Linde 133-01 – D12, D12HP, D14 Workshop Manuals SN 03.07 and up SN up to W4X133V02096

$40.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN 03.07 and up SN up to W4X133V02096

- Format: PDF

- Size: 320.9MB

- Number of Pages: 2651

- Serial Number:

SN 03.07 and up SN up to W4X133V02096

Category: Linde Workshop Manual PDF

-

Model List:

- D12

- D12HP

- D14

- 1. Anleitung Logviewer SDK 4KMatic, LMatic, PMatic, RMatic, TMatic

- 1.1. Inhaltsverzeichnis

- 1.2. Allgemeines

- 1.3. LogviewerFunktionen

- 2. Linde ApprovedRemanufacturing GuidelineTNLindustrial trucks

- 2.1. Table of content

- 2.2. Elementary checks

- 2.3. Comprehensive inspection for quotation

- 2.4. Maintenance and safety checks

- 2.5. Reconditioning process

- 2.6. Option packages

- 2.7. Finishing

- 2.8. Documentation and predelivery inspection

- 3. Logviewer instructions (SDK 3.x)LMATIC, PMATIC, TMATIC

- 3.1. Table of content

- 3.2. General

- 3.3. Logviewer functions

- 4. Regular testing

- 4.1. Table of content

- 4.2. Regular testing

- 4.3. Electric motor

- 4.4. Internal combustion engine

- 4.5. Drive axle

- 4.6. Chassis

- 4.7. Drivers compartment

- 4.8. Steering systems

- 4.9. Wheels and tyres

- 4.10. Brake system

- 4.11. Operating devices

- 4.12. Electrics.electronics

- 4.13. Hydraulics

- 4.14. Lift mast

- 4.15. Load support

- 4.16. Attachments

- 4.17. Special equipment.accessories

- 5. Regular testingMatic industrial trucks (SDK 4.x)LMatic, KMatic, PMatic, RMatic, TMatic

- 5.1. Table of content

- 5.2. Basic principles

- 5.3. Preparing for testing

- 5.4. Tests

- 5.5. Test log

- 6. Regular testingMaticindustrial trucks (SDK 3.x)LMATIC, PMATIC, TMATIC

- 6.1. Table of content

- 6.2. Basic principles

- 6.3. Preparing for testing

- 6.4. Tests

- 6.5. Test log

- 7. Service TrainingMatic industrial trucksKMatic, LMatic, PMatic, RMatic, TMatic

- 7.1. Table of content

- 7.2. General

- 7.3. Supervisor

- 7.4. Token platform

- 7.5. Dimensions and settings of the components

- 7.6. Safety laser scanner

- 7.7. Navigation laser scanner

- 7.8. Logistics unit presence detectors

- 7.9. Calibrations

- 7.10. Communication components

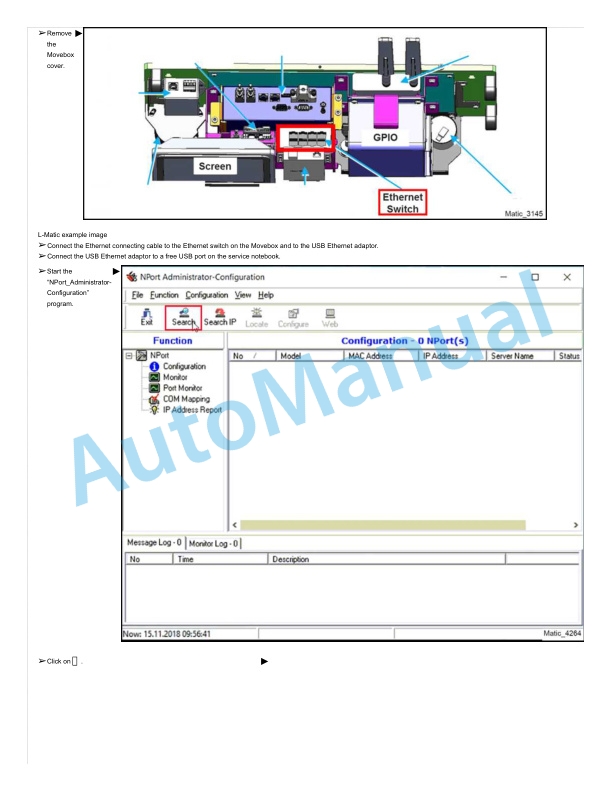

- 7.11. Serial to Ethernet converter

- 7.12. Balyo PC

- 7.13. Troubleshooting

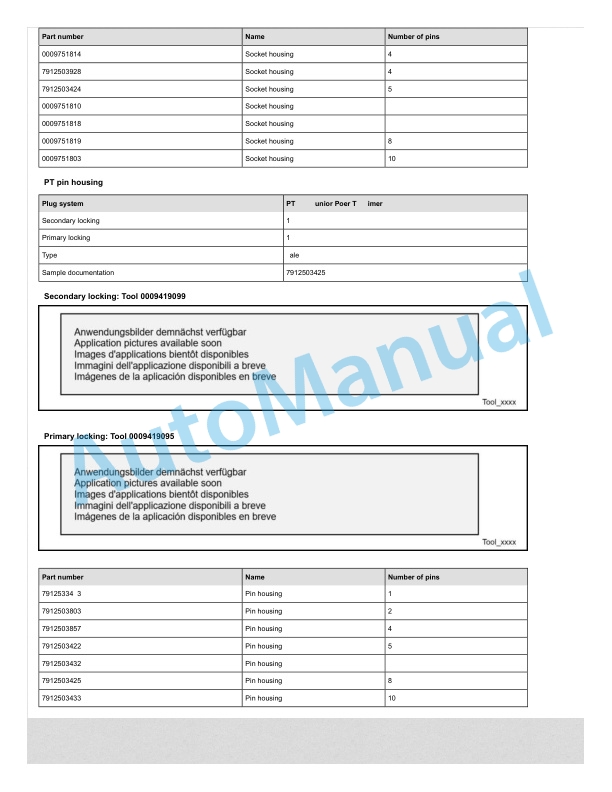

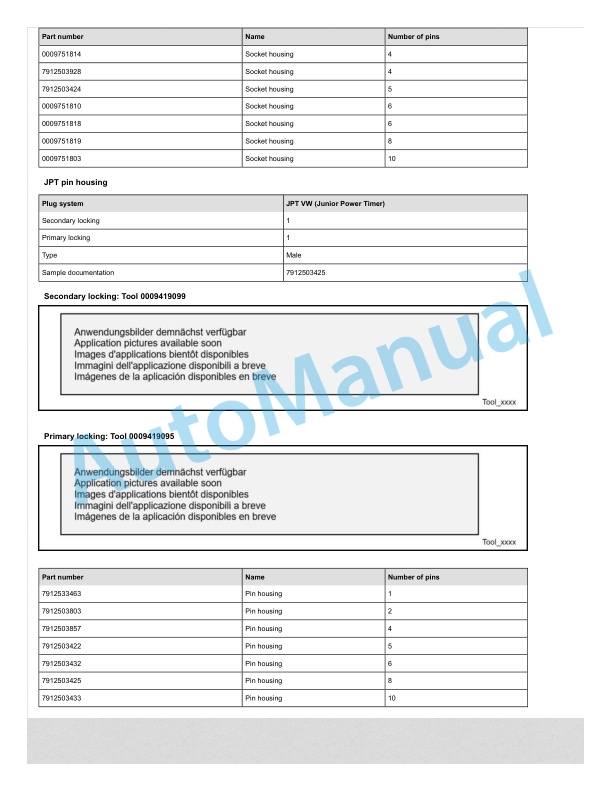

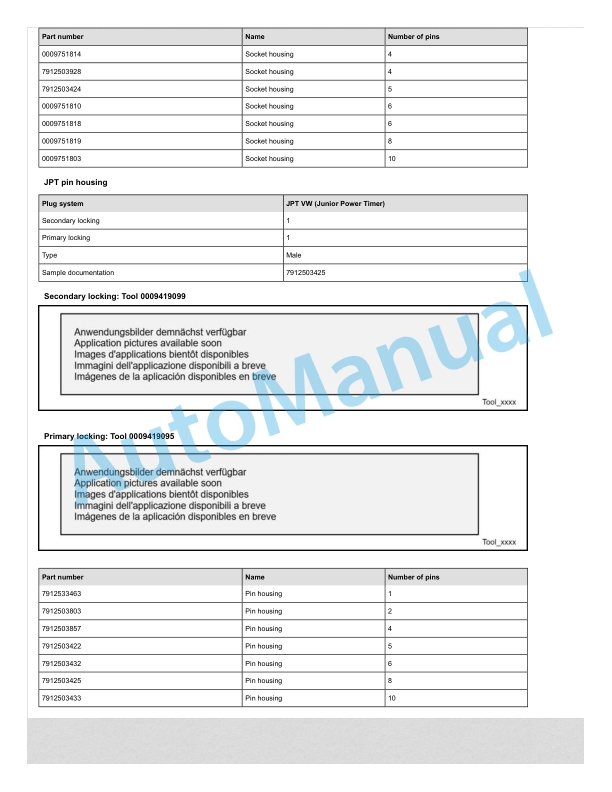

- 8. Service case Release tools for contacts

- 8.1. Table of content

- 8.2. Safety information

- 8.3. Information

- 8.4. Overview

- 8.5. Plug systems

- 9. Double pallet stacker.pallet stackerL12, L14, D12, D14, D12 HP

- 9.1. Table of content

- 9.2. Product information

- 9.3. Service

- 9.4. Diagnostic

- 9.5. Motor

- 9.6. Transmission

- 9.7. Chassis, bodywork and fittings

- 9.8. Steering, braking and wheels

- 9.9. Control devices

- 9.10. Electrical equipment

- 9.11. Hydraulic assembly

- 9.12. Load lift system

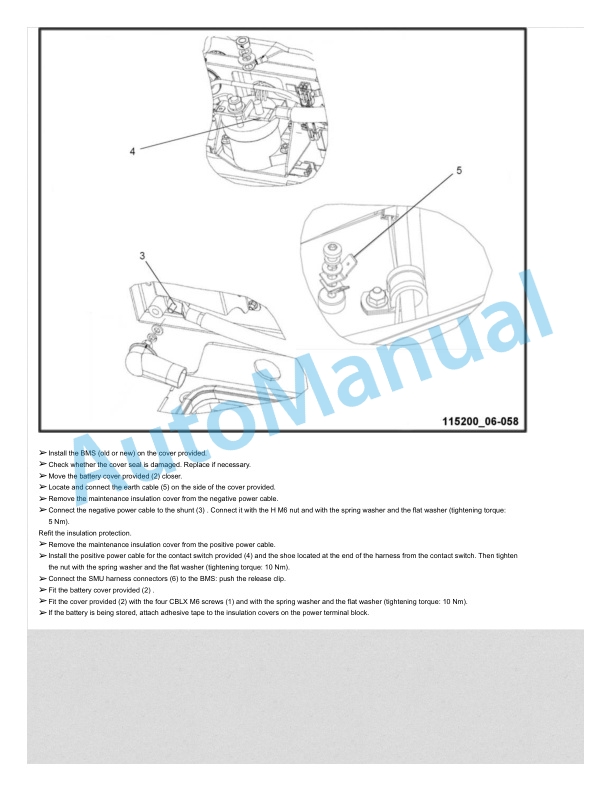

- 10. LTO AGV battery Balyo type 24 V 140 AhLMATIC, PMATIC, TMATIC

- 10.1. Table of content

- 10.2. Product information

- 10.3. Service

- 10.4. Transport guidelines

- 10.5. Diagnostics

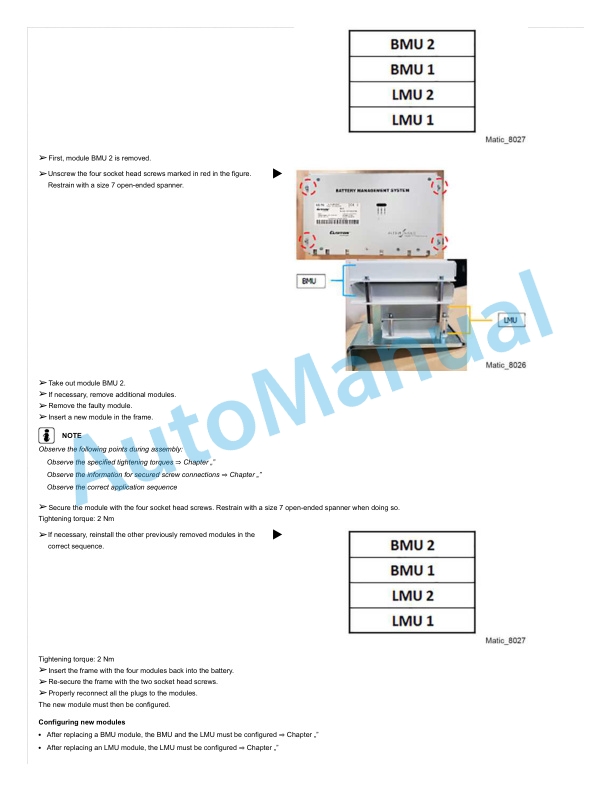

- 10.6. LTO battery

- 11. connectdesk

- 11.1. Table of content

- 11.2. Introduction

- 11.3. System overview

- 11.4. Hardware

- 11.5. Software

- 11.6. Status checking (PreOpCheck)

- 12. connectportal

- 12.1. Table of content

- 12.2. Introduction

- 12.3. Data transfer

- 12.4. Hardware

- 12.5. Software

- 13. Circuit diagramsPallet stacker.double pallet stackerL12, L14, D12, D14, D12 HP

- 13.1. Table of content

- 13.2. Circuit diagrams from 03.2018

- 13.3. Circuit diagrams from 02.2017 to 03.2018

- 13.4. Circuit diagrams from 07.2015 (W4X133F01356) to 02.2017

- 13.5. Circuit diagrams from 09.2013 to 07.2015 (W4X133F01355)

- 13.6. Circuit diagrams from 09.2009 (W4X133Z00698) to 09.2013

- 13.7. Circuit diagrams from 12.2007 to 09.2009 (W4X133Z00697)

- 14. Wiring diagramsLTO BatteryLMatic, PMatic, TMatic

- 14.1. Table of content

- 14.2. Wiring diagrams from SN2020091101

- 14.3. Wiring diagrams from SN20190700001

- 14.4. Wiring diagrams from SN20180900001

- 15. Spare parts documentationBatteries

- 15.1. Table of content

- 15.2. Safety information

- 15.3. Water filling system

- 15.4. Air agitation (EUW)

- 15.5. Plug

- 15.6. Cable connector for cells

- 16. Spare parts lists COMBOX

- 16.1. Table of content

- 16.2. COMBOX 3 Buttons

- 16.3. COMBOX I.O

- 16.4. COMBOX WiMesh

- 16.5. COMBOX Radio

- 17. Spare parts lists LTO AGV Battery with docking stationLMatic, LMatic AC, LMatic HD, LMatic HP, PMatic, TMatic

- 17.1. Table of content

- 17.2. LTO AGV Battery

- 17.3. Charger and Docking Station

- 18. CARACTERISTIQUES TECHNIQUES SERIE 133133_D12, 133_D12HP, 133_D14, 133_L12, 133_L14

- 19. Maintenance plansL12, D12, D12 HP, L14, D14

- 19.1. Table of content

- 19.2. Introduction

- 19.3. Pallet stacker.Double pallet stacker

- 19.4. Truck with lithiumion battery

- 20. connectdt operating hoursRetrofitting the connectdt operating hours

- 20.1. Table of content

- 20.2. connectdt operating hours

- 21. connectdt trouble codesRetrofitting connectdt trouble codes

- 21.1. Table of content

- 21.2. connectdt trouble codes

Rate this product

You may also like

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Workshop Manuals

$40.00