Linde 372-00 – L14, L16 Workshop Manuals SN 10.98 and up

$40.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN 10.98 and up

- Format: PDF

- Size: 27.2MB

- Number of Pages: 272

- Serial Number:

SN 10.98 and up

Category: Linde Workshop Manual PDF

-

Model List:

- L14

- L16

- 1. Linde ApprovedRemanufacturing GuidelineTNLindustrial trucks

- 1.1. Table of content

- 1.2. Elementary checks

- 1.2.1. Carry out the initial preliminary checks after receiving of the truck

- 1.2.2. Carry out the appraisal main check

- 1.2.3. Perform a test drive

- 1.3. Comprehensive inspection for quotation

- 1.3.1. Standard repair kit

- 1.3.2. Inspect the truck for leakages

- 1.3.3. Steam clean the warehouse truck

- 1.3.4. Check the truck for open FASI and FASL points

- 1.3.5. Perform a diagnosis using Linde diagnostic software

- 1.3.6. Test the hydraulic functions according to the read out parameters

- 1.3.7. Check the chassis and the overhead guard (e.g. L12R, D12R) for cracks and damages

- 1.3.8. Check the platform

- 1.3.9. Check the lift mast

- 1.3.10. Check the load chains

- 1.3.11. Check the cylinders

- 1.3.12. Check the initial lift mechanism

- 1.3.13. Check the carriage and the fork arms

- 1.3.14. Check the parking brake

- 1.3.15. Check the steering system

- 1.3.16. Check the drive unit

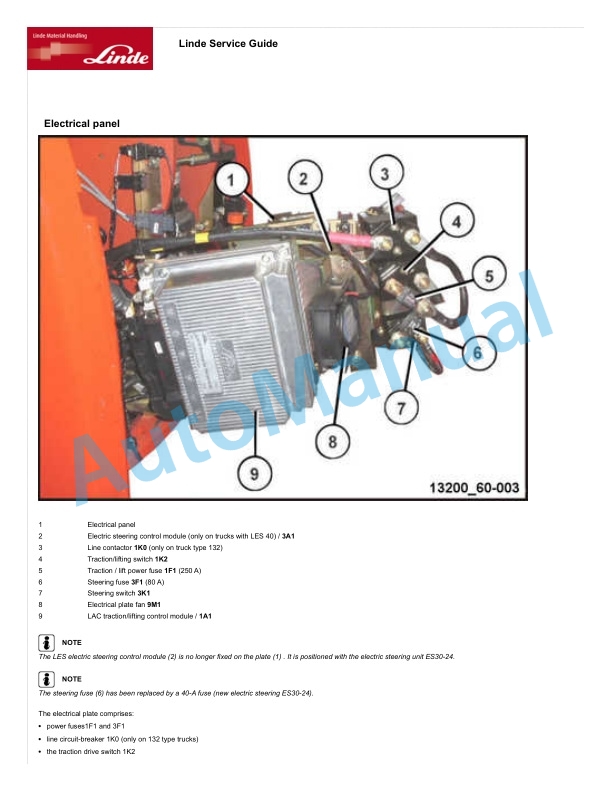

- 1.3.17. Check the electronic components

- 1.3.18. Check the harnesses

- 1.3.19. Check the drivers compartment

- 1.3.20. Check the operating elements

- 1.3.21. Visually check the battery compartment and the traction battery

- 1.3.22. Check the integrated and external chargers

- 1.3.23. Inspect the PU High Quality tyres for wear and damages

- 1.3.24. Check the stabilizer system

- 1.3.25. Inspect the plastic and rubber parts

- 1.3.26. Check the completeness of plates and decals

- 1.3.27. Check the status of the maintenance

- 1.3.28. Calculate the cost estimate

- 1.3.29. Order the spare parts

- 1.4. Maintenance and safety checks

- 1.4.1. Actions overview

- 1.4.2. Carry out maintenance

- 1.4.3. Operating hour meter

- 1.5. Reconditioning process

- 1.5.1. Standard repair kit

- 1.5.2. Eliminate leakages

- 1.5.3. Process open FASI and FASL points

- 1.5.4. Clear the error memory using Linde diagnostic software

- 1.5.5. Overhaul the operating hydraulic components

- 1.5.6. Overhaul the mast

- 1.5.7. Replace or adjust the load chains

- 1.5.8. Overhaul the cylinders

- 1.5.9. Overhaul the initial lift mechanism

- 1.5.10. Overhaul the carriage

- 1.5.11. Overhaul the steering system

- 1.5.12. Repair the drive unit

- 1.5.13. Repair or replace the electronic components

- 1.5.14. Repair or replace the harnesses

- 1.5.15. Repair or replace the chassis and the overhead guard

- 1.5.16. Overhaul the platform

- 1.5.17. Repair or replace the drivers compartment components

- 1.5.18. Overhaul the operating elements

- 1.5.19. Recondition and service the traction battery

- 1.5.20. Service the integrated and external charger

- 1.5.21. Overhaul the parking break

- 1.5.22. Sand the truck

- 1.5.23. Mask the truck

- 1.5.24. Fill the truck

- 1.5.25. Paint the truck

- 1.5.26. Replace the PU High Quality tyres

- 1.5.27. Recondition or replace the plastic and rubber parts

- 1.5.28. Plastic reconditioning process

- 1.5.29. Mount the components

- 1.5.30. Fit new plates and decals

- 1.6. Option packages

- 1.6.1. Option Packages

- 1.7. Finishing

- 1.7.1. Clean the truck

- 1.7.2. Clean the drivers compartment

- 1.8. Documentation and predelivery inspection

- 1.8.1. Compile the truck documents for the customer

- 1.8.2. Certificates for the customer

- 1.8.2.1. Certificate of Linde Approved Truck

- 1.8.2.2. Certificate of Warranty

- 1.8.3. Carry out a predelivery inspection

- 1.8.4. Fit the Linde Approved decals

- 1.8.5. Carry out a safety inspection according to FEM 4.004

- 2. Regular testing

- 2.1. Table of content

- 2.2. Regular testing

- 2.2.1. Principles for testing industrial trucks

- 2.2.2. Test log

- 2.2.3. Testing instruments, measuring devices, tools and devices

- 2.3. Electric motor

- 2.3.1. Test steps for the electric traction motor

- 2.4. Internal combustion engine

- 2.4.1. Test steps for the exhaust system

- 2.4.2. Diesel internal combustion engine

- 2.4.2.1. Exhaust gas test

- 2.4.2.2. Setpoint values for the exhaustgas check

- 2.4.3. LPG internal combustion engine

- 2.4.3.1. Exhaust gas test

- 2.5. Drive axle

- 2.5.1. Drive axle test steps

- 2.6. Chassis

- 2.6.1. Test steps for chassis

- 2.7. Drivers compartment

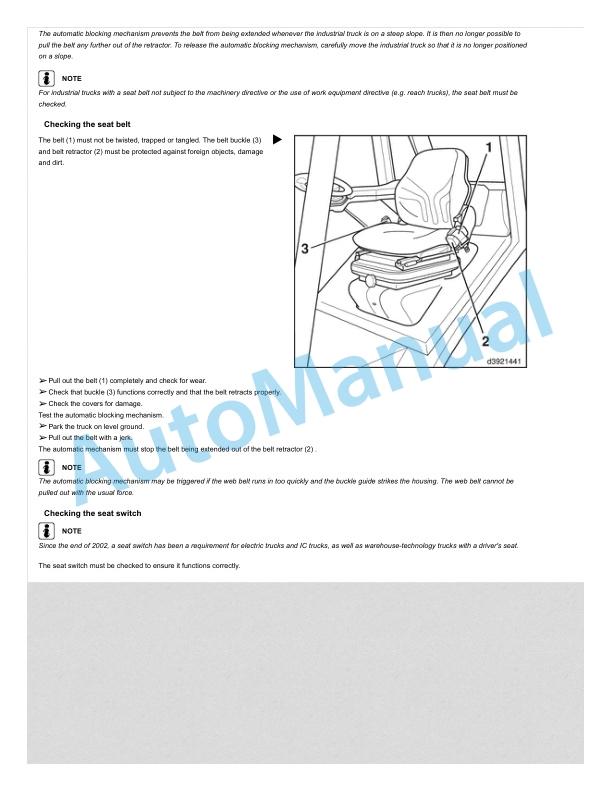

- 2.7.1. Test steps for drivers compartment

- 2.8. Steering systems

- 2.8.1. Test steps for the steering

- 2.9. Wheels and tyres

- 2.9.1. Test steps for wheels

- 2.9.2. Tyre test steps

- 2.10. Brake system

- 2.10.1. Definition and description of the industrial truck groups

- 2.10.2. Permissible braking distances for unladen industrial trucks

- 2.10.3. Service brake

- 2.10.4. Parking brake

- 2.11. Operating devices

- 2.11.1. Test steps for operating devices

- 2.12. Electrics.electronics

- 2.12.1. Test steps for electrical equipment

- 2.12.2. Notes regarding insulation testing

- 2.12.3. Insulation testing

- 2.12.4. Test steps for the battery and battery connection assemblies

- 2.13. Hydraulics

- 2.13.1. Test steps for hydraulic system

- 2.13.2. Safety regulations for hydraulic hose lines

- 2.14. Lift mast

- 2.14.1. Test steps for lift mast

- 2.14.2. Test steps for load chains

- 2.15. Load support

- 2.15.1. Test steps for fork arms

- 2.15.2. Combined testing device for testing fork arms, lifting chains and lifting hydraulics

- 2.16. Attachments

- 2.16.1. Test steps for attachments and other lifting accessories

- 2.17. Special equipment.accessories

- 2.17.1. LPG tanks on trucks

- 2.17.2. Test steps for other accessories

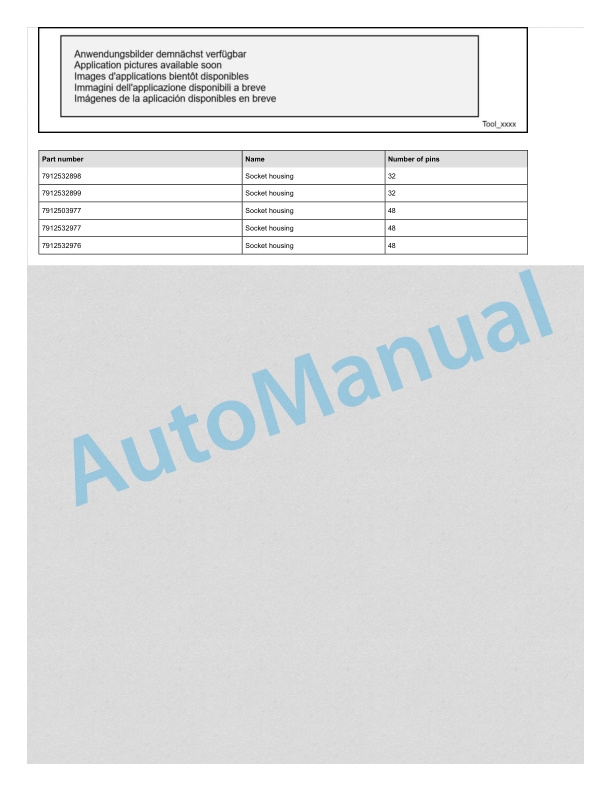

- 3. Service case Release tools for contacts

- 3.1. Table of content

- 3.2. Safety information

- 3.2.1. Safety information for repair and maintenance work

- 3.3. Information

- 3.3.1. Information

- 3.4. Overview

- 3.4.1. Overview of service cases

- 3.5. Plug systems

- 3.5.1. ATS 2.8 plug connector

- 3.5.2. CMC plug connector

- 3.5.3. DCS 9.5 plug connector

- 3.5.4. DIN 1.5mm circular connector

- 3.5.5. DIN 2.5mm circular connector

- 3.5.6. Deutsch DTM plug connector

- 3.5.7. ECU appliance plug

- 3.5.8. MCON appliance plug

- 3.5.9. Appliance plug with JPT and MQS contacts

- 3.5.10. Appliance plug with MT2 and JPT contacts

- 3.5.11. SICMA appliance plug

- 3.5.12. Econoseal JMark 2 plug connector

- 3.5.13. Elobau 11pin receptacle housing

- 3.5.14. E5931 plug connector

- 3.5.15. FASTINFASTON 6.3mm plug connector

- 3.5.16. GT150 plug connector

- 3.5.17. HDSCS plug connector

- 3.5.18. JPT plug connector

- 3.5.19. JPT SLD plug connector

- 3.5.20. JPT plug connector Saab

- 3.5.21. JPT plug connector VW

- 3.5.22. Kompakt 1.1 plug connector

- 3.5.23. Bosch Kompakt 4 plug connector

- 3.5.24. Leavyseal plug connector

- 3.5.25. MCON 1.2mm LL plug connector

- 3.5.26. MCON 1.2mm CB plug connector

- 3.5.27. MCP plug connector

- 3.5.28. MetriPack 150 plug connector

- 3.5.29. MiniFit plug connector

- 3.5.30. Mini Universal MATENLOK plug connector

- 3.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 3.5.32. MKR Plus plug connector

- 3.5.33. MQS plug connector

- 3.5.34. MR plug connector

- 3.5.35. MTA plug housing and fuse housing

- 3.5.36. MT2 plug connector

- 3.5.37. MT2 1.5mm plug connector VW

- 3.5.38. Multilock plug connector

- 3.5.39. MX150 plug connector

- 3.5.40. NG1 plug connector

- 3.5.41. Phönix Contact HC plug connector

- 3.5.42. PT 3F plug connector

- 3.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 3.5.44. Relay socket with SPT and MPT contacts

- 3.5.45. Fuse holder with SPT contacts

- 3.5.46. Sicma plug connector

- 3.5.47. SLK 2.8 plug connector

- 3.5.48. Souriau UTL7 plug connector

- 3.5.49. Superseal 1.5mm plug connector

- 3.5.50. Trident Neptune plug connector

- 3.5.51. Universal MATENLOK plug connector

- 3.5.52. VW 9.5mm plug connector

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1110-01 – V08-01, V08-02 Workshop Manuals SN 11.09 and up SN up to W41110V00528

$40.00