Linde 133-01 – L12 EXAP to L14 EXSP Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 21.8MB

- Number of Pages: 216

Category: Linde Operator Manual PDF

-

Model List:

- L12 EXAP

- L12 EXL

- L12 EXL AP

- L12 EXL SP

- L12 EXSP

- L14 EXAP

- L14 EXL

- L14 EXL AP

- L14 EXL SP

- L14 EXSP

- 1. Leadacid battery charger 24V

- 2. Leadacid battery charger 24V . 48V

- 3. Leadacid battery charger 24V . 48V . 80V

- 4. Pallet stacker .Double pallet stackerL12.14 L AP.SP EX, D14 SP Ex

- 4.1. Table of content

- 4.2. Introduction

- 4.2.1. Your industrial truck

- 4.2.2. Conformity marking

- 4.2.3. Declaration that reflects the content of the declaration of conformity

- 4.2.4. Intended use

- 4.2.5. Impermissible use

- 4.2.6. Basic information on explosion protection

- 4.2.7. Symbols used

- 4.2.8. Taking delivery of the industrial truck

- 4.2.9. Documentation

- 4.2.10. Disposing of gel and lead batteries

- 4.3. Safety

- 4.3.1. Explosion protection safety guidelines

- 4.3.2. Protective equipment for explosion protection

- 4.3.3. Residual risks

- 4.3.4. Stability

- 4.3.5. Noise emission values

- 4.3.6. Vibration values for upper limbs

- 4.3.7. Competent person

- 4.4. Overview

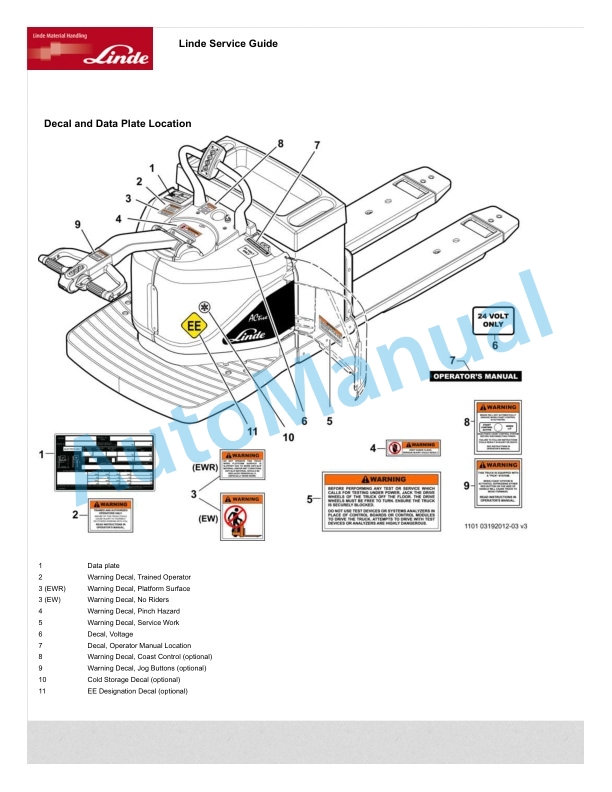

- 4.4.1. Labels

- 4.4.2. Nameplate

- 4.4.3. Truck overview

- 4.4.4. Console

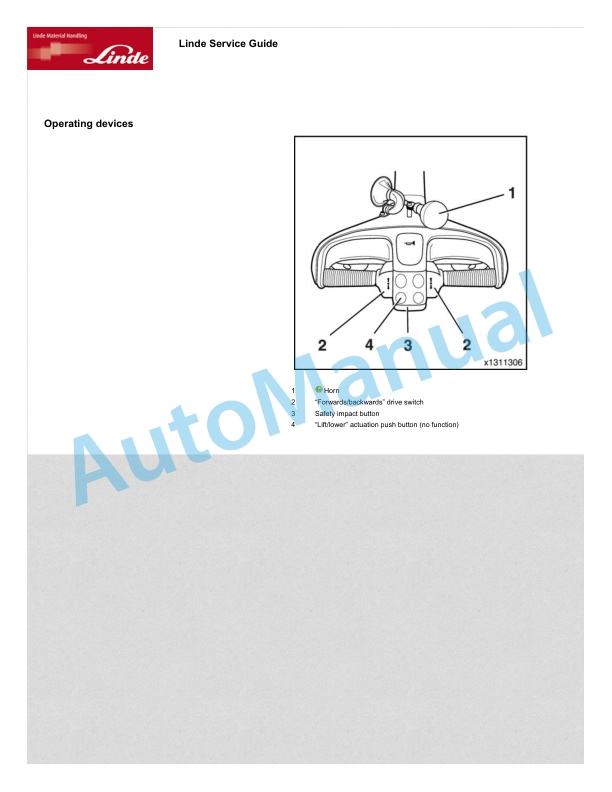

- 4.4.5. Operating devices

- 4.5. Operation

- 4.5.1. Technical description

- 4.5.2. Industrial trucks with explosion protection

- 4.5.2.1. Description of use and climatic conditions

- 4.5.2.2. Technical description of explosion protection

- 4.5.2.3. Regular testing

- 4.5.2.4. Batteries for explosion protection

- 4.5.2.5. Wheels and tyres for explosion protection

- 4.5.2.6. Checking the tyres

- 4.5.2.7. Checking the leak resistance

- 4.5.2.8. Handling consumables

- 4.5.2.9. Towing

- 4.5.3. Testing prior to initial commissioning

- 4.5.4. Preshift checks

- 4.5.5. Switching the truck on and off

- 4.5.6. Driving

- 4.5.7. Forward travel

- 4.5.8. Reverse travel

- 4.5.9. Changing the drive direction

- 4.5.10. Driving, driver on fixed platform

- 4.5.11. Steering

- 4.5.12. Using the truck on a gradient

- 4.5.13. Impact button Safety switchover

- 4.5.14. Braking

- 4.5.15. Horn

- 4.5.16. Emergency off switch

- 4.5.17. Working with a load

- 4.5.17.1. Capacity of L12L14, D12D14, D12 HP versions

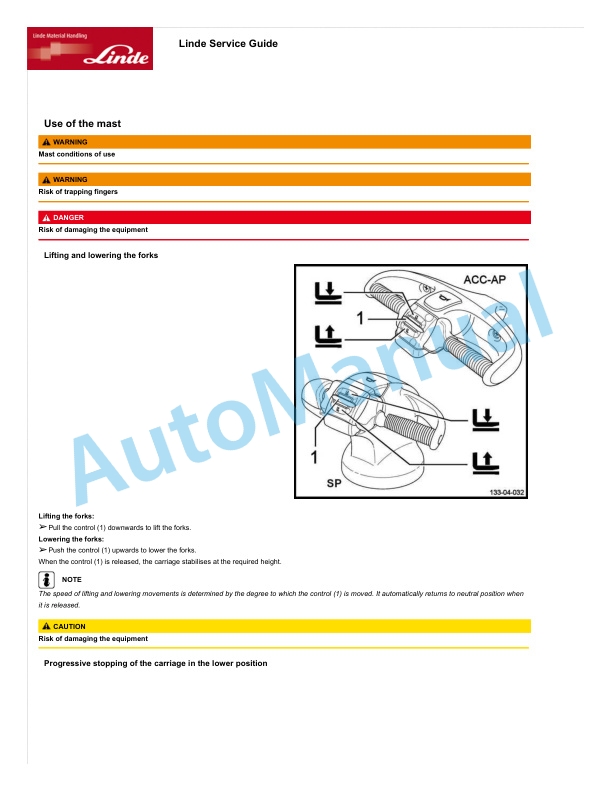

- 4.5.17.2. Use of the mast

- 4.5.17.3. Handling a single load

- 4.5.17.4. Handling two stacked pallets

- 4.5.18. Suspended platform (option)

- 4.5.19. Symmetrical handlebar (option)

- 4.5.20. Transporting and lifting the industrial truck

- 4.5.20.1. Slinging the truck

- 4.5.20.2. Lifting the truck

- 4.6. Maintenance

- 4.6.1. Safety information regarding servicing work

- 4.6.2. Technical data for inspection and maintenance

- 4.6.3. Recommended lubricants

- 4.6.4. Inspection and maintenance overview

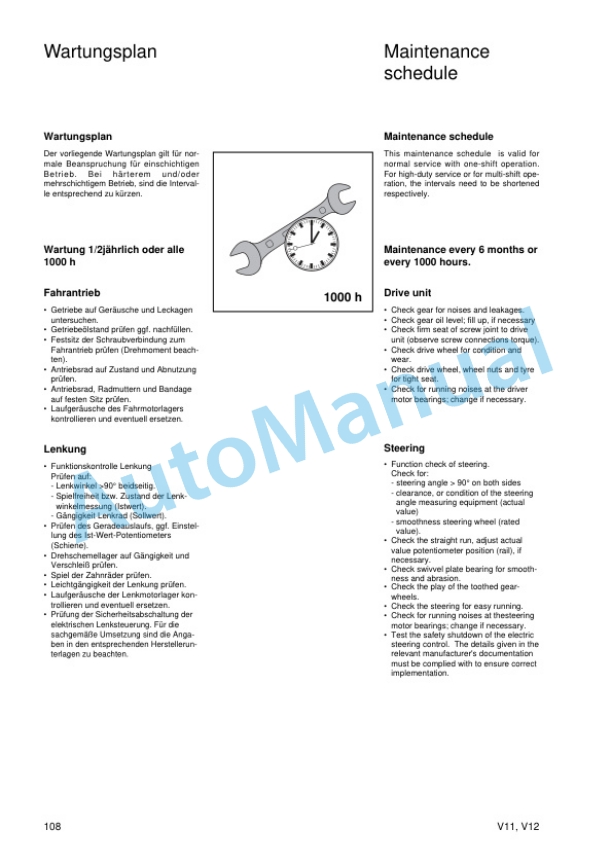

- 4.6.4.1. Regular maintenance

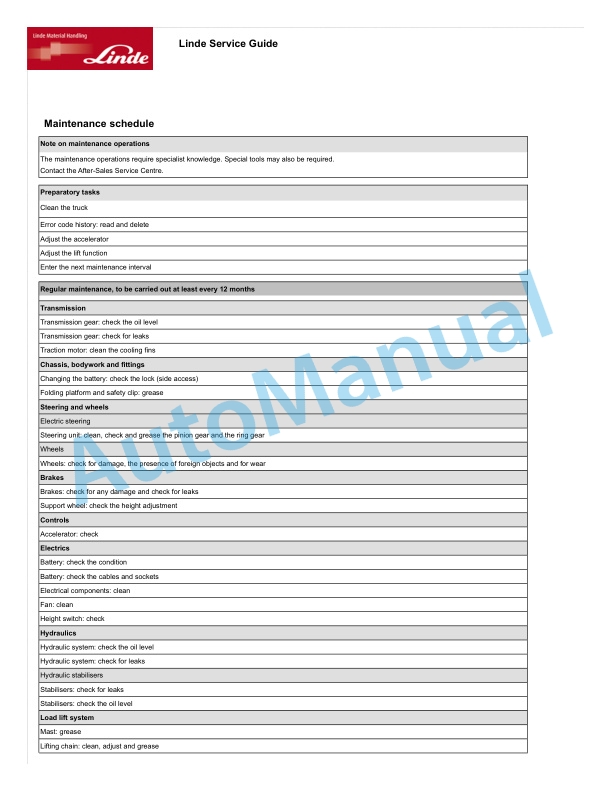

- 4.6.4.2. Maintenance schedule

- 4.6.4.3. Additional service plan for explosion protection

- 4.6.5. Preparatory tasks

- 4.6.5.1. Cleaning the industrial truck

- 4.6.5.2. Diagnostic connector

- 4.6.6. Gearbox

- 4.6.6.1. Checking the transmission gear oil level

- 4.6.6.2. Drain the transmission gear

- 4.6.7. Chassis, bodywork and fittings

- 4.6.7.1. Checking the pressuretight housings

- 4.6.7.2. Other cleaning and greasing

- 4.6.8. Chassis frame

- 4.6.8.1. Checking the condition of the wheels

- 4.6.8.2. Servicing the wheels and rollers

- 4.6.8.3. Brake test

- 4.6.8.4. Testing the safety devices specific to the AP model

- 4.6.8.5. Checking the steering

- 4.6.9. Operating devices

- 4.6.9.1. Checking that the horn is working correctly

- 4.6.9.2. Testing the drive direction twoway switch

- 4.6.9.3. Testing the emergency off switch

- 4.6.9.4. Checking the operating lever

- 4.6.10. Electrical equipment

- 4.6.10.1. Checking the condition and secure attachment of electric cables, cable connectors, cable connections and explosionprotected screw joints

- 4.6.10.2. Connecting.disconnecting the battery male connectors

- 4.6.10.3. Checking the battery charge status

- 4.6.10.4. Cleaning the battery and the battery compartment.

- 4.6.10.5. Battery maintenance

- 4.6.10.6. Charging the battery

- 4.6.10.7. Preparing battery connectors for removal

- 4.6.10.8. Side battery loading

- 4.6.10.9. Battery replacement

- 4.6.10.10. Replacing the battery using a transportation trolley

- 4.6.11. Hydraulics

- 4.6.11.1. Primary hydraulic circuit

- 4.6.11.2. Hydraulic system

- 4.6.12. Load lift system

- 4.6.12.1. Checking the antispark protection on the fork arms for wear

- 4.6.12.2. Specific mast maintenance

- 4.6.12.3. Hoist assembly

- 4.6.12.4. Hoist assembly, greasing the rings and articulations (greased option)

- 4.6.13. Troubleshooting

- 4.6.13.1. Fuses

- 4.6.13.2. Opening the hood

- 4.6.14. Storage of truck

- 4.6.15. Disposal of industrial trucks

- 4.7. Technical data

- 4.7.1. Datasheet for L12 EX AP, L12 EX L SP, L14 EX L AP model 133

- 4.7.2. Datasheet D12SPEx . D14SPEx

- 4.7.3. Ecodesign requirements for electric motors and variable speed drives

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00