

- 1.6.6.5. Engine Protection System (optional equipment)

- 1.6.6.6. Troubleshooting Chart Engine

- 1.6.6.7. Troubleshooting Chart Hydraulic System

- 1.6.6.8. Troubleshooting the LP Level Display System (optional equipment)

- 1.7. Technical data

- 1.7.1. Specifications

- 1.7.2. Mast Heights

- 1.7.3. Noise Emission Values

- 1.7.4. Vibration Data

Rate this product

You may also like

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

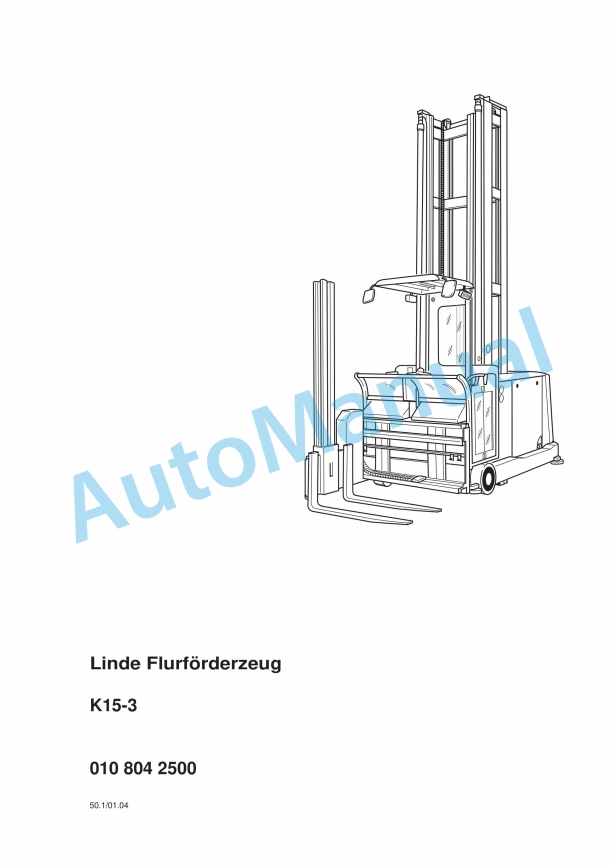

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00