Linde 1408-01 – HT100D, HT80D Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 37.1MB

- Number of Pages: 222

-

Model List:

- HT100D

- HT80D

- 1. Internal Combustion Counterbalanced Forklift TruckHT80D, HT100D

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. General information

- 1.2.3. Conformity marking

- 1.2.4. Declaration that reflects the content of the declaration of conformity

- 1.2.5. Nameplate

- 1.2.6. Intended use

- 1.2.7. Hazard assessment

- 1.2.8. Improper use

- 1.2.9. Symbols used

- 1.2.10. Engine registration

- 1.2.11. Description of use and climatic conditions

- 1.2.12. Configuration code explanationChina IV

- 1.2.13. Technical description

- 1.3. Safety

- 1.3.1. Residual risks

- 1.3.2. Stability

- 1.3.3. In the event of tipover

- 1.3.4. Handling consumables

- 1.3.5. Regulations

- 1.3.6. Competent person

- 1.3.7. Do not operate with guards removed

- 1.3.8. Malfunctions

- 1.3.9. Accident prevention check

- 1.3.10. Fitting attachments

- 1.3.11. Manually lowering the fork arms

- 1.4. Views

- 1.4.1. General view

- 1.4.2. Operating interface

- 1.4.3. Labels

- 1.4.4. Display unit QSB4.5

- 1.4.4.1. Display unit

- 1.4.5. Display unit F4.5

- 1.4.5.1. Display unit

- 1.5. Operations

- 1.5.1. Instructions for runningin

- 1.5.2. Preshift checks

- 1.5.3. Daily checks QSB4.5

- 1.5.4. Daily checks F4.5

- 1.5.5. Mounting.dismounting

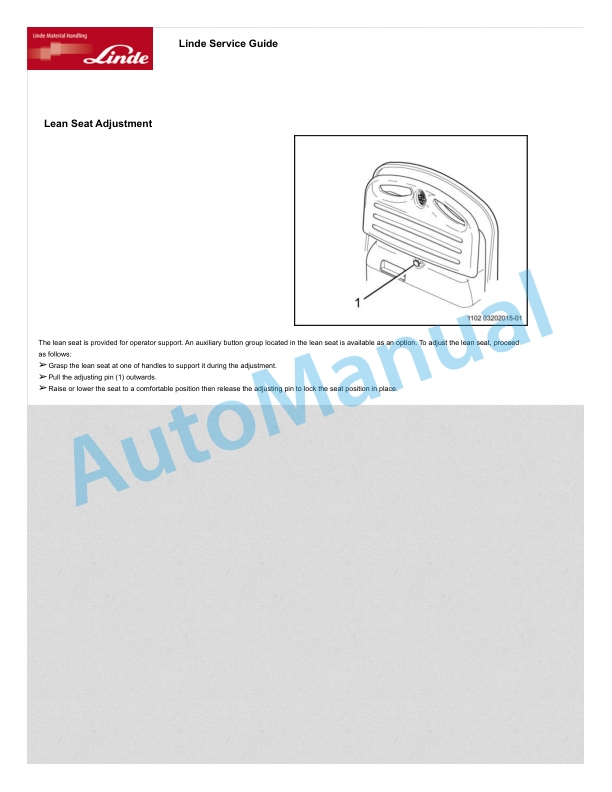

- 1.5.6. Adjusting the drivers seat and seat belt

- 1.5.6.1. Adjusting the drivers seat

- 1.5.6.2. Adjusting the drivers seat

- 1.5.6.3. Seat belt

- 1.5.6.4. Driver presence monitoring (for LX)

- 1.5.7. Adjusting the steering column

- 1.5.8. Vehicle terminal system (China IV)

- 1.5.9. Particulate filter regeneration F4.5

- 1.5.10. Driver warning system and driving performance restricting system (China IV)

- 1.5.11. Override switch (China IV)

- 1.5.12. RFID card reader (for LX)

- 1.5.13. Driving

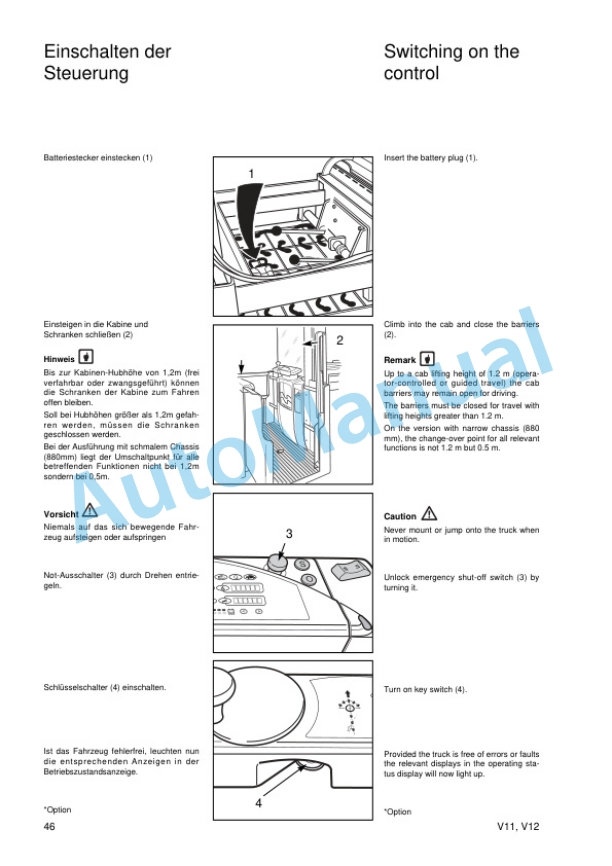

- 1.5.13.1. Starting the engine

- 1.5.13.2. Engine shutdown

- 1.5.13.3. Driving

- 1.5.13.4. Forward and reverse travel of the forklift

- 1.5.13.5. Changing the drive direction

- 1.5.13.6. Inching control

- 1.5.13.7. Moving off on a ramp

- 1.5.13.8. Parking

- 1.5.14. Steering system

- 1.5.14.1. Steering system

- 1.5.15. Brake system

- 1.5.15.1. Service brake

- 1.5.15.2. Parking brake

- 1.5.15.3. Brake system fault

- 1.5.16. Operating the lifting devices and attachments

- 1.5.16.1. Operating the lifting devices and attachments

- 1.5.17. Indicator lights and horn

- 1.5.17.1. Switching on the direction indicators

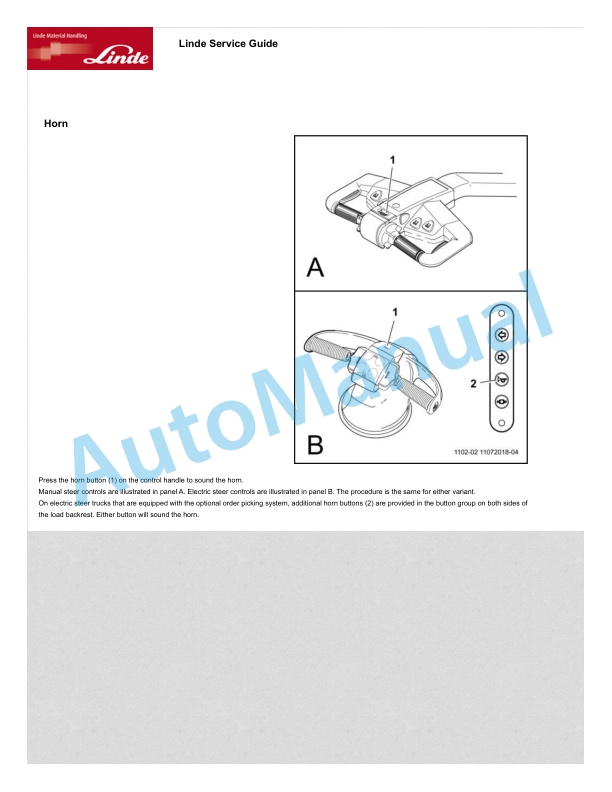

- 1.5.17.2. Operating the horn

- 1.5.18. Before lifting a load

- 1.5.19. Transporting loads

- 1.5.19.1. Load centre distance and load capacity

- 1.5.19.2. Capacity rating plate

- 1.5.19.3. Transporting pallets or other containers

- 1.5.19.4. Adjusting the fork spacing

- 1.5.19.5. Loading

- 1.5.19.6. Travel with a load

- 1.5.19.7. Transport of swinging loads

- 1.5.19.8. Driving on loading bridges

- 1.5.19.9. Unloading

- 1.5.19.10. Trailer load

- 1.5.20. Before exiting the truck

- 1.5.21. Truck transport

- 1.5.22. Truck Storage

- 1.5.23. Decommissioning the truck

- 1.5.23.1. Measures before taking the truck out of operation

- 1.5.23.2. Putting the truck back into service

- 1.5.23.3. Disposal of old trucks

- 1.6. Maintenance

- 1.6.1. Recommended fuels and oils

- 1.6.2. Regular maintenance

- 1.6.3. Engine emission requirements (China IV)

- 1.6.3.1. List of emission parts and components under warranty

- 1.6.4. Service plan table QSB4.5

- 1.6.4.1. Maintenance every 500 operating hours, or at least once every 6 months

- 1.6.4.2. Additional maintenance every 1000 operating hours, or at least once every 12 months

- 1.6.4.3. Additional maintenance every 2000 operating hours or at least once every 2 years

- 1.6.4.4. Additional maintenance every 5000 operating hours or at least once every 5 years.

- 1.6.5. Service plan table F4.5

- 1.6.5.1. Service plan table F4.5

- 1.6.6. Cleaning

- 1.6.6.1. Cleaning the truck

- 1.6.6.2. Cleaning the electrical system

- 1.6.6.3. Cleaning lifting chains

- 1.6.6.4. After washing

- 1.6.7. Engine QSB4.5

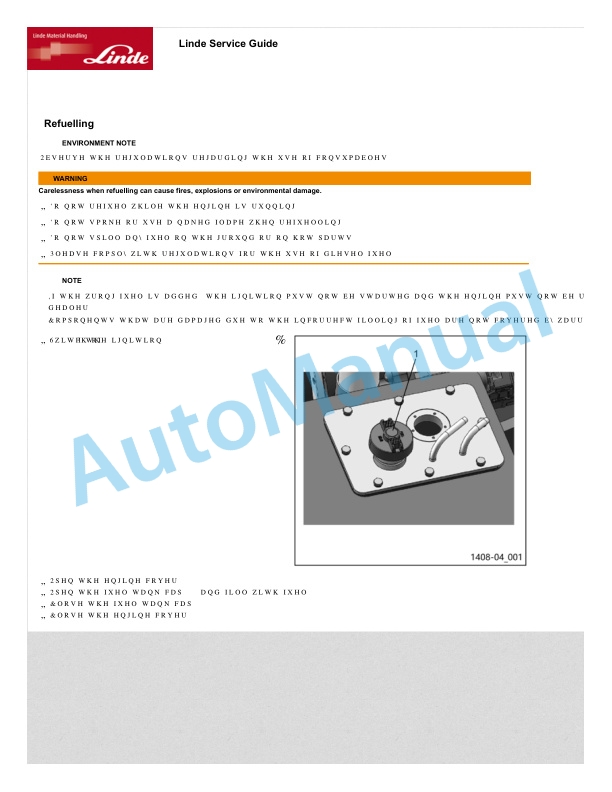

- 1.6.7.1. Refuelling

- 1.6.7.2. Fuel.water separator

- 1.6.7.3. Checking the engine oil level

- 1.6.7.4. Checking the intake pipe

- 1.6.7.5. Radiator

- 1.6.7.6. Replacing the fuel filter (screwtype)

- 1.6.7.7. Oil and filter

- 1.6.7.8. Radiator pressure cap

- 1.6.7.9. Belt drive fan hub

- 1.6.7.10. Belt tensioner

- 1.6.7.11. Radiator hose

- 1.6.7.12. Overhead mechanism

- 1.6.7.13. Checking and cleaning the radiator fins

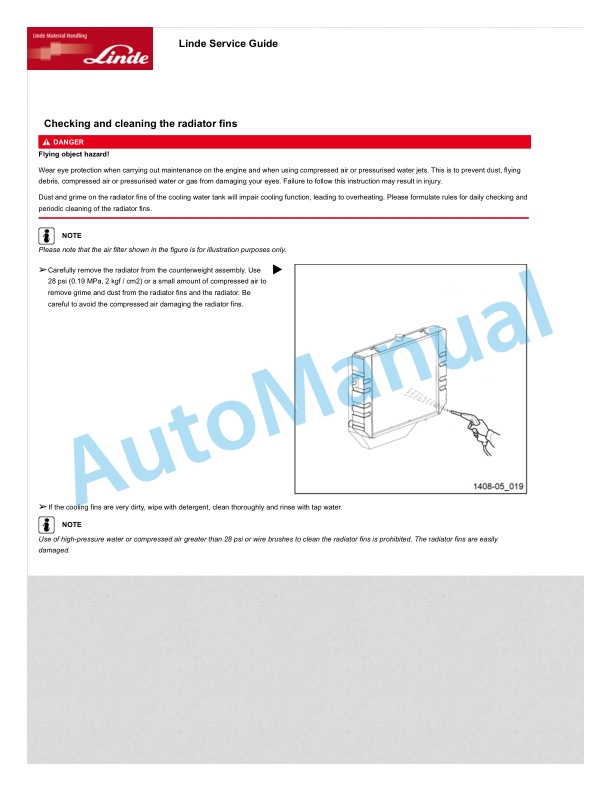

- 1.6.7.14. Changing the coolant

- 1.6.7.15. Checking the coolant level

- 1.6.8. Engine F4.5

- 1.6.8.1. Checking the fuel level

- 1.6.8.2. Refuelling

- 1.6.8.3. Drain all water from the water trap.

- 1.6.8.4. Checking the engine oil level

- 1.6.8.5. Checking the coolant level

- 1.6.8.6. Checking the intake pipe

- 1.6.8.7. Checking the drive belt

- 1.6.8.8. Check the belt tension

- 1.6.8.9. Checking the fastening of the engine retainer plate

- 1.6.8.10. Cleaning the air filter insert

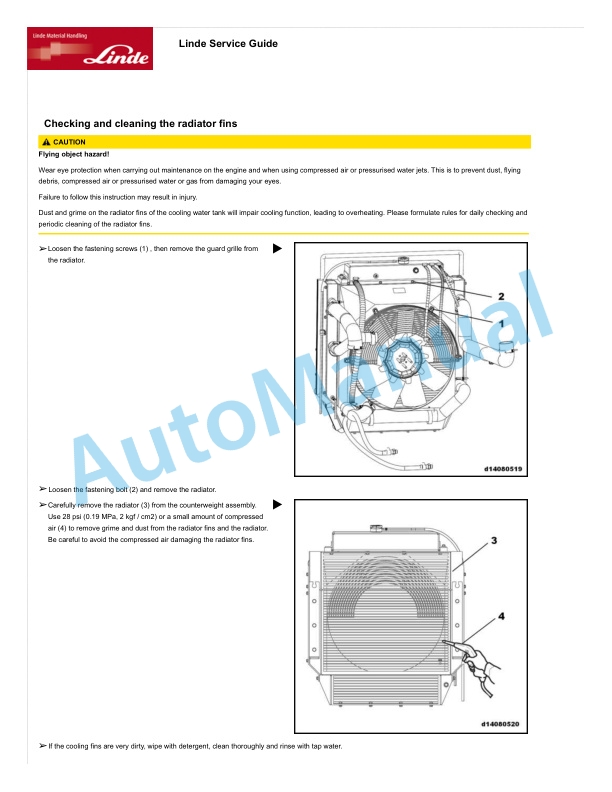

- 1.6.8.11. Checking and cleaning the radiator fins

- 1.6.8.12. Checking the crankcase respirator tube

- 1.6.8.13. Check the drive belt fan housing.

- 1.6.8.14. Check the radiator hose

- 1.6.8.15. Check the radiator pressure cap.

- 1.6.8.16. Changing the engine oil

- 1.6.8.17. Replace the water trap

- 1.6.8.18. Charging the fuel system

- 1.6.8.19. Changing the fuel filter

- 1.6.8.20. Changing the air filter insert and checking the vacuum switch

- 1.6.8.21. Change the air filter safety insert

- 1.6.8.22. Changing the coolant

- 1.6.9. Drive system transmission mechanism

- 1.6.9.1. Replacing the hydraulic transmission oil filter

- 1.6.9.2. Checking the oil level of the hydraulic transmission gearbox

- 1.6.9.3. Replace the hydraulic transmission oil.

- 1.6.9.4. Checking the drive axle gearbox oil

- 1.6.9.5. Changing the drive axle gearbox oil

- 1.6.10. Steering axle and wheels

- 1.6.10.1. Clean and lubricate the steering axle

- 1.6.10.2. Checking the tyres for damage and foreign matter

- 1.6.10.3. Check the tyre inflation pressure

- 1.6.10.4. Tightening the tyre nuts

- 1.6.11. Chassis

- 1.6.11.1. Checking seat belt condition and correct operation

- 1.6.11.2. Checking the fastening of the engine bracket, overhead guard, tilt cylinder, steering axle and wheel drive

- 1.6.12. Control system

- 1.6.12.1. Checking the operation of the parking brake

- 1.6.12.2. Checking the operation of the service brake

- 1.6.12.3. Checking the normal operation of the inching control

- 1.6.13. Electrical components

- 1.6.13.1. Check the battery status

- 1.6.13.2. Checking the condition and tightness of cables and connections

- 1.6.13.3. Checking the fuse box

- 1.6.13.4. Checking fuse box F4.5

- 1.6.14. Hydraulics

- 1.6.14.1. Changing the hydraulic oil filter insert

- 1.6.14.2. Replacing the breather

- 1.6.14.3. Change the hydraulic oil

- 1.6.14.4. Checking the hydraulic oil level

- 1.6.15. Mast type

- 1.6.15.1. Checking the operation and installation of the lift mast, lifting chain and limit block

- 1.6.15.2. Lubricating the lift mast and the chains with chain spray

- 1.6.15.3. Lubricating the lift mast and the tilt cylinder bearings

- 1.6.15.4. Adjusting lifting chain length and lubricating with chain spray (for standard triple mast)

- 1.6.16. Troubleshooting

- 1.6.16.1. Causes and solutions of hydraulic transmission gearbox malfunction

- 1.7. Technical datasheet

- 1.7.1. Technical datasheet QSB4.5

- 1.7.1.1. HT80D, HT100D model vehicle type sheet

- 1.7.2. Technical datasheet F4.5

- 1.7.2.1. Technical datasheet

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

Linde Operator Manual PDF