- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 5195-01 – R15SX to RTX22P Production site Xiamen Operating Instructions SN C15159J00001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN C15159J00001 and up

- Format: PDF

- Size: 30.3MB

- Number of Pages: 248

- Serial Number:

SN C15159J00001 and up

Category: Linde Operator Manual PDF

-

Model List:

- R15SX

- R17SX

- R22SX

- RTX15PD

- RTX17

- RTX17P

- RTX22P

- 1. series Electric Reach TruckModels R17SX, R22SX, R15SXD North America

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Scope

- 1.2.2. Obligations of the Equipment Owner

- 1.2.3. Operator Responsibilities

- 1.2.4. Proper use

- 1.2.5. Hazard messages

- 1.3. Safety

- 1.3.1. Before Operation

- 1.3.2. Operator Daily Checklist

- 1.3.3. Operating Position

- 1.3.4. Pedestrians

- 1.3.5. Travel

- 1.3.6. Lifting and Lowering

- 1.3.7. Inclines, Ramps, Docks, Elevators

- 1.3.8. Avoiding Falls and Tipovers

- 1.3.9. Suspended Loads

- 1.3.10. Parking

- 1.3.11. Battery Safety

- 1.3.12. Safety During Maintenance

- 1.3.12.1. Personnel Qualifications

- 1.3.12.2. Hazardous Substances

- 1.3.13. Operator warning decals

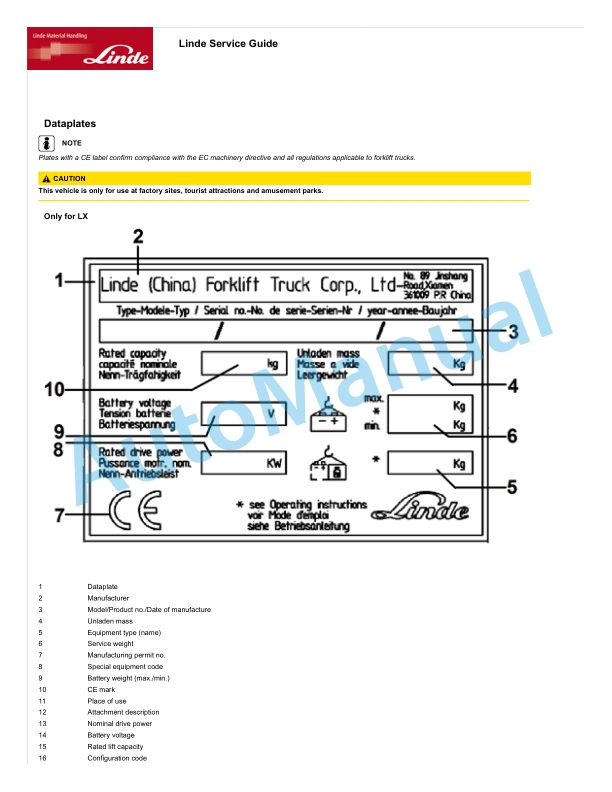

- 1.3.13.1. Data plate

- 1.3.13.2. Operator warning decal

- 1.3.13.3. Trained operator warning decal

- 1.3.13.4. Test or service warning decal

- 1.3.13.5. Never stand or walk under forks warning decal

- 1.3.13.6. Voltage decal

- 1.3.13.7. Do not lift personnel warning decal

- 1.3.13.8. Crushed fingers warning decal

- 1.3.13.9. No step warning decal

- 1.3.13.10. Back up alarm warning decal

- 1.4. Overview

- 1.4.1. Technical Description

- 1.4.2. Truck Components

- 1.4.3. Display Unit

- 1.4.4. Controls

- 1.4.5. Decal and Data Plate Location

- 1.4.6. Data Plate

- 1.4.7. Definition of directions

- 1.5. Operation

- 1.5.1. Unloading and Preparing a New Truck for Operation

- 1.5.2. Steering Wheel Height Adjustment

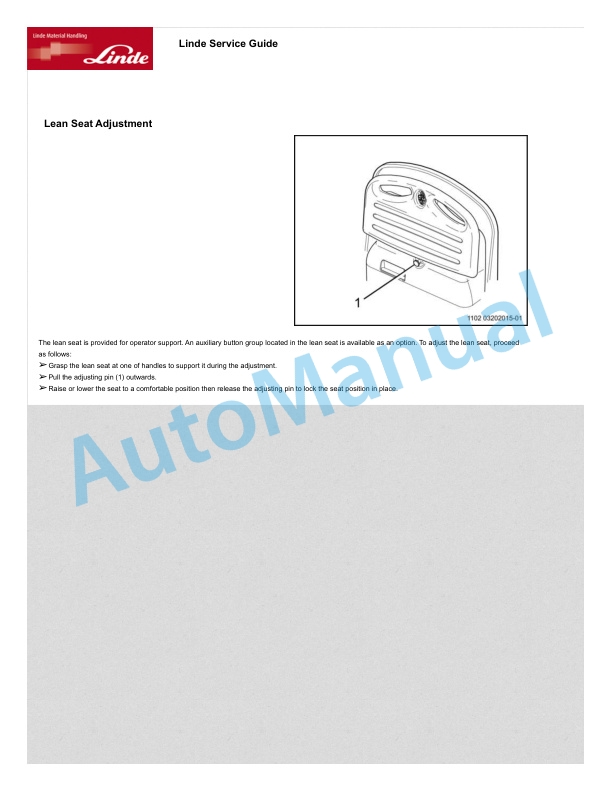

- 1.5.3. Armrest Adjustment

- 1.5.4. Operating the Display Unit

- 1.5.5. Turning the Truck On and Off

- 1.5.6. Driving

- 1.5.7. Braking

- 1.5.8. Steering System

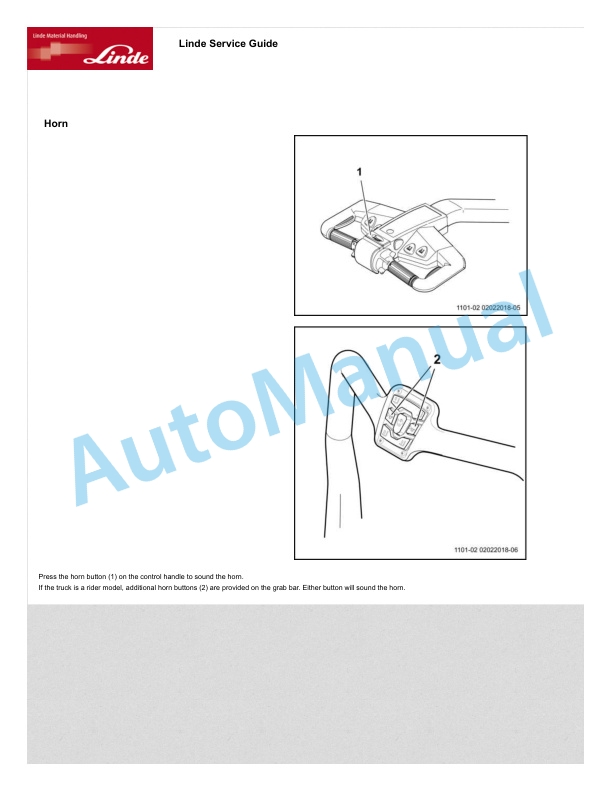

- 1.5.9. Horn

- 1.5.10. Emergency Stop Switch

- 1.5.11. Fork Position Adjustment

- 1.5.12. Hydraulic Controls

- 1.5.13. Tilt Memory (optional equipment)

- 1.5.14. Lift Limit Function (optional equipment)

- 1.5.15. Fan (optional equipment)

- 1.5.16. Lights and BackUp Alarm

- 1.5.17. Changing the Battery

- 1.5.18. Connecting the Battery to an External Charger

- 1.5.19. Manual Lowering of Fork Carriage

- 1.5.20. Towing the Truck

- 1.5.21. Securing the Truck for Transport

- 1.5.22. Hoisting the Truck

- 1.5.23. Long term storage

- 1.6. Maintenance

- 1.6.1. Personnel Qualifications

- 1.6.2. Cleaning

- 1.6.2.1. Cleaning the Truck

- 1.6.2.2. Cleaning the Lift Chains

- 1.6.3. Operator Inspection and Maintenance

- 1.6.3.1. Daily Inspection Overview

- 1.6.3.2. Daily Inspection Checklist

- 1.6.3.3. Check for fluid leakage

- 1.6.3.4. Check overhead guard

- 1.6.3.5. Check hydraulic cylinders

- 1.6.3.6. Check lift chains

- 1.6.3.7. Check fork carriage

- 1.6.3.8. Check battery retention

- 1.6.3.9. Check battery connector

- 1.6.3.10. Check hydraulic oil level

- 1.6.3.11. Check decal condition

- 1.6.3.12. Check Drive Wheel and Fasteners

- 1.6.3.13. Check all wheels for debris

- 1.6.3.14. Check multifunction handle bellows

- 1.6.3.15. Antistatic strap (optional equipment)

- 1.6.3.16. Operational checks

- 1.6.4. Routine Lubrication and Inspection

- 1.6.4.1. Routine Lubrication and Inspection Intervals

- 1.6.4.2. Testing and Cleaning the Fans

- 1.6.4.3. Checking Gear Oil Level

- 1.6.4.4. Checking Pedals

- 1.6.4.5. Hydraulic Tank Pressure Valve Test

- 1.6.4.6. Lubricate Steering Gear

- 1.6.4.7. Lift Chain Lubrication and Length Inspection

- 1.6.4.8. Mast Roller Lubrication and Inspection

- 1.6.4.9. Caster Wheel Inspection and Lubrication

- 1.6.4.10. Lubricate Load Wheel Axles

- 1.6.4.11. Lubricating the Reach Unit and Sideshifter

- 1.6.5. Scheduled Maintenance

- 1.6.5.1. General Maintenance Information

- 1.6.5.2. Scheduled Maintenance Chart

- 1.6.6. Fluids and Lubricants

- 1.6.6.1. Capacities

- 1.6.6.2. Fluid and Lubricant Specifications

- 1.6.7. Troubleshooting

- 1.6.7.1. Fuses

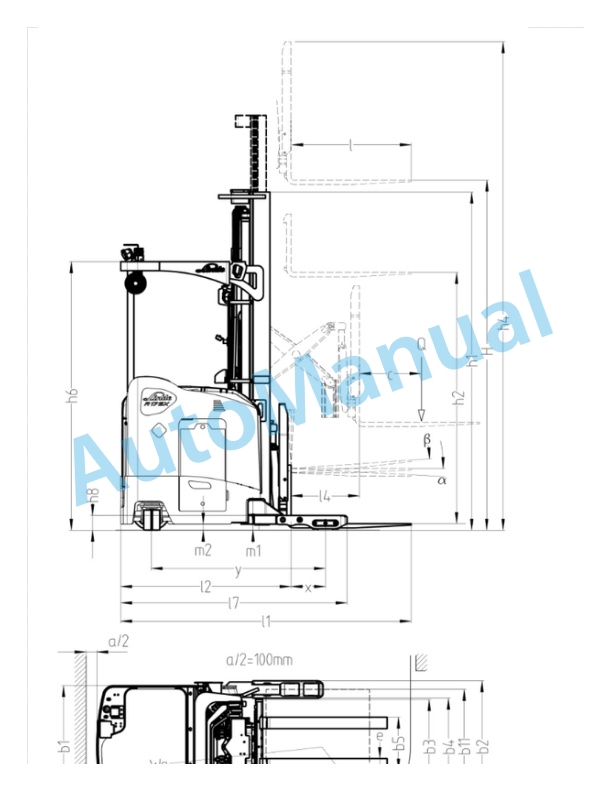

- 1.7. Specifications

- 1.7.1. Specifications

- 1.7.2. Mast Heights

- 2. Electric Reach TruckR15SX, R17SX24V, R17SX36V, R22SX

- 2.1. Table of content

- 2.2. Introduction and overview

- 2.2.1. Introduction

- 2.2.2. Intended use

- 2.2.3. Improper use

- 2.2.4. Additional information

- 2.2.5. Symbols used

- 2.2.6. Description of use and climatic conditions

- 2.2.7. Technical description

- 2.3. Safety

- 2.3.1. Safety guidelines

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. Handling consumables

- 2.3.5. EMC Electromagnetic compatibility

- 2.3.6. Regulations

- 2.3.7. Competent person

- 2.3.8. Noise level

- 2.3.9. Frequency characteristic for vibrations imparted to the human body

- 2.3.10. Emergency lowering

- 2.3.11. Releasing the parking brake

- 2.4. Truck overview

- 2.4.1. View of the truck

- 2.4.2. Identification plates and labels

- 2.4.3. Dataplates

- 2.4.4. Display unit

- 2.4.5. Setting the drive direction

- 2.5. Operation

- 2.5.1. Preliminary inspection

- 2.5.2. Battery

- 2.5.3. Adjusting the drivers armrest

- 2.5.4. Operating the display unit

- 2.5.5. Horn operation

- 2.5.6. Steering

- 2.5.7. Driving

- 2.5.8. Braking

- 2.5.9. Moving off on a ramp

- 2.5.10. Operating the lift mast and attachments

- 2.5.11. Transporting the truck

- 2.5.12. Towing procedure

- 2.5.13. Lift mast

- 2.5.14. Before leaving the machine

- 2.5.15. Fleet management system

- 2.5.16. Fleet management system (LFM Go.LKU10, option)

- 2.5.17. Use in cold stores

- 2.5.18. Taking the truck out of operation

- 2.6. Maintenance

- 2.6.1. Maintenance and safety instructions

- 2.6.2. General Knowledge

- 2.6.3. Recommended lubricants

- 2.6.4. Inspection and maintenance data

- 2.6.5. Preliminary inspection

- 2.6.6. Maintenance checklist to be completed after every 1000 hours of operation

- 2.6.7. Maintenance checklist to be completed after every 2000 hours of operation

- 2.6.8. Maintenance checklist to be completed after every 5000 hours of operation

- 2.6.9. Cleaning the truck

- 2.6.10. Checking the battery electrolyte level and specific gravity

- 2.6.11. Checking the battery and battery cables

- 2.6.12. Checking wheels and tyres

- 2.6.13. Checking fuses

- 2.6.14. Checking if the hydraulic hoses and pipe lines are damaged

- 2.6.15. Changing the hydraulic hoses and pipe lines

- 2.6.16. Check the hydraulic oil level

- 2.6.17. Changing the breather filter of the hydraulic oil tank

- 2.6.18. Changing the hydraulic oil and the suction filter

- 2.6.19. Changing the hydraulic oil pressure filter

- 2.6.20. Checking the brake system

- 2.6.21. Lubricating the drive motor and gearbox connections

- 2.6.22. Checking the condition and tightness of electrical connectors and cables

- 2.6.23. Stabilising wheel adjustment

- 2.6.24. Lubricating the lift chain and the lift mast guide slot

- 2.6.25. Adjusting the lift chain

- 2.6.26. Lubricating the fork carriage and sideshift slide

- 2.7. Technical datasheet

- 2.7.1. Technical datasheet

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF