New Holland TD4.80F, TD4.90F, TD4.100F Tractor Operation and Maintenance Manual 51560219

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 51560219

- Format: PDF

- Size: 30.4MB

- Number of Pages: 254

- Serial Number:

51560219

-

Model List:

- TD4.80F Tractor

- TD4.90F Tractor

- TD4.100F Tractor

- 1. GENERAL INFORMATION

- 1.1. Note to the Owner

- 1.2. Advice

- 1.3. Advice

- 1.4. Abbreviation

- 1.5. Note to the Owner

- 1.6. Product identification

- 1.7. Foreword

- 1.8. International symbols

- 1.9. Noise level

- 1.10. Vibration level

- 1.11. Advice

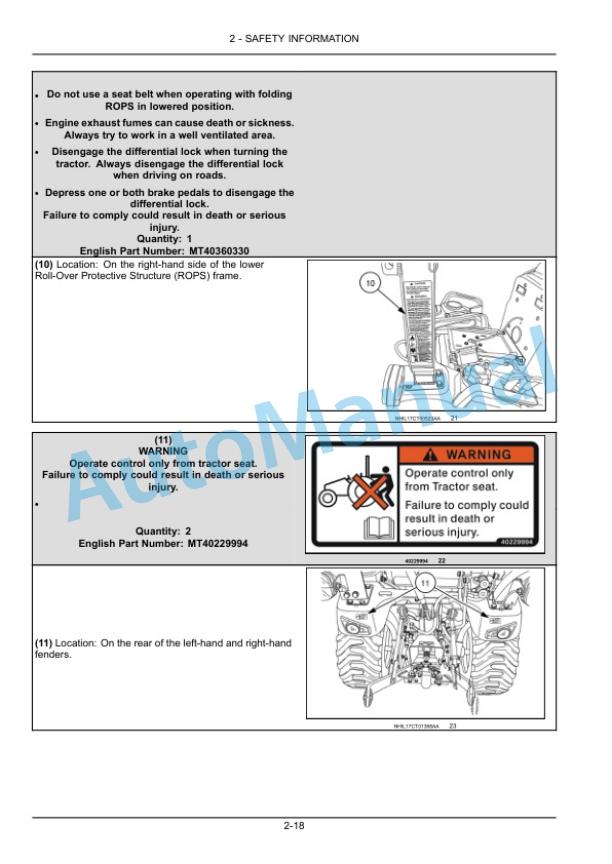

- 2. SAFETY INFORMATION

- 2.1. Personal safety

- 2.2. Safety aspects in accordance with Regulation (EU) 1322/2014 Annex XXII and subsequent amendments and modifications

- 2.3. Personal safety

- 2.4. Warning indicators, alarms, and instruments Personal safety

- 2.5. Frame Safety rules

- 2.6. Note to the Owner

- 2.7. Safety signs

- 2.8. Basic instructions

- 2.9. Frame Personal safety

- 3. CONTROLS AND INSTRUMENTS

- 3.1. Operators seat

- 3.1.1. Pneumaticallyadjusted operator seat Adjust

- 3.1.2. Seat restraints Adjust

- 3.2. Forward controls

- 3.2.1. Electrical system Operating

- 3.2.2. Fuel tanks Operating

- 3.2.3. Electrical system Control

- 3.2.4. External lighting Control

- 3.2.5. Mechanical transmission Operating

- 3.2.6. Power shuttle transmission Operating

- 3.2.7. Mechanical transmission Operating

- 3.2.8. Differential lock Control

- 3.2.9. Differential lock Control

- 3.2.10. Electrohydraulic control Control

- 3.2.11. Steering column Control

- 3.3. Lefthand side controls

- 3.3.1. Console Lefthand console Operating

- 3.4. Righthand side controls

- 3.4.1. Platform, cab, bodywork, and decals Localization overview

- 3.5. Display

- 3.5.1. Electrical system Part identification Instrument Cluster

- 3.5.2. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Control identification

- 3.5.3. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Calibrate Ground speed calibration

- 3.5.4. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Calibrate Calibrating tool width

- 3.5.5. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Program Programming maintenance work

- 3.5.6. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Program Activating/deactivating buzzer

- 3.5.7. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Program Setting units of measurement

- 3.5.8. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Program Resetting the oil change counter

- 3.5.9. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Program Viewing error codes

- 3.5.10. Electrical system Warning SYMPTOM(S)

- 4. OPERATING INSTRUCTIONS

- 4.1. Starting the unit

- 4.1.1. Engine Operating

- 4.2. Stopping the unit

- 4.2.1. Engine Operating

- 5. TRANSPORT OPERATIONS

- 5.1. Preparing for road transport

- 5.1.1. Brakes and controls Secure

- 5.2. Recovery transport

- 5.2.1. Brakes and controls Tow

- 6. WORKING OPERATIONS

- 6.1. Onespeed rear Power TakeOff (PTO)

- 6.1.1. Power TakeOff (PTO) Operating

- 6.1.2. Power TakeOff (PTO) Operating

- 6.1.3. Power TakeOff (PTO) General specification

- 6.1.4. Power TakeOff (PTO) Operating

- 6.1.5. Power TakeOff (PTO) Operating

- 6.2. Rear hitch

- 6.2.1. Main lift system Control

- 6.2.2. Threepoint hitch control valve Operating

- 6.3. Remote control valves

- 6.3.1. Remote control valves Control

- 6.4. Rear threepoint hitch linkage

- 6.4.1. Rear threepoint hitch linkage Localization overview

- 6.4.2. Top link arm Adjust

- 6.4.3. Vertical rod Adjust

- 6.4.4. Stabilizer Adjust

- 6.4.5. Stabilizer Adjust

- 6.4.6. Stabilizer Adjust

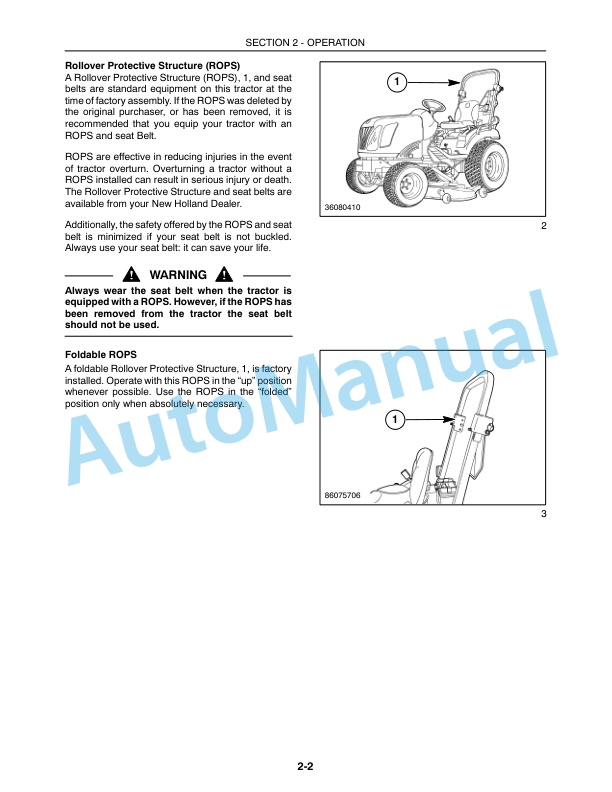

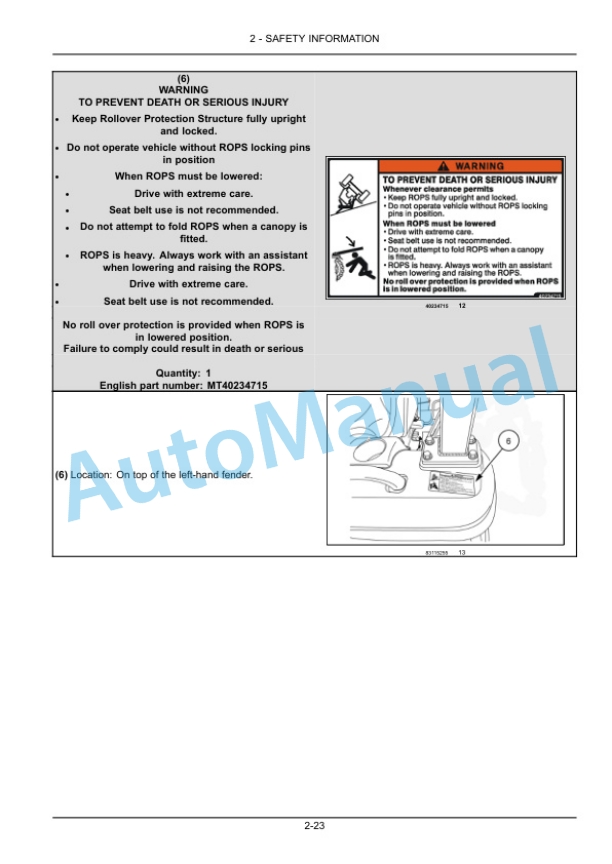

- 6.5. Roll Over Protective Structure (ROPS) frame

- 6.5.1. Roll Over Protective Structure (ROPS) frame Adjust

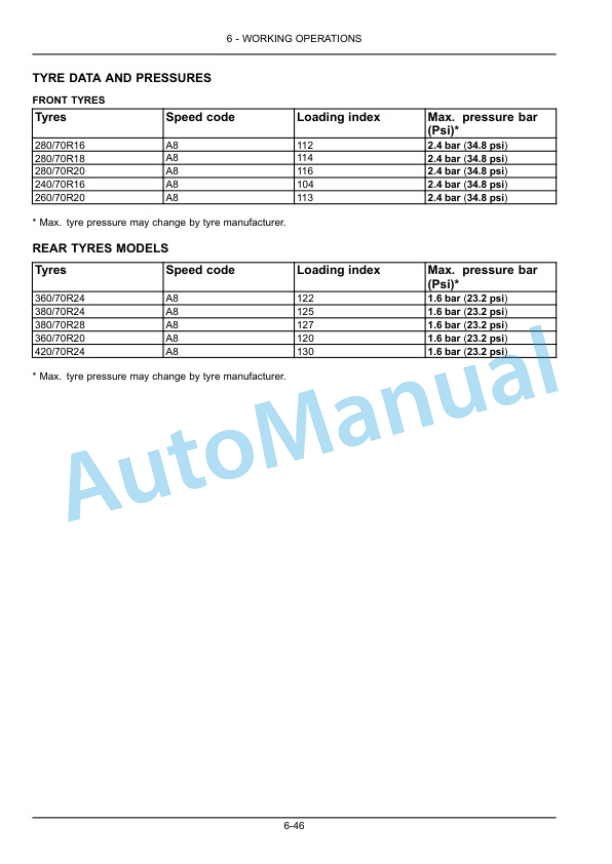

- 6.6. Front wheels

- 6.6.1. Front wheels General specification

- 6.7. Rear wheels

- 6.7.1. Rear wheels General specification

- 6.8. Wheels

- 6.8.1. Wheels Static description

- 6.8.2. Wheels General specification

- 6.9. Ballasts and supports

- 6.9.1. Ballasts and supports Static description BALLASTING

- 6.9.2. Frames and ballasting Static description LIQUID BALLASTING

- 6.9.3. Frames and ballasting Weight

- 7. MAINTENANCE

- 7.1. General information

- 7.1.1. Grouped Safety Message

- 7.1.2. Foreword

- 7.1.3. Basic instructions

- 7.1.4. Fuel tanks Capacities

- 7.1.5. Definition

- 7.1.6. Engine cooling system Basic instructions

- 7.1.7. Consumables

- 7.1.8. Hood Basic instructions

- 7.2. Flexible Maintenance

- 7.2.1. Clutch Check

- 7.2.2. Brake pedals Check Adjusting height of service brake pedals

- 7.2.3. Alternator drive system Belt Check ALTERNATOR BELT INSPECTION

- 7.2.4. Air cleaner Check AIR FILTER VALVE

- 7.2.5. External lighting Check TRACTOR LIGHT

- 7.2.6. Hand brake lever Adjust HANDBRAKE

- 7.2.7. Engine cooling system Check RADIATOR FLUID LEVEL

- 7.2.8. Radiator Cleaning

- 7.2.9. Wheels Check TYRE PRESSURE

- 7.2.10. Wheels Check WHEEL DISKS NUT TORQUE

- 7.3. WHEN THE WARNING LAMP LIGHTS

- 7.3.1. Brake fluid reservoir Fluid Check

- 7.3.2. Air cleaner Cleaning

- 7.4. EVERY 10 HOURS OR DAILY

- 7.4.1. Engine lubrication system Check ENGINE OIL LEVEL

- 7.5. EVERY 50 HOURS

- 7.5.1. Rear threepoint hitch linkage Grease

- 7.6. EVERY 300 HOURS

- 7.6.1. Oil filters Replace TRANSMISSION AND HYDRAULIC LIFT OIL FILTER

- 7.6.2. Air cleaner Cleaning DRY AIR FILTER, EXTERNAL CARTRIDGE

- 7.6.3. Alternator drive system Belt Check ALTERNATOR BELT INSPECTION

- 7.6.4. Steering knuckle and king pin Grease KING PIN BEARINGS 4WD

- 7.6.5. Transmission Check TRANSMISSION AND HYDRAULIC LIFT OIL

- 7.6.6. Axle housing Check FRONT AXLE HOUSING 4WD

- 7.6.7. Wheel hub Check FRONT AXLE REDUCTION HUBS 4WD

- 7.7. EVERY 600 HOURS

- 7.7.1. Engine lubrication system Replace

- 7.7.2. Fuel filters Replace FUEL FILTER

- 7.8. EVERY 1200 HOURS

- 7.8.1. Air cleaner Cleaning DRY AIR FILTER, EXTERNAL CARTRIDGE

- 7.8.2. Fuel tank Cleaning FUEL TANK

- 7.8.3. Drive shaft Check DRIVE SHAFT SLEEVE FOR 4WD FRONT AXLE CONNECTION

- 7.9. EVERY 1200 HOURS OR EVERY 2 YEARS

- 7.9.1. Axle housing Change fluid FRONT AXLE HOUSING 4WD

- 7.9.2. Wheel hub Change fluid FRONT AXLE HOUSING

- 7.9.3. Transmission Change fluid TRANSMISSION AND HYDRAULIC LIFT OIL

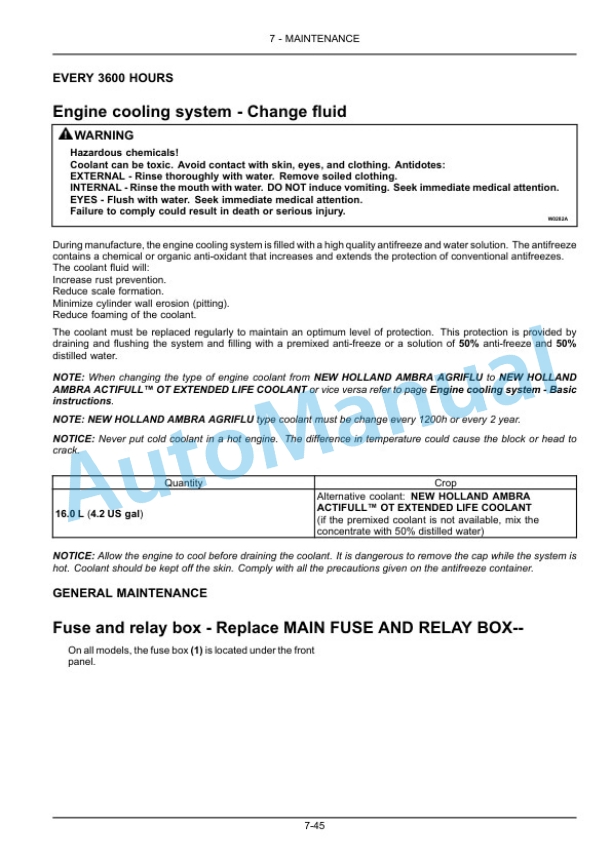

- 7.10. EVERY 3600 HOURS

- 7.10.1. Engine cooling system Change fluid

- 7.11. GENERAL MAINTENANCE

- 7.11.1. Fuse and relay box Replace MAIN FUSE AND RELAY BOX

- 7.11.2. Headlight Adjust FRONT HEADLIGHT ADJUSTMENT

- 7.11.3. External lighting Replace REPLACING THE FRONT HEADLIGHT BULBS

- 7.11.4. Platform, cab, bodywork, and decals Cleaning

- 7.12. STORAGE

- 7.12.1. Frame Storing

- 8. TROUBLESHOOTING

- 8.1. Alarm(s)

- 8.1.1. Remote control valve Closed center mechanical remote valve Troubleshooting

- 8.1.2. Engine Troubleshooting

- 8.1.3. Electrical system Troubleshooting

- 8.1.4. Electrical systems Troubleshooting

- 8.1.5. Rear threepoint hitch Troubleshooting

- 8.1.6. Hydraulic service brakes Troubleshooting

- 8.1.7. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Basic instructions

- 8.1.8. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Part identification

- 8.1.9. Instrument cluster Part identification

- 8.1.10. Instrument cluster General specification

- 8.1.11. Instrument cluster AnalogDigital Instrument Cluster (ADIC) Part identification

- 9. SPECIFICATIONS

- 9.1. Frame Dimension

- 9.2. Frames and ballasting Weight (OPTIONAL)(kg)

- 9.3. Frame Weight

- 9.4. General specification

- 9.5. Wheels General specification

- 9.6. Electrical systems General specification

- 10. ACCESSORIES

- 10.1. Beacon Localization overview

- 10.2. Drawbars and towing hitches Operating

- 10.3. Hitches, drawbars, and implement couplings General specification

- 10.4. Hitches, drawbars, and implement couplings General specification Front Hook

- 10.5. Trailer brake hydraulic control Static description

- 10.6. Trailer brake hydraulic control Operating Dual line

- 10.7. Trailer brake hydraulic control Operating Dualline, compatible with trailers with universal single line

- 11. FORMS AND DECLARATIONS

- 11.1. Service record 1st 50 hour, Owner copy

- 11.2. Service record 1st 50 hour, Dealers copy

New Holland Operator Manual PDF

New Holland 1530, 1630 Tractor Operation and Maintenance Manual 42153021

New Holland Operator Manual PDF

New Holland 1030, 230GM Boomer Operation and Maintenance Manual 87487351

New Holland Operator Manual PDF

New Holland 18LA Loader Operation and Maintenance Manual 87571257

New Holland Operator Manual PDF

New Holland 230TL Loader Operation and Maintenance Manual 87541767

New Holland Operator Manual PDF

New Holland 25S Workmaster Tier 4B Final Compact Tractor Operation and Maintenance Manual 51409930

New Holland Operator Manual PDF

New Holland 140TL Loader Operation and Maintenance Manual 48070328

New Holland Operator Manual PDF

New Holland 26 Rotary Tiller Attachment Operation Manual and Part List 42002611

New Holland Operator Manual PDF

New Holland 160GMS Mower Deck Operation and Maintenance Manual 51410112

New Holland Operator Manual PDF

New Holland 25 Boomer Tier 3 Compact Tractor Operation and Maintenance Manual 48098985

New Holland Operator Manual PDF

New Holland 2300BF With PTO Pump Operation and Maintenance Manual 86574145