New Holland L213 – L228 Tier 4B Final 200 Series Skid Steer Loader – C227 – C237 Tier 4B Final 200 Series Compact Track Loader Operation and Maintenance Manual 48068134

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 48068134

- Format: PDF

- Size: 36.2MB

- Number of Pages: 328

- Serial Number:

48068134

-

Model List:

- L213 Tier 4B Final 200 Series Skid Steer Loader

- L216 Tier 4B Final 200 Series Skid Steer Loader

- L218 Tier 4B Final 200 Series Skid Steer Loader

- L220 Tier 4B Final 200 Series Skid Steer Loader

- L221 Tier 4B Final 200 Series Skid Steer Loader

- L228 Tier 4B Final 200 Series Skid Steer Loader

- C227 Tier 4B Final 200 Series Compact Track Loader

- C232 Tier 4B Final 200 Series Compact Track Loader

- C237 Tier 4B Final 200 Series Compact Track Loader

- 1. GENERAL INFORMATION

- 1.1. Note to the owner

- 1.2. ElectroMagnetic Compatibility (EMC)

- 1.3. Product identification

- 1.4. Operators manual storage on the machine

- 1.5. Machine orientation

- 1.6. Machine components

- 1.7. Emissions overview (L221, L228, C227, C232, and C237)

- 1.8. Emissions overview (L213, L216, L218, and L220)

- 2. SAFETY INFORMATION

- 2.1. Safety rules and signal word definitions

- 2.2. Safety rules

- 2.3. Utility safety

- 2.4. Proper entry and exit

- 2.5. Starting and stopping precautions

- 2.6. Seat belt precautions

- 2.7. Specific precautions to this machine

- 2.8. Fire extinguisher

- 2.9. Safety rules California Proposition 65 Warning

- 2.10. Roll Over Protective Structure (ROPS)

- 2.11. Welding on the machine

- 2.12. Loader arm lock and cab tilt procedure radial lift machines

- 2.13. Loader arm lock and cab tilt procedure vertical lift machines

- 2.14. No engine power loader arm up and down control

- 2.15. Emergency exit

- 2.16. Ecology and the environment

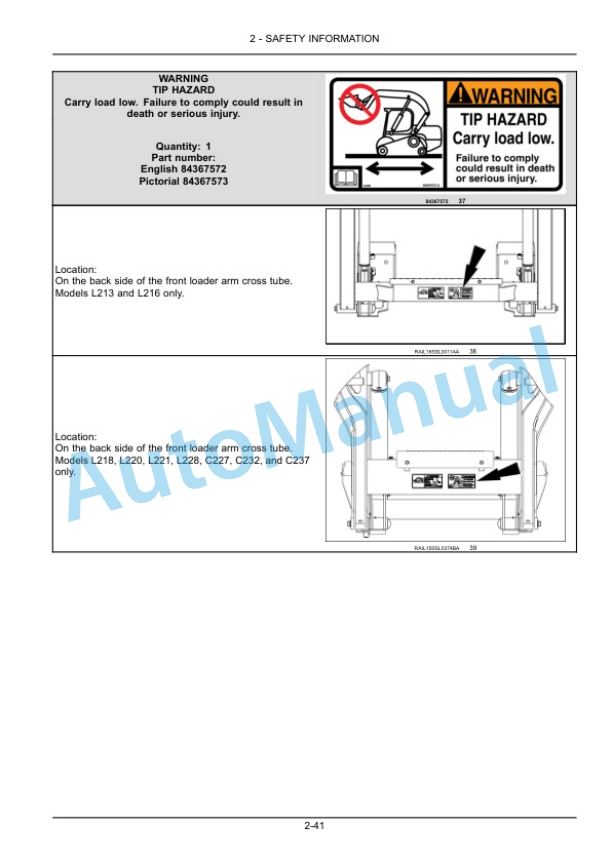

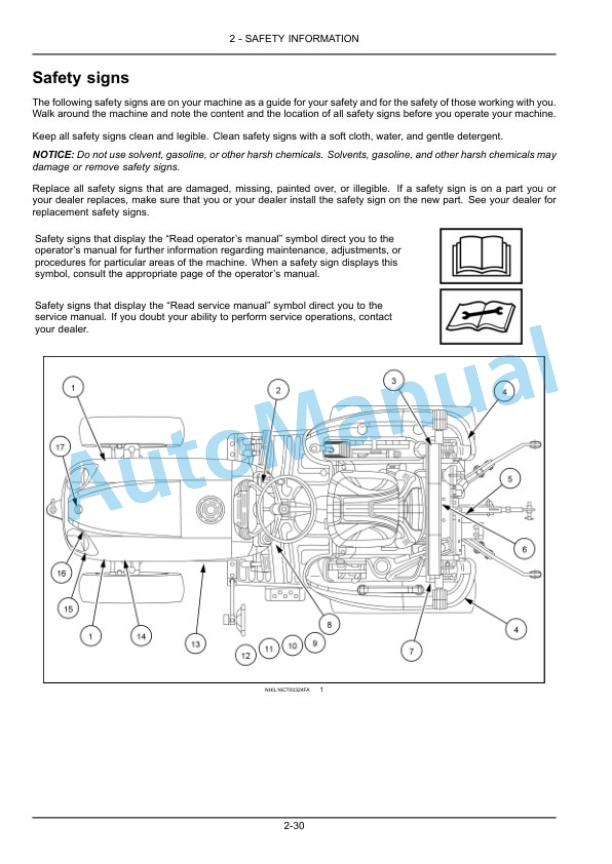

- 2.17. Safety signs

- 3. CONTROLS AND INSTRUMENTS

- 3.1. ACCESS TO OPERATORS PLATFORM

- 3.1.1. Door latches, cab

- 3.1.2. Window glass, cab

- 3.1.3. Windshield wiper and washer controls

- 3.1.4. Cab air louvers

- 3.2. OPERATORS SEAT

- 3.2.1. Standard seat

- 3.2.2. Mechanical suspension seat

- 3.2.3. Air seat

- 3.2.4. Seat belt operation

- 3.2.5. Shoulder belt

- 3.2.6. Restraint bar (if equipped)

- 3.3. MECHANICAL HYDRAULIC CONTROLS

- 3.3.1. Steering and travel

- 3.3.2. Lift arm and bucket controls

- 3.3.3. Moving the machine

- 3.3.4. Turning the machine

- 3.3.5. Hand controls

- 3.3.6. Foot controls

- 3.4. ELECTROHYDRAULIC CONTROLS

- 3.4.1. Control pattern overview

- 3.4.2. H control pattern steering and travel

- 3.4.3. H control pattern lift arm and bucket controls

- 3.4.4. ISO control pattern steering and travel

- 3.4.5. ISO control pattern lift arm and bucket controls

- 3.4.6. Standard H control pattern

- 3.4.7. Standard ISO control pattern

- 3.4.8. Electrohydraulic control handle adjustment

- 3.4.9. Hand controls

- 3.4.10. Moving the machine

- 3.4.11. Turning the machine

- 3.4.12. Lift arm raise/lower control

- 3.4.13. Bucket curl/dump control

- 3.4.14. Moving the machine

- 3.4.15. Turning the machine

- 3.4.16. Lift arm and bucket controls

- 3.5. CONTROL LEVERS

- 3.5.1. Switch configurations

- 3.5.2. Twospeed function

- 3.6. AUXILIARY HYDRAULICS

- 3.6.1. Standard auxiliary hydraulics

- 3.6.2. High flow auxiliary hydraulics

- 3.6.3. Enhanced High Flow (EHF) auxiliary hydraulics

- 3.7. INSTRUMENT CLUSTER

- 3.7.1. Electronic Instrument Cluster (EIC)

- 3.7.2. Advanced Instrument Cluster (AIC)

- 3.7.3. Instrument cluster

- 3.7.4. Instrument cluster SETUP menu

- 3.7.5. Instrument cluster display setting

- 3.7.6. ElectroHydraulic (EH) controllability selection

- 3.7.7. Temperature display selection

- 3.7.8. View or reset Job Timer (JTIME)

- 3.7.9. Regeneration inhibit

- 3.7.10. Oil life reset

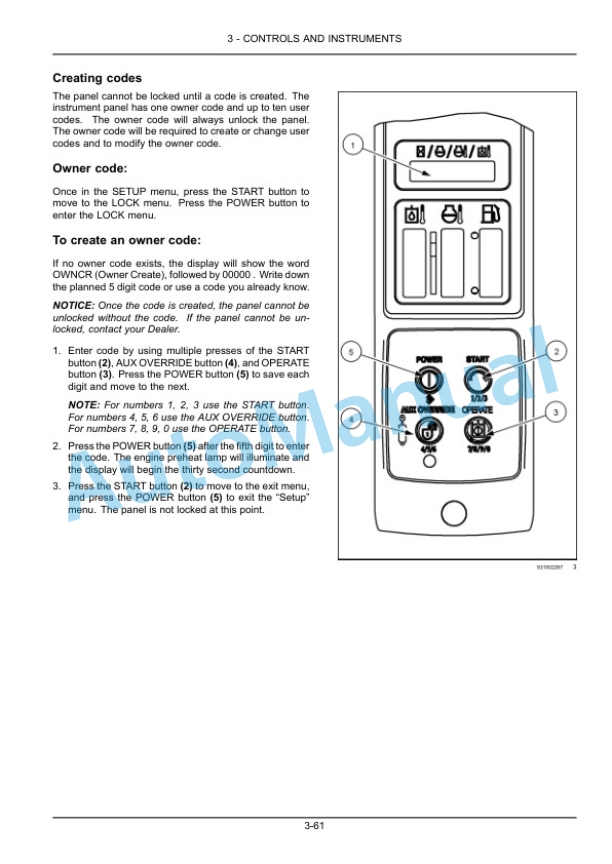

- 3.7.11. Antitheft protection

- 3.7.12. Instrument cluster timeout feature

- 3.7.13. Lefthand column switch identification

- 3.7.14. ISO or H pattern control switch

- 3.7.15. Machine lights

- 3.7.16. Radio (if equipped)

- 4. OPERATING INSTRUCTIONS

- 4.1. COMMISSIONING THE UNIT

- 4.1.1. Operating Instructions

- 4.2. STARTING THE UNIT

- 4.2.1. Engine operation

- 4.2.2. Operating in extreme temperatures

- 4.2.3. Throttle control

- 4.2.4. Booster battery procedure

- 4.3. STOPPING THE UNIT

- 4.3.1. Parking the machine and stopping the engine

- 4.4. MOVING THE UNIT

- 4.4.1. Machine operation

- 5. TRANSPORT OPERATIONS

- 5.1. SHIPPING TRANSPORT

- 5.1.1. Transporting the machine

- 5.2. RECOVERY TRANSPORT

- 5.2.1. Moving a disabled machine

- 6. WORKING OPERATIONS

- 6.1. GENERAL INFORMATION

- 6.1.1. Mechanical attachment mounting systems

- 6.1.2. Hydraulic attachment mounting systems

- 6.1.3. Field operation

- 7. MAINTENANCE

- 7.1. GENERAL INFORMATION

- 7.1.1. General safety before you service

- 7.1.2. Lubrication analysis program

- 7.1.3. Plastic and resin parts

- 7.1.4. Machine cleaning

- 7.1.5. Cab door removal and installation

- 7.1.6. Battery safety check and cleaning

- 7.1.7. Fire extinguisher

- 7.1.8. Engine hourmeter

- 7.1.9. Fluids and lubricants

- 7.1.10. Engine oil viscosity

- 7.1.11. Hydraulic oil viscosity

- 7.1.12. Organic Acid Technology (OAT) coolant

- 7.1.13. General specification Diesel fuel

- 7.1.14. General specification Biodiesel fuels

- 7.1.15. Lubrication and maintenance access

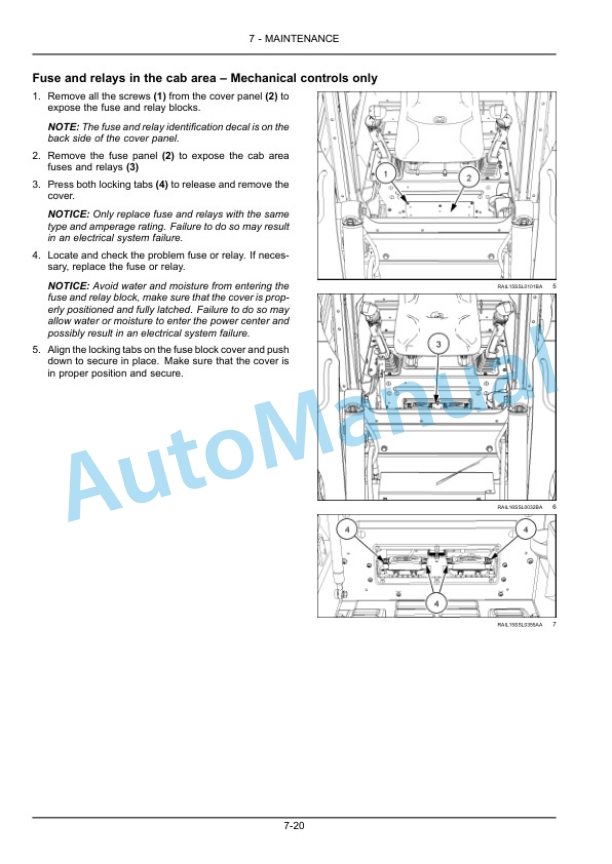

- 7.1.16. Fuses and relays

- 7.2. MAINTENANCE CHART

- 7.2.1. Maintenance chart

- 7.3. INITIAL 10 HOURS

- 7.3.1. Track tension check and adjustment

- 7.3.2. Tire pressure and wheel hardware torque

- 7.3.3. Alternator and air conditioning compressor (if equipped) belt tension (models L213, L216, L218, and L220 only)

- 7.4. EVERY 10 HOURS OR DAILY

- 7.4.1. Clean tracks and components

- 7.4.2. Engine and hydraulic coolers

- 7.4.3. Engine coolant level

- 7.4.4. Engine oil level

- 7.4.5. Loader arm pivot points, coupler pins, and cylinder pins

- 7.4.6. Hydraulic oil level

- 7.4.7. Loader arm and bucket hydraulic interlock

- 7.5. INITIAL 50 HOURS

- 7.5.1. Roll Over Protective Structure (ROPS) mechanism and hardware check

- 7.6. EVERY 50 HOURS

- 7.6.1. Track tension check and adjustment

- 7.6.2. Cab intake filter

- 7.6.3. Seat restraints Check

- 7.7. INITIAL 100 HOURS

- 7.7.1. Final drive oil (track models)

- 7.8. EVERY 250 HOURS

- 7.8.1. Inline fuel filter (models L213 and L216 only)

- 7.8.2. Fuelwater separator filter drain fluid

- 7.8.3. Drive chain tension check

- 7.8.4. Tire pressure and wheel hardware torque

- 7.9. EVERY 500 HOURS

- 7.9.1. Engine oil and filter

- 7.9.2. Fuelwater separator filter element

- 7.9.3. Fuel filter

- 7.9.4. Hydraulic oil filter

- 7.9.5. Final drive chain tank oil

- 7.9.6. Air cleaner elements

- 7.9.7. Final drive oil (track models)

- 7.9.8. Roll Over Protective Structure (ROPS) mechanism and hardware check

- 7.9.9. Cab door Grease

- 7.10. EVERY 1000 HOURS

- 7.10.1. Hydraulic fluid and filter

- 7.10.2. Final drive chain tank oil

- 7.10.3. Oil Mist Separator (OMS) filter (models L213, L216, L218, and L220 only)

- 7.11. EVERY 2000 HOURS

- 7.11.1. Blowby recirculation system (models L221, L228, C227, C232, and C237 only)

- 7.12. EVERY 4000 HOURS

- 7.12.1. Diesel Particulate Filters (DPF) Cleaning (models L213 and L216 only)

- 7.12.2. Engine cooling system Change fluid L213, L216, L218, and L220 only

- 7.12.3. Engine cooling system Change fluid L221, L228, C227, C232, and C237 only

- 7.13. AS REQUIRED

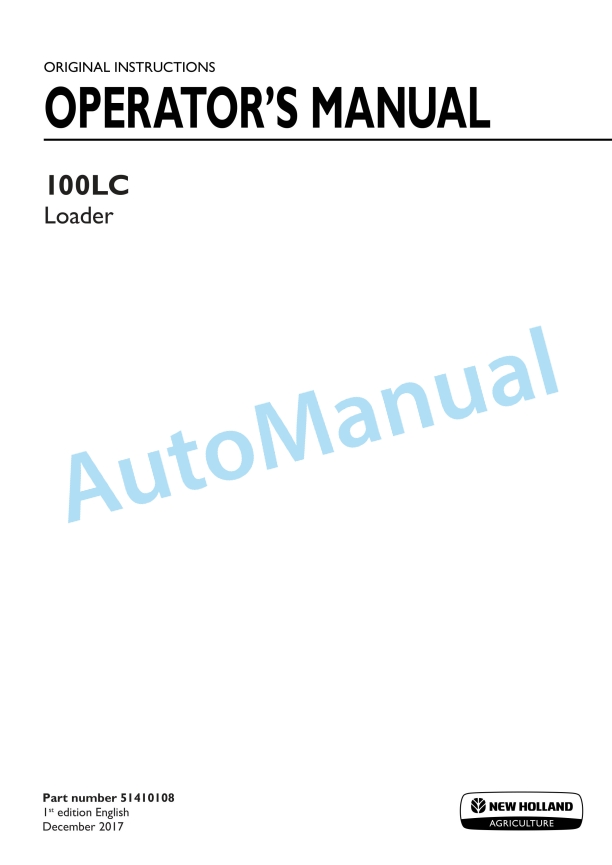

- 7.13.1. Autoregeneration

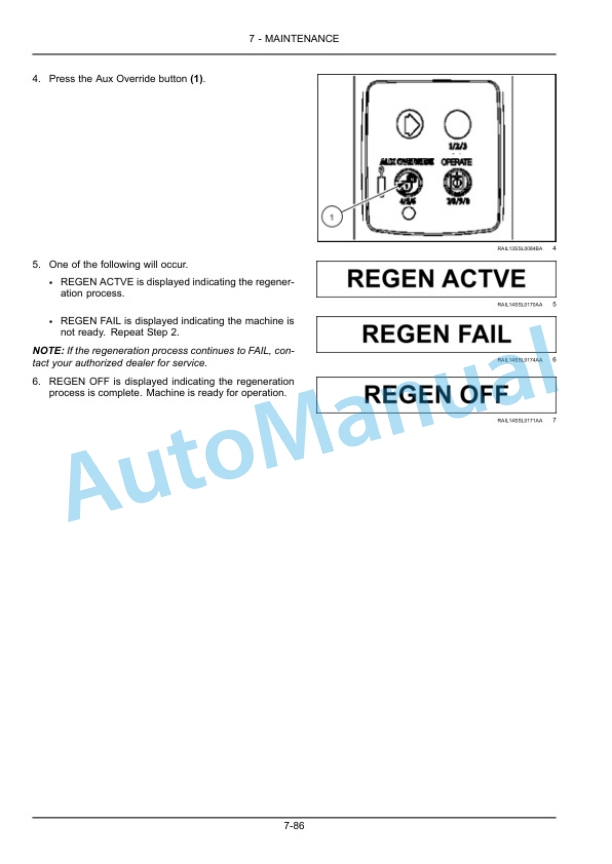

- 7.13.2. Manual regeneration

- 7.13.3. Hardware loose or damaged

- 7.13.4. Window removal and cleaning

- 7.14. STORAGE

- 7.14.1. Storing the machine

- 7.14.2. Preparing the machine after storage

- 8. TROUBLESHOOTING

- 8.1. FAULT CODE RESOLUTION

- 8.1.1. Display warnings

- 8.1.2. Fault code index

- 9. SPECIFICATIONS

- 9.1. Fluids and lubricants

- 9.2. General specification

- 9.3. Product identification attachments

- 9.4. Material weights

- 9.5. Units of measure and conversion

- 9.6. Torque charts Minimum tightening torques for normal assembly

- 10. ACCESSORIES

- 10.1. Telematics Overview with New Holland FleetForce

New Holland Operator Manual PDF

New Holland 100LC Loader Operation and Maintenance Manual 51410108

New Holland Operator Manual PDF

New Holland 250TL For Boomer 8N Tractor Operation and Maintenance Manual 84207117

New Holland Operator Manual PDF

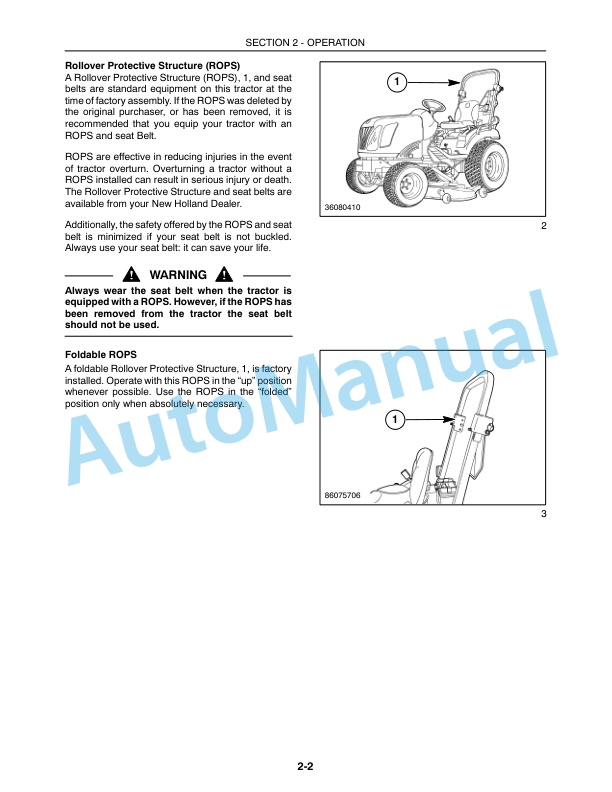

New Holland 1030, 230GM Boomer Operation and Maintenance Manual 87487351

New Holland Operator Manual PDF

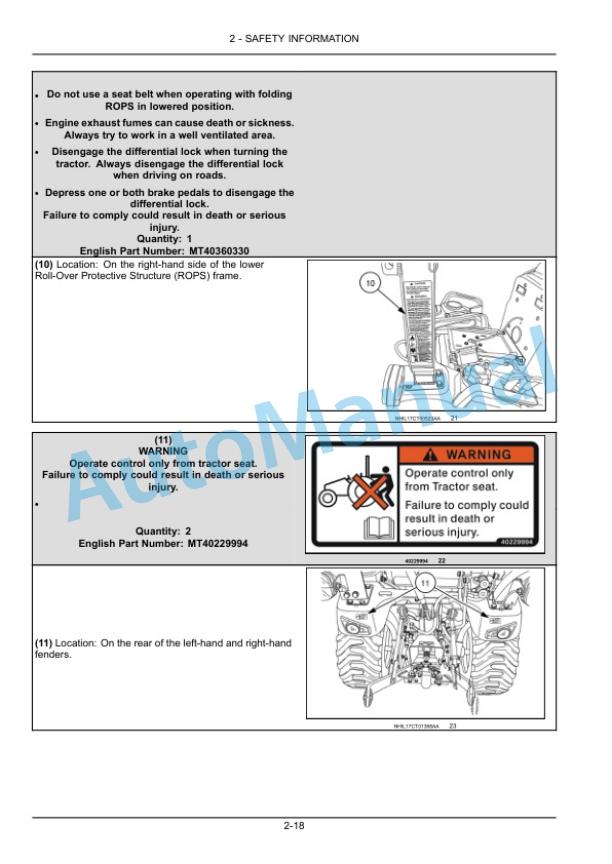

New Holland 25S Workmaster Tier 4B Final Compact Tractor Operation and Maintenance Manual 51409930

New Holland Operator Manual PDF

New Holland 200LC Loader Operation and Maintenance Manual 51421058

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 48116702

New Holland Operator Manual PDF

New Holland 250TLA Farm Loader Operation and Maintenance Manual 48077338

New Holland Operator Manual PDF

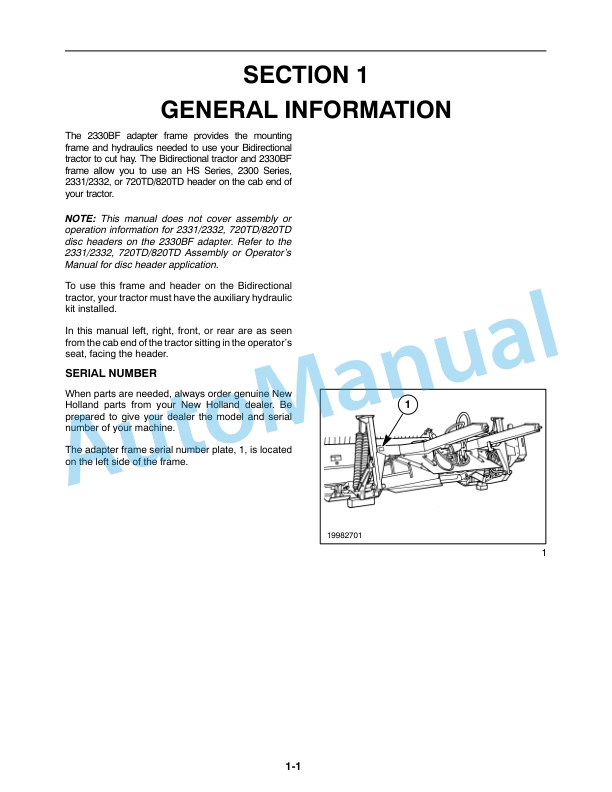

New Holland 2330BF Adapter Frame Operation and Maintenance Manual 87716208

New Holland Operator Manual PDF

New Holland 24 Boomer Compact Tractor Operation and Maintenance Manual 47727071

New Holland Operator Manual PDF

New Holland 1720 Tractor Operation and Maintenance Manual 42172010