Linde 351-05 – H25D, H25T, H30D Production site Xiamen Operating Instructions SN 07.08 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 07.08 and up

- Format: PDF

- Size: 38.7MB

- Number of Pages: 296

- Serial Number:

SN 07.08 and up

-

Model List:

- H25D

- H25T

- H30D

- 1. Diesel truckH25D05, H30D05

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your truck

- 1.2.2. Proper use

- 1.2.3. Impermissible use

- 1.2.4. Description of use and climatic condition

- 1.2.5. Modifications to the truck

- 1.2.6. Symbols used

- 1.2.7. Technical description

- 1.2.8. Truck takeover

- 1.2.9. Legal requirements for marketing

- 1.2.10. Service plan before initial commissioning

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the case of tipover

- 1.3.5. Handling consumables

- 1.3.6. Competent person

- 1.3.7. Operation of industrial trucks in plant area

- 1.3.8. Periodic safety inspection

- 1.4. Overview

- 1.4.1. Type plates

- 1.4.2. General view

- 1.4.3. Controls and indicators

- 1.4.4. Composite instrument

- 1.5. Operation

- 1.5.1. Runningin instructions

- 1.5.2. Preshiftchecks

- 1.5.3. Pre shift checks

- 1.5.3.1. Opening the engine cover

- 1.5.3.2. Checking the fuel level

- 1.5.3.3. Filling with fuel

- 1.5.3.4. Checking the engine oil level

- 1.5.3.5. Checking the tyre pressure

- 1.5.3.6. Applying the seat belt

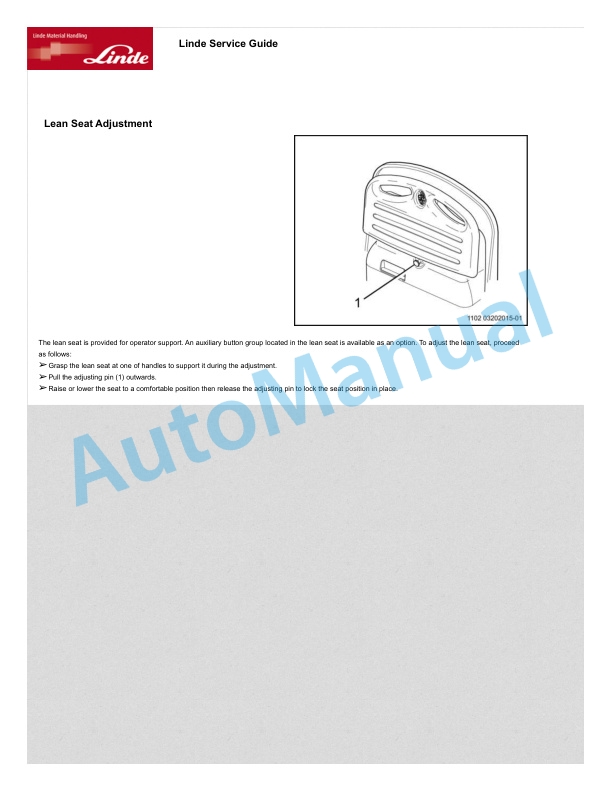

- 1.5.3.7. Adjusting the operator seat

- 1.5.4. Two pedal operation

- 1.5.4.1. Starting the engine

- 1.5.4.2. Cold start (option)

- 1.5.4.3. Stopping the engine

- 1.5.4.4. Malfunctions during operation

- 1.5.4.5. Driving

- 1.5.5. Single pedal operation

- 1.5.5.1. Starting the engine

- 1.5.5.2. Cold start (option)

- 1.5.5.3. Stopping the engine

- 1.5.5.4. Malfunctions during operation

- 1.5.5.5. Driving

- 1.5.6. Steering

- 1.5.7. Service brake

- 1.5.8. Parking brake

- 1.5.9. Lifting device and attachments (centrallever control)

- 1.5.10. Lifting device and attachments (singlelever control)

- 1.5.11. Windscreen wipers, lighting, working lights, Direction indicators (options)

- 1.5.12. Heater (option)

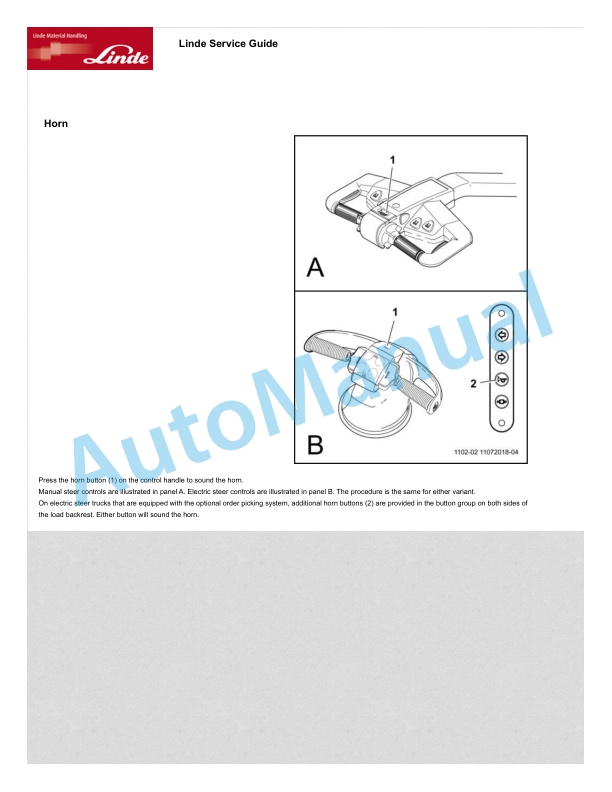

- 1.5.13. Horn

- 1.5.14. Data logger (option)

- 1.5.15. Working with loads

- 1.5.15.1. Before lifting a load

- 1.5.15.2. Adjusting the fork spread

- 1.5.15.3. Picking up a load

- 1.5.15.4. Travel with a load

- 1.5.15.5. Unloading

- 1.5.15.6. Before leaving the truck

- 1.5.15.7. Trailer coupling

- 1.5.16. Loading.Transporting

- 1.5.16.1. Transport with a lorry or lowloader

- 1.5.16.2. Hoisting the truck with a crane

- 1.5.16.3. Hoisting the truck with the eyebolts (option)

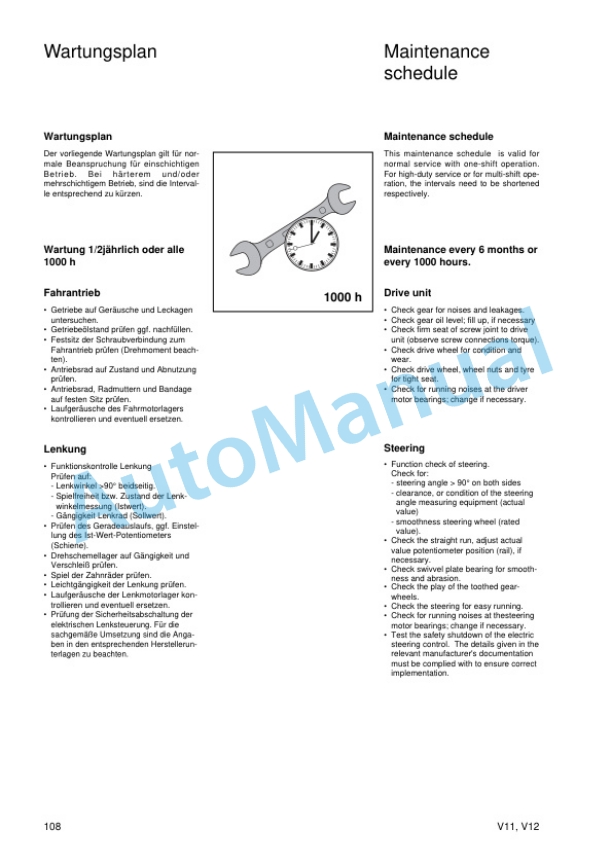

- 1.6. Maintenance

- 1.6.1. General information

- 1.6.2. Work on the mast and on the front part of the truck

- 1.6.3. Inspection and maintenance data

- 1.6.4. Recommendations for consumables

- 1.6.5. Inspection and maintenance overview

- 1.6.5.1. h Service plan

- 1.6.5.2. h service plan

- 1.6.5.3. h service plan

- 1.6.5.4. h service plan

- 1.6.5.5. h service plan

- 1.6.5.6. h service plan

- 1.6.5.7. h service plan

- 1.6.6. Engine

- 1.6.6.1. Cleaning the air filter

- 1.6.6.2. Renewing the safety element (option)

- 1.6.6.3. Checking the dust discharge valve

- 1.6.6.4. Cleaning the prefilter (option)

- 1.6.6.5. Regenerate the soot particulate filter variant I (option)

- 1.6.6.6. Regenerate the soot particulate filter variant II (option)

- 1.6.6.7. Clean and check the radiator and hydraulic oil cooler for leaks

- 1.6.6.8. Drain the fuel system water preseparator

- 1.6.6.9. Renew the engine oil

- 1.6.6.10. Renew the fuel filter

- 1.6.6.11. Renew the engine oil filter cartridge

- 1.6.6.12. Renew the fuel system water preseparator

- 1.6.6.13. Bleed the fuel system

- 1.6.6.14. Check and adjust valve clearance

- 1.6.6.15. Check the mounting of the compact axle at the engine

- 1.6.6.16. Checking the soot particulate filter system (option)

- 1.6.6.17. Renew the air filter element, check the vacuum switch

- 1.6.6.18. Check the engine mounting for condition and tightness

- 1.6.6.19. Check the air intake and exhaust pipes for leaks

- 1.6.6.20. Check the soot particulate filter system (option) (variant II)

- 1.6.6.21. Clean the fuel pump strainer

- 1.6.6.22. Check the Vbelt

- 1.6.6.23. Tighten the Vbelt

- 1.6.6.24. Check and adjust the timing belt and tension pulley

- 1.6.6.25. Check crankcase pressure vent valve

- 1.6.6.26. Check the injection nozzles

- 1.6.6.27. Renew the Vbelt

- 1.6.6.28. Renew the timing belt and tension pulley

- 1.6.6.29. Renew the injection nozzles

- 1.6.6.30. Renew the engine mountings

- 1.6.7. Chassis, bodywork and fittings

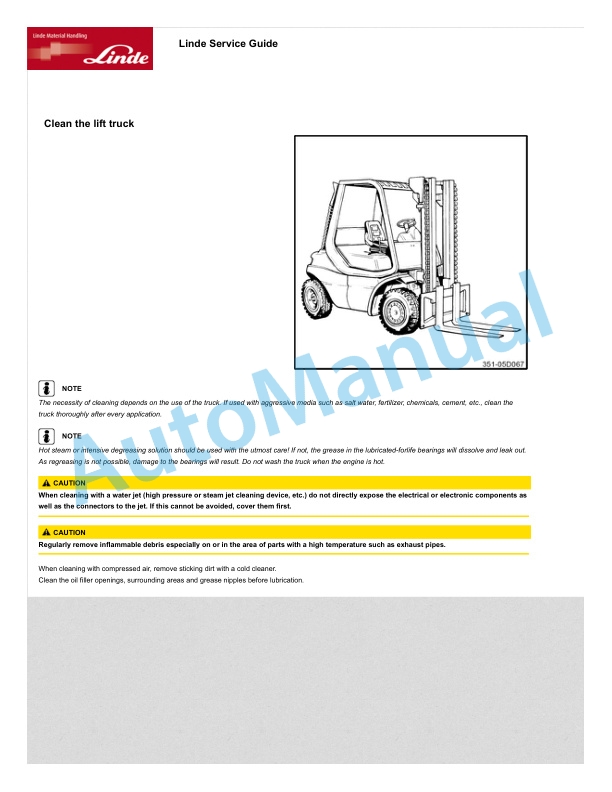

- 1.6.7.1. Clean the lift truck

- 1.6.7.2. Check seat belt for condition and proper operation

- 1.6.7.3. Check the mounting of the engine, counterweight, overhead guard, steering axle, tilt cylinder and wheel drives for tightness

- 1.6.7.4. Check and oil other pivots and joints

- 1.6.8. Undercarriage

- 1.6.8.1. Wheel change

- 1.6.8.2. Tighten the wheel fasteners

- 1.6.8.3. Check the tyres for damage and foreign objects

- 1.6.8.4. Lubricate the steer axle, mast and tilt cylinder bearings

- 1.6.8.5. Clean and grease the steering axle

- 1.6.9. Controls

- 1.6.9.1. Check and oil the pedals, travel control and engine control linkages

- 1.6.9.2. Check the parking brake handle and cable

- 1.6.9.3. Check the parking brake

- 1.6.10. Electrics

- 1.6.10.1. Check electric cables, cable connectors and connections for condition and tightness

- 1.6.10.2. Battery Check condition, electrolyte level and specific gravity

- 1.6.11. Hydraulics

- 1.6.11.1. Check the hydraulic system oil level

- 1.6.11.2. Check the pretension of double hoses if attachments are fitted

- 1.6.11.3. Check the hydraulic system, compact axle, pumps, valves and lines for leaks

- 1.6.11.4. Renew the pressure filter

- 1.6.11.5. Renew the suction filter

- 1.6.11.6. Renew the breather filter

- 1.6.11.7. Renew the hydraulic oil

- 1.6.12. Load lift system

- 1.6.12.1. Grease the mast and tilt cylinder bearings

- 1.6.12.2. Cleaning and spraying the mast chain

- 1.6.12.3. Clean and lubricate the sideshift (option), check the fasteners

- 1.6.12.4. Check the forks and fork quickreleases

- 1.6.12.5. Check the mast, lift chains and stops for condition, mounting and operation

- 1.6.12.6. Adjust the lift chain length (standard mast)

- 1.6.12.7. Adjust the lift chain length (Duplex and Triplex masts)

- 1.6.13. Troubleshooting

- 1.6.13.1. Fuses

- 1.6.13.2. Fuses, soot particulate filter system (option)

- 1.6.13.3. Emergency exit for trucks with rear windscreen

- 1.6.13.4. Towing instructions

- 1.6.13.5. Taking the truck out of operation

- 1.6.13.6. Troubleshooting guide (Diesel engine)

- 1.6.13.7. Troubleshooting guide (hydraulic system)

- 1.7. Technical data

- 1.7.1. Type sheet H 25

- 1.7.2. Type sheet H 30

- 1.7.3. Load diagrams and lift mast data

- 1.7.4. Noise emission levels

- 1.8. Circuit diagrams

- 1.8.1. Wiring diagrams

- 1.8.1.1. Basic equipment

- 1.8.1.2. Wiring diagram (lighting)

- 1.8.2. Hydraulic diagrams

- 1.8.2.1. Traction, working and steering hydraulics

- 2. Operating Instruction (DataLogger)

- 3. Operating Instruction (T)

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

Linde Operator Manual PDF