Linde 1346-01 – E18S, E20S Production site Summerville Workshop Manuals

$40.00

- Type Of Manual: Workshop Manuals

- Format: PDF

- Size: 40.7MB

- Number of Pages: 282

Category: Linde Workshop Manual PDF

-

Model List:

- E18S

- E20S Production site Summerville

- 1. Service case Release tools for contacts

- 1.1. Table of content

- 1.2. Safety information

- 1.2.1. Safety information for repair and maintenance work

- 1.3. Information

- 1.3.1. Information

- 1.4. Overview

- 1.4.1. Overview of service cases

- 1.5. Plug systems

- 1.5.1. ATS 2.8 plug connector

- 1.5.2. CMC plug connector

- 1.5.3. DCS 9.5 plug connector

- 1.5.4. DIN 1.5mm circular connector

- 1.5.5. DIN 2.5mm circular connector

- 1.5.6. Deutsch DTM plug connector

- 1.5.7. ECU appliance plug

- 1.5.8. MCON appliance plug

- 1.5.9. Appliance plug with JPT and MQS contacts

- 1.5.10. Appliance plug with MT2 and JPT contacts

- 1.5.11. SICMA appliance plug

- 1.5.12. Econoseal JMark 2 plug connector

- 1.5.13. Elobau 11pin receptacle housing

- 1.5.14. E5931 plug connector

- 1.5.15. FASTINFASTON 6.3mm plug connector

- 1.5.16. GT150 plug connector

- 1.5.17. HDSCS plug connector

- 1.5.18. JPT plug connector

- 1.5.19. JPT SLD plug connector

- 1.5.20. JPT plug connector Saab

- 1.5.21. JPT plug connector VW

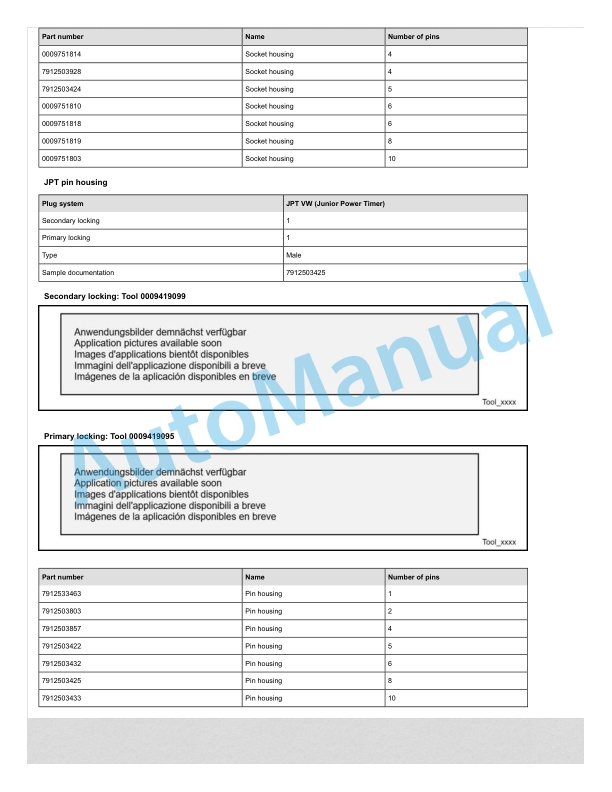

- 1.5.22. Kompakt 1.1 plug connector

- 1.5.23. Bosch Kompakt 4 plug connector

- 1.5.24. Leavyseal plug connector

- 1.5.25. MCON 1.2mm LL plug connector

- 1.5.26. MCON 1.2mm CB plug connector

- 1.5.27. MCP plug connector

- 1.5.28. MetriPack 150 plug connector

- 1.5.29. MiniFit plug connector

- 1.5.30. Mini Universal MATENLOK plug connector

- 1.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 1.5.32. MKR Plus plug connector

- 1.5.33. MQS plug connector

- 1.5.34. MR plug connector

- 1.5.35. MTA plug housing and fuse housing

- 1.5.36. MT2 plug connector

- 1.5.37. MT2 1.5mm plug connector VW

- 1.5.38. Multilock plug connector

- 1.5.39. MX150 plug connector

- 1.5.40. NG1 plug connector

- 1.5.41. Phönix Contact HC plug connector

- 1.5.42. PT 3F plug connector

- 1.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 1.5.44. Relay socket with SPT and MPT contacts

- 1.5.45. Fuse holder with SPT contacts

- 1.5.46. Sicma plug connector

- 1.5.47. SLK 2.8 plug connector

- 1.5.48. Souriau UTL7 plug connector

- 1.5.49. Superseal 1.5mm plug connector

- 1.5.50. Trident Neptune plug connector

- 1.5.51. Universal MATENLOK plug connector

- 1.5.52. VW 9.5mm plug connector

- 2. Electric TruckModels E18S.E20S

- 2.1. Table of content

- 2.2. Product information

- 2.2.1. Tightening torques

- 2.2.1.1. Tightening torques for standard pitch threads

- 2.2.1.2. Tightening torques for fine pitch threads

- 2.2.1.3. Special torque

- 2.2.2. Diagnostic software

- 2.2.2.1. CAN box

- 2.2.2.2. Software update

- 2.2.2.3. Pathfinder

- 2.2.2.4. Log files

- 2.2.2.5. Code lists

- 2.2.2.6. Error codes

- 2.3. Motor

- 2.3.1. Drive axle PMS621

- 2.3.1.1. Overview of drive axle

- 2.3.1.2. Filling the gearbox

- 2.3.1.3. Oil draining

- 2.3.2. Drive motor

- 2.3.2.1. Drive motor

- 2.3.2.2. Motor terminals

- 2.3.3. Sensors

- 2.3.3.1. Drive axle temperature sensor

- 2.3.3.2. Incremental transducer

- 2.4. Gearbox

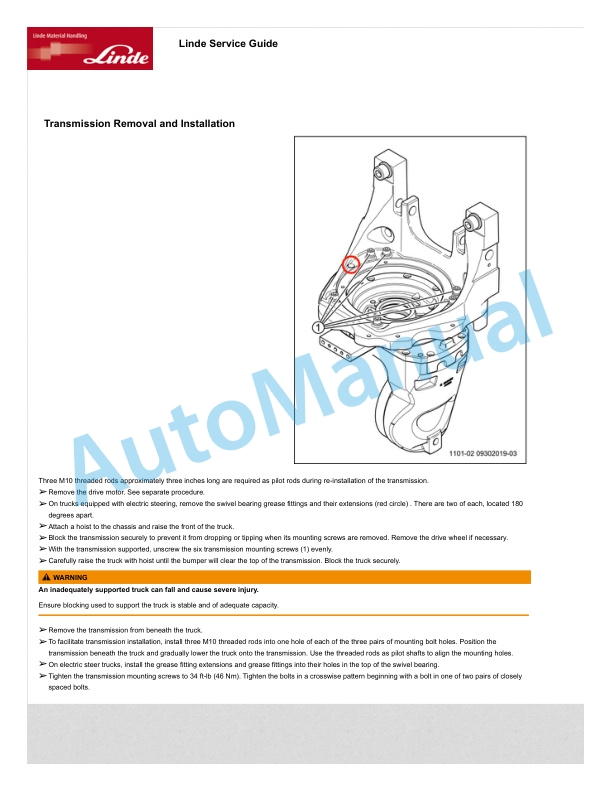

- 2.4.1. Planetary transmission

- 2.4.1.1. Drive axle parts

- 2.5. Chassis, bodywork and fittings

- 2.5.1. Chassis

- 2.5.1.1. Overhead guard

- 2.5.1.2. Replacing operator presence switch

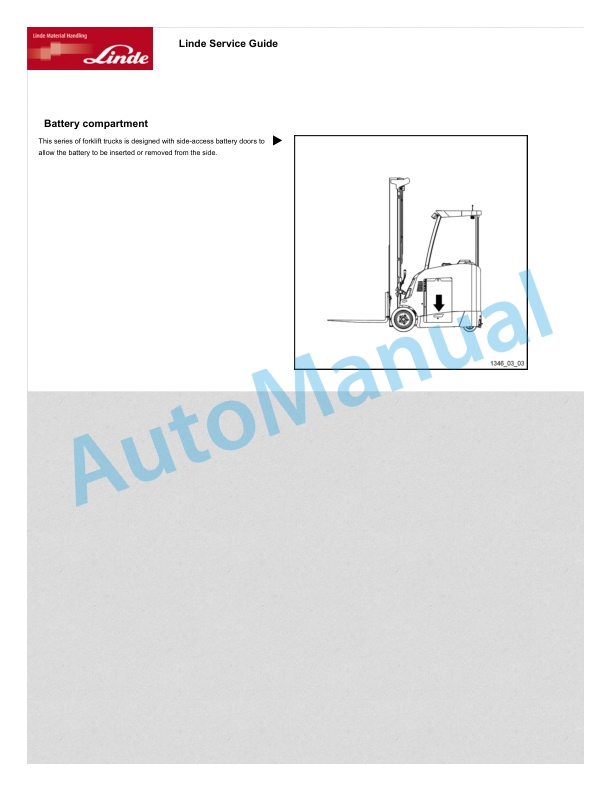

- 2.5.1.3. Battery compartment

- 2.5.1.4. Drive axle and steering axle

- 2.6. Steering

- 2.6.1. Steering system

- 2.6.1.1. Steering system

- 2.6.1.2. Compact steering axle features

- 2.6.2. Steering angle sensor

- 2.6.2.1. Steering angle sensor

- 2.6.3. Steering column sensor 3B2

- 2.6.3.1. Steering column sensor 3B2

- 2.6.3.2. Changing the steering column sensor 3B2

- 2.6.4. Wheels and tires

- 2.6.4.1. Tyre specifications

- 2.7. Controls

- 2.7.1. Operating handle

- 2.7.1.1. Overview of the joystick

- 2.7.1.2. Joystick function

- 2.7.1.3. MFH joystick

- 2.7.2. Brake system

- 2.7.2.1. General

- 2.7.2.2. Brake system

- 2.7.2.3. Electrical connection

- 2.7.2.4. Troubleshooting and fault elimination

- 2.8. Electrics . Electronics

- 2.8.1. General

- 2.8.1.1. Safety instructions for electrical equipment

- 2.8.1.2. Cleaning the electrical system

- 2.8.1.3. Insulation test

- 2.8.1.4. EMC Electromagnetic compatibility

- 2.8.1.5. CAN bus

- 2.8.1.6. Electrostatic charging

- 2.8.1.7. Functional description

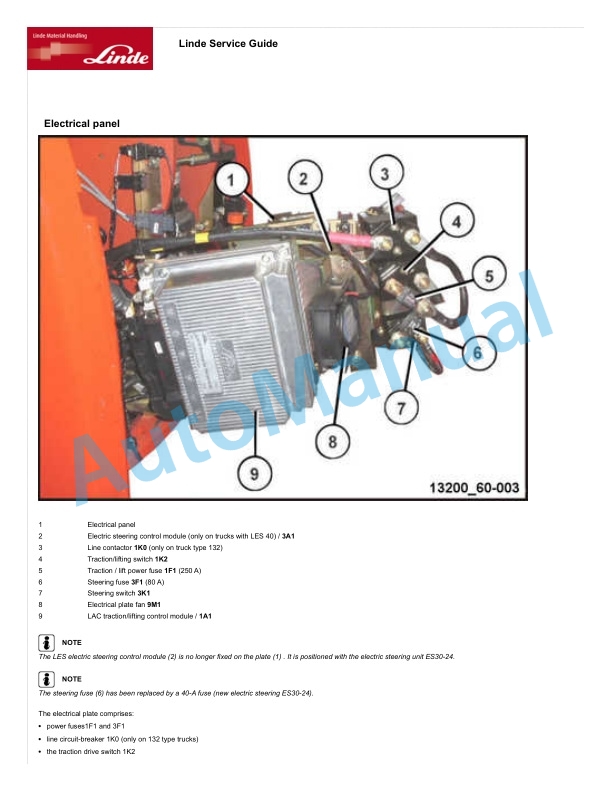

- 2.8.1.8. Layout of main electrical components

- 2.8.2. Control unit

- 2.8.2.1. Overview of control unit

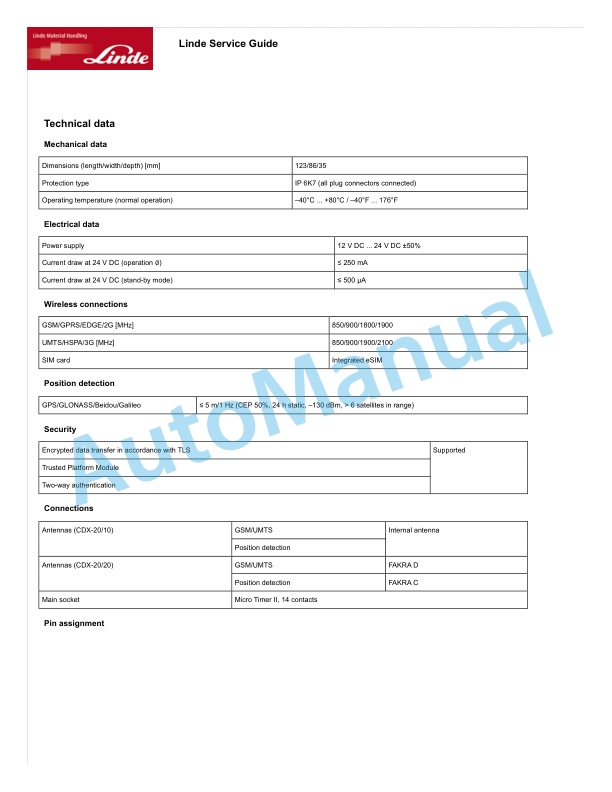

- 2.8.2.2. Control unit specifications

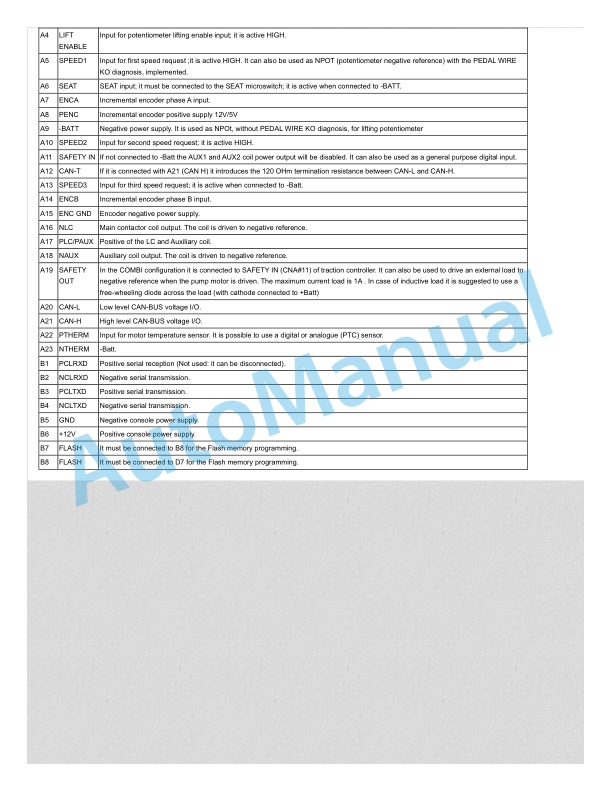

- 2.8.2.3. Control unit pins

- 2.8.2.4. Power supply

- 2.8.3. Vehicle Control Master

- 2.8.3.1. Overview of Vehicle Control Master

- 2.8.3.2. Introduction

- 2.8.3.3. Vehicle Control Master specifications

- 2.8.3.4. Vehicle Control Master pins

- 2.8.4. Electrical components

- 2.8.4.1. Main contactor

- 2.8.4.2. Main current fuses

- 2.8.4.3. Emergency stop switch

- 2.8.4.4. Fuse box

- 2.8.4.5. Discharging circuit

- 2.8.4.6. Voltage transformers

- 2.8.4.7. Battery plug connector

- 2.8.4.8. Lighting switches

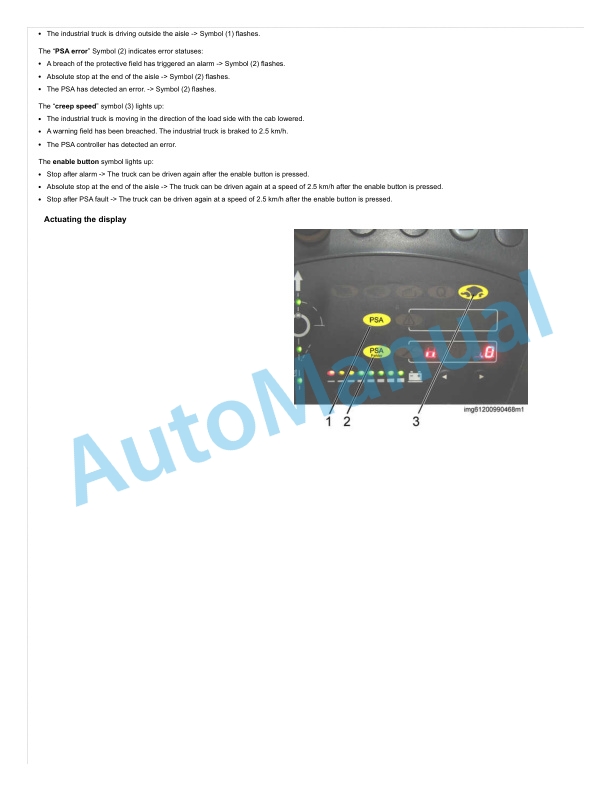

- 2.8.5. Display unit

- 2.8.5.1. Display unit

- 2.8.5.1.1. Display unit

- 2.8.5.1.2. Pin definition of the display

- 2.8.5.1.3. Display unit introduction

- 2.9. Hydraulics

- 2.9.1. General

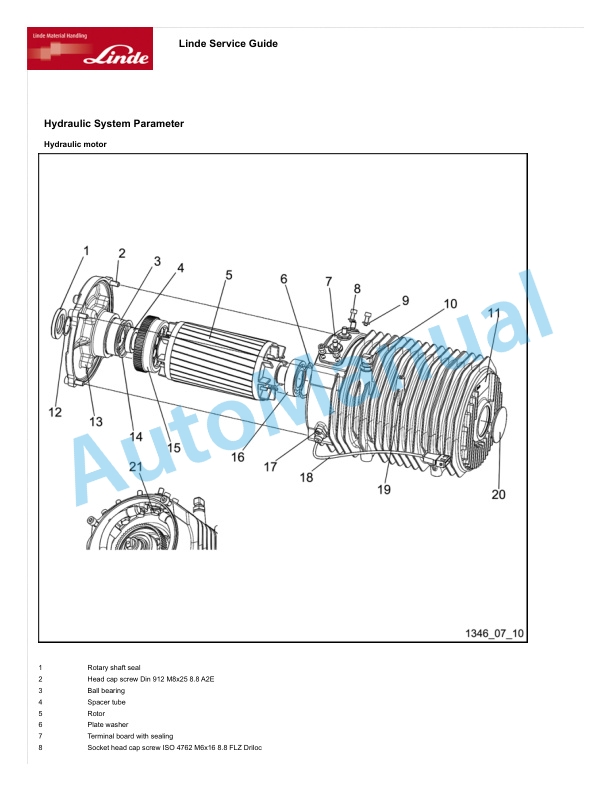

- 2.9.1.1. Hydraulic System Parameter

- 2.9.1.2. Hydraulic system contamination

- 2.9.2. Hydraulic pump unit

- 2.9.2.1. Hydraulic pump unit

- 2.9.2.2. Hydraulic control valve

- 2.9.3. Control valve unit

- 2.9.3.1. Priority valve

- 2.9.3.2. Emergency lowering screw

- 2.9.4. Hydraulic components

- 2.9.4.1. Highpressure filter

- 2.9.4.2. Tilt cylinder

- 2.10. Load lift system

- 2.10.1. Mast

- 2.10.1.1. Safety information for lift mast operations

- 2.10.1.2. Lift mast chains

- 2.10.1.3. Adjusting the lift mast chain

- 2.10.2. Lift mast

- 2.10.2.1. Fork arms (basic type)

- 2.10.2.2. Fork carriage (basic type)

- 2.10.2.3. Mast (basic type)

- 2.10.2.4. Basic line

- 2.10.2.5. Chains

- 2.10.2.6. Rupture valve

- 3. Circuit diagramsElectric forklift truck1346_E18S, 1346_E20S

- 3.1. Table of content

- 3.2. Circuit diagrams

- 3.2.1. Wire diagram

- 3.2.1.1. Wire Diagram 1

- 3.2.1.2. Wire Diagram 2

- 3.2.1.3. Wire Diagram 3

- 3.2.2. Hydraulic diagram

- 3.2.2.1. Hydraulic diagram

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Workshop Manuals SN A11102V00001 and up

$40.00

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

Linde 1110-01 – V08-01, V08-02 Workshop Manuals SN 11.09 and up SN up to W41110V00528

$40.00

Linde Workshop Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Workshop Manuals

$40.00