Linde 318-01 – C90 Operating Instructions SN 09.08 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 09.08 and up

- Format: PDF

- Size: 31.5MB

- Number of Pages: 276

- Serial Number:

SN 09.08 and up

Category: Linde Operator Manual PDF

-

Model List:

- C90

- 1. EHDC 80.3, C 80.4, C 80.5, C 80.6

- 1.1. Table of content

- 1.2. Electric circuit schematics

- 1.2.1. Cummins engine electrical circuit

- 1.2.1.1. Cummins engine electrical circuit drawing

- 1.2.2. Electrical drawing Cummins fault code list

- 1.2.2.1. Cummins fault code list

- 1.2.3. Electrical drawing

- 1.2.3.1. Electrical Circuit

- 1.2.4. Elme electrical circuit

- 1.2.4.1. Elme electrical schematic

- 1.3. Hydraulic circuit

- 1.3.1. Hydraulic layout drawing

- 1.3.1.1. Hydraulic circuit

- 1.3.2. Elme hydraulic circuit

- 1.3.2.1. Elme hydraulic schematic

- 2. Arctic oils supplement357 05, 318

- 2.1. Table of content

- 2.2. Information

- 2.2.1. Arctic Oils Information

- 3. Container Handler318_C905, 318_C906, 318_C907, 318_C908

- 3.1. Table of content

- 3.2. Introduction

- 3.2.1. Your Linde truck

- 3.2.2. Technical description

- 3.2.3. Intended use

- 3.2.4. Improper use

- 3.2.5. Symbols used

- 3.2.6. Commissioning

- 3.2.7. Truck takeover

- 3.2.8. EC declaration of conformity

- 3.3. Safety

- 3.3.1. Safety rules

- 3.3.1.1. Safety rules

- 3.3.1.2. Residual risks

- 3.3.1.3. Stability

- 3.3.2. Frequency characteristic for human body vibrations

- 3.3.2.1. Frequency characteristic for human body vibrations

- 3.3.3. Noise emission data

- 3.3.3.1. Noise emission data

- 3.4. Overview

- 3.4.1. General view

- 3.4.2. Type plates

- 3.4.3. Controls and indicators

- 3.4.4. Controls and indicators

- 3.5. Operation

- 3.5.1. Wheel removal drive axle

- 3.5.2. Wheel removal steer axle

- 3.5.3. Wheel assembly inspection

- 3.5.4. Wheel refitting drive axle

- 3.5.5. Wheel refitting steer axle

- 3.5.6. Examples of restraining devices

- 3.5.7. Mirrors

- 3.5.8. Beginning operation

- 3.5.9. Opening the right hand side window

- 3.5.10. Emergency exit

- 3.5.11. Setting the clock

- 3.5.12. Cab interior light

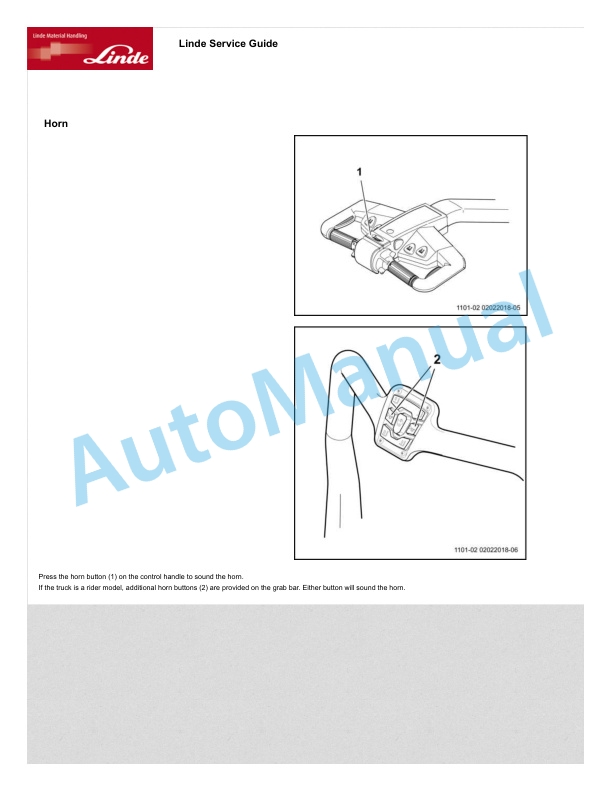

- 3.5.13. Hazard warning lights, Turn indicators lights, Horn

- 3.5.14. Heater, Climate control

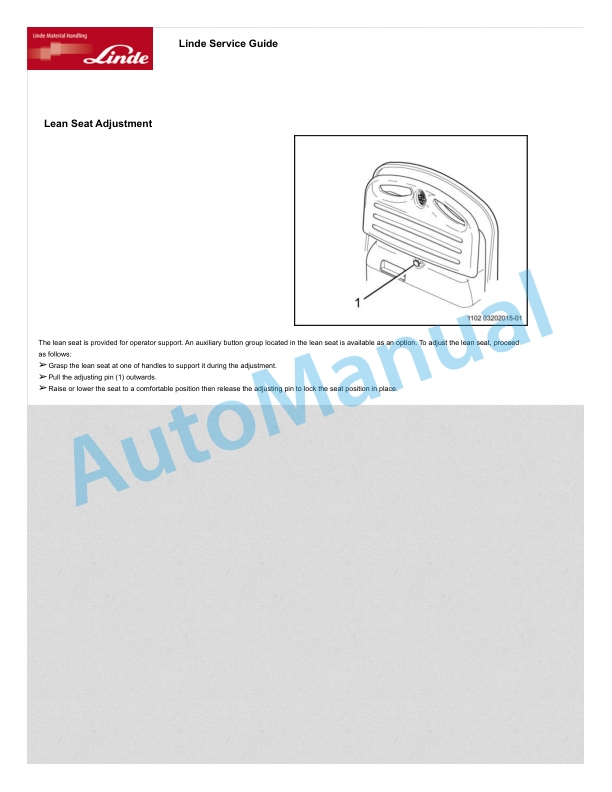

- 3.5.15. Adjusting the drivers seat

- 3.5.16. To turn on the road lights

- 3.5.17. Operating the windscreen wipers

- 3.5.18. Filling the windscreen washer bottle

- 3.5.19. Control levers (joysticks)

- 3.5.20. Engine Access

- 3.5.21. Engine oil level check

- 3.5.22. Checking the fuel

- 3.5.23. Checking the coolant level in the reservoir

- 3.5.24. Check the tyres for damage and foreign objects

- 3.5.25. Battery access opening

- 3.5.26. Isolating the battery

- 3.5.27. Fuses

- 3.5.28. Working hydraulics filter panel removal

- 3.5.29. Hydraulic system oil level check

- 3.5.30. Starting the engine double pedal models

- 3.5.31. Driving Double pedal models

- 3.5.32. Stopping the engine double pedal models

- 3.5.33. Starting the engine Single pedal models

- 3.5.34. Driving single pedals

- 3.5.35. Stopping the Engine Single pedal models

- 3.5.36. Malfunctions during operation

- 3.5.37. Steering

- 3.5.38. Braking system

- 3.5.39. Installation of additional equipment

- 3.5.40. Before lifting a load

- 3.5.41. Double container handling operation

- 3.5.42. Lifting a load

- 3.5.43. Travelling with load

- 3.5.44. Depositing the load

- 3.5.45. Before leaving the truck unattended

- 3.5.46. Trailer coupling

- 3.5.47. Locations for jacks when changing wheels

- 3.5.48. Towing

- 3.5.49. Measures before taking the truck out of operation

- 3.5.50. Putting the truck back into operation

- 3.5.51. Optional equipment

- 3.6. Maintenance

- 3.6.1. General remarks

- 3.6.1.1. Wheel removal drive axle

- 3.6.1.2. Wheel removal steer axle

- 3.6.1.3. Wheel assembly inspection

- 3.6.1.4. Wheel refitting drive axle

- 3.6.1.5. Wheel refitting steer axle

- 3.6.1.6. Examples of restraining devices

- 3.6.1.7. General information

- 3.6.1.8. Work on the mast and the front part of the truck

- 3.6.1.9. Filling capacity.rated values

- 3.6.1.10. Fuel and oil recommendations

- 3.6.1.11. Diesel fuel

- 3.6.1.12. Check the condition of structured components

- 3.6.1.13. Truck welds inspection

- 3.6.1.14. Checks various

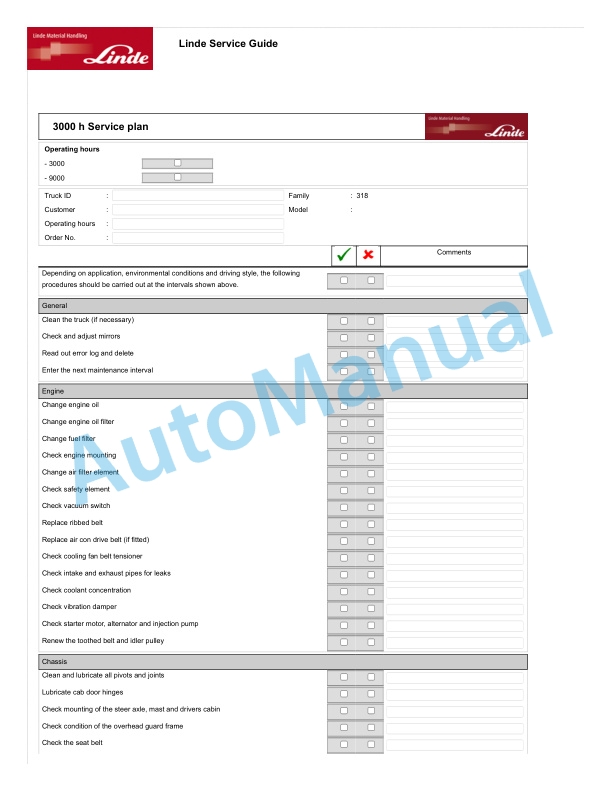

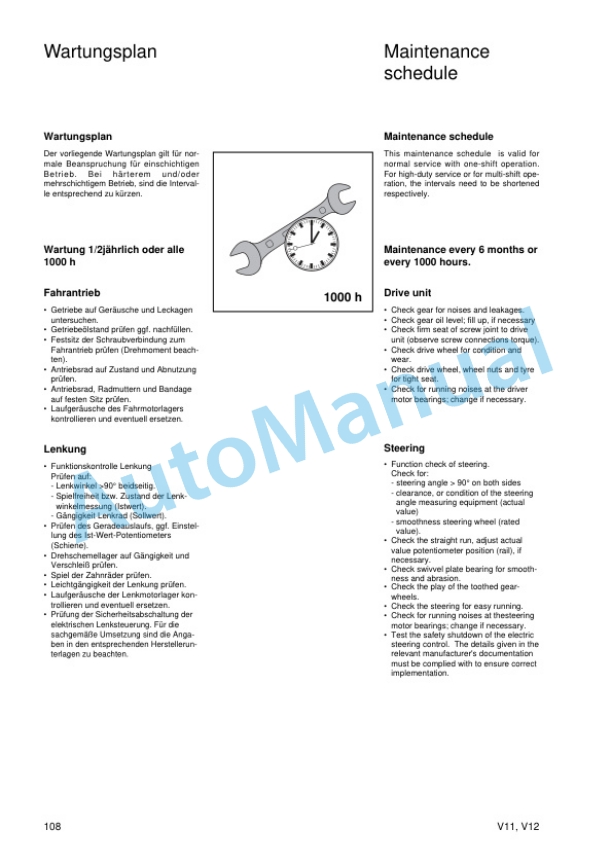

- 3.6.2. Inspection and maintenance schedule

- 3.6.2.1. As required Service plan

- 3.6.2.2. h Service plan

- 3.6.2.3. h Service plan

- 3.6.2.4. h Service plan

- 3.6.2.5. h Service plan

- 3.6.2.6. h Service plan

- 3.6.2.7. h Service plan

- 3.6.2.8. h Service plan

- 3.6.3. Engine

- 3.6.3.1. Engine oil level check

- 3.6.3.2. Change the engine oil (every 12 months minimum)

- 3.6.3.3. Clean the fuel filter

- 3.6.3.4. Change the fuel prefilter with water monitor

- 3.6.3.5. Check the condition of the Vbelt

- 3.6.3.6. Check the condition of the drive belt

- 3.6.3.7. Check the cooling fan belt tensioner

- 3.6.3.8. Check the engine mounting for condition and security

- 3.6.3.9. Check intake and exhaust systems for leaks and security

- 3.6.3.10. Check the air filter

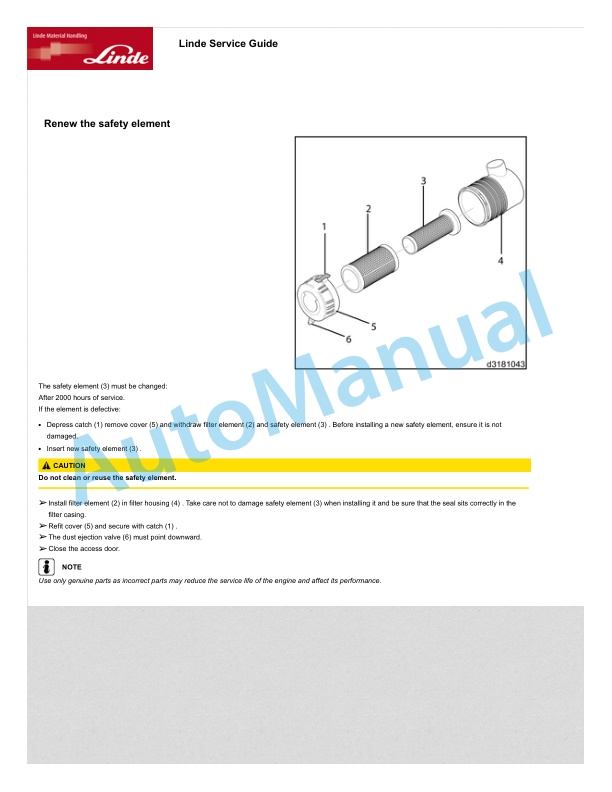

- 3.6.3.11. Renew the safety element

- 3.6.3.12. Check coolant strength

- 3.6.3.13. Renew engine coolant

- 3.6.3.14. Clean the radiator and oil cooler, check for leaks

- 3.6.3.15. Check the vibration damper

- 3.6.3.16. Check valve clearances

- 3.6.4. Gearbox

- 3.6.4.1. Final drive oil level check

- 3.6.4.2. Change final drive hub oil

- 3.6.5. Chassis bodywork and fittings

- 3.6.5.1. Clean the truck

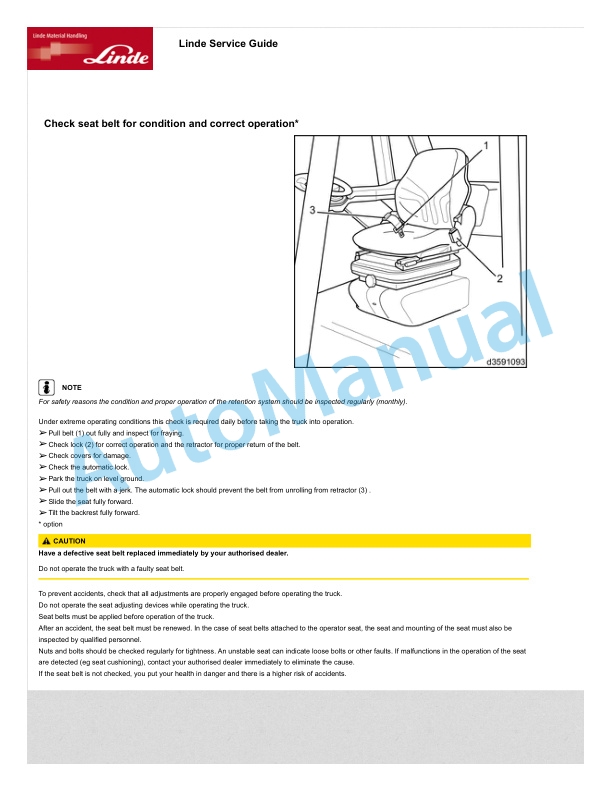

- 3.6.5.2. Check seat belt for condition and correct operation

- 3.6.5.3. Mirrors

- 3.6.5.4. Check the tyres for damage and foreign objects

- 3.6.5.5. Check the cab mountings

- 3.6.6. Chassis frame

- 3.6.6.1. Check the security of the axle clamp and drive motors

- 3.6.6.2. Clean and lubricate the steer axle

- 3.6.7. Controls

- 3.6.7.1. Brake control mechanism

- 3.6.7.2. Check the parking brake for proper operation

- 3.6.8. Electrics

- 3.6.8.1. Check the batteries.

- 3.6.9. Hydraulics

- 3.6.9.1. Check the hydraulic tank breather filter

- 3.6.9.2. Hydraulic system oil level check

- 3.6.9.3. Renew hydraulic oil of working hydraulic system

- 3.6.9.4. Renew the main hydraulic system oil return line filters

- 3.6.9.5. Check the tension of double hoses

- 3.6.10. Load lift system

- 3.6.10.1. Lubricate the mast and tilt cylinder pivots

- 3.6.10.2. Lubricate the spreader

- 3.6.10.3. Check and adjust mast chains, lubricate with chain spray

- 3.6.10.4. Renewing the lift chains (at least every 6000h, 3 years and when 2 stretch has been attained)

- 3.6.10.5. Renewing the twistlocks

- 3.6.11. Troubleshooting

- 3.6.11.1. Troubleshooting guide (Diesel engine)

- 3.6.11.2. Troubleshooting guide (Hydraulic system)

- 3.6.12. User manual feedback

- 3.6.12.1. User manual improvement record.

- 3.7. Technical data

- 4. Double container handling override function

- 4.1. Table of content

- 4.2. Operation

- 4.2.1. Double handling override

- 4.3. Installation

- 4.3.1. Fitting the kit

- 4.3.2. Electrical installation.

- 4.3.3. Hydraulic installation.

- 4.4. Schematic diagrams

- 4.5. Photographs

- 5. Load lift system lubrication supplement

- 5.1. Table of content

- 5.2. Load lift system lubrication

- 5.2.1. Scheduled maintenance intervals

- 5.2.2. Load lift device service plan

- 5.2.3. Check and adjust mast chains, lubricate with chain spray

- 5.2.4. Lubricate the spreader

- 5.2.5. Lubricate the mast and tilt cylinder pivots

- 5.2.6. Load lift device lubrication information

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

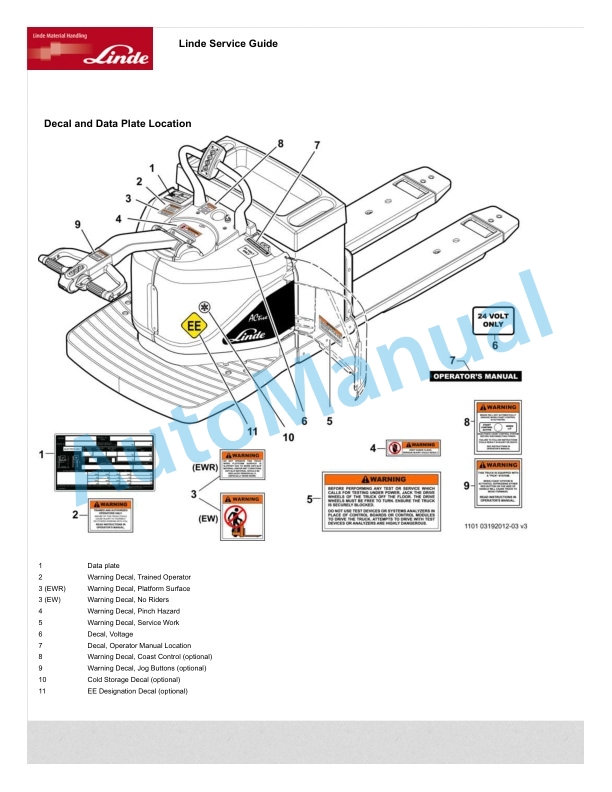

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00