Linde 1402-01 – H180, H200, H220, H250, H280, H300, H320 Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 38.5MB

- Number of Pages: 247

Category: Linde Operator Manual PDF

-

Model List:

- H180

- H200

- H220

- H250

- H280

- H300

- H320

- 1. Linde Forklift Truck1402_H180, 1402_H200, 1402_H220, 1402_H250, 1402_H280, 1402_H300, 1402_H320

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your Linde truck

- 1.2.2. Technical description

- 1.2.3. Intended use

- 1.2.4. Improper use

- 1.2.5. Symbols used

- 1.2.6. Commissioning

- 1.2.7. Truck Takeover

- 1.2.8. EC declaration of conformity

- 1.3. Safety

- 1.3.1. Safety Rules

- 1.3.1.1. Safety Rules

- 1.3.1.2. Handling Fuel, Lubricants and Coolant

- 1.3.1.3. Residual risks

- 1.3.1.4. Stability

- 1.3.2. Frequency characteristic for human body vibrations

- 1.3.2.1. Frequency characteristic for human body vibrations

- 1.3.3. Noise emission data

- 1.3.3.1. Noise emission data

- 1.4. Overview

- 1.4.1. Description

- 1.4.1.1. General view of Truck

- 1.4.1.2. Type Plates

- 1.4.2. Controls and Indicators

- 1.4.2.1. Controls and indicators

- 1.4.2.2. Instruments and switches

- 1.5. Operation

- 1.5.1. Truck access doors and covers

- 1.5.1.1. Beginning operation

- 1.5.1.2. Opening the right hand side window

- 1.5.1.3. Engine Access

- 1.5.1.4. Service station

- 1.5.1.5. Isolating the batteries

- 1.5.1.6. Opening the fuse box cover

- 1.5.1.7. Emergency exit

- 1.5.2. Checks and tasks

- 1.5.2.1. Mirrors

- 1.5.2.2. Checking the fuel

- 1.5.2.3. Engine oil level check

- 1.5.2.4. Checking the coolant level

- 1.5.2.5. Transmission oil level check

- 1.5.2.6. Hydraulic system oil level check

- 1.5.2.7. Tyres check condition and pressure

- 1.5.2.8. Filling the windscreen washer bottle

- 1.5.2.9. Adjusting the drivers seat

- 1.5.2.10. Cab interior light

- 1.5.3. Starting and stopping the engine

- 1.5.3.1. Starting the engine

- 1.5.4. Truck status display

- 1.5.4.1. Truck status display

- 1.5.5. Malfunctions

- 1.5.5.1. Malfunctions during operation

- 1.5.5.2. Emergency Shutdown

- 1.5.5.3. Overload safety switch

- 1.5.6. Driving

- 1.5.6.1. Driving

- 1.5.6.2. Steering

- 1.5.7. Braking system

- 1.5.7.1. Service brake

- 1.5.7.2. Parking brake

- 1.5.8. Truck lighting and turn indicators

- 1.5.8.1. Hazard warning lights, Turn indicators lights, Horn

- 1.5.8.2. Road lights and Working lights

- 1.5.9. Washers and wipers

- 1.5.9.1. Windscreen wipers

- 1.5.10. Ventilation and heating

- 1.5.10.1. Heater, Climate control

- 1.5.11. Fuses

- 1.5.11.1. Fuses

- 1.5.12. Operating the truck

- 1.5.12.1. Before lifting a load

- 1.5.12.2. Lifting a load

- 1.5.12.3. Lift slow down

- 1.5.12.4. Travelling with load

- 1.5.12.5. Depositing the load

- 1.5.12.6. Before leaving the truck unattended

- 1.5.12.7. Loading

- 1.5.12.8. Control levers (joysticks)

- 1.5.12.9. Installation of additional equipment

- 1.5.12.10. Operating optional attachments

- 1.5.13. Mast, lifting device and attachment controls

- 1.5.13.1. Mast, lifting device and attachment controls

- 1.5.14. Trailer coupling

- 1.5.14.1. Trailer coupling

- 1.5.15. Wheel change

- 1.5.15.1. Location of jacks when changing wheels

- 1.5.16. Towing

- 1.5.16.1. Towing

- 1.6. Maintenance

- 1.6.1. General remarks

- 1.6.1.1. Wheel removal drive axle

- 1.6.1.2. Wheel removal steer axle

- 1.6.1.3. Wheel assembly inspection

- 1.6.1.4. Wheel refitting drive axle

- 1.6.1.5. Wheel refitting steer axle

- 1.6.1.6. Examples of restraining devices

- 1.6.1.7. General information

- 1.6.1.8. Inspection and maintenance data

- 1.6.1.9. Fuel and oil recommendations

- 1.6.1.10. Hoisting the truck

- 1.6.1.11. Measures before taking the truck out of operation

- 1.6.1.12. Putting the truck back into operation

- 1.6.1.13. Truck welds inspection

- 1.6.2. Inspection and maintenance schedule

- 1.6.2.1. As required service plan

- 1.6.2.2. First 50 hours service plan

- 1.6.2.3. h service plan

- 1.6.2.4. h service plan

- 1.6.2.5. h Service plan

- 1.6.2.6. h service plan

- 1.6.2.7. h service plan

- 1.6.2.8. h service plan

- 1.6.3. Engine

- 1.6.3.1. Engine oil level check

- 1.6.3.2. Change the engine oil (every 12 months minimum)

- 1.6.3.3. Clean the fuel filter

- 1.6.3.4. Change the fuel prefilter with water monitor

- 1.6.3.5. Change the fuel filter

- 1.6.3.6. Check the condition of the drive belt

- 1.6.3.7. Check the cooling fan belt tensioner

- 1.6.3.8. Check the engine mounting for condition and security

- 1.6.3.9. Check intake and exhaust systems for leaks and security

- 1.6.3.10. Check the fuel tank breather filter

- 1.6.3.11. Check the air filter

- 1.6.3.12. Air filter element renew

- 1.6.3.13. Safety element renew

- 1.6.3.14. Checking the coolant level

- 1.6.3.15. Check coolant strength

- 1.6.3.16. Renew engine coolant

- 1.6.3.17. Clean the radiator and oil cooler, check for leaks

- 1.6.3.18. Check the turbocharger

- 1.6.3.19. Check the vibration damper

- 1.6.3.20. Check valve clearances

- 1.6.4. Gearbox

- 1.6.4.1. Transmission oil level check

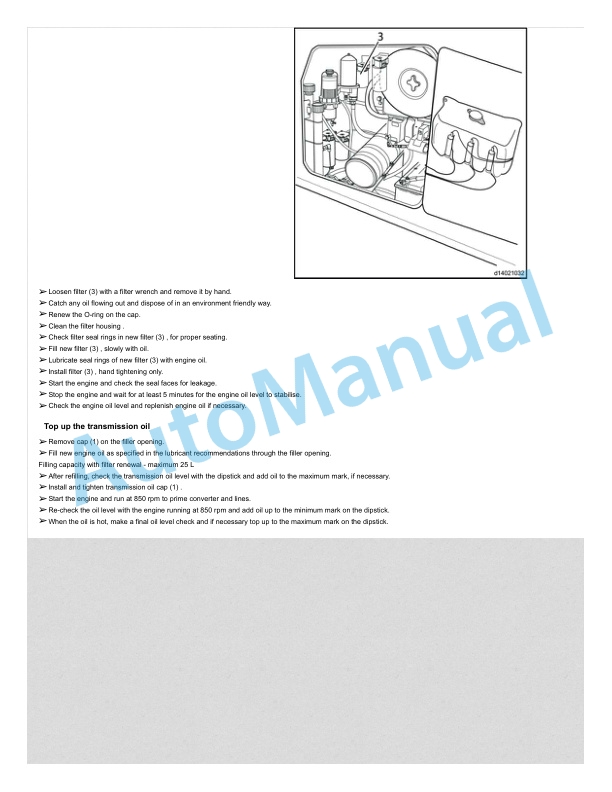

- 1.6.4.2. Change the transmission oil

- 1.6.4.3. Check transmission mountings

- 1.6.5. Chassis bodywork and fittings

- 1.6.5.1. Clean the truck

- 1.6.5.2. Check seat belt for condition and correct operation

- 1.6.5.3. Check the cab mountings

- 1.6.5.4. Check the tyres for damage and foreign objects

- 1.6.5.5. Tighten the wheel nuts

- 1.6.6. Chassis frame

- 1.6.6.1. Truck welds inspection

- 1.6.6.2. Clean and lubricate the steer axle

- 1.6.6.3. Checks various

- 1.6.7. Controls

- 1.6.7.1. Check the parking brake for proper operation

- 1.6.7.2. Brake control mechanism

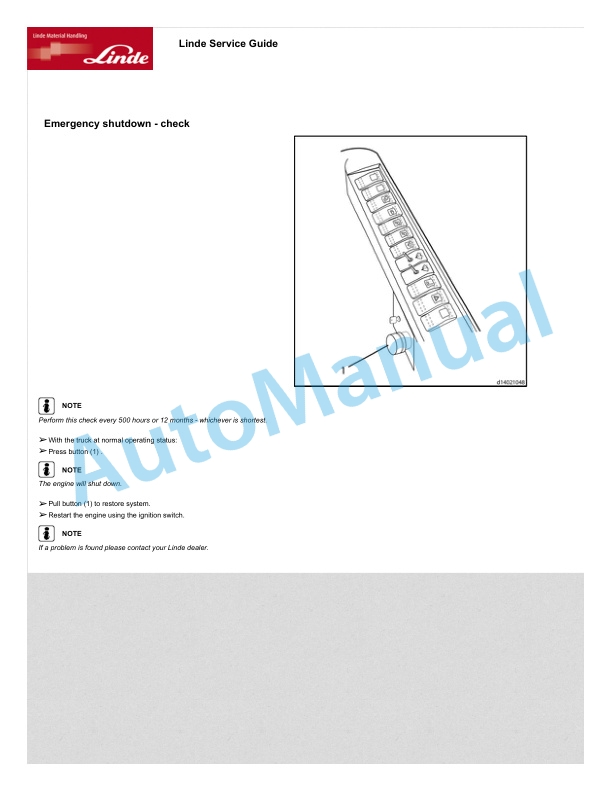

- 1.6.7.3. Emergency shutdown check

- 1.6.8. Electrics

- 1.6.8.1. Check the battery . batteries.

- 1.6.8.2. Check electric cables, connectors and connections for conditionand tightness

- 1.6.9. Hydraulics

- 1.6.9.1. Stored hydraulic energy

- 1.6.9.2. Breather filters replace

- 1.6.9.3. Check the hydraulic tank breather filter

- 1.6.9.4. Check the brake tank breather filter

- 1.6.9.5. Hydraulic system oil level check

- 1.6.9.6. Check the hydraulic system, pumps, valves and lines

- 1.6.9.7. Renew the main hydraulic system oil return line filters

- 1.6.9.8. Renew hydraulic oil of working hydraulic system

- 1.6.9.9. Renew hydraulic oil of brake system

- 1.6.10. Load lift system

- 1.6.10.1. Lubricate the mast and tilt cylinder pivots

- 1.6.10.2. Lubricate fork carriage cylinder bearings

- 1.6.10.3. Check and adjust mast chains, lubricate with chain spray

- 1.6.10.4. Check the tension of double hoses

- 1.6.10.5. Renewing the lift chains (at least every 6000h, 3 years and when 3 stretch has been attained)

- 1.6.11. Special equipment, accessories

- 1.6.11.1. Check the central lubrication lubricating points

- 1.6.11.2. Fill central lubrication canister with grease

- 1.6.12. Troubleshooting

- 1.6.12.1. Troubleshooting guide (Diesel engine)

- 1.6.12.2. Troubleshooting guide (Hydraulic system)

- 1.6.13. User manual feedback

- 1.6.13.1. User manual improvement record.

- 1.7. Technical data

- 1.7.1. Datasheet

- 1.7.1.1. Technical Data

- 1.8. Circuit diagrams

- 1.8.1. Electrical circuit diagrams

- 1.8.1.1. Electrical circuit drawing

- 1.8.2. Hydraulic circuit diagram

- 1.8.2.1. Hydraulic circuit drawing

- 2. Rear view monitor supplement

- 2.1. Table of content

- 2.2. Operation

- 2.2.1. Operation

- 2.3. System Settings

- 2.3.1. System settings

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00