- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

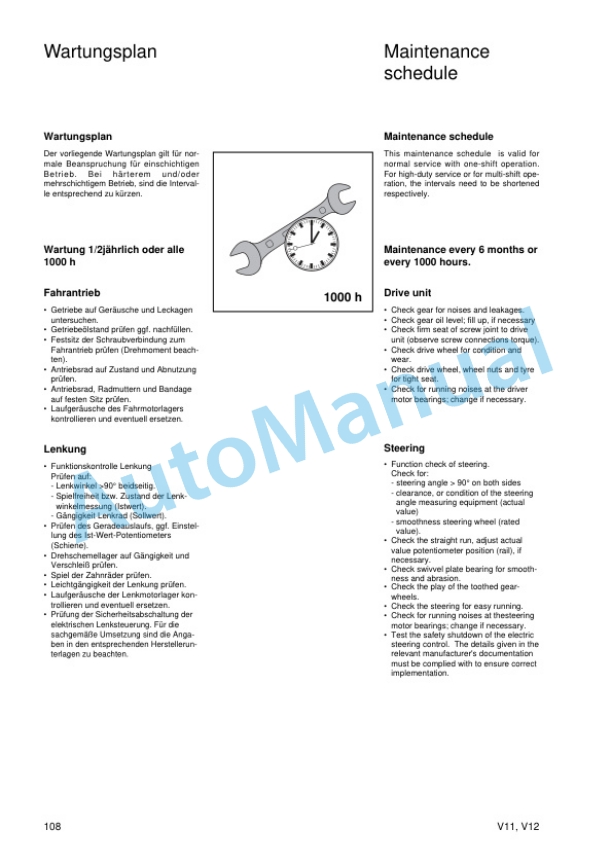

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 5222-01 – A Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 35.2MB

- Number of Pages: 289

Category: Linde Operator Manual PDF

-

Model List:

- A

- 1. Aisle Safety Assistant (GSA)5213_V, 5222_A

- 1.1. Table of content

- 1.2. Foreword

- 1.2.1. Linde Material Handling Your Partner

- 1.3. Aisle Safety Assistant (GSA)

- 1.3.1. Aisle Safety Assistant (GSA)

- 2. Battery frames011_K, 5212_V10, 5213_V, 5222_A

- 2.1. Table of content

- 2.2. Foreword

- 2.2.1. General foreword

- 2.3. Intended use

- 2.4. Versions

- 2.4.1. Types and variants

- 2.4.2. Battery racks without carrier plate

- 2.4.3. Battery racks with carrier plate

- 2.4.4. Manual drive

- 2.4.5. Electric drive

- 2.5. Replacing the battery

- 2.5.1. Procedure

- 2.6. Maintenance

- 2.6.1. General maintenance operations

- 2.6.2. Maintenance operations for battery racks with a battery carrier plate

- 2.6.3. Maintenance operations for battery racks with an electric drive

- 3. Linde forklift data management (LFM)011_K, 5213_V, 5222_A

- 3.1. Table of content

- 3.2. Linde forklift data management (LFM)

- 3.2.1. Linde forklift data management (LFM) with PIN

- 3.2.2. Status code

- 3.2.3. Linde forklift data management (LFM) with RFID

- 4. Trucks operating in Cold Storage Warehouse

- 4.1. Table of content

- 4.2. Foreword

- 4.2.1. General

- 4.2.2. Product support documentation

- 4.2.3. Safekeeping and passing on

- 4.2.4. Copyright and proprietary rights

- 4.3. Safety

- 4.3.1. Safety instructions

- 4.4. Intended use

- 4.4.1. Fields of application

- 4.4.2. Operating temperature

- 4.5. Overview

- 4.5.1. Battery in cold storage environments

- 4.5.2. Description of the equipment for lowtemperature operation

- 4.6. Maintenance

- 4.6.1. Maintenance

- 4.6.2. Lowtemperature lubricants

- 5. Trucks operating in Cold Storage Warehouse5222

- 5.1. Table of content

- 5.2. Foreword

- 5.2.1. General

- 5.2.2. Product support documentation

- 5.2.3. Safekeeping and passing on

- 5.2.4. Copyright and proprietary rights

- 5.3. Safety

- 5.3.1. Safety instructions

- 5.4. Intended use

- 5.4.1. Fields of application

- 5.4.2. Operating temperature

- 5.5. Overview

- 5.5.1. Battery in cold storage environments

- 5.5.2. Description of the equipment for lowtemperature operation

- 5.6. Operation

- 5.6.1. Driver cab for cold storage use

- 5.6.2. Operating panel

- 5.7. Maintenance

- 5.7.1. Maintenance and repair work

- 5.7.2. Maintenance

- 5.7.3. Lowtemperature lubricants

- 6. Turret truck

- 6.1. Table of content

- 6.2. Foreword

- 6.2.1. Linde Material Handling Your Partner

- 6.2.2. General

- 6.2.3. EC declaration of conformity

- 6.2.4. Safety instructions

- 6.2.5. Standard design and options Special version Special equipment

- 6.2.6. Truck identification, Factory nameplate

- 6.2.7. Product documentation

- 6.2.8. Storage and transfer

- 6.2.9. Copyright and proprietary rights

- 6.2.10. Operator,Form of address

- 6.3. Safety

- 6.3.1. General safety information

- 6.3.2. General safety information

- 6.3.3. Medical equipment, implants

- 6.3.4. Vibrations

- 6.3.5. Special safety advices for engaging loads

- 6.3.6. Safe handling of consumables

- 6.3.7. Risk assessment

- 6.3.8. Residual risks

- 6.3.9. Regular testing

- 6.3.10. Area of application

- 6.3.11. Original parts

- 6.3.12. Directives and guidelines

- 6.3.13. Drivers licence

- 6.4. Overview

- 6.4.1. Intended use

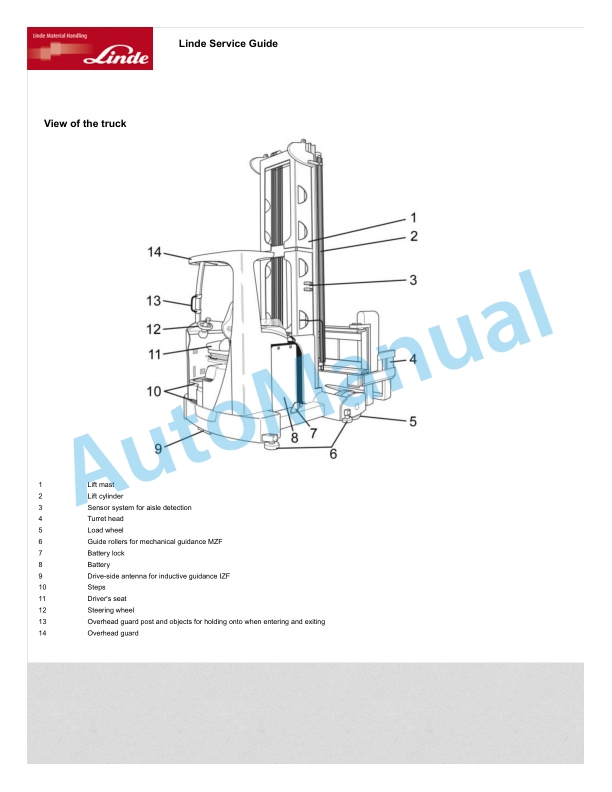

- 6.4.2. View of the truck

- 6.4.3. Functions

- 6.5. Operation

- 6.5.1. Initial commissioning

- 6.5.2. Transporting and loading

- 6.5.3. Installing the battery

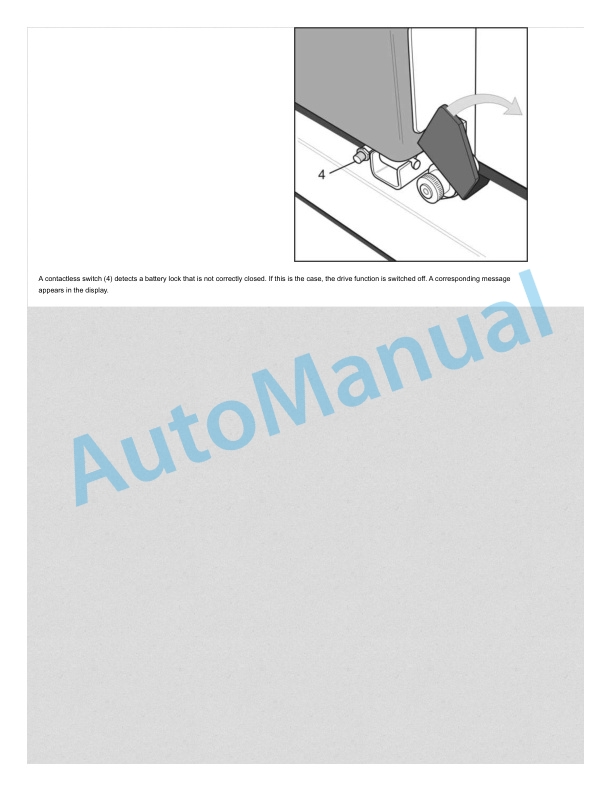

- 6.5.4. Battery lock

- 6.5.5. Battery discharge indicator

- 6.5.6. Preshift checklist

- 6.5.7. Entering and leaving

- 6.5.8. Seat switch

- 6.5.9. Display and Operating panel

- 6.5.10. Switching the display

- 6.5.11. Displays

- 6.5.12. Pedal operation

- 6.5.13. Initial driving exercises

- 6.5.14. Joystick functions

- 6.5.15. Picking up a load

- 6.5.16. Mechanical guidance MZF

- 6.5.17. Fork arms, adjustable

- 6.5.18. Parking and leaving the industrial truck

- 6.5.19. Emergency operation

- 6.5.20. Retrieving the truck

- 6.5.21. Decommissioning

- 6.6. Maintenance

- 6.6.1. Fuses

- 6.6.2. General information about maintenance and servicing

- 6.6.3. Maintenance schedule, 1000 hours

- 6.6.4. Lubrication plan

- 6.6.5. Lubricants

- 6.7. Technical Data

- 6.7.1. Technical data

- 6.8. Optional Equipment

- 6.8.1. Inductive guidance IZF

- 6.8.2. Acoustic warning signal

- 6.8.3. Working platforms

- 6.8.4. Special equipment for cold store application

- 6.8.5. Clipboard

- 6.8.6. Working spotlights

- 6.8.7. Electronic access control

- 6.8.8. Dualpedal version

- 6.8.9. Intermediate lift cutout

- 6.8.10. Hydraulic fork arm positioner

- 6.8.11. Attachments

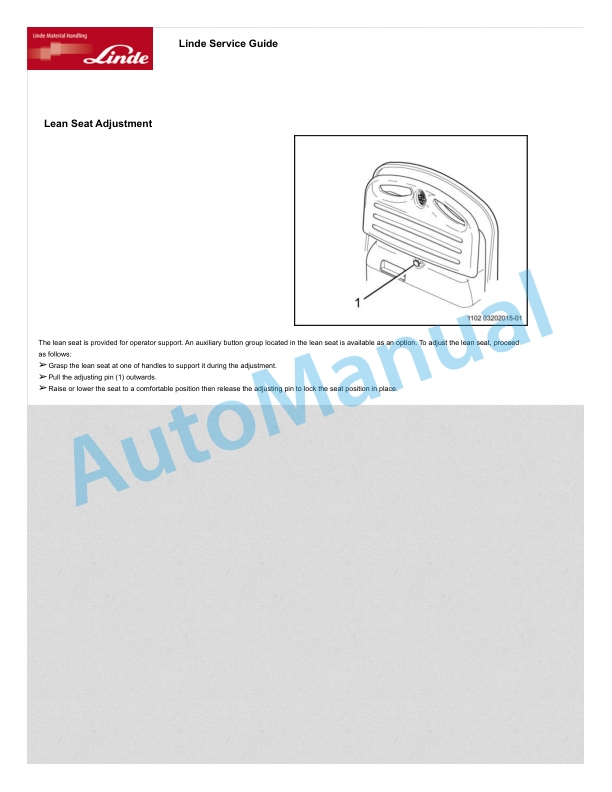

- 6.8.12. Electrical seat adjustment

- 6.8.13. Telescopic table

- 6.8.14. Height preselection system

- 7. Turret truck5220

- 7.1. Table of content

- 7.2. Foreword

- 7.2.1. Linde Your Partner

- 7.2.2. General

- 7.2.3. EC declaration of conformity in accordance with Machinery Directive

- 7.2.4. Safety instructions

- 7.2.5. Standard version and optional equipment

- 7.2.6. Truck identification, Factory nameplate

- 7.2.7. Product support documentation

- 7.2.8. Accessories accompanying the product

- 7.2.9. Safekeeping and passing on

- 7.2.10. Copyright and proprietary rights

- 7.2.11. Operator, form of address

- 7.3. Safety

- 7.3.1. General safety information

- 7.3.2. General safety information

- 7.3.3. Nonionising radiation

- 7.3.4. Vibrations

- 7.3.5. Special safety advices for engaging loads

- 7.3.6. Safe handling of operating media

- 7.3.7. Risk assessment

- 7.3.8. Residual dangers

- 7.3.9. Regular testing

- 7.3.10. Application area

- 7.3.11. Original parts

- 7.3.12. Directives and guidelines

- 7.3.13. Drivers licence

- 7.3.14. Personal protective equipment

- 7.4. Overview

- 7.4.1. View of the truck

- 7.4.2. Display and Operating panel

- 7.4.3. Displays

- 7.4.4. Purpose of use

- 7.4.5. Functions

- 7.5. Operation

- 7.5.1. Commissioning

- 7.5.2. Daily commissioning

- 7.5.3. Control devices

- 7.5.4. Driving

- 7.5.5. Load pickup

- 7.5.6. Emergency operation

- 7.5.7. Parking and Decommissioning the truck

- 7.6. Maintenance

- 7.6.1. Fuses

- 7.6.2. General maintenance information

- 7.6.3. Maintenance plan

- 7.6.4. Lubricants

- 7.6.5. Lubrication plan

- 7.6.6. Battery check

- 7.7. Technical Data

- 7.7.1. Technical data

- 7.8. Optional Equipment

- 7.8.1. Inductive guidance IZF

- 7.8.2. Acoustic warning signal

- 7.8.3. Working platforms

- 7.8.4. Trucks for use in cold storage

- 7.8.5. Clipboard

- 7.8.6. Working spotlights

- 7.8.7. LFM, electronic access control

- 7.8.8. Electronic access control

- 7.8.9. Twopedal design

- 7.8.10. Intermediate lift restriction

- 7.8.11. Hydraulic fork arm positioner

- 7.8.12. Attachments

- 7.8.13. Electrical seat adjustment

- 7.8.14. Telescopic table

- 7.8.15. Height preselection system

- 8. Visual warning unit

- 8.1. Table of content

- 8.2. Visual warning unit

- 8.2.1. Safety headlight

- 8.2.2. Retrofitting

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF