Linde 386-01 – E14 EX, E16 EX, E18 EX, E20 EX Operating Instructions SN up to 03.15

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN up to 03.15

- Format: PDF

- Size: 26.7MB

- Number of Pages: 185

- Serial Number:

SN up to 03.15

Category: Linde Operator Manual PDF

-

Model List:

- E14 EX

- E16 EX

- E18 EX

- E20 EX

- 1. Electric forklift truckE14EX E20EX

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your industrial truck

- 1.2.2. Intended use

- 1.2.3. Improper use

- 1.2.4. Description of use and climatic condition

- 1.2.5. Symbols used

- 1.2.6. Technical description

- 1.2.7. Receiving the industrial truck

- 1.2.8. Legal requirements for placing on the market

- 1.2.9. Service plan before initial commissioning

- 1.3. Safety

- 1.3.1. Safety regulations

- 1.3.1.1. Safety regulations

- 1.3.1.2. In the case of tipover

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. Handling consumables

- 1.3.5. Qualified person

- 1.3.6. Regulations

- 1.4. Overview

- 1.4.1. Identification plate.adhesive label

- 1.4.2. Truck overview

- 1.4.3. Nameplate

- 1.4.4. Controls

- 1.4.5. Display unit

- 1.4.6. Indicator lights

- 1.5. Operation

- 1.5.1. Instructions for runningin

- 1.5.2. Preshift checks

- 1.5.3. Standard equipment

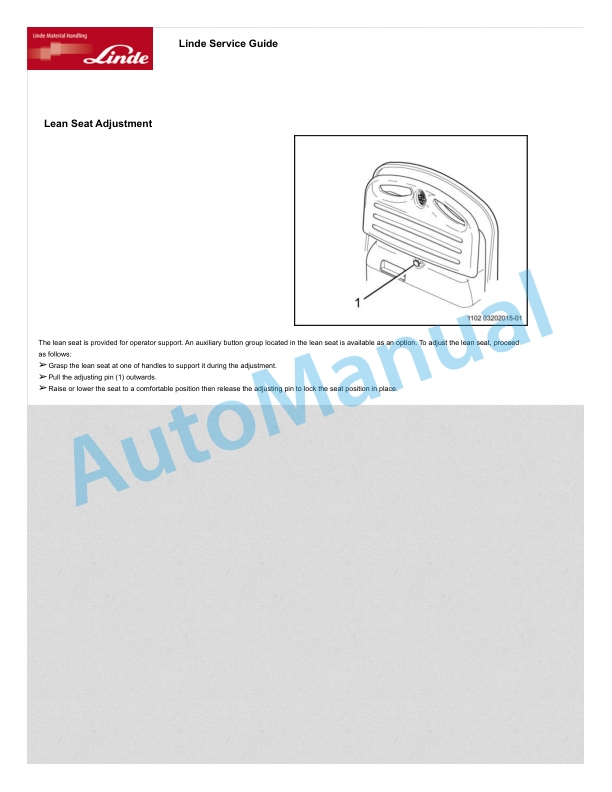

- 1.5.3.1. Adjusting drivers seat

- 1.5.3.2. Entering and exiting the truck

- 1.5.3.3. Adjusting the steering column

- 1.5.3.4. Setting the time

- 1.5.3.5. Seat belt

- 1.5.3.6. Switching the truck on and off

- 1.5.3.7. Driving (dualpedal operation)

- 1.5.3.8. Driving (singlepedal operation)

- 1.5.3.9. Steering system

- 1.5.3.10. Brake system

- 1.5.3.11. Horn

- 1.5.3.12. JoystickCentral lever operation

- 1.5.3.13. Emergency stop switch

- 1.5.4. Special equipment

- 1.5.4.1. Lighting

- 1.5.5. Working under load

- 1.5.5.1. Before load pick up

- 1.5.5.2. Adjust fork arm distance

- 1.5.5.3. Taking up load

- 1.5.5.4. Driving under load

- 1.5.5.5. Setting down loads

- 1.5.5.6. Towing device

- 1.5.6. Loading . Transporting

- 1.5.6.1. Removing the lift mast

- 1.5.6.2. Driving without the lift mast

- 1.5.6.3. Crane loading

- 1.5.6.4. Transportation by truck or low loading truck

- 1.5.7. Leaving the truck

- 1.5.7.1. Before leaving the truck

- 1.6. Maintenance

- 1.6.1. General information

- 1.6.2. Working on the lift mast and at the front of the truck

- 1.6.3. Inspection and maintenance data

- 1.6.4. Recommendations for consumables

- 1.6.5. Inspection and maintenance overview

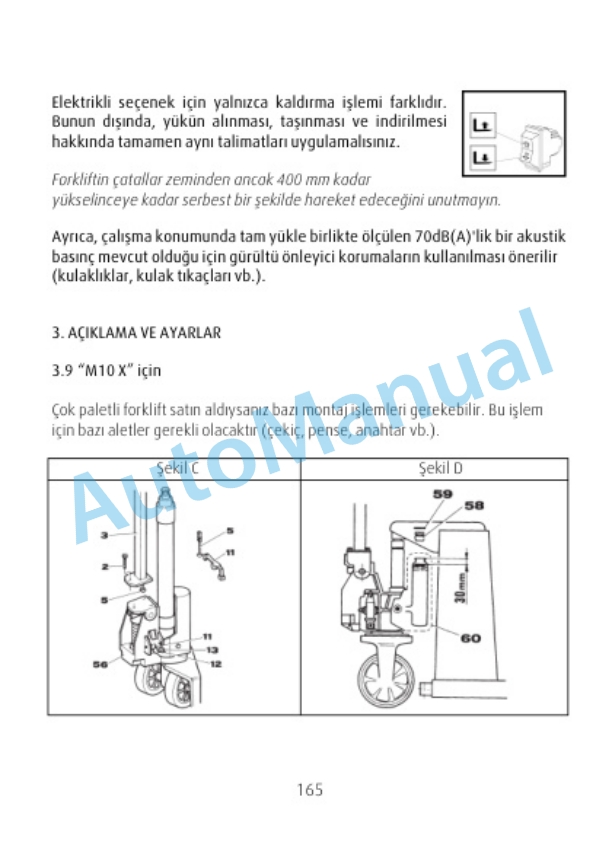

- 1.6.5.1. Service plan after 50 hours after 3 months at the latest

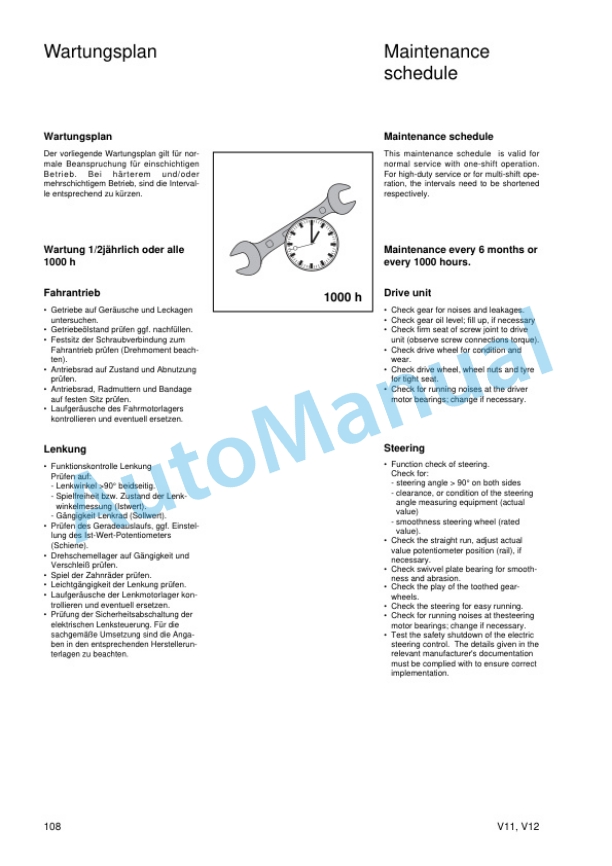

- 1.6.5.2. Service plan every 500 hours after 6 months at the latest

- 1.6.5.3. Service plan every 1000 hours after a year at the latest

- 1.6.5.4. Service plan every 2000 hours after 2 years at the latest

- 1.6.6. Gearbox

- 1.6.6.1. Checking the planetary transmission oil level

- 1.6.6.2. Check wheel gear for leaks

- 1.6.6.3. Changing the oil in the planetary transmission

- 1.6.6.4. Drive axlechecking the side stops,adjusting

- 1.6.7. Chassis, bodywork and fittings

- 1.6.7.1. Check fastenings

- 1.6.7.2. General information.cleaning

- 1.6.7.3. Cleaning the truck

- 1.6.7.4. Opening and closing the battery hood

- 1.6.7.5. Checking battery door catch locking, adjust if necessary

- 1.6.7.6. Checking the condition and correct function of the seat belt

- 1.6.7.7. Check bellows on joystick

- 1.6.7.8. Check the tilt cylinder bearings for wear

- 1.6.7.9. Check other bearings and joints and oil

- 1.6.7.10. Other cleaning and greasing

- 1.6.8. Chassis frame

- 1.6.8.1. Checking the brake system

- 1.6.8.2. Checking the tyres

- 1.6.8.3. Changing wheels

- 1.6.8.4. Tighten wheel fastenings

- 1.6.8.5. Cleaning the turntable steering axle

- 1.6.8.6. Cleaning and lubricating the combined axle

- 1.6.8.7. Checking the heat sinks of the drive axle for contamination, cleaning if necessary

- 1.6.9. Controls

- 1.6.9.1. Check pedals and linkage and oil

- 1.6.10. Electrics . Electronics

- 1.6.10.1. Battery check

- 1.6.10.2. Checking the battery charge status

- 1.6.10.3. Connecting the battery to an external battery charger

- 1.6.10.4. Battery replacement

- 1.6.10.5. Checking the main contactor (switchon contactor)

- 1.6.10.6. Adjusting the accelerator

- 1.6.10.7. Cleaning and checking fans for correct operation

- 1.6.10.8. Checking the condition and secure attachment of electric cables, cable connectors, cable connections and explosionprotected screw joints

- 1.6.11. Hydraulics

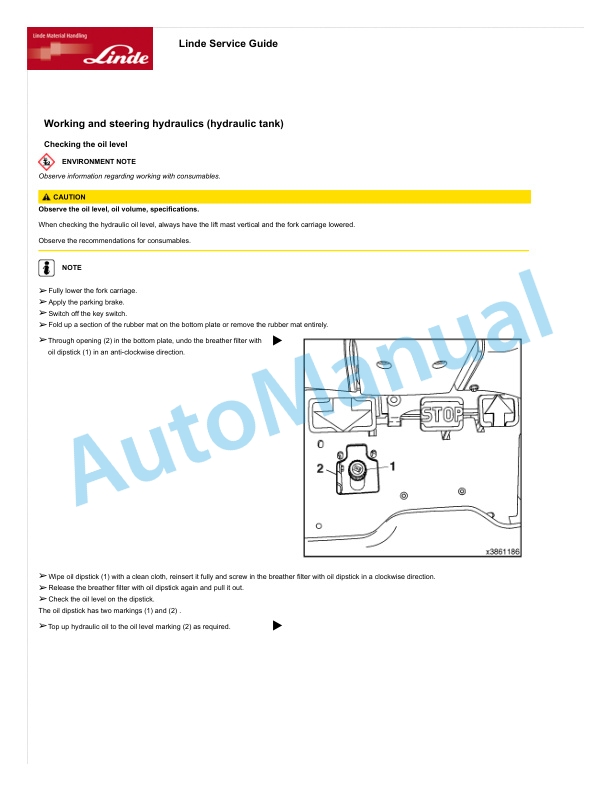

- 1.6.11.1. Working and steering hydraulics (hydraulic tank)

- 1.6.11.2. Checking the working and steering hydraulics for leaks

- 1.6.11.3. Changing the breather filter

- 1.6.11.4. Changing the pressure filter

- 1.6.11.5. Changing the suction filter

- 1.6.11.6. Changing the hydraulic oil

- 1.6.11.7. Double hosesChecking the pretension

- 1.6.12. Load lift system

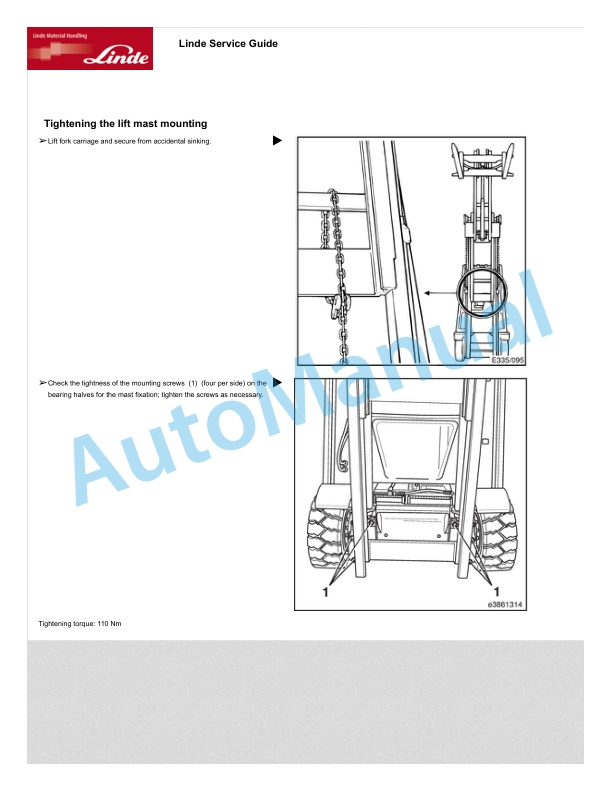

- 1.6.12.1. Tightening the lift mast mounting

- 1.6.12.2. Cleaning and spraying the lift mast chain

- 1.6.12.3. Adjusting the lift mast chain

- 1.6.12.4. Checking the mounting, condition and function of the lift mast, lift mast chains, lift cylinders and end stops

- 1.6.12.5. Checking the hose carrier

- 1.6.12.6. Checking fork arms and arm safety devices

- 1.6.13. Special equipment

- 1.6.13.1. Clean and grease the sideshift, check that it is securely fastened

- 1.6.13.2. Checking the slide guides on the sideshift (special equipment) for wear

- 1.6.14. Troubleshooting

- 1.6.14.1. Fuses for basic equipment

- 1.6.14.2. Fuses for special equipment

- 1.6.14.3. Diagnostic connector

- 1.6.14.4. Fork carriage emergency lowering

- 1.6.14.5. Emergency exit with attached rear window

- 1.6.14.6. Towing regulations

- 1.6.14.7. Shutting down the industrial truck

- 1.6.14.8. Disposal of old trucks

- 1.6.14.9. Malfunctions during operation

- 1.7. Technical data

- 1.7.1. Type sheet E 14 EX, as at 01.2008

- 1.7.2. Type sheet E 16 EX, as at 01.2008

- 1.7.3. Type sheet E 16 L_EX, as at 01.2008

- 1.7.4. Type sheet E 16 P_EX, as at 01.2008

- 1.7.5. Type sheet E 20 L_EX, as at 01.2008

- 1.7.6. Type sheet E 20 PL_EX, as at 01.2008

- 1.7.7. Vibration characteristics for bodily vibrations

- 1.7.8. Noise emission values

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00