Linde 5215-01 – V15, V15HP, V15P Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 39.5MB

- Number of Pages: 250

Category: Linde Operator Manual PDF

-

Model List:

- V15

- V15HP

- V15P

- 1. series Vertical Order PickerModel V15 North America

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Scope

- 1.2.2. Obligations of the Equipment Owner

- 1.2.3. Operator Responsibilities

- 1.2.4. Proper use

- 1.2.5. Hazard messages

- 1.3. Safety

- 1.3.1. Before Operation

- 1.3.2. Operator Daily Checklist

- 1.3.3. Operating Position

- 1.3.4. Pedestrians

- 1.3.5. Travel

- 1.3.6. Raising and Lowering the Operator Compartment

- 1.3.7. Avoiding Falls and Tipovers

- 1.3.8. Parking

- 1.3.9. Battery Safety

- 1.3.10. Safety During Maintenance

- 1.3.10.1. Personnel Qualifications

- 1.3.10.2. Hazardous Substances

- 1.3.11. Operator Warning Decals

- 1.3.11.1. Data plate

- 1.3.11.2. Voltage decal

- 1.3.11.3. Operator warning decal

- 1.3.11.4. Trained operator warning decal

- 1.3.11.5. Never stand or walk under forks warning decal

- 1.3.11.6. Do not lift personnel warning decal

- 1.3.11.7. Crushed fingers warning decal

- 1.3.11.8. Back up alarm warning decal

- 1.3.11.9. Platform surface warning decal

- 1.4. Overview

- 1.4.1. Technical Description

- 1.4.2. Truck Components

- 1.4.3. Controls

- 1.4.4. Display Unit

- 1.4.5. Definition of directions

- 1.4.6. Decal and Data Plate Location

- 1.4.7. Data Plate

- 1.5. Operation

- 1.5.1. Unloading and Preparing a New Truck for Operation

- 1.5.2. Safety Harness

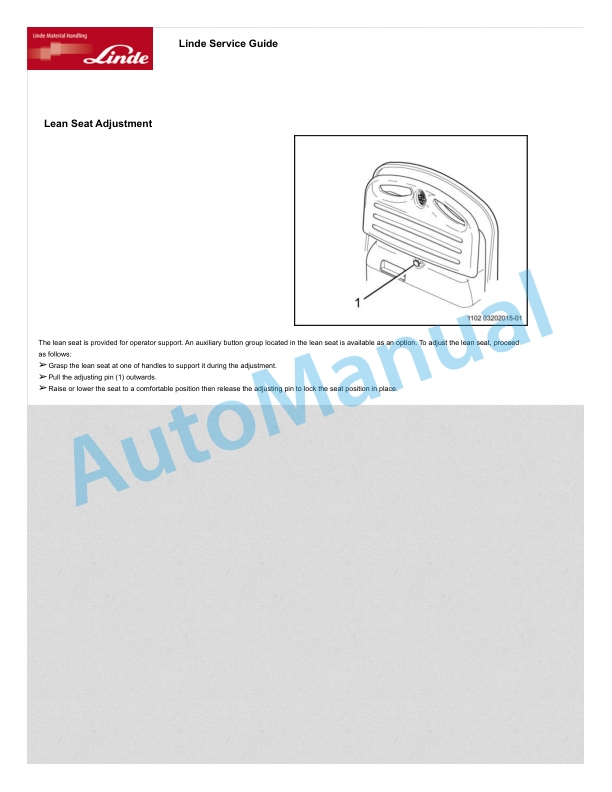

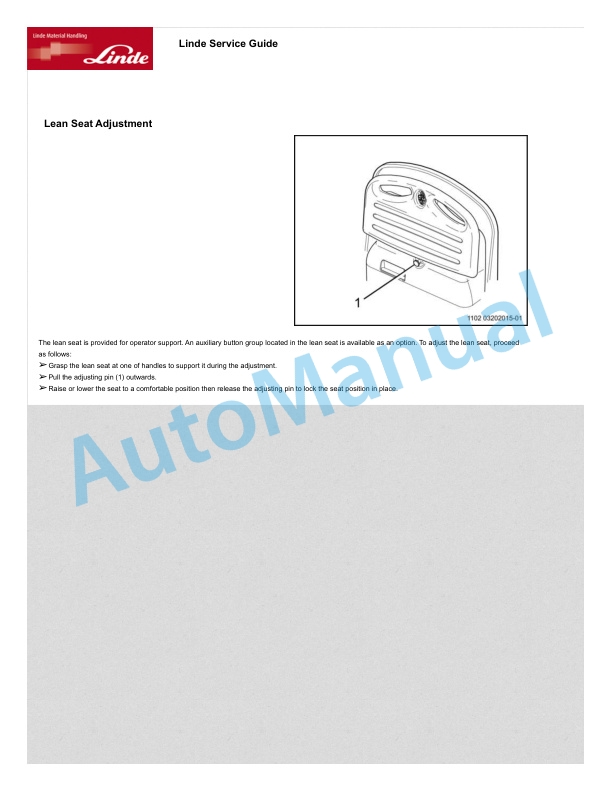

- 1.5.3. Console Height Adjustment (optional equipment)

- 1.5.4. Operating the Display Unit

- 1.5.5. Turning the Truck On and Off

- 1.5.6. Driving

- 1.5.7. Mechanical Aisle Guidance (optional equipment)

- 1.5.8. Inductive Guidance (optional equipment)

- 1.5.9. Braking

- 1.5.10. Steering

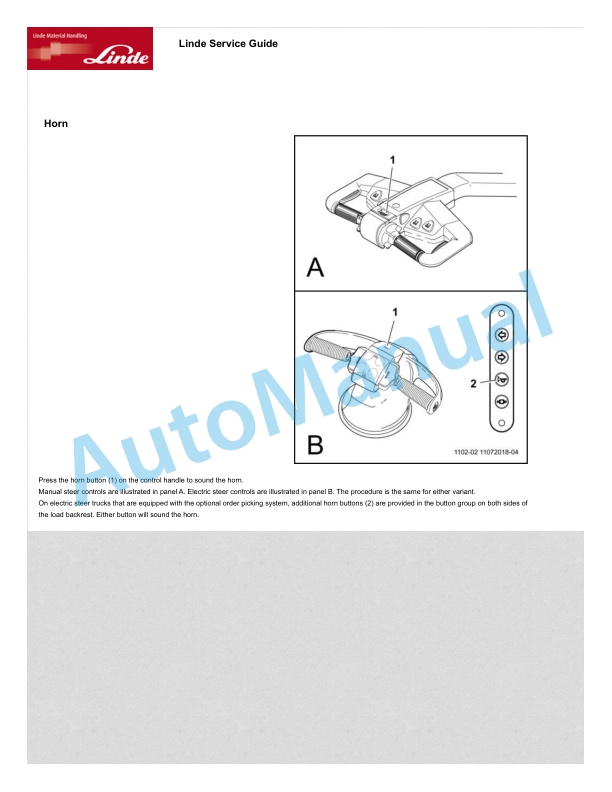

- 1.5.11. Horn

- 1.5.12. Pallet Clamp

- 1.5.13. Raising and Lowering the Operator Compartment

- 1.5.14. Lift Limit Function (optional equipment)

- 1.5.15. Manual Lowering of Operator Compartment

- 1.5.16. Lights and BackUp Alarm

- 1.5.17. Fan (optional equipment)

- 1.5.18. Changing the Battery

- 1.5.19. Connecting the Battery to an External Charger

- 1.5.20. Towing the Truck

- 1.5.21. Securing the Truck for Transport

- 1.5.22. Hoisting the Truck

- 1.5.23. Long term storage

- 1.6. Maintenance

- 1.6.1. Personnel Qualifications

- 1.6.2. Cleaning

- 1.6.2.1. Cleaning the Truck

- 1.6.2.2. Cleaning the Lift Chains

- 1.6.3. Operator Inspection and Maintenance

- 1.6.3.1. Daily Inspection Overview

- 1.6.3.2. Daily Inspection Checklist

- 1.6.3.3. Check for fluid leakage

- 1.6.3.4. Check overhead guard

- 1.6.3.5. Check hydraulic cylinders

- 1.6.3.6. Check lift chains

- 1.6.3.7. Check fork carriage

- 1.6.3.8. Check battery retention

- 1.6.3.9. Check battery connector

- 1.6.3.10. Check hydraulic oil level

- 1.6.3.11. Check Drive Wheel and Fasteners

- 1.6.3.12. Check all wheels for debris

- 1.6.3.13. Antistatic strap (optional equipment)

- 1.6.3.14. Check decal condition

- 1.6.3.15. Operational checks

- 1.6.4. Routine Lubrication and Inspection

- 1.6.4.1. Routine Lubrication and Inspection Intervals

- 1.6.4.2. Hydraulic Tank Pressure Valve Test

- 1.6.4.3. Checking Gear Oil Level

- 1.6.4.4. Lubricate Steering Gear

- 1.6.4.5. Testing and Cleaning the Fans

- 1.6.5. Scheduled Maintenance

- 1.6.5.1. General Maintenance Information

- 1.6.5.2. Scheduled Maintenance Chart

- 1.6.6. Fluids and Lubricants

- 1.6.6.1. Capacities

- 1.6.6.2. Fluid and Lubricant Specifications

- 1.6.7. Troubleshooting

- 1.6.7.1. Fuses

- 1.7. Specifications

- 1.7.1. Specifications

- 1.7.2. Mast Heights

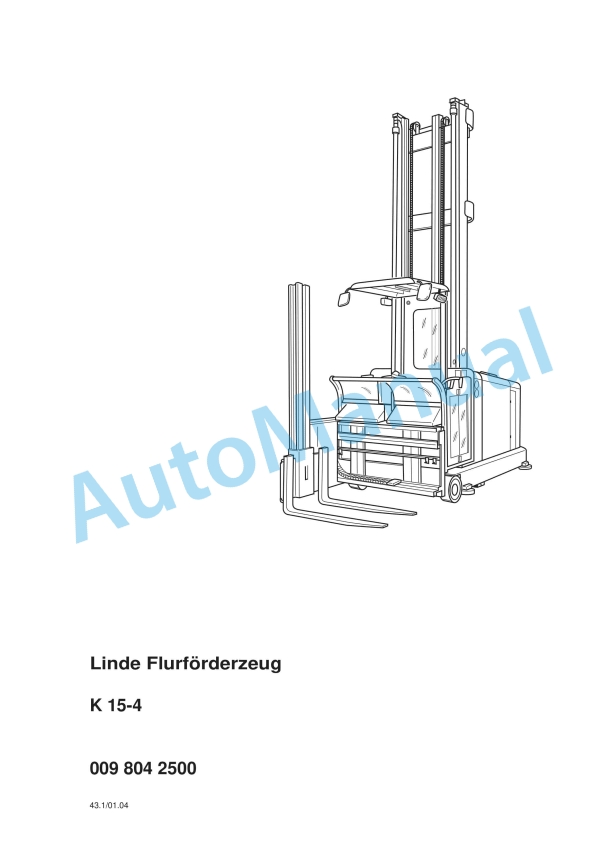

- 2. Highlevel order pickerV15

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Introduction

- 2.2.2. Intended use

- 2.2.3. Improper use

- 2.2.4. Extra information

- 2.2.5. Description of use

- 2.2.6. Symbols used

- 2.3. Safety

- 2.3.1. Safety guidelines

- 2.3.2. Stability

- 2.3.3. Residual risks

- 2.3.4. Use of lubricants

- 2.3.5. Handling consumables

- 2.3.6. Regulations

- 2.3.7. Periodic general checks on trucks

- 2.4. Views

- 2.4.1. Description of truck

- 2.4.2. View of the truck

- 2.4.3. Display unit

- 2.4.4. View of main components

- 2.4.5. Safety protective devices

- 2.4.6. Safety devices and warning labels

- 2.4.7. Control panel

- 2.4.8. Identification plates

- 2.4.9. Label (only for CE)

- 2.4.10. Drive directions

- 2.5. Operation

- 2.5.1. General commissioning

- 2.5.1.1. Test run

- 2.5.1.2. Transporting and loading

- 2.5.1.3. Display

- 2.5.1.4. Supporting block

- 2.5.1.5. Pallet clamping device

- 2.5.2. Daily commissioning

- 2.5.2.1. Preshift checklist

- 2.5.3. Safety protective devices

- 2.5.3.1. Checking the safety protective devices

- 2.5.3.2. Using the safety rope

- 2.5.3.3. Using the safety rope

- 2.5.3.4. Using the selfretracting device

- 2.5.4. Operating the truck

- 2.5.4.1. Operating instructions

- 2.5.4.2. Switching the truck on and off

- 2.5.4.3. Fleet management system

- 2.5.4.4. Fleet management system (LFM Go.LKU10, option)

- 2.5.4.5. Inductive Guidance (IZF)

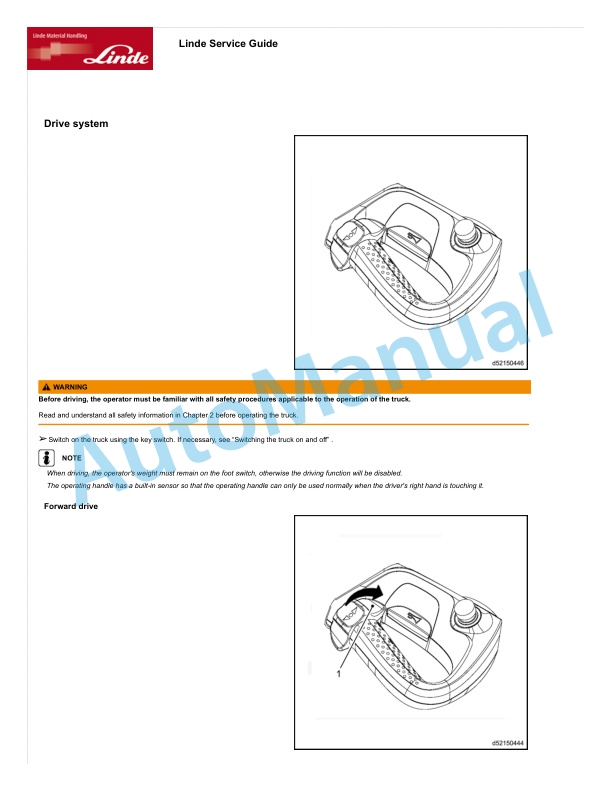

- 2.5.5. Driving

- 2.5.5.1. Drive system

- 2.5.5.2. Braking

- 2.5.5.3. Steering

- 2.5.5.4. Horn

- 2.5.6. Picking

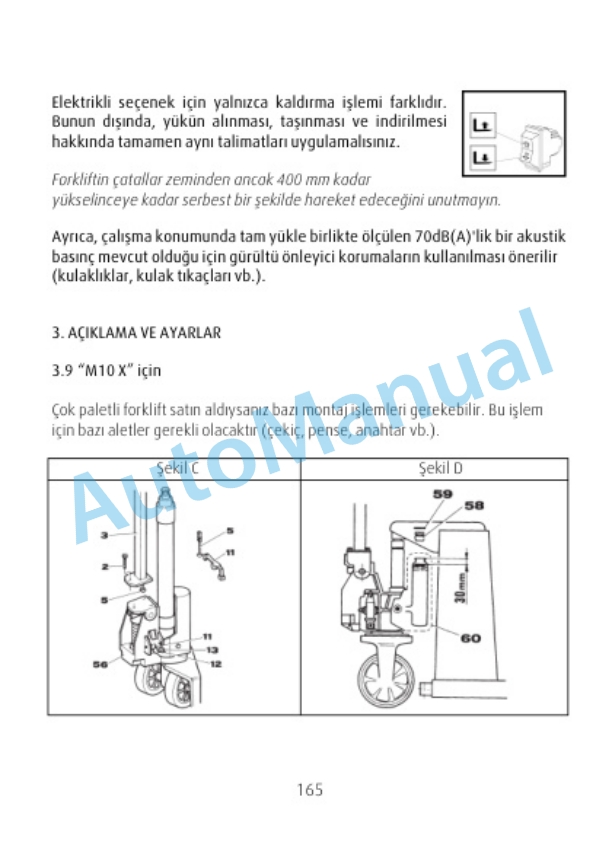

- 2.5.6.1. Picking up and setting down loads

- 2.5.6.2. Picking

- 2.5.6.3. Load diagram

- 2.5.7. Parking

- 2.5.7.1. Parking and leaving the truck

- 2.5.7.2. Decommissioning

- 2.5.8. Emergency operation

- 2.5.8.1. Emergency operation

- 2.5.8.2. Emergency lowering valve

- 2.6. Maintenance

- 2.6.1. Safety information for inspection and maintenance work

- 2.6.2. Cleaning

- 2.6.2.1. Cleaning the truck

- 2.6.3. Inspection and maintenance work tables

- 2.6.3.1. Regular maintenance

- 2.6.3.2. Service plan Every 1000 hours or every 6 months

- 2.6.3.3. Service plan Every 3000 hours or every 18 months

- 2.6.3.4. Lubrication plan

- 2.6.3.5. Lubricants

- 2.6.3.6. Inspection and maintenance data

- 2.6.4. Safety protective devices

- 2.6.4.1. Maintenance methods for safety protective devices

- 2.6.5. Transmission system

- 2.6.5.1. Checking the gearbox for leaks

- 2.6.5.2. Changing the gearbox oil

- 2.6.5.3. Lubricating the steering bearing

- 2.6.5.4. Checking the parking brake gap

- 2.6.6. Steering axle and wheels

- 2.6.6.1. Checking the drive wheels

- 2.6.6.2. Checking the load wheels

- 2.6.6.3. Checking the condition of the antistatic belt

- 2.6.7. Chassis

- 2.6.7.1. Checking the overhead guard

- 2.6.7.2. Checking the pallet clamping device

- 2.6.8. Control system

- 2.6.8.1. Checking the brake system

- 2.6.8.2. Checking the horn

- 2.6.9. Electrical system

- 2.6.9.1. Checking electrical cables

- 2.6.9.2. Troubleshooting

- 2.6.9.3. Connecting the rechargeable battery to an external charger

- 2.6.9.4. Changing the battery

- 2.6.10. Hydraulic system

- 2.6.10.1. Checking the hydraulic system for leaks

- 2.6.10.2. Checking the breather filter is working normally

- 2.6.10.3. Checking the oil level in the oil tank

- 2.6.10.4. Changing the hydraulic oil

- 2.6.11. Lifting system

- 2.6.11.1. Lubricate the lift mast and chains with chain spray

- 2.6.11.2. Adjusting the length of the lift chains, and lubricating using chain spray

- 2.7. Technical data

- 2.7.1. Technical data

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00