New Holland E26C Mini Excavator Operation and Maintenance Manual 90436680

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 90436680

- Format: PDF

- Size: 12.3MB

- Number of Pages: 282

- Serial Number:

90436680

-

Model List:

- E26C Mini Excavator

- 1. GENERAL INFORMATION

- 1.1. Note to the Owner

- 1.2. Intended use

- 1.3. ElectroMagnetic Compatibility (EMC)

- 1.4. Telematics (optional)

- 1.5. Manual scope and required training level

- 1.6. Product identification

- 1.7. Operators manual storage on the machine

- 1.8. Machine orientation

- 1.9. Machine components

- 1.10. Emissions overview

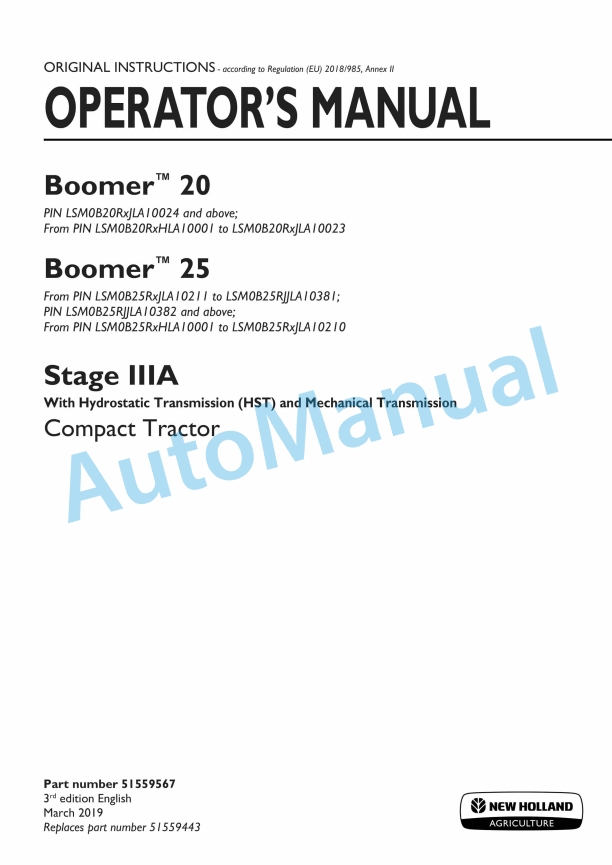

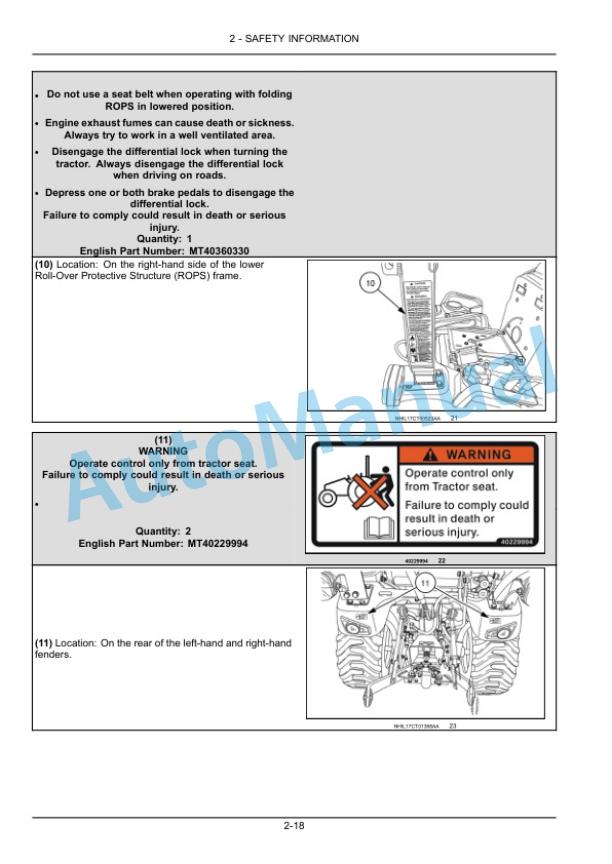

- 2. SAFETY INFORMATION

- 2.1. Signal word definitions

- 2.2. Safety rules Utility precautions

- 2.3. Safety rules

- 2.4. Ecology and environment

- 2.5. Hand signals

- 2.6. Safety signs

- 3. CONTROLS AND INSTRUMENTS

- 3.1. Access to operators platform

- 3.1.1. Door and steps

- 3.2. Operators seat

- 3.2.1. Operators seat

- 3.3. Forward controls

- 3.3.1. Forward controls

- 3.3.2. Windshield

- 3.4. Lefthand side controls

- 3.4.1. Lefthand side controls

- 3.4.2. Safety lock lever

- 3.4.3. Engine speed control lever

- 3.4.4. Emergency exit hammer

- 3.4.5. Windshield washer reservoir

- 3.5. Righthand side controls

- 3.5.1. Righthand side controls

- 3.5.2. Dozer blade control lever

- 3.5.3. Instrument cluster

- 3.5.4. Ventilation and heating

- 3.6. Rearward controls

- 3.6.1. Storage compartment

- 3.7. Overhead controls

- 3.7.1. Cab internal lighting

- 3.7.2. Radio

- 3.8. Exterior controls

- 3.8.1. Side doors

- 3.8.2. Rear view mirrors

- 3.8.3. Battery disconnect switch

- 3.8.4. Fuel tank

- 4. OPERATING INSTRUCTIONS

- 4.1. Starting the unit

- 4.1.1. Antitheft protection

- 4.1.2. Starting the engine

- 4.1.3. Bringing the machine up to operating temperature

- 4.1.4. Operating the machine in hot or cold weather

- 4.1.5. Operating the machine

- 4.1.6. Lowering the attachment in the event of a failure

- 4.1.7. Bucket replacement

- 4.1.8. Hydraulic control lever operating pattern

- 4.1.9. Caution while using rubber crawlers

- 4.2. Stopping the unit

- 4.2.1. Stopping the engine

- 4.3. Moving the unit

- 4.3.1. Machine travel

- 4.4. Parking the unit

- 4.4.1. Parking the machine

- 5. TRANSPORT OPERATIONS

- 5.1. Road transport

- 5.1.1. Loading the machine onto a transport trailer

- 5.2. Preparing for road transport

- 5.2.1. Tie downs for shipping

- 5.2.2. Unloading the machine from a transport trailer

- 5.3. Shipping transport

- 5.3.1. Handling the machine

- 5.4. Recovery transport

- 5.4.1. Towing the machine

- 6. MAINTENANCE

- 6.1. General information

- 6.1.1. Basic instructions

- 6.1.2. General specification Biodiesel fuels

- 6.1.3. Fluids and lubricants

- 6.1.4. Releasing pressure in the hydraulic system

- 6.1.5. Fuel system bleeding

- 6.1.6. Protecting the electronic and electrical systems during battery charging or welding

- 6.2. Maintenance planning

- 6.2.1. Maintenance chart

- 6.3. Breakin period

- 6.3.1. Grease points (Bucket)

- 6.3.2. Grease points (Boom and arm)

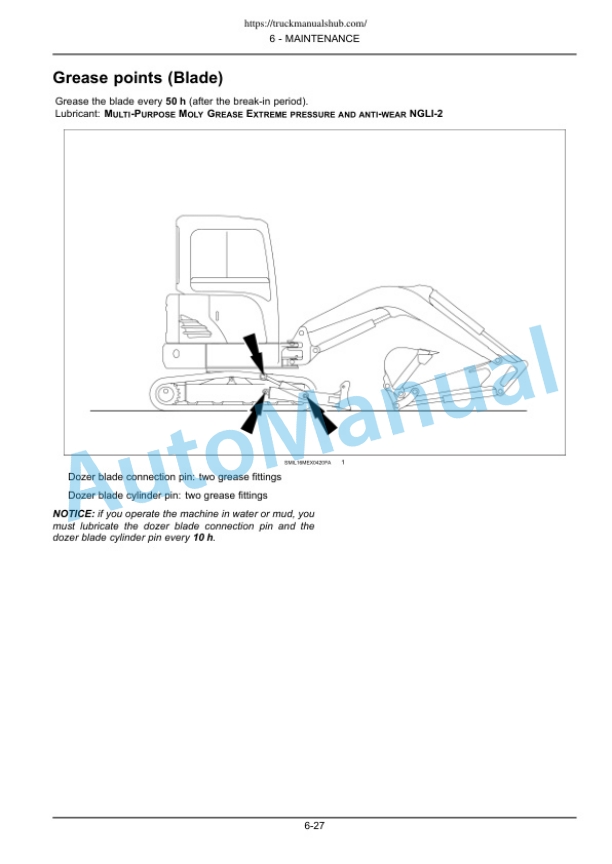

- 6.3.3. Grease points (Blade)

- 6.3.4. Tightening torques

- 6.3.5. Fuel filter

- 6.3.6. Hydraulic oil return filter

- 6.3.7. Pilot line filter

- 6.3.8. Travel reduction gears

- 6.3.9. Boom swing cylinder

- 6.4. Every 10 hours

- 6.4.1. Engine oil level

- 6.4.2. Engine coolant level

- 6.4.3. Hydraulic oil level

- 6.4.4. Fuel filter water separator

- 6.4.5. Fan and alternator drive belt

- 6.5. Every 50 hours

- 6.5.1. Grease points (Bucket)

- 6.5.2. Grease points (Blade)

- 6.5.3. Track tension

- 6.5.4. Swing ring gear

- 6.5.5. Fuel tank drain

- 6.6. Every 100 hours

- 6.6.1. Fuel filter water separator

- 6.7. Every 250 hours

- 6.7.1. Engine oil and filter

- 6.7.2. Battery

- 6.7.3. Swing bearing

- 6.7.4. Boom swing cylinder

- 6.7.5. Tightening torques

- 6.7.6. Grease points (Boom and arm)

- 6.8. Every 400 hours

- 6.8.1. Fuel filter

- 6.9. Every 500 hours

- 6.9.1. Air cleaner

- 6.9.2. Radiator and coolers

- 6.10. Every 750 hours

- 6.10.1. Valve clearance

- 6.11. Every 1000 hours

- 6.11.1. Hydraulic oil return filter

- 6.11.2. Pilot line filter

- 6.11.3. Travel reduction gears

- 6.12. Every 1500 hours

- 6.12.1. Injection nozzle

- 6.13. Every 2000 hours

- 6.13.1. Air cleaner

- 6.13.2. Engine coolant

- 6.13.3. Hydraulic oil suction filter

- 6.13.4. Hydraulic hoses

- 6.13.5. Biodegradable hydraulic oil

- 6.14. Every 3000 hours

- 6.14.1. Injection pump

- 6.14.2. Fuel injection system

- 6.15. Every 5000 hours

- 6.15.1. Hydraulic oil

- 6.16. When necessary

- 6.16.1. Cab and working lights

- 6.16.2. Cab air filter

- 6.16.3. Fuel tank strainer

- 6.16.4. Control levers

- 6.16.5. Plastic and resin parts

- 6.17. Fuse and relay locations

- 6.17.1. Fuses

- 6.18. Storage

- 6.18.1. Preparing for storage

- 6.18.2. Periodic checks

- 6.18.3. Starting up the machine after storage

- 7. TROUBLESHOOTING

- 7.1. Fault code resolution

- 7.1.1. Engine Troubleshooting

- 7.1.2. Electrical systems Troubleshooting

- 7.1.3. Other systems Troubleshooting

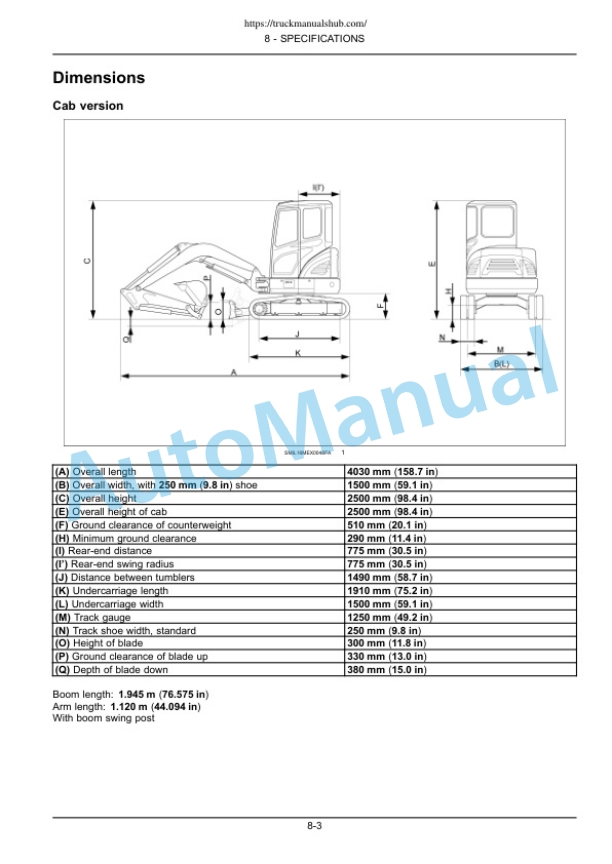

- 8. SPECIFICATIONS

- 8.1. Machine specifications

- 8.2. Dimensions

- 8.3. Weights

- 9. ACCESSORIES

- 9.1. Direct fit buckets

- 9.2. Klac type buckets

- 9.3. Standard buckets with mechanical coupler

- 9.4. Standard buckets with Hydraulic pin grabber coupler

- 9.5. Auxiliary hydraulic circuits

- 9.6. Hydraulic oil breaker/auger

- 9.7. Quick coupling system Klac type

- 9.8. Quick coupling system Mechanical pingrabber type

- 9.9. Quick coupling system Hydraulic pingrabber type

- 9.10. Load handling

- 9.11. Thumb bracket

- 9.12. Rotating beacon

- 9.13. Fire extinguisher

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 51559567

New Holland Operator Manual PDF

New Holland 24 Boomer Compact Tractor Operation and Maintenance Manual 47727071

New Holland Operator Manual PDF

New Holland 25S Workmaster Tier 4B Final Compact Tractor Operation and Maintenance Manual 51409930

New Holland Operator Manual PDF

New Holland 16LA, 17LA Loader Operation and Maintenance Manual 87571253

New Holland Operator Manual PDF

New Holland 18LA Loader Operation and Maintenance Manual 87571257

New Holland Operator Manual PDF

New Holland 105LC For Boomer 25 Compact Front Loader Operation and Maintenance Manual 51562809

New Holland Operator Manual PDF

New Holland 160GMS For Boomer 25 Compact Mower Deck Operation and Maintenance Manual 51567834

New Holland Operator Manual PDF

New Holland 250TL For Boomer 8N Tractor Operation and Maintenance Manual 84207117

New Holland Operator Manual PDF

New Holland 1530, 1630 Tractor Operation and Maintenance Manual 42153021

New Holland Operator Manual PDF

New Holland 140TL Loader Operation and Maintenance Manual 48070328