Linde 335-03 – E16C, E16P, E20P Production site Xiamen Operating Instructions SN 09.11 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 09.11 and up

- Format: PDF

- Size: 43.8MB

- Number of Pages: 197

- Serial Number:

SN 09.11 and up

Category: Linde Operator Manual PDF

-

Model List:

- E16C

- E16P

- E20P

- 1. Electric forklift truckE16C03, E16P03, E20P03

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. Intended use

- 1.2.3. Impermissible use

- 1.2.4. Description of use and climatic conditions

- 1.2.5. Symbols used

- 1.2.6. Technical description

- 1.2.7. Legal requirements for marketing

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the case of tipover

- 1.3.5. Handling consumables

- 1.3.6. Qualified person

- 1.3.7. Regulations

- 1.3.8. Fit attachments

- 1.3.9. Emergency exit with attached rear window

- 1.3.10. Manually tilting the mast and lowering the fork

- 1.3.11. Do not use cables to open the overhead guard by force

- 1.4. Overview of the forklift truck

- 1.4.1. Identification plate

- 1.4.2. Overview of the forklift truck

- 1.4.3. Operating devices

- 1.4.4. Display unit

- 1.5. Operation

- 1.5.1. Preuse daily checks and maintenance

- 1.5.1.1. Preshift checks

- 1.5.1.2. Opening the overhead guard

- 1.5.1.3. Checking the battery level

- 1.5.1.4. Battery change

- 1.5.1.5. Preuse daily checks and maintenance

- 1.5.1.6. Adjusting the drivers seat

- 1.5.2. Emergency off switch

- 1.5.3. Driving

- 1.5.4. Singlepedal operation (optional)

- 1.5.5. Steering system

- 1.5.6. Brake system

- 1.5.7. Operating the lift mast and attachments using the centralised control lever (joystick)

- 1.5.8. Single lever operation of the lift mast and attachments

- 1.5.9. Working spotlights, windscreen wipers, headlights,direction indicator lights

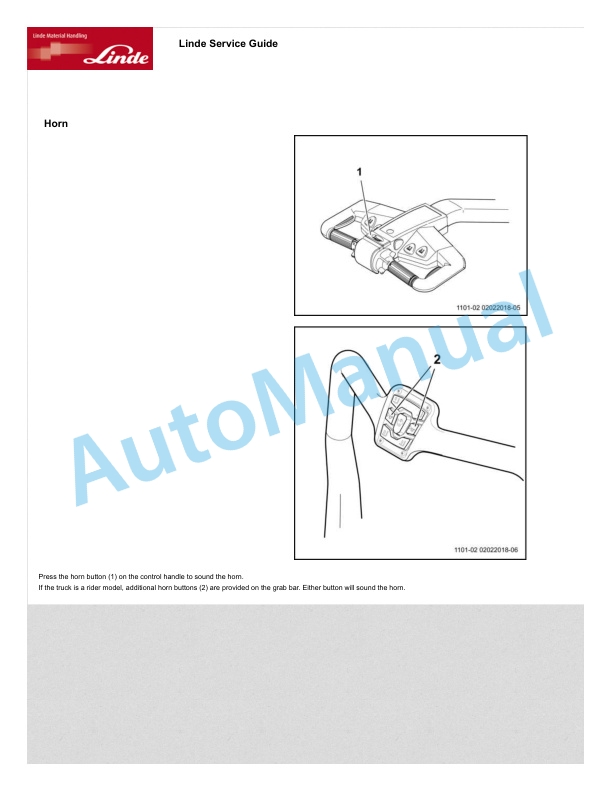

- 1.5.10. Horn, electrical system cover

- 1.5.11. Fuses

- 1.5.12. Before loading

- 1.5.13. Loading

- 1.5.14. Tow coupling

- 1.5.15. Truck transport

- 1.5.15.1. Towing regulations

- 1.5.15.2. Carrying and lifting the forklift truck

- 1.5.16. Wheel change

- 1.5.17. Use in cold stores

- 1.5.18. Truck storage

- 1.5.18.1. Taking the forklift truck out of operation

- 1.5.19. Disposal of old trucks

- 1.6. Maintenance

- 1.6.1. Summary

- 1.6.2. Working on the lift mast or front section of the fork lift truck

- 1.6.3. Inspection and maintenance parameters

- 1.6.4. Recommended lubricants

- 1.6.5. hour maintenance plan

- 1.6.6. hour maintenance plan

- 1.6.7. Reduction gearbox

- 1.6.7.1. Checking the wheel gear oil level

- 1.6.7.2. Checking whether the speed reduction gearbox is leaking

- 1.6.7.3. Cleaning both sides of the traction motor, the power steering and working hydraulic pump motor

- 1.6.7.4. Replacing the gear oil in the speed reduction gearbox

- 1.6.8. Frame and installation

- 1.6.8.1. Checking the counterweight, motors, chassis, speed reduction gearbox, overhead guard and steering axle fastenings

- 1.6.8.2. Lubricating the overhead guard pin shaft

- 1.6.8.3. Checking and lubricating other pins and swivel points

- 1.6.8.4. Checking the status of the antistatic belts (only for trucks fitted with super clean tyres)

- 1.6.9. Chassis frame

- 1.6.9.1. Check the brake system

- 1.6.9.2. Tighten the wheel nuts

- 1.6.9.3. Cleaning.lubricating the steering axle

- 1.6.9.4. Replacing the brake fluid

- 1.6.10. Operating devices

- 1.6.10.1. Checking the joystick pad

- 1.6.10.2. Checking and lubricating the pedal mechanisms, control linkage mechanisms and the overhead guard locking devices

- 1.6.11. Electrical system

- 1.6.11.1. Checking the status and tightness of the electrical cables, electrical connections and plug connectors

- 1.6.11.2. (As required) Clean the power modules of the traction and lift controls, the fans and the radiator housing with compressed air

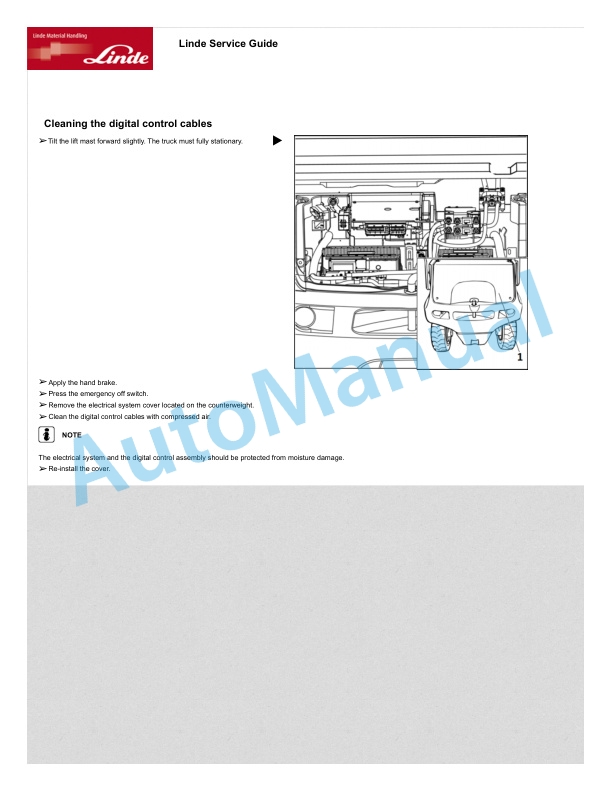

- 1.6.11.3. Cleaning the digital control cables

- 1.6.11.4. Inspect the contactor contacts, and replace if necessary

- 1.6.12. Hydraulic system

- 1.6.12.1. Check the hydraulic oil level

- 1.6.12.2. Checking the leak resistance of the working and steering hydraulic systems

- 1.6.12.3. Replacing the air, pressure and suction filters

- 1.6.12.4. Replacing the hydraulic oil (if it is Bio hydraulic oil, the Aral Forbex SE46 is 6000operating hours)

- 1.6.13. Load lift system

- 1.6.13.1. Checking the condition, tightness and function of the lift mast, lift chains and stop block

- 1.6.13.2. Adjusting the length of the lift chains, and lubricating using chain spray

- 1.6.13.3. Checking the trucks releasing and locking equipment

- 1.7. Technical data

- 1.7.1. List of technical parameter marks

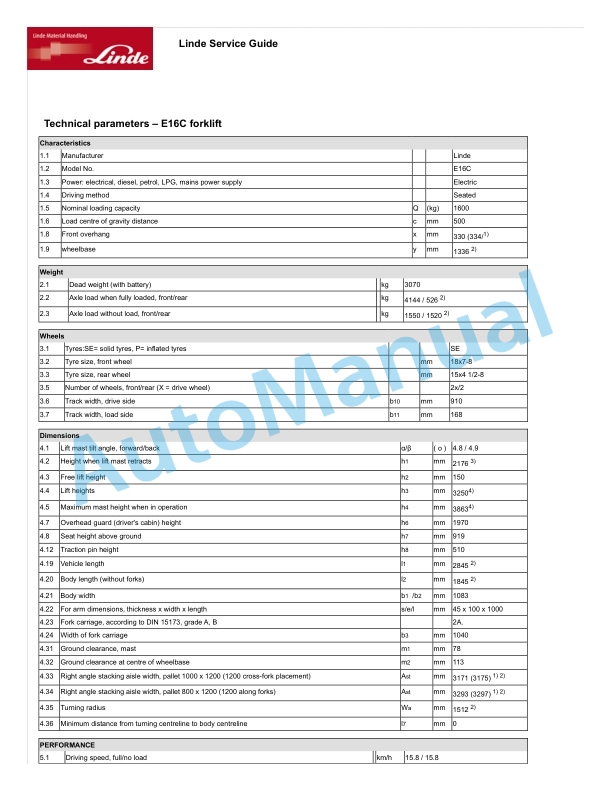

- 1.7.2. Technical parameters E16C forklift

- 1.7.3. Technical parameters E16P forklift

- 1.7.4. Technical parameters E20P forklift

- 1.7.5. Lift mast data

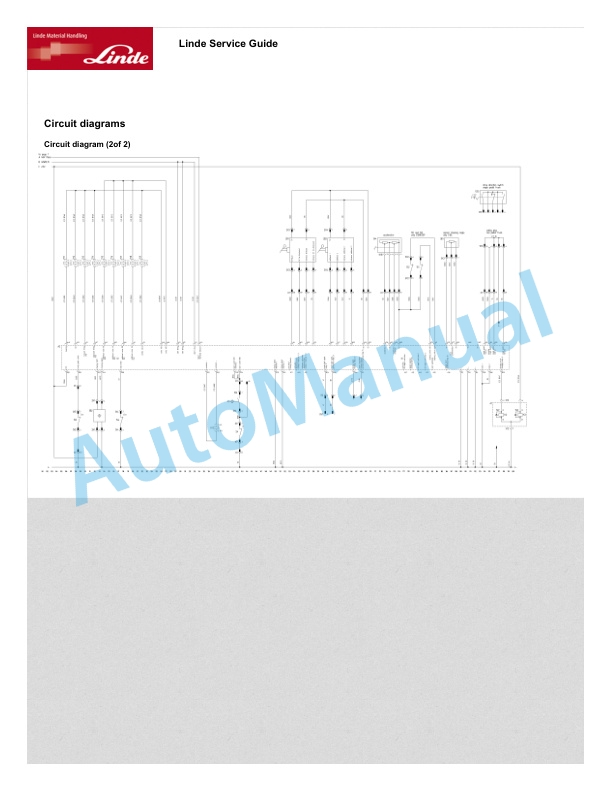

- 1.8. Circuit diagrams

- 1.8.1. Electrical circuit diagram

- 1.8.1.1. Circuit diagrams

- 1.8.1.2. Circuit diagrams

- 1.8.1.3. Circuit diagrams

- 1.8.2. Hydraulic oil diagram

- 1.8.2.1. Working and steering hydraulic system circuit diagrams

- 1.8.2.2. Working and steering hydraulic system circuit diagrams

- 2. Operating Instruction (DataLogger)

Rate this product

You may also like

Linde Operator Manual PDF

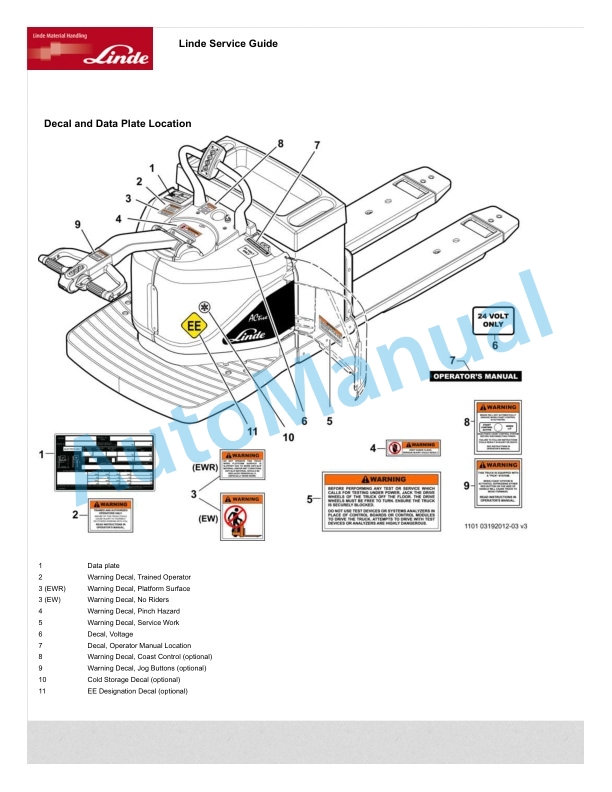

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00