Linde 358-01 – HT120, HT150, HT160, HT180 Production site Xiamen Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 26.2MB

- Number of Pages: 217

-

Model List:

- HT120

- HT150

- HT160

- HT180 Production site Xiamen

- 1. Diesel truckH120 H160

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your Linde truck

- 1.2.2. Technical Description

- 1.2.3. Intended use

- 1.2.4. Improper use

- 1.2.5. Symbols Used

- 1.2.6. Commissioning

- 1.2.7. Truck takeover

- 1.2.8. EC declaration of conformity

- 1.3. Safety

- 1.3.1. Safety Rules

- 1.3.2. Do not operate with guards removed

- 1.3.3. Park Brake

- 1.3.4. Malfunctions

- 1.3.5. Handling Fuel, Lubricants and Coolant

- 1.3.6. Residual risks

- 1.3.7. Stability

- 1.4. Overview

- 1.4.1. General view of Truck

- 1.4.2. Type plates

- 1.4.3. Controls and indicators

- 1.4.4. Gauges, switches and warning lights

- 1.5. Operation

- 1.5.1. Cab door opening and closing

- 1.5.2. Cab interior light

- 1.5.3. Opening the engine cover

- 1.5.4. Opening the cabin rear compartment door

- 1.5.5. Working hydraulic filter panel

- 1.5.6. Battery access

- 1.5.7. Adjusting the drivers seat

- 1.5.8. Check battery condition

- 1.5.9. Tyres check condition and pressure

- 1.5.10. Tighten the wheel nuts

- 1.5.11. Hydraulic system oil level check

- 1.5.12. Engine oil level check

- 1.5.13. Checking the fuel level

- 1.5.14. Transmission oil level check

- 1.5.15. Coolant level check

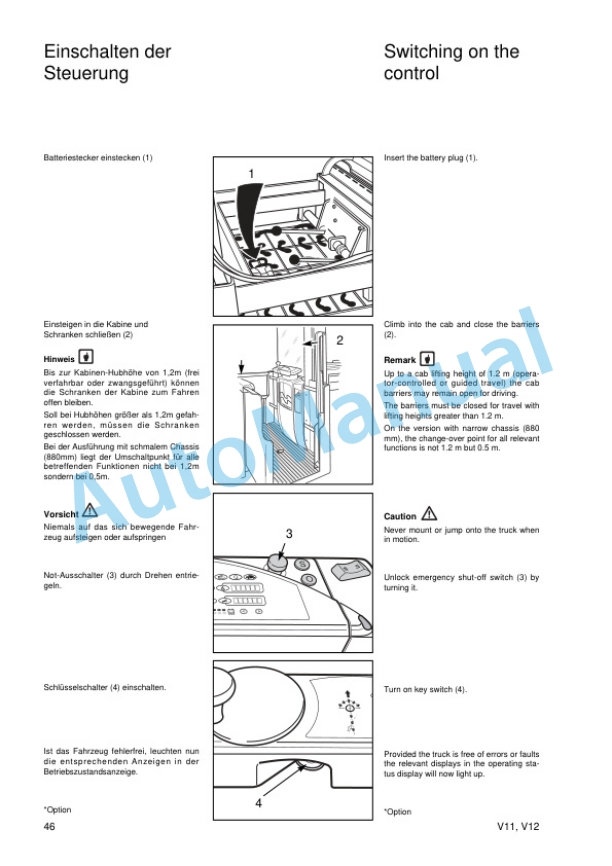

- 1.5.16. Normal start

- 1.5.17. Truck status display

- 1.5.18. Gear shift control

- 1.5.19. Driving

- 1.5.20. Steering

- 1.5.21. Stopping the truck

- 1.5.22. Transmission inching

- 1.5.23. Braking system

- 1.5.24. Automatic Parking brake operation

- 1.5.25. Malfunctions during operation

- 1.5.26. Truck lighting

- 1.5.27. Operating the hazard warning lights

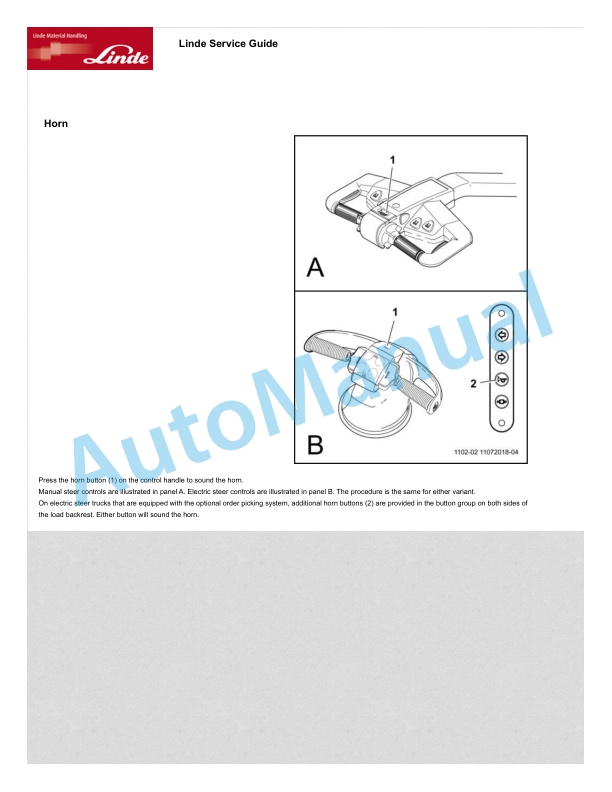

- 1.5.28. Operating the horn

- 1.5.29. Windscreen wipers and washers

- 1.5.30. To operate the cab preheater system

- 1.5.31. Fuses

- 1.5.32. Load lift controls

- 1.5.33. Before lifting a load

- 1.5.34. Lifting a load

- 1.5.35. Travelling with load

- 1.5.36. Depositing the load

- 1.5.37. Parking the truck

- 1.5.38. Locations for jacks when changing wheels

- 1.5.39. Trailer coupling

- 1.5.40. Towing

- 1.5.41. Hoisting the truck

- 1.6. Maintenance

- 1.6.1. General remarks

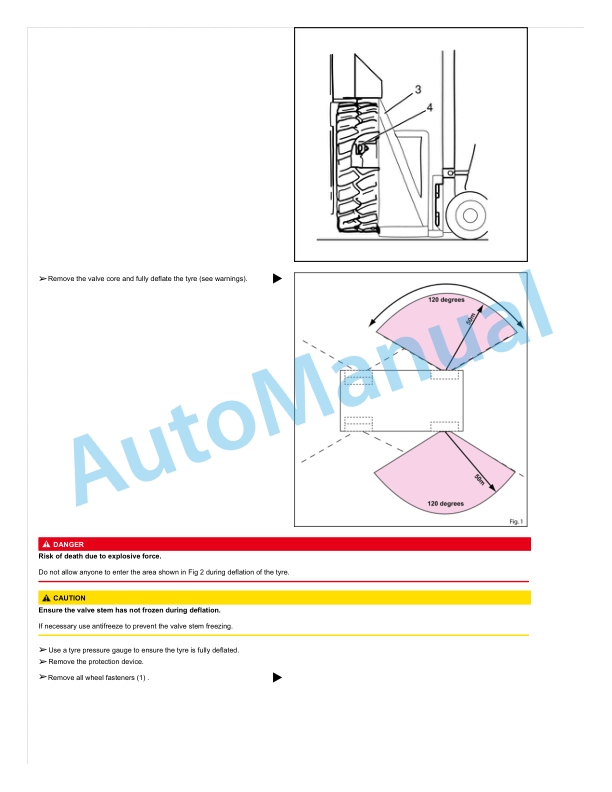

- 1.6.1.1. Wheel removal drive axle

- 1.6.1.2. Wheel removal steer axle

- 1.6.1.3. Wheel assembly inspection

- 1.6.1.4. Wheel refitting drive axle

- 1.6.1.5. Wheel refitting steer axle

- 1.6.1.6. Examples of restraining devices

- 1.6.1.7. Mirrors

- 1.6.1.8. Taking the truck out of operation

- 1.6.1.9. Work on the mast and the front part of the truck

- 1.6.1.10. Fuel and oil recommendations

- 1.6.1.11. Diesel fuel

- 1.6.1.12. Truck welds inspection

- 1.6.1.13. Check the condition of structured components

- 1.6.1.14. Checks various

- 1.6.1.15. General information

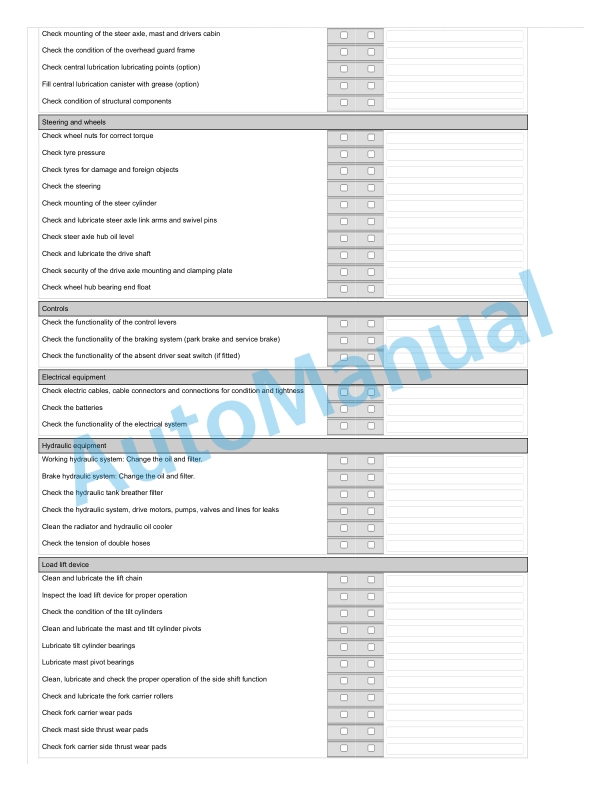

- 1.6.2. Inspection and maintenance schedule

- 1.6.2.1. As required service plan

- 1.6.2.2. First 50 hours service plan

- 1.6.2.3. h Service plan

- 1.6.2.4. h Service plan

- 1.6.2.5. h Service plan

- 1.6.2.6. h Service plan

- 1.6.2.7. h Service plan

- 1.6.2.8. h Service plan

- 1.6.2.9. Rated capacity

- 1.6.3. Engine

- 1.6.3.1. Engine oil level check

- 1.6.3.2. Change the engine oil (every 12 months minimum)

- 1.6.3.3. Clean the fuel filter

- 1.6.3.4. Change the fuel prefilter with water monitor

- 1.6.3.5. Check the engine mounting for condition and security

- 1.6.3.6. Check intake and exhaust systems for leaks and security

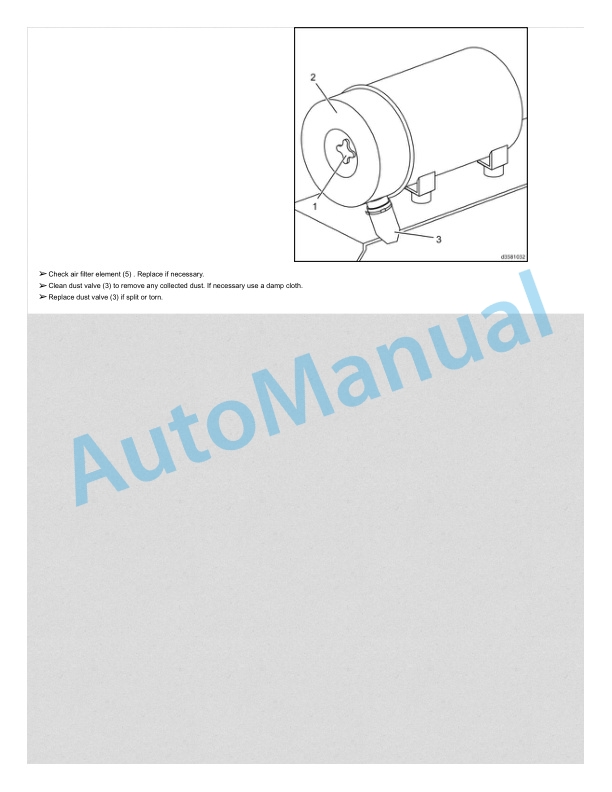

- 1.6.3.7. Check the air filter

- 1.6.3.8. Renew the safety element

- 1.6.3.9. Check coolant strength

- 1.6.3.10. Renew engine coolant

- 1.6.3.11. Clean the radiator and oil cooler, check for leaks

- 1.6.3.12. Check the vibration damper

- 1.6.3.13. Replace the toothed belt and idler pulley

- 1.6.3.14. Check Valve Clearances

- 1.6.3.15. Check the injection nozzles

- 1.6.4. Transmission

- 1.6.4.1. Check transmission mountings

- 1.6.4.2. Transmission oil level check

- 1.6.4.3. Transmission filter change

- 1.6.4.4. Transmission oil change

- 1.6.5. Chassis bodywork and fittings

- 1.6.5.1. Clean the truck

- 1.6.5.2. Check seat belt for condition and correct operation (option)

- 1.6.5.3. Mirrors

- 1.6.5.4. Tyres check condition and pressure

- 1.6.5.5. Tighten the wheel nuts

- 1.6.5.6. Check the cab mountings

- 1.6.6. Chassis frame

- 1.6.6.1. Check and lubricate the drive shaft

- 1.6.6.2. Clean and lubricate the steer axle

- 1.6.6.3. Drive axle mountings check

- 1.6.6.4. Drive axle oil level check

- 1.6.7. Controls

- 1.6.7.1. Check the parking brake for proper operation

- 1.6.8. Electrics

- 1.6.8.1. Check the batteries.

- 1.6.8.2. Check electric cables, connectors and connections for conditionand tightness

- 1.6.9. Hydraulics

- 1.6.9.1. Check the hydraulic tank breather filter

- 1.6.9.2. Hydraulic system oil level check

- 1.6.9.3. Renew hydraulic oil of working hydraulic system

- 1.6.9.4. Renew the main hydraulic system oil return line filters

- 1.6.9.5. Check the tension of double hoses

- 1.6.10. Load lift system

- 1.6.10.1. Lubricate the mast and tilt cylinder pivots

- 1.6.10.2. Check and adjust mast chains, lubricate with chain spray

- 1.6.10.3. Renewing the lift chains (at least every 6000h, 3 years and when 2 stretch has been attained)

- 1.6.11. Troubleshooting

- 1.6.11.1. Troubleshooting guide (Diesel engine)

- 1.6.11.2. Troubleshooting guide (Hydraulic system)

- 1.6.12. User manual feedback

- 1.6.12.1. User manual improvement record.

- 1.7. Technical data

- 1.8. Circuit diagrams

- 1.8.1. Electrical

- 1.8.1.1. Electrical circuit drawing

- 1.8.2. Hydraulic

- 1.8.2.1. Hydraulic circuit drawing

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

Linde Operator Manual PDF

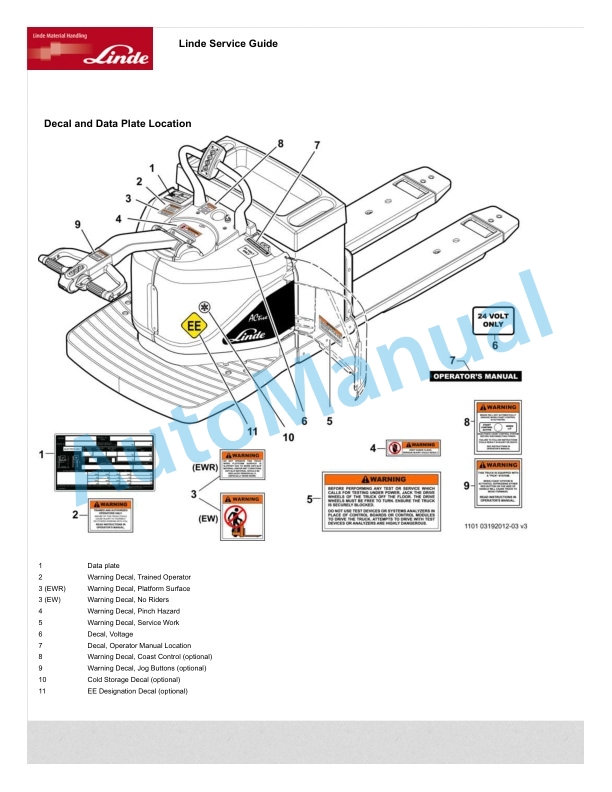

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up