Linde 316-01 – S30, S30T, S30W, S40, S40T, S40W, S50, S50T, S50W, S60, S60T, S60W Operating Instructions SN up to 06.13

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN up to 06.13

- Format: PDF

- Size: 21.4MB

- Number of Pages: 185

- Serial Number:

SN up to 06.13

Category: Linde Operator Manual PDF

-

Model List:

- S30

- S30T

- S30W

- S40

- S40T

- S40W

- S50

- S50T

- S50W

- S60

- S60T

- S60W

- 1. Linde Forklift TruckS30, S40, S50, S60

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your Linde truck

- 1.2.2. Technical Description

- 1.2.3. Intended use

- 1.2.4. Impermissible use

- 1.2.5. Symbols used

- 1.2.6. Commissioning

- 1.2.7. Truck Takeover

- 1.2.8. EC declaration of conformity

- 1.3. Safety

- 1.3.1. Safety Rules

- 1.3.1.1. Safety Rules

- 1.3.1.2. Handling Fuel, Lubricants and Coolant

- 1.3.1.3. Residual risks

- 1.3.1.4. Stability

- 1.4. Overview

- 1.4.1. Description

- 1.4.1.1. General view of Truck

- 1.4.1.2. Type Plates

- 1.5. Operation

- 1.5.1. Wheel change

- 1.5.1.1. Location for jacks

- 1.5.1.2. Wheel removal drive axle

- 1.5.1.3. Wheel removal steer axle

- 1.5.1.4. Wheel assembly inspection

- 1.5.1.5. Wheel refitting drive axle

- 1.5.1.6. Wheel refitting steer axle

- 1.5.1.7. Examples of restraining devices

- 1.5.2. Truck access doors and covers

- 1.5.2.1. Drivers cabin

- 1.5.2.2. Engine access

- 1.5.3. Checks and tasks

- 1.5.3.1. Engine oil level check

- 1.5.3.2. Fuel level check

- 1.5.3.3. Coolant level check

- 1.5.3.4. Brake fluid check

- 1.5.3.5. Hydraulic oil level check

- 1.5.3.6. Filling the windscreen washer bottle

- 1.5.3.7. Adjusting the drivers seat

- 1.5.3.8. Tyres check

- 1.5.4. Starting and stopping the engine

- 1.5.4.1. Starting stopping the engine

- 1.5.5. Malfunctions

- 1.5.5.1. Malfunctions engine

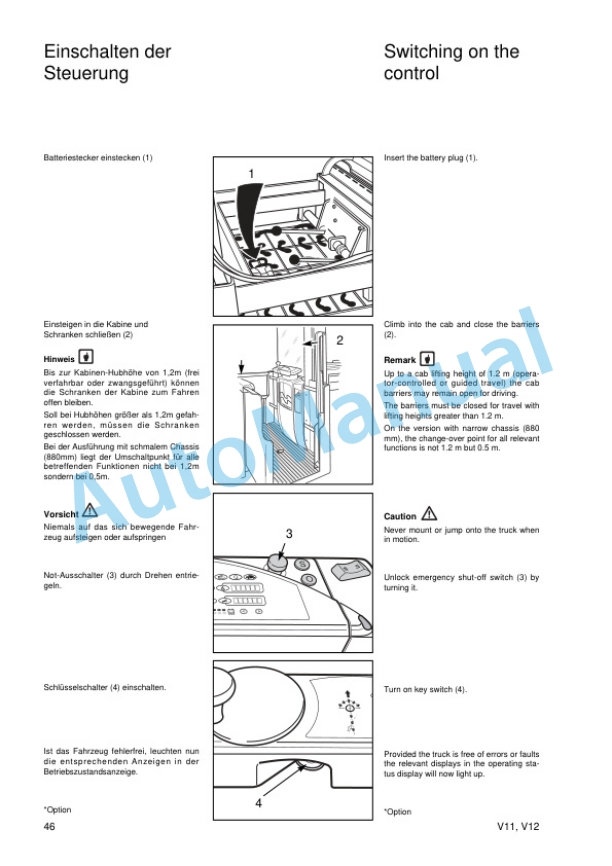

- 1.5.6. Driving

- 1.5.6.1. Driving

- 1.5.6.2. Steering

- 1.5.6.3. Operate the horn

- 1.5.6.4. Cab interior light

- 1.5.6.5. Mirrors

- 1.5.7. Braking system

- 1.5.7.1. Braking system

- 1.5.8. Truck lighting and turn indicators

- 1.5.8.1. Lights, hazard and turn indicators

- 1.5.9. Washers and wipers

- 1.5.9.1. Operating the wipers

- 1.5.10. Ventilation and heating

- 1.5.10.1. Heater control and ventilation

- 1.5.11. Fuses

- 1.5.11.1. Fuses

- 1.5.12. Operating the truck

- 1.5.12.1. Before lifting a load

- 1.5.12.2. Lifting a load

- 1.5.12.3. Travelling with load

- 1.5.12.4. Depositing a load

- 1.5.12.5. Control levers

- 1.5.12.6. Before leaving the truck unattended

- 1.5.13. Towing

- 1.5.13.1. Towing

- 1.5.14. Optional equipment

- 1.5.14.1. Optional equipment

- 1.6. Maintenance

- 1.6.1. General remarks

- 1.6.1.1. Hoisting the truck

- 1.6.1.2. Measures before taking the truck out of operation

- 1.6.1.3. Putting the truck back into service

- 1.6.1.4. General information

- 1.6.1.5. Fuel and oil recommendations

- 1.6.1.6. Diesel fuel

- 1.6.2. Inspection and maintenance schedule

- 1.6.2.1. As required Service plan

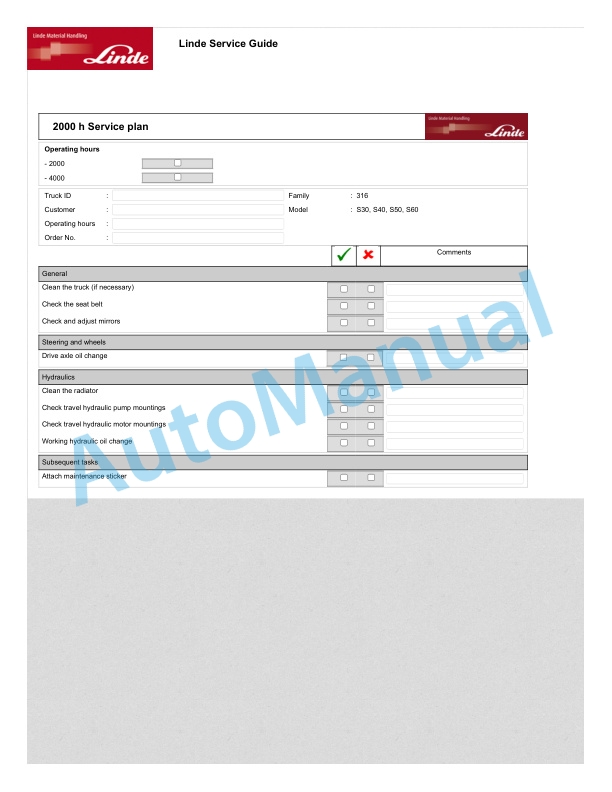

- 1.6.2.2. h Service plan

- 1.6.2.3. h Service plan

- 1.6.2.4. h Service plan

- 1.6.2.5. h Service plan

- 1.6.2.6. h Service plan

- 1.6.2.7. h Service plan

- 1.6.2.8. Inspection and maintenance data

- 1.6.3. Engine

- 1.6.3.1. Engine oil level check

- 1.6.3.2. Engine oil change

- 1.6.3.3. Fuel prefilter clean

- 1.6.3.4. Fuel filter_change

- 1.6.3.5. Bleeding the fuel system

- 1.6.3.6. Dust valve check

- 1.6.3.7. Air filter element renew

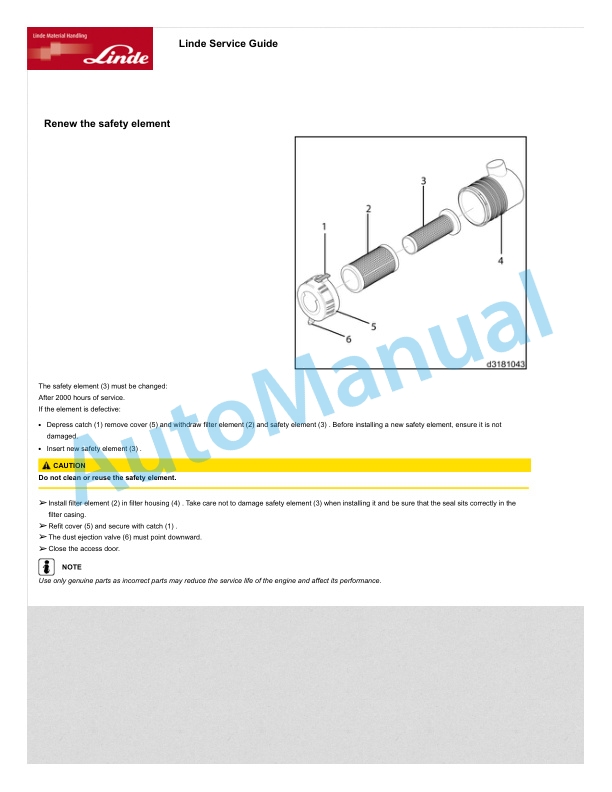

- 1.6.3.8. Renew the safety element

- 1.6.3.9. Coolant level check

- 1.6.3.10. Coolant strength check

- 1.6.3.11. Coolant renew

- 1.6.3.12. Check and clean the radiator and hydraulic oil cooler

- 1.6.3.13. Engine mountings check

- 1.6.3.14. Intake and exhaust system check

- 1.6.3.15. Drive belt check

- 1.6.3.16. Valve clearances check

- 1.6.3.17. Check engine accessories

- 1.6.4. Chassis bodywork and fittings

- 1.6.4.1. Clean the truck

- 1.6.4.2. Check seat belt for condition and correct operation

- 1.6.4.3. Mirrors

- 1.6.4.4. Wheel nuts tighten

- 1.6.4.5. Drive axle hub oil level check

- 1.6.4.6. Drive axle oil change

- 1.6.4.7. Steer axle clean and lubricate

- 1.6.5. Chassis frame

- 1.6.5.1. Structured components check

- 1.6.6. Controls

- 1.6.6.1. Parking brake lubricate

- 1.6.7. Electrics

- 1.6.7.1. Battery check

- 1.6.8. Hydraulics

- 1.6.8.1. Hydraulic oil level check

- 1.6.8.2. Hydraulic oil filters change

- 1.6.8.3. Hydraulic oil renew

- 1.6.9. Load lift system

- 1.6.9.1. Work on the lifting device

- 1.6.9.2. Mast and traverse cylinders lubrication

- 1.6.9.3. Mast chains check and adjust

- 1.6.9.4. Lubrication points

- 1.6.9.5. Renewing the lift chains (at least every 6000h, 3 years and when 2 stretch has been attained)

- 1.6.10. Troubleshooting

- 1.6.10.1. Troubleshooting guide (Diesel engine)

- 1.6.10.2. Troubleshooting guide (Hydraulic system)

- 1.7. Technical data

- 1.7.1. Datasheet

- 1.7.1.1. Datasheet

- 1.7.2. Mast variations

- 1.7.2.1. Mast Variations

- 1.8. Circuit diagrams

- 1.8.1. Electrical circuit diagrams

- 1.8.1.1. Electrical Circuit

- 1.8.2. Hydraulic circuit diagrams

- 1.8.2.1. Hydraulic circuit

Rate this product

You may also like

Linde Operator Manual PDF

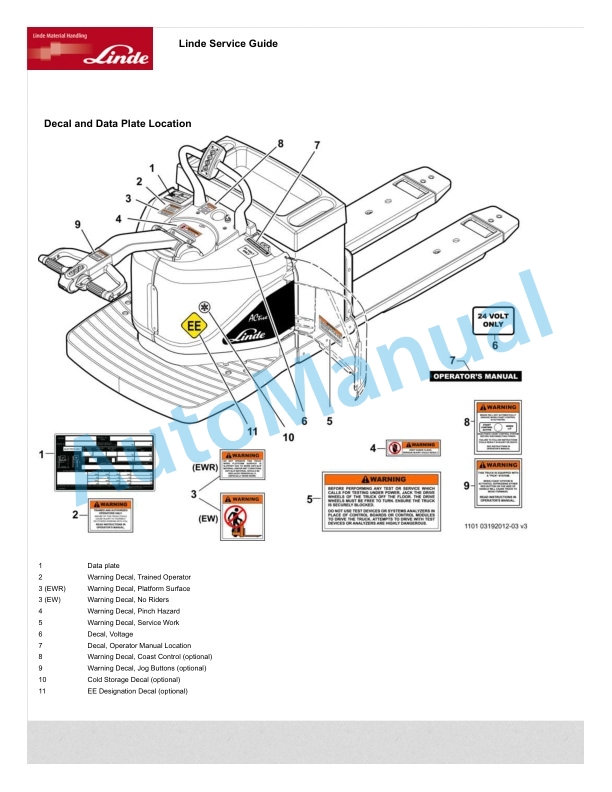

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00