Linde 351-05 – H20D EX, H25D EX, H30D EX Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 29.5MB

- Number of Pages: 220

Category: Linde Operator Manual PDF

-

Model List:

- H20D EX

- H25D EX

- H30D EX

- 1. Diesel truck with Kubota engineH20.25.30D05

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your truck

- 1.2.2. Intended use

- 1.2.3. Impermissible use

- 1.2.4. Basic information on explosion protection

- 1.2.5. Description of use and climatic conditions

- 1.2.6. Symbols used

- 1.2.7. Technical description

- 1.2.8. Receiving the industrial truck

- 1.2.9. Legal requirements for placing on the market

- 1.3. Safety

- 1.3.1. Safety regulations

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the case of tipover

- 1.3.5. Handling consumables

- 1.3.6. Qualified person

- 1.3.7. Regulations

- 1.4. Overview

- 1.4.1. Identification plates

- 1.4.2. Overview

- 1.4.3. Operating devices

- 1.4.4. Display unit

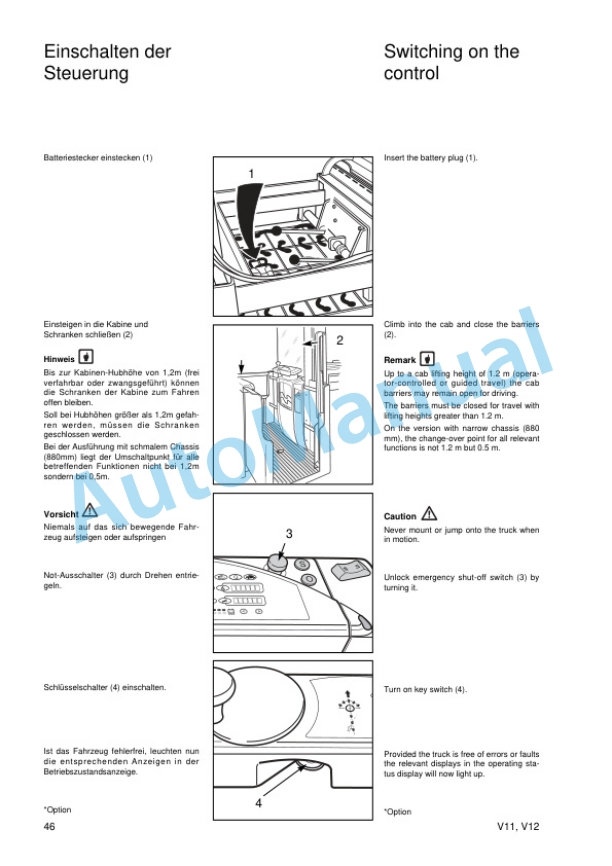

- 1.5. Operation

- 1.5.1. Runningin instructions

- 1.5.2. Service plan before initial commissioning

- 1.5.3. Preshift checks

- 1.5.3.1. Overview of tests

- 1.5.3.2. Opening the engine cover

- 1.5.3.3. Checking the fuel level

- 1.5.3.4. Refuelling

- 1.5.3.5. Checking the engine oil level

- 1.5.3.6. Checking the tyre pressure

- 1.5.3.7. Applying the seat belt

- 1.5.3.8. Adjusting the operator seat

- 1.5.4. Dualpedal operation

- 1.5.4.1. Starting the motor

- 1.5.4.2. Cold start

- 1.5.4.3. Switching off the motor

- 1.5.4.4. Malfunctions during operation

- 1.5.4.5. Traction

- 1.5.5. Singlepedal operation

- 1.5.5.1. Starting the motor

- 1.5.5.2. Cold start

- 1.5.5.3. Switching off the motor

- 1.5.5.4. Malfunctions during operation

- 1.5.5.5. Traction

- 1.5.6. Steering

- 1.5.7. Service brake

- 1.5.8. Parking brake

- 1.5.9. Lifting device and attachments (centrallever control)

- 1.5.10. Lifting device and attachments (singlelever control)

- 1.5.11. Operating the switch panel

- 1.5.12. Heating system

- 1.5.13. Working with a load

- 1.5.13.1. Before lifting a load

- 1.5.13.2. Adjusting the fork spread

- 1.5.13.3. Loading

- 1.5.13.4. Travel with a load

- 1.5.13.5. Unloading

- 1.5.13.6. Before leaving the truck

- 1.5.13.7. Trailer coupling

- 1.5.14. Loading.transporting

- 1.5.14.1. Transport with lorry or lowbed semitrailer

- 1.5.14.2. Hoisting the truck with a crane

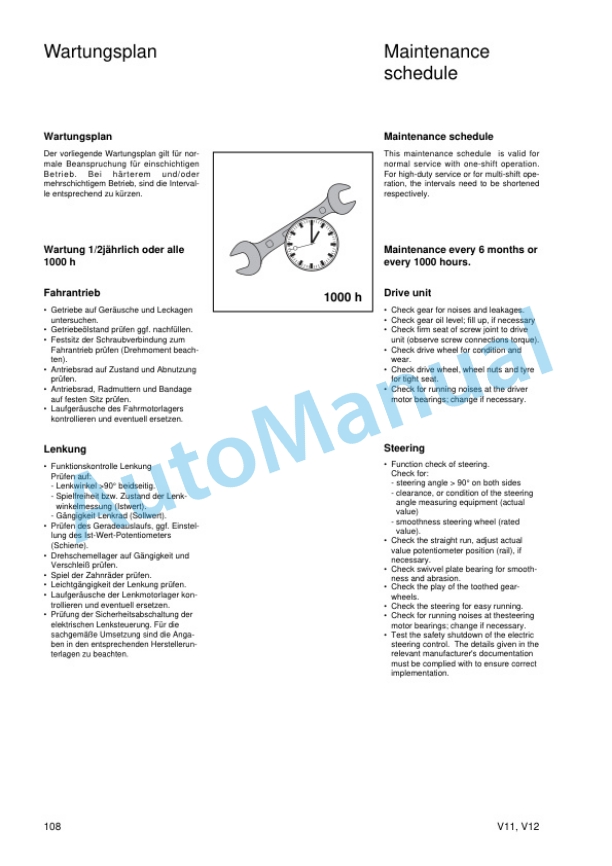

- 1.6. Maintenance

- 1.6.1. General information

- 1.6.2. Work on the mast and on the front part of the truck

- 1.6.3. Inspection and maintenance data

- 1.6.4. Recommendations for consumables

- 1.6.5. Inspection and maintenance overview

- 1.6.5.1. hour service plan

- 1.6.5.2. hour service plan

- 1.6.5.3. hour service plan

- 1.6.5.4. hour service plan

- 1.6.5.5. hour service plan

- 1.6.5.6. hour service plan

- 1.6.5.7. hour service plan

- 1.6.5.8. hour service plan

- 1.6.5.9. hour service plan

- 1.6.5.10. Service plan according to time

- 1.6.6. Engine

- 1.6.6.1. Cleaning the air filter

- 1.6.6.2. Renewing the safety element (option)

- 1.6.6.3. Checking the dust discharge valve

- 1.6.6.4. Cleaning the prefilter (option)

- 1.6.6.5. Regenerating the particulate filter

- 1.6.6.6. Checking the coolant level

- 1.6.6.7. Clean and check the radiator and hydraulic oil cooler for leaks

- 1.6.6.8. Draining the fuel system water trap

- 1.6.6.9. Changing the engine oil

- 1.6.6.10. Changing the fuel filter

- 1.6.6.11. Renew the engine oil filter cartridge

- 1.6.6.12. Renew the fuel system water preseparator

- 1.6.6.13. Bleeding the fuel system

- 1.6.6.14. Check the mounting of the compact axle at the engine

- 1.6.6.15. Changing the air filter element, checking the vacuumoperated switch

- 1.6.6.16. Check the engine mounting for condition and tightness

- 1.6.6.17. Checking the air intake and exhaust pipes for leaks

- 1.6.6.18. Checking the Vbelt

- 1.6.6.19. Tightening the Vbelt

- 1.6.6.20. Renew the Vbelt

- 1.6.6.21. Renew the engine mountings

- 1.6.7. Chassis, bodywork and fittings

- 1.6.7.1. Cleaning the forklift truck

- 1.6.7.2. Check seat belt for condition and proper operation

- 1.6.7.3. Check the mounting of the engine, counterweight, overhead guard, steering axle, tilt cylinder and wheel drives for tightness

- 1.6.7.4. Check and oil other pivots and joints

- 1.6.8. Chassis frame

- 1.6.8.1. Changing wheels

- 1.6.8.2. Tighten the wheel fasteners

- 1.6.8.3. Checking the tyres for damage and foreign objects

- 1.6.8.4. Lubricate the steer axle, mast and tilt cylinder bearings

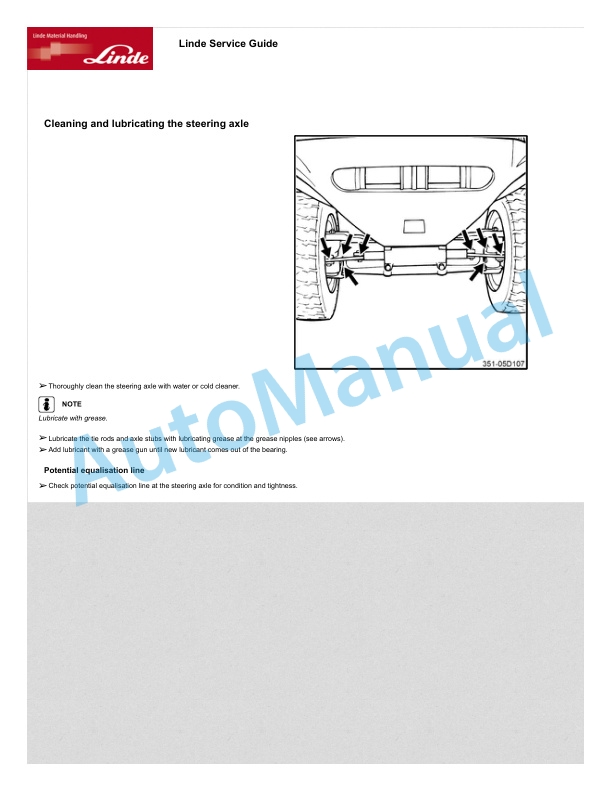

- 1.6.8.5. Cleaning and lubricating the steering axle

- 1.6.9. Operating devices

- 1.6.9.1. Check and oil the pedals, travel control and engine control linkages

- 1.6.9.2. Check the parking brake handle and cable

- 1.6.9.3. Check the parking brake

- 1.6.10. Electrics

- 1.6.10.1. Checking electric cables and connections for condition and tightness

- 1.6.10.2. Checking the condition of pressuretight housings

- 1.6.10.3. Battery condition check

- 1.6.11. Hydraulics

- 1.6.11.1. Checking the hydraulic oil level

- 1.6.11.2. Check the pretension of double hoses if attachments are fitted

- 1.6.11.3. Check the hydraulic system, compact axle, pumps, valves and lines for leaks

- 1.6.11.4. Renew the pressure filter

- 1.6.11.5. Renew the suction filter

- 1.6.11.6. Changing the breather filter

- 1.6.11.7. Changing the hydraulic oil

- 1.6.12. Load lift system

- 1.6.12.1. Grease the mast and tilt cylinder bearings

- 1.6.12.2. Cleaning and spraying the mast chain

- 1.6.12.3. Clean and lubricate the sideshift (option), check the fasteners

- 1.6.12.4. Checking the load fork

- 1.6.12.5. Check the mast, lift chains and stops for condition, mounting and operation

- 1.6.12.6. Adjust the lift chain length (standard mast)

- 1.6.12.7. Adjust the lift chain length (Duplex and Triplex masts)

- 1.6.13. Troubleshooting

- 1.6.13.1. Fuses

- 1.6.13.2. Emergency exit for trucks with rear windscreen

- 1.6.13.3. Towing instructions

- 1.6.13.4. Taking the truck out of operation

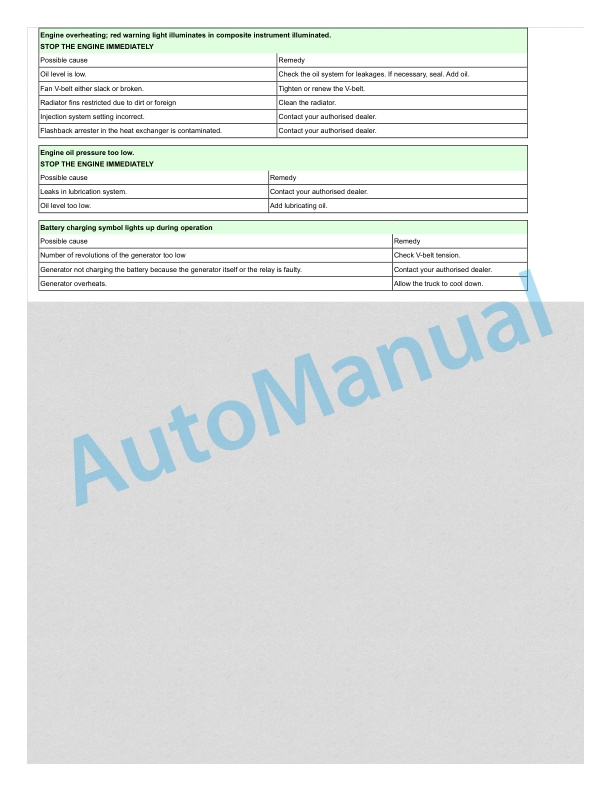

- 1.6.13.5. Troubleshooting guide (diesel engine)

- 1.6.13.6. Troubleshooting guide (hydraulic system)

- 1.7. Technical data

- 1.7.1. Technical data

- 1.7.2. Load diagrams and lift mast data

- 1.7.3. Noise emission levels

- 2. Operating Instruction (DataLogger)

Rate this product

You may also like

Linde Operator Manual PDF

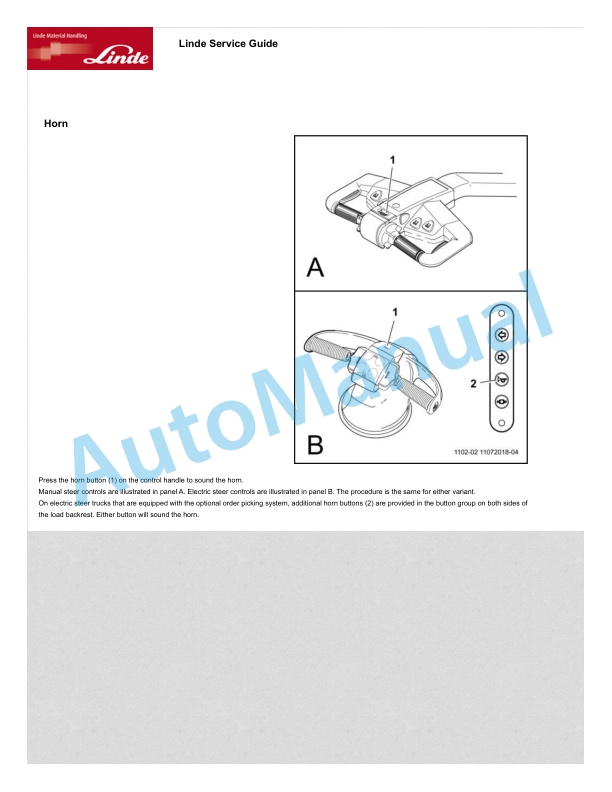

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00