- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 356-10 – C400 Operating Instructions SN 03.06 and up SN up to 10.13

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 03.06 and up SN up to 10.13

- Format: PDF

- Size: 31.3MB

- Number of Pages: 290

- Serial Number:

SN 03.06 and up SN up to 10.13

Category: Linde Operator Manual PDF

-

Model List:

- C400

- 1. Linde Forklift Truck356_C400

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your 356 Forklift Truck

- 1.2.2. Technical Description

- 1.2.3. Intended use

- 1.2.4. Improper use

- 1.2.5. Symbols Used

- 1.2.6. Commissioning

- 1.2.7. Truck Takeover

- 1.2.8. EC declaration of conformity

- 1.3. Safety

- 1.3.1. Safety Rules

- 1.3.1.1. Safety Rules

- 1.3.1.2. Handling Fuel, Lubricants and Coolant

- 1.3.1.3. Residual risks

- 1.3.1.4. Stability

- 1.4. Overview

- 1.4.1. General view of Truck

- 1.4.2. Type Plates

- 1.4.3. Controls

- 1.4.4. Controls, Switches, Gauges and Warning Lights

- 1.5. Operation

- 1.5.1. Wheel removal drive axle

- 1.5.2. Wheel removal steer axle

- 1.5.3. Wheel assembly inspection

- 1.5.4. Wheel refitting drive axle

- 1.5.5. Wheel refitting steer axle

- 1.5.6. Examples of restraining devices

- 1.5.7. Mirrors

- 1.5.8. Cab door opening and closing

- 1.5.9. Emergency exit

- 1.5.10. Opening the bonnet

- 1.5.11. Opening the transmission cover

- 1.5.12. Opening the cabin rear compartment door

- 1.5.13. Opening the working hydraulic system oil tank cover

- 1.5.14. Opening the brake hydraulic system oil tank cover

- 1.5.15. Opening the battery and air filter compartment door

- 1.5.16. Opening the radiator grille

- 1.5.17. Opening the fuse box cover

- 1.5.18. Isolating the battery

- 1.5.19. Check tyre condition and pressure

- 1.5.20. Tighten wheel nuts

- 1.5.21. Check working hydraulic system oil level

- 1.5.22. Check brake hydraulic system oil level

- 1.5.23. Check battery condition

- 1.5.24. Check the brake relay system oil level

- 1.5.25. Check coolant level in radiator header tank

- 1.5.26. Check engine oil level

- 1.5.27. Check windscreen washer reservoir fluid level

- 1.5.28. Checking the fuel level

- 1.5.29. Filling fuel

- 1.5.30. Check the transmission oil level

- 1.5.31. Checking the handler for visible damage

- 1.5.32. Checking the twistlocks and warning lights for proper operation

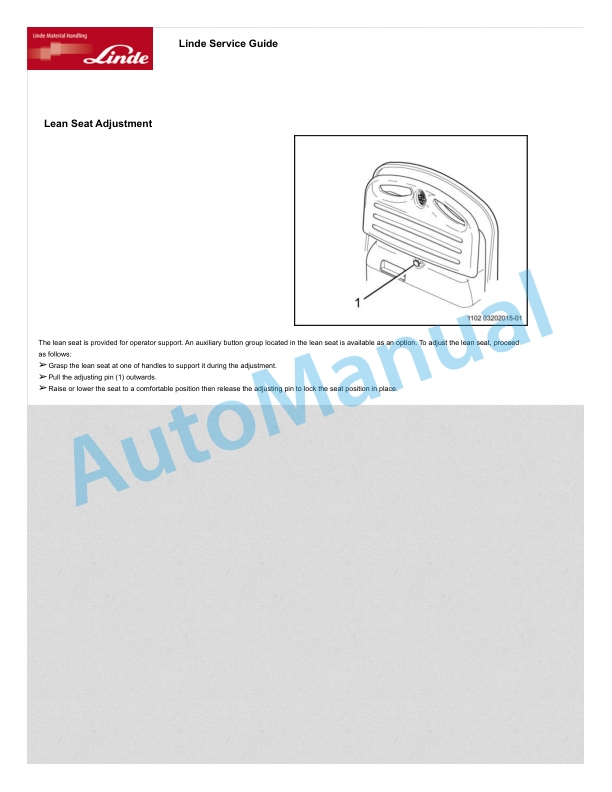

- 1.5.33. Adjusting the drivers seat

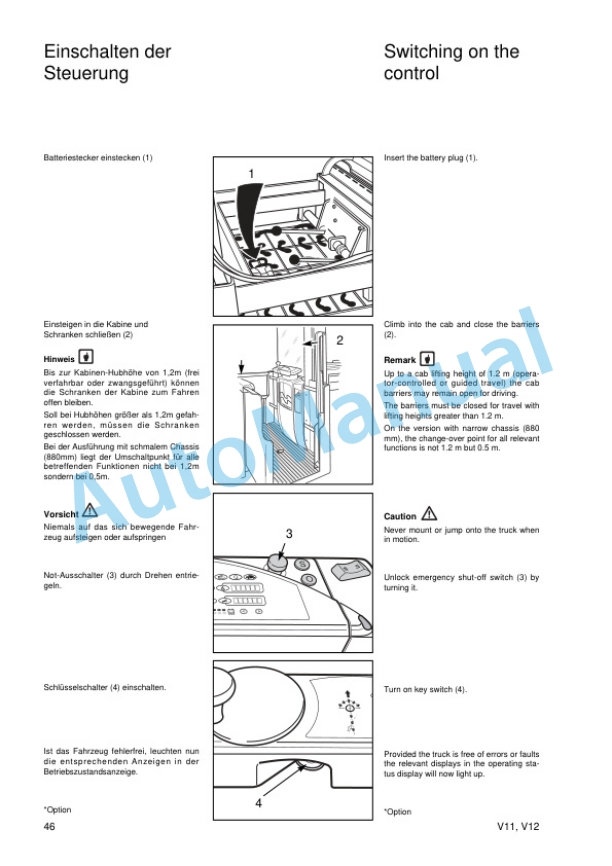

- 1.5.34. Normal start

- 1.5.35. Malfunctions during operation

- 1.5.36. Overload safety switch

- 1.5.37. Startup indications

- 1.5.38. Truck status display

- 1.5.39. Gear shift control

- 1.5.40. Stopping the truck

- 1.5.41. Operating transmission dump

- 1.5.42. Steering

- 1.5.43. Service brake

- 1.5.44. Parking brake

- 1.5.45. Automatic Parking brake operation

- 1.5.46. Turning on the lights

- 1.5.47. Operating the hazard warning lights

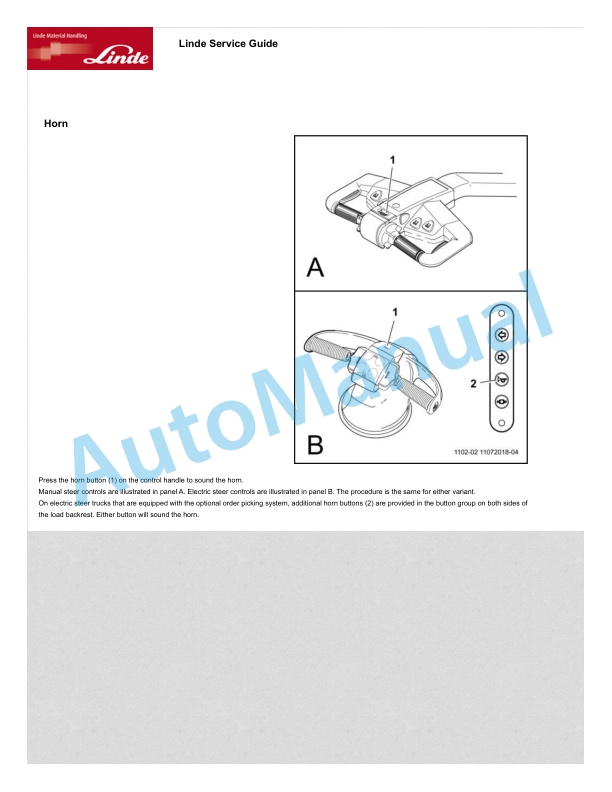

- 1.5.48. Operating the horn

- 1.5.49. Turning on the front windscreen wiper

- 1.5.50. To operate the cab preheater system

- 1.5.51. Fuses

- 1.5.52. Mast and handler controls

- 1.5.53. Spreader

- 1.5.54. Operating the twistlocks

- 1.5.55. Before lifting a load

- 1.5.56. Picking up a container

- 1.5.57. Travelling with loads

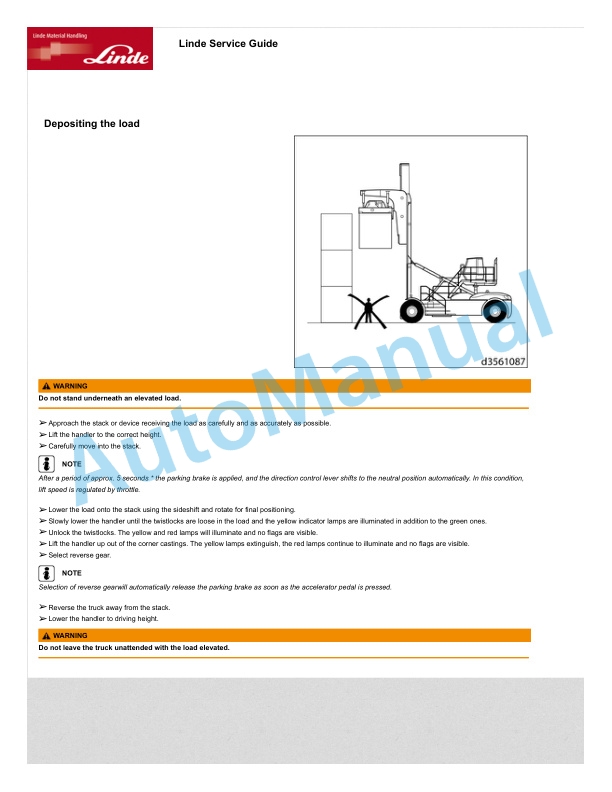

- 1.5.58. Depositing the load

- 1.5.59. Parking the truck

- 1.5.60. Trailer coupling

- 1.5.61. Towing

- 1.6. Maintenance

- 1.6.1. General remarks

- 1.6.1.1. Wheel removal drive axle

- 1.6.1.2. Wheel removal steer axle

- 1.6.1.3. Wheel assembly inspection

- 1.6.1.4. Wheel refitting drive axle

- 1.6.1.5. Wheel refitting steer axle

- 1.6.1.6. Examples of restraining devices

- 1.6.1.7. Taking the truck out of operation

- 1.6.1.8. General information

- 1.6.1.9. Work on the mast, handler and the front part of the truck

- 1.6.1.10. Hoisting the truck

- 1.6.1.11. Inspection and maintenance data

- 1.6.1.12. Fuel and oil recommendations

- 1.6.1.13. Check the condition of structured components

- 1.6.1.14. Truck welds inspection

- 1.6.2. Inspection and maintenance schedule

- 1.6.2.1. General overall check

- 1.6.2.2. Daily checks

- 1.6.2.3. As required Service plan

- 1.6.2.4. h service plan

- 1.6.2.5. h service plan

- 1.6.2.6. h service plan

- 1.6.2.7. h service plan

- 1.6.2.8. h service plan

- 1.6.2.9. h service plan

- 1.6.2.10. h service plan

- 1.6.3. Engine

- 1.6.3.1. Check engine oil level

- 1.6.3.2. Change the engine oil

- 1.6.3.3. Change the engine oil filters

- 1.6.3.4. Drain the fuel filter

- 1.6.3.5. Change the fuel filter

- 1.6.3.6. Prime the fuel system

- 1.6.3.7. Check the air filter

- 1.6.3.8. Change the air filter safety element

- 1.6.3.9. Change the air filter element check the vacuum switch

- 1.6.3.10. Check the cooling system for leaks and tightness

- 1.6.3.11. Flush the cooling system

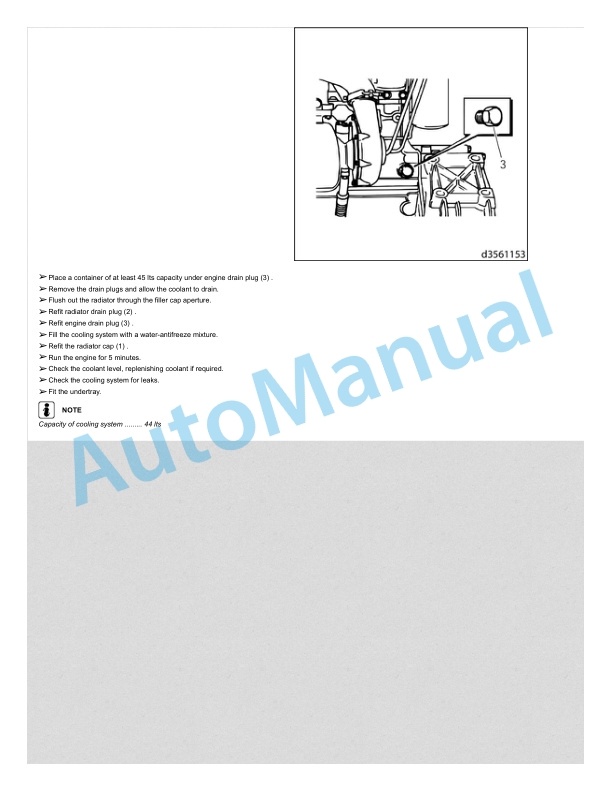

- 1.6.3.12. Change engine coolant

- 1.6.3.13. Check drive belt tension

- 1.6.3.14. Check the fan drive idler pulley assembly

- 1.6.3.15. Fan hub, belt driven

- 1.6.3.16. Clean the radiator and check for leaks

- 1.6.3.17. Check the engine mountings

- 1.6.3.18. Check the intake and exhaust systems for leaks and tightness

- 1.6.3.19. Check the vibration damper

- 1.6.3.20. Check the turbocharger

- 1.6.3.21. Check valve clearances

- 1.6.4. Gearbox

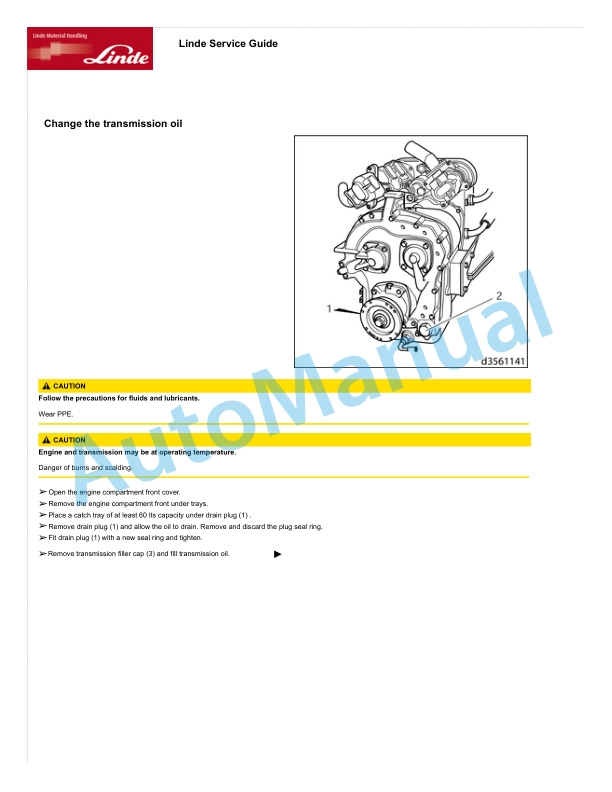

- 1.6.4.1. Change the transmission oil

- 1.6.4.2. Change transmission oil filters

- 1.6.4.3. Check transmission mountings

- 1.6.5. Chassis, bodywork and fittings

- 1.6.5.1. Clean the truck

- 1.6.5.2. Check seat belt for condition and correct operation

- 1.6.5.3. Tighten wheel nuts

- 1.6.5.4. Check the tyres for damage and foreign objects

- 1.6.5.5. Check the cab mountings

- 1.6.5.6. Truck welds inspection

- 1.6.6. Chassis frame

- 1.6.6.1. Check steer axle hub oil level

- 1.6.6.2. Change the steer axle hub differential oil

- 1.6.6.3. Clean and lubricate steer axle, check the mounting

- 1.6.6.4. Check the drive axle centre differential oil level

- 1.6.6.5. Change the drive axle centre differential oil

- 1.6.6.6. Check the drive axle hub differential oil level

- 1.6.6.7. Change the drive axle hub differential oil

- 1.6.6.8. Check the drive axle mounting

- 1.6.6.9. Check and lubricate the drive shaft

- 1.6.6.10. Check and adjust hub bearings

- 1.6.7. Controls

- 1.6.7.1. Check the steering lock

- 1.6.7.2. Check the parking brake condition and mounting

- 1.6.7.3. Check the brake disc wear

- 1.6.8. Electrics

- 1.6.8.1. Check battery condition

- 1.6.8.2. Check electric cables, connectors and connections for conditionand tightness

- 1.6.9. Hydraulics

- 1.6.9.1. Check the hydraulic system, pumps, valves and lines

- 1.6.9.2. Change the working hydraulic system oil suction filters

- 1.6.9.3. Change the hydraulic oil working system

- 1.6.9.4. Change the brake hydraulic system oil suction filter

- 1.6.9.5. Change the brake hydraulic system oil pressure filter

- 1.6.9.6. Change the brake hydraulic system oil

- 1.6.10. Load lift system

- 1.6.10.1. Check condition of mast, handler, gantry and mountings

- 1.6.10.2. Check and lubricate the mast and tilt cylinder pivot pins

- 1.6.10.3. Check and lubricate the mast main and side thrust bearings

- 1.6.10.4. Check the condition and security of the lift chains

- 1.6.10.5. Check and adjust the lift chain length and lubricate with chainspray

- 1.6.10.6. Change the lift chains

- 1.6.10.7. Check and lubricate gantry main and side thrust bearings

- 1.6.10.8. Check and lubricate the twistlocks

- 1.6.10.9. Change the twistlocks

- 1.6.10.10. Check and lubricate the handler sliding bearings

- 1.6.10.11. Lubricate the locking cylinder pin on the handler

- 1.6.10.12. Check and lubricate the handler suspension and hydraulic cylinderbearings

- 1.6.11. Special equipment, accessories

- 1.6.11.1. Check the central lubrication lubricating points

- 1.6.11.2. Fill central lubrication canister with grease

- 1.6.12. Trouble shooting

- 1.6.12.1. Troubleshooting guide Diesel engine

- 1.6.12.2. Troubleshooting guide hydraulic system

- 1.6.13. User manual feedback

- 1.6.13.1. User manual improvement record.

- 1.7. Technical Data

- 1.7.1. Datasheet

- 1.7.1.1. Technical Datasheet

- 1.7.1.2. Technical Datasheet

Rate this product

You may also like

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF