New Holland T1254B, T1404B Tractor Operation and Maintenance Manual 51426551

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 51426551

- Format: PDF

- Size: 11.4MB

- Number of Pages: 334

- Serial Number:

51426551

-

Model List:

- T1254B Tractor

- T1404B Tractor

- 1. GENERAL INFORMATION

- 1.1. Metric and imperial units abbreviations

- 1.2. To the owner

- 1.3. Product Identification

- 1.4. Engine identification

- 1.5. Drive line identification

- 1.6. Product identification plate

- 1.7. Ecology and the environment

- 1.8. Safety rules

- 1.9. Personal safety

- 1.10. Driving the tractor

- 1.11. Operating the tractor

- 1.12. Fire extinguisher

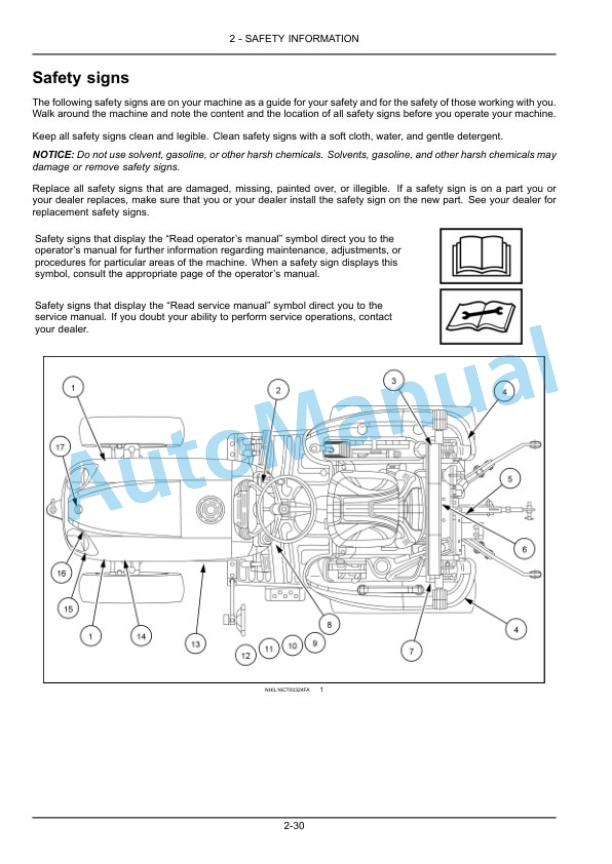

- 1.13. Safety decals

- 1.14. International symbols

- 1.15. Airborne noise emission

- 1.16. Tractor vibration level information sheet

- 1.17. Machine stability

- 1.18. About this manual

- 1.19. Programming tractor functions

- 1.20. Before operating

- 1.21. Instructors seat

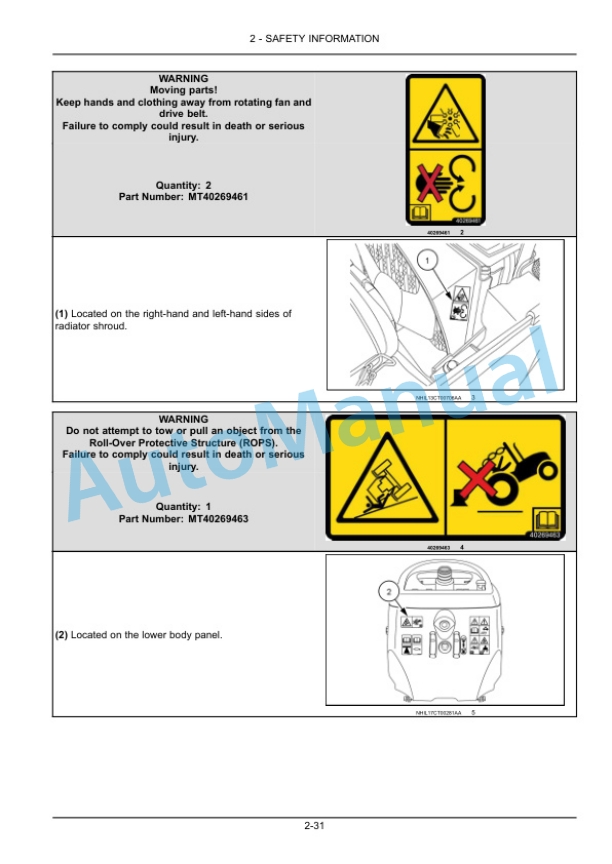

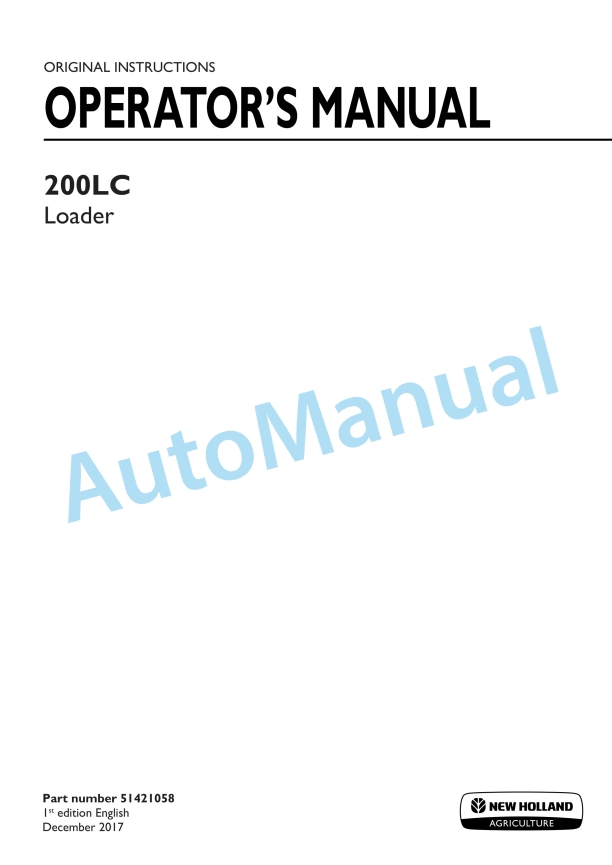

- 2. SAFETY INFORMATION

- 2.1. Safety precautions

- 2.2. Safety decals

- 2.3. Safety rules

- 2.4. Fire or explosion prevention

- 2.5. Fire extinguisher

- 2.6. Protection offered by the tractor

- 2.7. Intended use statement

- 3. CONTROLS AND INSTRUMENTS

- 3.1. ACCESS TO OPERATORS PLATFORM

- 3.1.1. Cab and platform Access/Exit

- 3.1.2. Cab air recirculation filter

- 3.1.3. Cable and harness routing

- 3.1.4. Mobile telephone usage

- 3.1.5. Implement monitor installation

- 3.1.6. Cab pressurization monitor (where fitted)

- 3.1.7. Runningin procedure

- 3.2. OPERATORS SEAT

- 3.2.1. Seat belt and operator presence switch (where fitted)

- 3.3. FORWARD CONTROLS

- 3.3.1. Key start switch

- 3.3.2. Hazard warning light operation

- 3.3.3. Lights and turn indicator lever

- 3.3.4. Windshield wiper and washer controls

- 3.3.5. Foot brakes

- 3.3.6. Steering column

- 3.3.7. Adjustable air vents

- 3.4. LEFTHAND SIDE CONTROLS

- 3.4.1. Handbrake

- 3.5. RIGHTHAND SIDE CONTROLS

- 3.5.1. Switch panel

- 3.6. REARWARD CONTROLS

- 3.6.1. Righthand side cab C pillar

- 3.7. OVERHEAD CONTROLS

- 3.7.1. Radio or audio system

- 3.8. INSTRUMENT CLUSTER

- 3.8.1. Instrument cluster

- 3.8.2. Gauges

- 3.8.3. Indicator and warning lights

- 3.8.4. Displays

- 3.8.5. Tractor ground speed display

- 3.8.6. Calibrating the ground speed display

- 3.8.7. Warning and advisory symbols

- 4. OPERATING INSTRUCTIONS

- 4.1. COMMISSIONING THE UNIT

- 4.1.1. Refueling the tractor

- 4.2. STARTING THE UNIT

- 4.2.1. Starting the engine

- 4.2.2. Fuel heater (where fitted)

- 4.2.3. Coolant immersion heater (where fitted)

- 4.2.4. Transmission oil heater (where fitted)

- 4.2.5. Booster battery procedure

- 4.3. STOPPING THE UNIT

- 4.3.1. Engine shutdown

- 4.4. MOVING THE UNIT

- 4.4.1. Operating in cold temperatures

- 5. TRANSPORT OPERATIONS

- 5.1. PREPARING FOR ROAD TRANSPORT

- 5.1.1. Carrying the tractor on a transporter

- 5.2. RECOVERY TRANSPORT

- 5.2.1. Towing the tractor

- 6. WORKING OPERATIONS

- 6.1. GENERAL INFORMATION

- 6.1.1. Differential control

- 6.1.2. Four wheel drive

- 6.2. TRANSMISSION

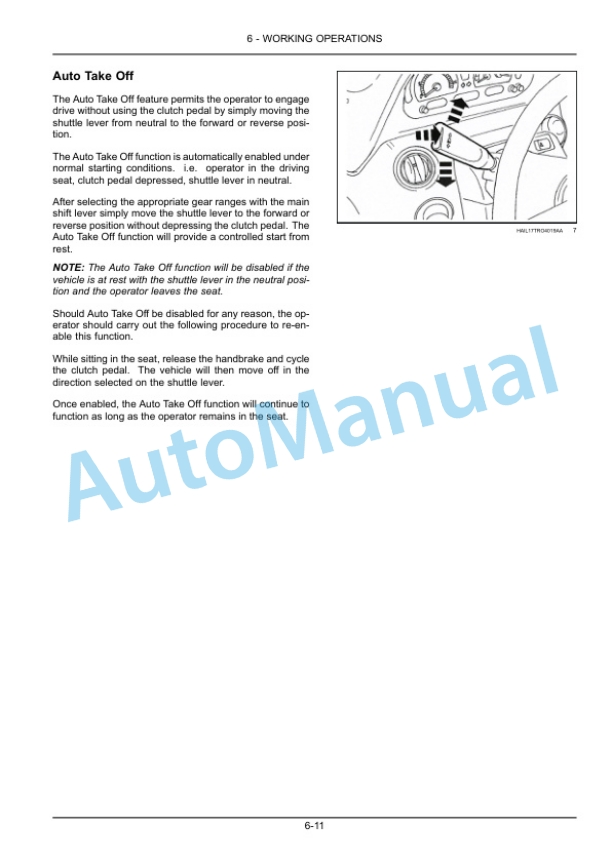

- 6.2.1. Full powershift transmission

- 6.2.2. Clutch pedal

- 6.2.3. Foot throttle pedal

- 6.2.4. Hand throttle lever

- 6.2.5. Transmission operation

- 6.2.6. Shuttle lever

- 6.2.7. Driving the tractor

- 6.2.8. Speed matching

- 6.3. REAR POWER TAKEOFF

- 6.3.1. PTO operation safety rules

- 6.3.2. Attaching PowerTake Off (PTO) driven equipment

- 6.3.3. PTO operation

- 6.3.4. Twospeed, shiftable P.T.O (where fitted)

- 6.3.5. Threespeed, shiftable P.T.O. (where fitted)

- 6.4. REAR HITCH

- 6.4.1. Electronic Draft Control (EDC)

- 6.4.2. Electronic Draft Control (EDC)

- 6.5. HYDRAULIC REMOTE CONTROL VALVES

- 6.5.1. ELECTROHYDRAULIC REMOTE CONTROL VALVES (where fitted)

- 6.5.2. Operating continuous flow hydraulic equipment

- 6.5.3. Connecting remote cylinders

- 6.5.4. Rear Axle Hydraulic Oil Level

- 6.6. HYDRAULIC POWER BEYOND PORT

- 6.6.1. Hydraulic Power Beyond Port forExternal Services (where fitted)

- 6.6.2. Power Beyond Selector Control

- 6.7. THREE POINT HITCH

- 6.7.1. Threepoint hitch

- 6.7.2. Lift rods

- 6.7.3. Top link

- 6.7.4. Quick hitch

- 6.7.5. Linkage Stabilisers

- 6.8. DRAWBARS AND TOWING ATTACHMENTS

- 6.8.1. Drawbars and towing attachments

- 6.8.2. Swinging drawbars

- 6.9. WHEEL TRACK ADJUSTMENT

- 6.9.1. Front wheels

- 6.9.2. Front wheel alignment

- 6.9.3. Steering stops

- 6.9.4. Front axle oscillation stops

- 6.9.5. Dynamic Front Fenders (where fitted)

- 6.9.6. Rear wheel track adjustment

- 6.10. BALLASTING AND TIRES

- 6.10.1. Ballasting and tires

- 6.10.2. Cast iron weights (where fitted)

- 6.10.3. Liquid Ballast

- 6.10.4. Tire care

- 6.10.5. Tire pressures and permissible loads

- 6.11. AUXILIARY POWER CONNECTIONS

- 6.11.1. Seven pin electrical power outlet

- 6.11.2. Internal power connectors

- 6.11.3. External power connectors

- 6.11.4. SEATS

- 7. MAINTENANCE

- 7.1. GENERAL INFORMATION

- 7.1.1. General Information

- 7.1.2. Preventing system contamination

- 7.1.3. Diesel Fuel Requirements

- 7.1.4. Biodiesel fuels

- 7.1.5. Guards

- 7.1.6. Lubricants and coolants

- 7.1.7. Tractor jacking points

- 7.1.8. Lubricant, fuel and coolant specifications

- 7.2. MAINTENANCE CHART

- 7.2.1. Maintenance chart

- 7.3. WHEN THE WARNING LAMP LIGHTS

- 7.3.1. Engine air cleaner

- 7.3.2. Drain the fuel system water separator

- 7.3.3. Check the brake fluid level

- 7.4. EVERY 10 HOURS OR EACH DAY

- 7.4.1. Check engine coolant level

- 7.4.2. Check engine oil level

- 7.4.3. Check windscreen washer reservoir

- 7.5. FIRST 50 HOURS

- 7.5.1. The First 50Hour Service

- 7.6. EVERY 50 HOURS

- 7.6.1. Clean the cab air filters

- 7.6.2. Clean the radiator, oil cooler and air conditioner condenser cores

- 7.6.3. Grease fittings

- 7.6.4. Check the front and the rear wheel nuts

- 7.6.5. Tire inflation pressures

- 7.7. EVERY 100 HOURS

- 7.7.1. Airconditioning compressor drive belt

- 7.7.2. Inspect the poly Vbelt

- 7.8. EVERY 300 HOURS

- 7.8.1. Battery

- 7.8.2. D Suspension cylinder upper bearing

- 7.8.3. Parking brake Adjust

- 7.8.4. Check transmission/rear axle and hydraulic oil level

- 7.9. EVERY 600 HOURS

- 7.9.1. Engine oil and filters

- 7.9.2. Fuel filters

- 7.9.3. Change the engine air cleaner outer element

- 7.9.4. Transmission / hydraulic oil filters

- 7.9.5. Check the engine air intake connections

- 7.10. EVERY 1200 HOURS OR ANNUALLY

- 7.10.1. Cab air filters

- 7.10.2. Changing the transmission andHydraulic oil filters with argo filter

- 7.10.3. Change transmission,rear axle and hydraulic oil and filters

- 7.10.4. Four wheel drive lubrication

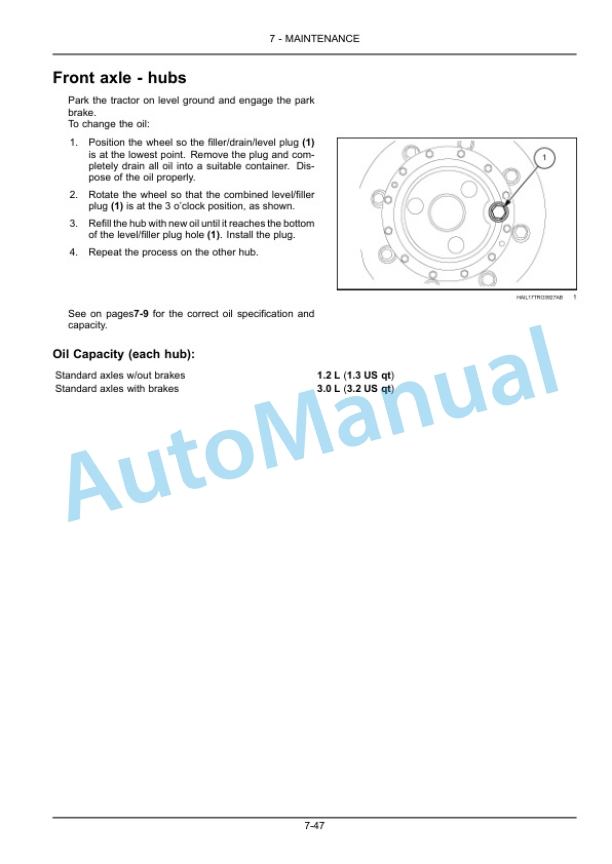

- 7.10.5. Front axle hubs

- 7.10.6. Front Power TakeOff (PTO)

- 7.11. EVERY 1200 HOURS OR EVERY 2 YEARS

- 7.11.1. Battery

- 7.11.2. Engine air cleaner

- 7.11.3. Check the valve tappet clearance

- 7.11.4. Change the air brake drier reservoir

- 7.11.5. Clean and reset fuel injectors

- 7.12. EVERY 3600 HOURS OR EVERY 4 YEARS

- 7.12.1. Cooling system OAT type coolant

- 7.13. EVERY 36 MONTHS

- 7.13.1. Service the air conditionersystem

- 7.14. GENERAL MAINTENANCE

- 7.14.1. Cleaning the tractor

- 7.14.2. Fuel prefilter (where fitted)

- 7.14.3. Fuel system bleeding

- 7.14.4. Brake pedals

- 7.14.5. Engine idle speed

- 7.14.6. Lighting system

- 7.14.7. Bulb replacement

- 7.14.8. Fuses and relays

- 7.14.9. Protection of the electronic modules during welding operations

- 7.15. STORAGE

- 7.15.1. Tractor storage

- 7.15.2. Removal of tractor from storage

- 8. TROUBLESHOOTING

- 8.1. FAULT CODE RESOLUTION

- 8.1.1. Threepoint hitch

- 8.1.2. Brakes

- 8.1.4. Electrical system

- 9. SPECIFICATIONS

- 9.1. General dimensions

- 9.2. Frame General specification

- 9.3. Capacities

- 9.4. Engine

- 9.5. Cooling system

- 9.6. Hydraulic system

- 9.7. Remote control valves

- 9.8. Lift capacities

- 9.9. Brakes

- 9.10. Steering system

- 9.11. Tightening torques

- 10. ACCESSORIES

- 10.1. Frontend loader fixation points

- 11. FORMS AND DECLARATIONS

- 11.1. Service record 1st 50 hour, Dealer copy

- 11.2. Service record 1st 50 hour, Owner copy

New Holland Operator Manual PDF

New Holland 250TLA Farm Loader Operation and Maintenance Manual 48077338

New Holland Operator Manual PDF

New Holland 140TL Loader Operation and Maintenance Manual 48070328

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 51559567

New Holland Operator Manual PDF

New Holland 200LC Loader Operation and Maintenance Manual 51421058

New Holland Operator Manual PDF

New Holland 250TL For Boomer 8N Tractor Operation and Maintenance Manual 84207117

New Holland Operator Manual PDF

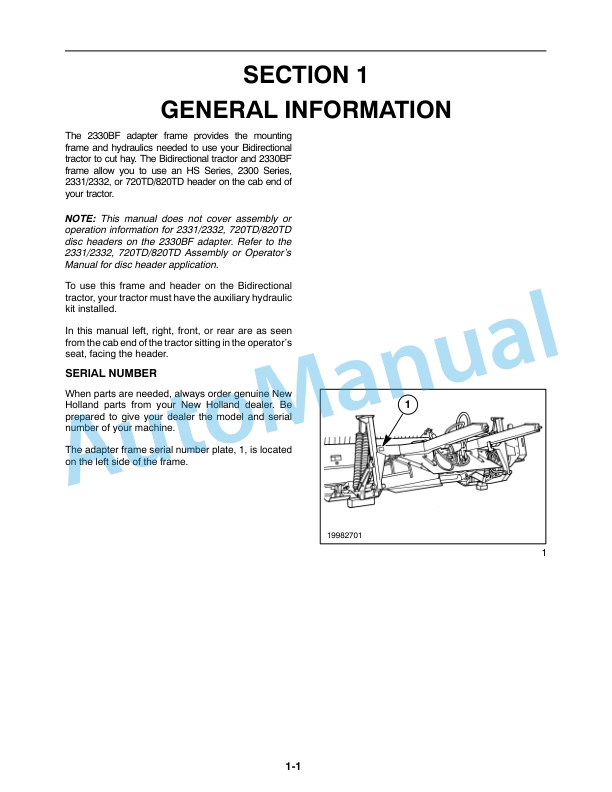

New Holland 2300BF With Auxiliary Hydraulic Operation and Maintenance Manual 86574146

New Holland Operator Manual PDF

New Holland 2330BF Adapter Frame Operation and Maintenance Manual 87716208

New Holland Operator Manual PDF

New Holland 160GMS Mower Deck Operation and Maintenance Manual 51410112

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 48116702

New Holland Operator Manual PDF

New Holland 105LC For Boomer 25 Compact Front Loader Operation and Maintenance Manual 51562809