- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Linde 8918-01 – MT12C, MT15C Production site Xiamen Workshop Manuals SN CT8918M00001 and up

$50.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN CT8918M00001 and up

- Format: PDF

- Size: 20.7MB

- Number of Pages: 148

- Serial Number:

SN CT8918M00001 and up

Category: Linde Workshop Manual PDF

-

Model List:

- MT12C

- MT15C

- 1. Electric pallet truckMT12C . MT15C

- 1.1. Table of content

- 1.2. Product information

- 1.2.1. Truck information

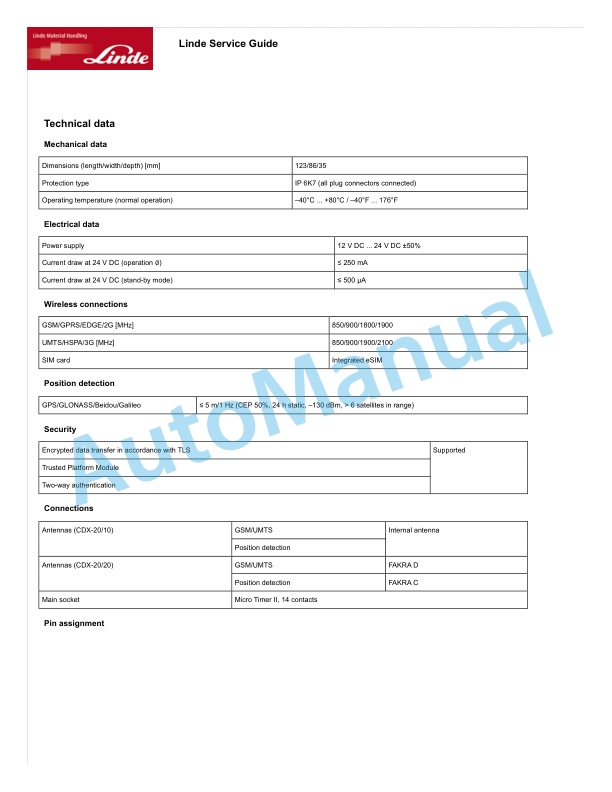

- 1.2.1.1. Technical description

- 1.2.1.2. General view

- 1.2.2. Aftersales service

- 1.2.2.1. Overview

- 1.2.2.2. Safety warnings

- 1.2.2.3. Operating tool

- 1.2.2.3.1. Commonly used tools

- 1.2.2.3.2. Torque for standard parts

- 1.2.2.4. Handheld unit

- 1.2.2.4.1. Handheld unit

- 1.2.2.4.2. Connecting the handheld unit

- 1.2.2.4.3. Handheld unit main screen

- 1.2.2.5. Maintenance and servicing

- 1.2.2.5.1. Cleaning the truck

- 1.2.2.5.2. Checks and maintenance

- 1.2.2.5.3. Service plan table

- 1.2.2.5.4. Inspection and maintenance data

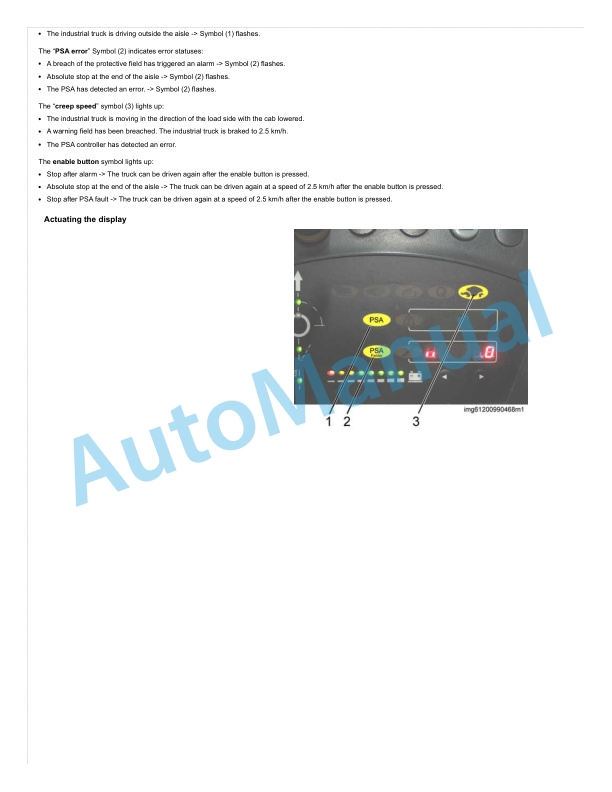

- 1.2.2.6. LED fault indicator light diagnostic

- 1.2.2.6.1. Fault indicator light

- 1.2.2.6.2. LED fault indicator diagnosis

- 1.2.2.7. Troubleshooting

- 1.2.2.7.1. Preparation before troubleshooting

- 1.2.2.7.2. Testing the battery voltage

- 1.2.2.7.3. Troubleshooting solutions to common faults

- 1.2.2.8. Aftersales software

- 1.2.2.8.1. Aftersales software

- 1.2.2.8.2. Linde Service Guide (LSG) diagnostics

- 1.2.3. Internal test specifications

- 1.2.3.1. Insulation test

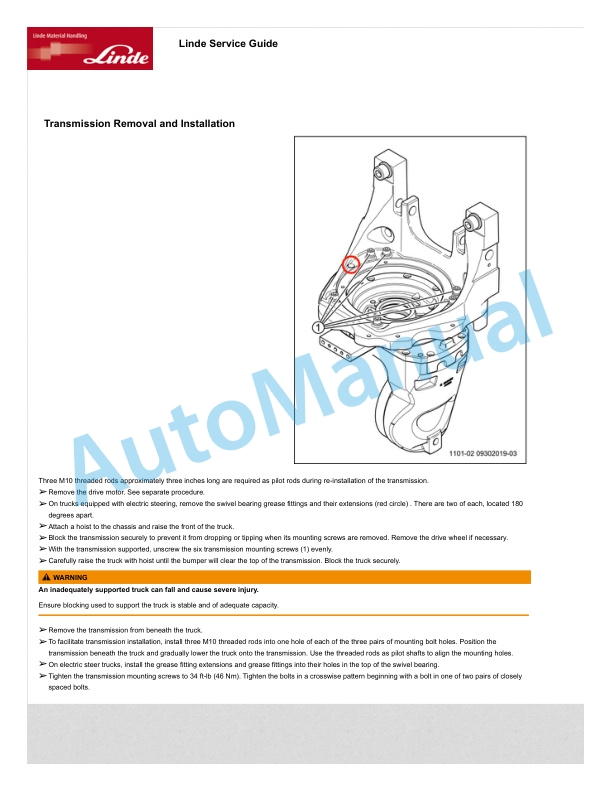

- 1.3. Drive mechanism and transmission system

- 1.3.1. Drive assembly

- 1.3.1.1. Drive assembly

- 1.3.1.2. Removing and installing

- 1.3.2. Electromagnetic brake

- 1.3.2.1. Electromagnetic brake

- 1.3.2.2. Removing and installing

- 1.3.2.3. Malfunctions and causes

- 1.3.2.4. Checking and testing

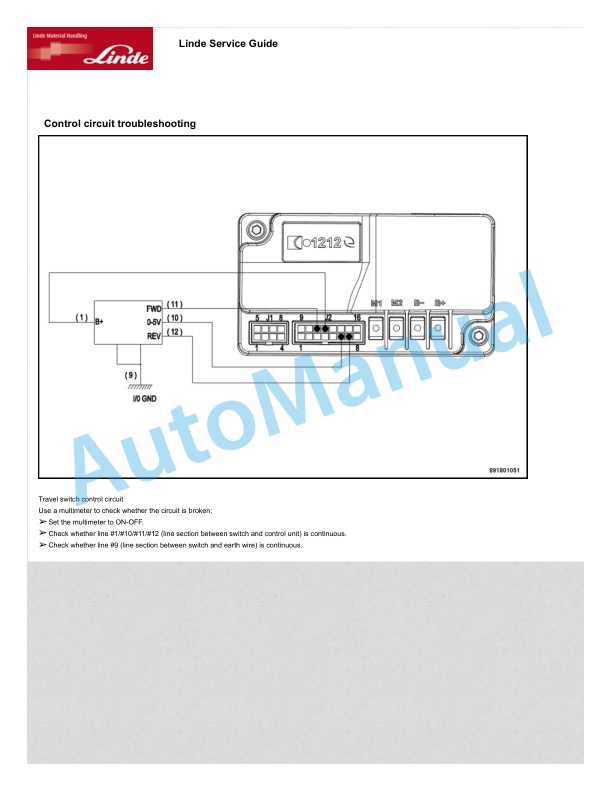

- 1.3.2.5. Control circuit troubleshooting

- 1.3.3. Drive wheel

- 1.3.3.1. Removing and installing

- 1.3.3.2. Malfunctions and causes

- 1.3.4. Drive motor

- 1.3.4.1. Removing and installing

- 1.3.4.2. Malfunctions and causes

- 1.3.4.3. Checking and testing

- 1.3.5. Gearbox

- 1.3.5.1. Removing and installing

- 1.3.5.2. Malfunctions and causes

- 1.4. Chassis and bodywork

- 1.4.1. Load wheel

- 1.4.1.1. Removing and installing

- 1.4.1.2. Malfunctions and causes

- 1.4.2. Front platform

- 1.4.2.1. Removing and installing

- 1.4.3. Cowling

- 1.4.3.1. Removing and installing

- 1.4.4. Castors

- 1.4.4.1. Removing and installing

- 1.4.5. Lifting mechanism

- 1.4.5.1. Checking the fork

- 1.4.5.2. Adjusting the connecting rod

- 1.4.5.3. Removing and installing

- 1.5. Drivers compartment

- 1.5.1. Structure and function

- 1.5.2. Operating handle

- 1.5.2.1. Operating handle

- 1.5.3. Pushbutton switch

- 1.5.3.1. Pushbutton switch

- 1.5.3.2. Removing and installing

- 1.5.3.3. Malfunctions and causes

- 1.5.3.4. Checking and testing

- 1.5.3.5. Control circuit troubleshooting

- 1.5.4. Drive switch

- 1.5.4.1. Drive switch

- 1.5.4.2. Malfunctions and causes

- 1.5.4.3. Checking and testing

- 1.5.4.4. Control circuit troubleshooting

- 1.5.5. Key switch

- 1.5.5.1. Key switch

- 1.5.5.2. Malfunctions and causes

- 1.5.5.3. Checking and testing

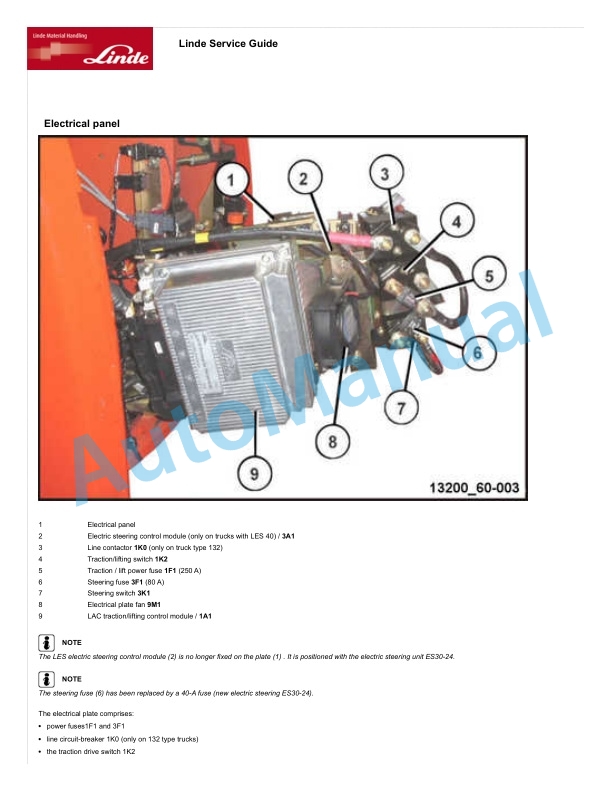

- 1.6. Electric.electronic module

- 1.6.1. Control unit (1212E)

- 1.6.1.1. Removing and installing

- 1.6.1.2. Control unit interface function

- 1.6.2. Interlock switch

- 1.6.2.1. Removing and installing

- 1.6.2.2. Malfunctions and causes

- 1.6.2.3. Checking and testing

- 1.6.2.4. Control circuit troubleshooting

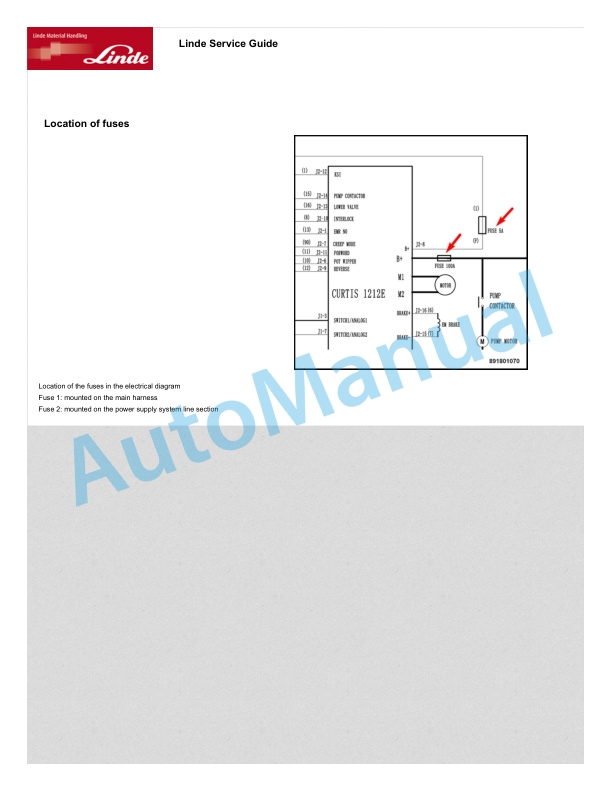

- 1.6.3. Fuse

- 1.6.3.1. Fuses

- 1.6.3.2. Location of fuses

- 1.6.3.3. Checking and testing

- 1.6.4. Lithiumion battery

- 1.6.4.1. Safety and warnings

- 1.6.4.2. Using the lithiumion battery

- 1.6.4.3. Maintenance and servicing

- 1.6.4.3.1. Maintenance of lithiumion batteries

- 1.6.4.3.2. Storage

- 1.6.4.3.3. Determining whether charging is normal

- 1.6.4.3.4. Determining whether the battery is normal

- 1.6.4.4. Lithiumion battery charging

- 1.6.4.4.1. Accessories

- 1.6.4.4.2. Charging precautions

- 1.6.4.4.3. External charging

- 1.6.4.4.4. Battery parameters

- 1.7. Hydraulic system

- 1.7.1. Hydraulic system

- 1.7.2. Hydraulic station

- 1.7.2.1. Removing and installing

- 1.7.2.2. Hydraulic station assembly

- 1.7.3. Pump motor

- 1.7.3.1. Removing and installing

- 1.7.3.2. Malfunctions and causes

- 1.7.3.3. Checking and testing

- 1.7.4. Pump contactor

- 1.7.4.1. Pump contactor

- 1.7.4.2. Removing and installing

- 1.7.4.3. Malfunctions and causes

- 1.7.4.4. Checking and testing

- 1.7.5. Solenoid valve

- 1.7.5.1. Solenoid valve

- 1.7.5.2. Malfunctions and causes

- 1.7.5.3. Checking and testing

- 1.7.6. Cylinder

- 1.7.6.1. Cylinder removal precautions

- 1.7.6.2. Cylinder installation precautions

- 1.7.6.3. Removing and installing

- 1.7.7. Hydraulics troubleshooting

- 1.7.7.1. Hydraulics troubleshooting

- 1.8. Schematic diagrams

- 1.8.1. Hydraulics diagrams

- 1.8.2. Electrical diagrams

- 1.8.2.1. Electrical diagrams

- 1.8.2.2. Wiring diagram

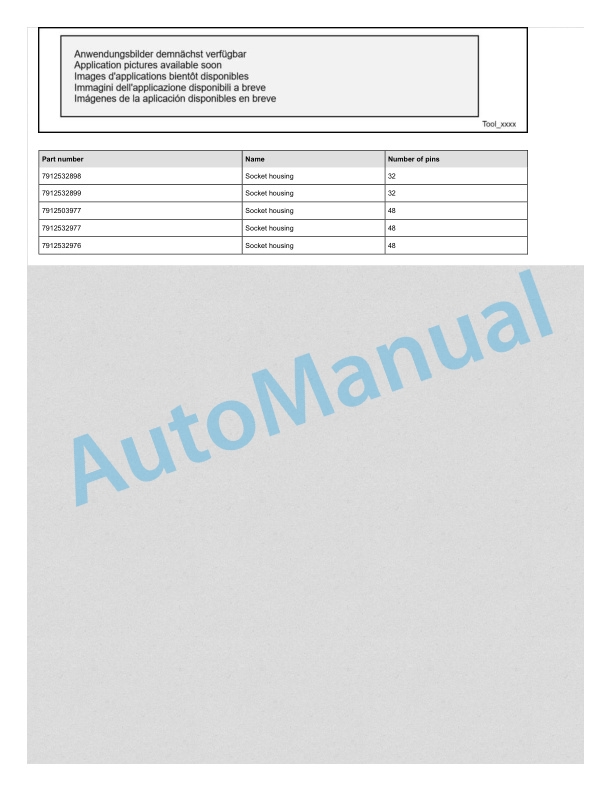

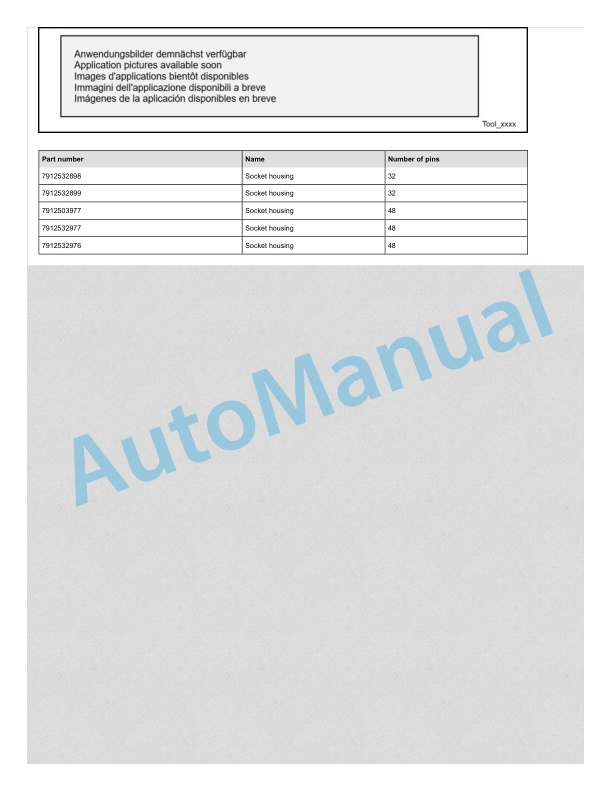

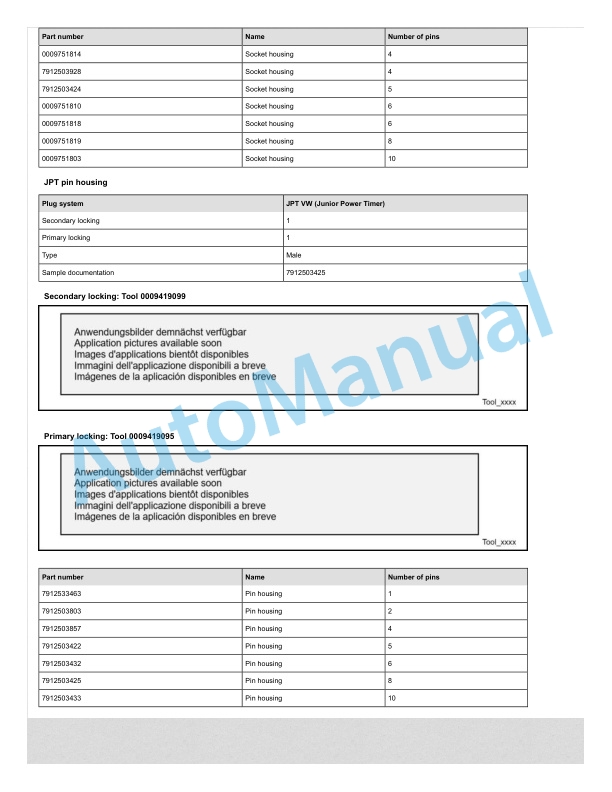

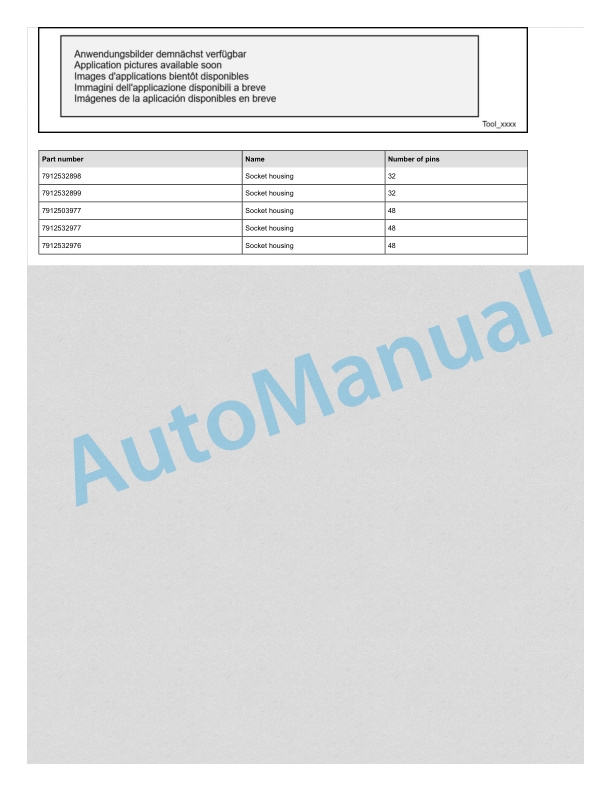

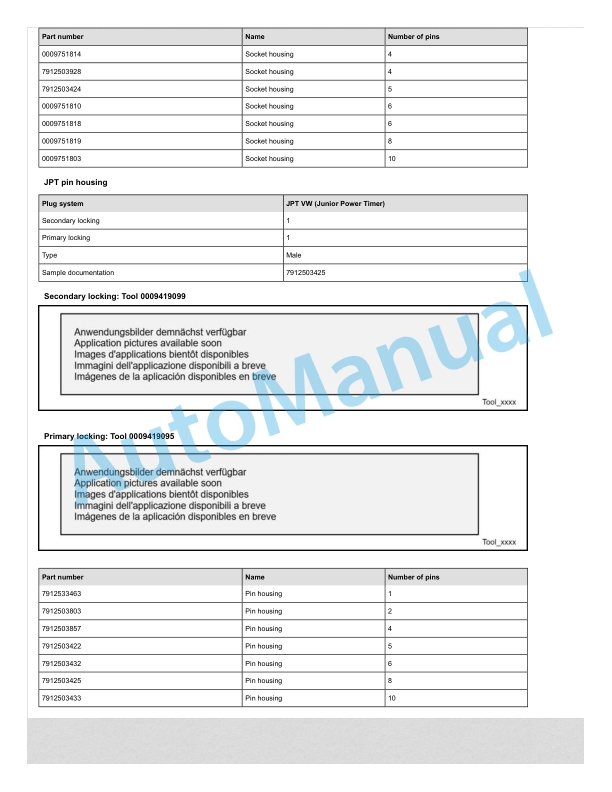

- 1.8.3. Harness and connector

Rate this product

You may also like

Linde Workshop Manual PDF

$50.00

Linde Workshop Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Workshop Manuals

$50.00

Linde Workshop Manual PDF

Linde 1110-01 – V08-01, V08-02 Workshop Manuals SN 11.09 and up SN up to W41110V00528

$50.00

Linde Workshop Manual PDF

$50.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF