New Holland TS6.110, TS6.110HC, TS6.120, TS6.120HC, TS6.130, T6.140 Tier 4B Final Tractor Operation and Maintenance Manual 51490476

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 51490476

- Format: PDF

- Size: 37.3MB

- Number of Pages: 368

- Serial Number:

51490476

-

Model List:

- TS6.110 Tier 4B Final Tractor

- TS6.110HC Tier 4B Final Tractor

- TS6.120 Tier 4B Final Tractor

- TS6.120HC Tier 4B Final Tractor

- TS6.130 Tier 4B Final Tractor

- T6.140 Tier 4B Final Tractor

- 1. GENERAL INFORMATION

- 1.1. Note to the owner

- 1.2. Intended use

- 1.3. ElectroMagnetic Compatibility (EMC)

- 1.4. Product identification

- 1.5. Product Identification Number (PIN)

- 1.6. Operators manual storage on the machine

- 1.7. Machine orientation

- 1.8. Machine components

- 1.9. Selective Catalytic Reduction (SCR) exhaust treatment Product overview

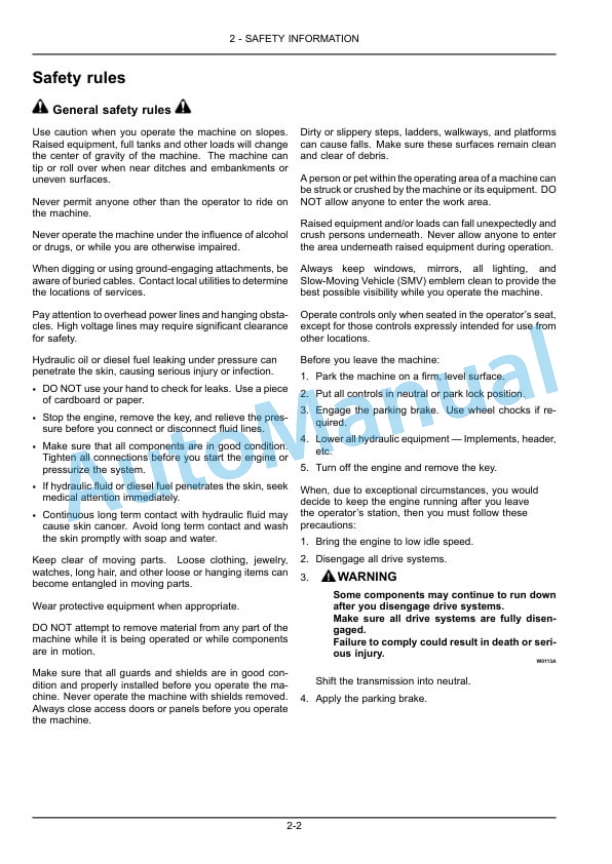

- 2. SAFETY INFORMATION

- 2.1. Safety rules and signal word definitions

- 2.2. Safety rules

- 2.3. Ecology and the environment

- 2.4. Safety signs

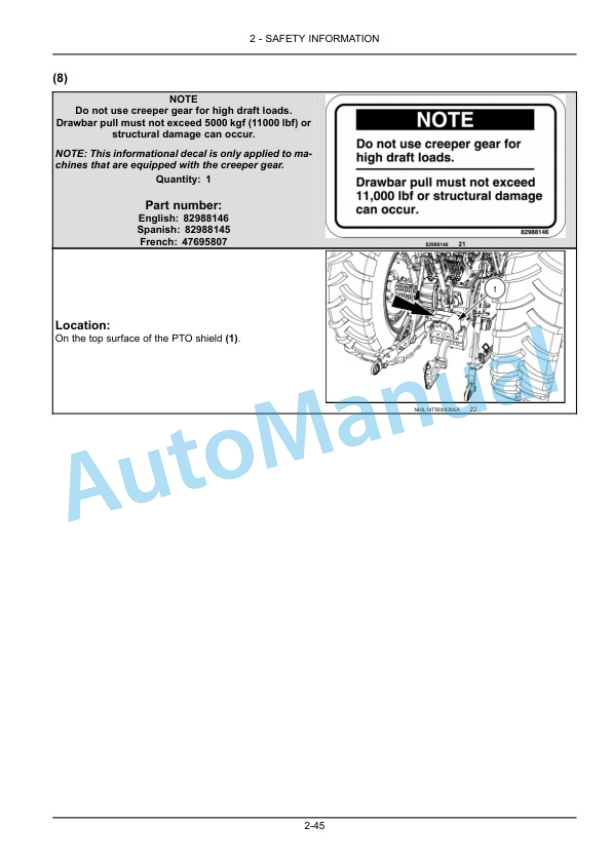

- 2.5. Informational decals

- 3. CONTROLS AND INSTRUMENTS

- 3.1. Access to operators platform

- 3.1.1. Proper entry and exit

- 3.2. Operators seat

- 3.2.1. Mechanical operators seat

- 3.2.2. Pneumatic operators seat

- 3.2.3. Seat belt operation

- 3.3. Instructional seat

- 3.3.1. Overview

- 3.4. Forward controls

- 3.4.1. Front console

- 3.4.2. Foot pedals

- 3.4.3. Selective Catalytic Reduction (SCR) exhaust treatment Overview

- 3.5. Lefthand side controls

- 3.5.1. Power TakeOff (PTO) (without cab)

- 3.5.2. Parking brake

- 3.5.3. Door and window operation

- 3.5.4. Storage

- 3.6. Righthand side controls

- 3.6.1. Transmission controls

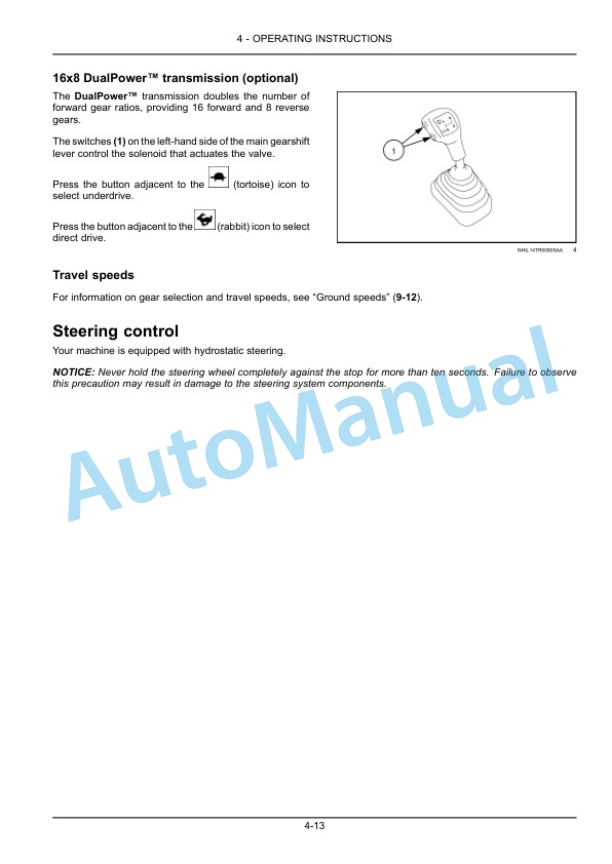

- 3.6.2. DualPower

- 3.6.3. Power TakeOff (PTO) (with cab)

- 3.6.4. Hydraulic controls

- 3.6.5. Righthand post

- 3.6.6. Heating, Ventilation, and Air Conditioning (HVAC) controls

- 3.6.7. Door and window operation

- 3.7. Rearward controls

- 3.7.1. Rear window operation

- 3.7.2. Rear window wiper

- 3.8. Overhead controls

- 3.8.1. Radio

- 3.8.2. Radio operation

- 3.8.3. Dome light

- 3.8.4. Roof hatch

- 3.9. Display

- 3.9.1. Setup menu

- 3.9.2. Backlighting and dimming

- 3.9.3. Analog/Digital Instrument Cluster (ADIC)

- 3.9.4. Warning and status indicators

- 3.9.5. Display overview

- 3.9.6. Alarms

- 3.9.7. Overview

- 3.9.8. Maintenance intervals

- 3.9.9. Audible alarm buzzer

- 3.9.10. Fuel consumption units

- 3.9.11. Active error codes and warnings

- 3.9.12. Lamps and gauges

- 3.9.13. Display

- 4. OPERATING INSTRUCTIONS

- 4.1. Commissioning the unit

- 4.1.1. Runin period of a new machine

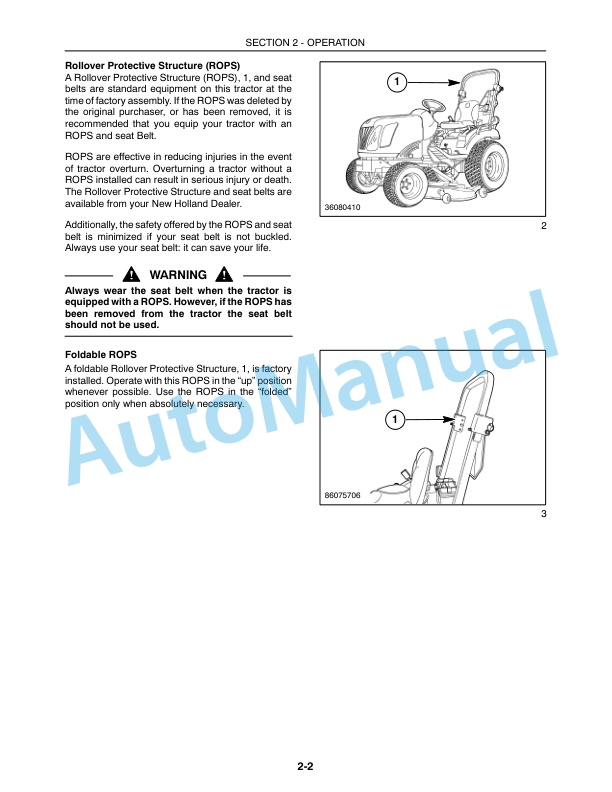

- 4.1.2. Roll Over Protective Structure (ROPS)

- 4.2. Starting the unit

- 4.2.1. Starting the engine

- 4.2.2. Engine starting aids

- 4.3. Stopping the unit

- 4.3.1. Stopping the tractor

- 4.3.2. Hydraulic trailer brakes

- 4.4. Moving the unit

- 4.4.1. General transmission operation

- 4.4.2. Steering control

- 5. TRANSPORT OPERATIONS

- 5.1. Road transport

- 5.1.1. Basic instructions

- 5.1.2. High visibility position markers

- 5.2. Recovery transport

- 5.2.1. Towing the tractor

- 6. WORKING OPERATIONS

- 6.1. Tires and wheels

- 6.1.1. Tire load and inflation charts

- 6.1.2. Tractor ballasting

- 6.1.3. Liquid ballast

- 6.1.4. Front wheel tread settings

- 6.1.5. Rear wheel tread settings

- 6.1.6. Bar axle adjustment

- 6.1.7. Dual rear wheels

- 6.2. Driveline

- 6.2.1. Creeper gears

- 6.2.2. FourWheel Drive (4WD)

- 6.2.3. Differential lock

- 6.2.4. Front axle oscillation

- 6.3. Hydraulic system

- 6.3.1. Bosch remote valves

- 6.3.2. Sohipren remote valves

- 6.3.3. Hydraulic Power Lift (HPL)

- 6.3.4. Hydraulic remote control valves

- 6.3.5. Connecting remote cylinders

- 6.3.6. Bleeding remote cylinders

- 6.3.7. Operating singleacting hydraulic cylinders

- 6.3.8. Operating doubleacting hydraulic cylinders

- 6.3.9. Operating continuous flow hydraulic equipment

- 6.3.10. Hydraulic remote control valves

- 6.3.11. Connecting remote cylinders

- 6.3.12. Operating singleacting hydraulic cylinders

- 6.3.13. Operating doubleacting hydraulic cylinders

- 6.4. Implements

- 6.4.1. Adjusting the drawbar

- 6.4.2. Hitch operation

- 6.4.3. Power TakeOff (PTO) operation

- 7. MAINTENANCE

- 7.1. General information

- 7.1.1. Safety rules Machine service access

- 7.1.2. Warranty notice

- 7.1.3. Jacking points

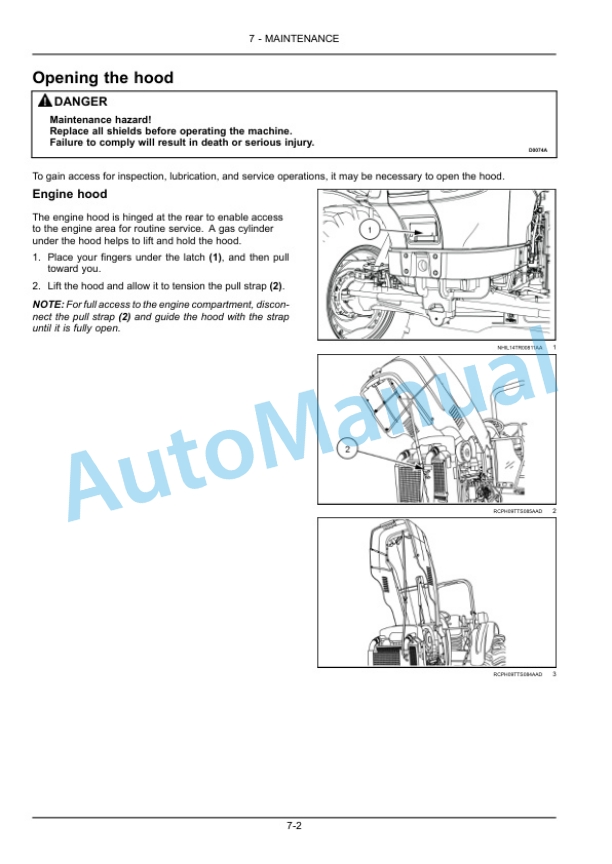

- 7.1.4. Opening the hood

- 7.1.5. Fueling the machine

- 7.1.6. Selective Catalytic Reduction (SCR) exhaust treatment Basic instructions

- 7.1.7. General specification Biodiesel fuels

- 7.1.8. General specification Diesel fuel

- 7.1.9. Torque Minimum tightening torques for normal assembly

- 7.1.10. Standard torque data for hydraulics

- 7.1.11. Organic Acid Technology (OAT) coolant

- 7.1.12. Fluid capacities and lubricants

- 7.1.13. Engine oil Recommended engine oil for operating temperature ranges

- 7.2. Maintenance planning

- 7.2.1. Maintenance chart

- 7.3. Warning light on

- 7.3.1. Engine air filter (outer element) Clean

- 7.3.2. Fuel filter water separator Drain fluid

- 7.3.3. Brake fluid Level make up

- 7.4. Every 10 hours or daily

- 7.4.1. Engine oil Level make up

- 7.4.2. Radiator, oil cooler, and condenser Clean

- 7.4.3. Engine cooling system Level make up

- 7.5. Every 50 hours

- 7.5.1. Tire pressure Check

- 7.5.2. Transmission, rear axle, and hydraulic system oil Level make up

- 7.5.3. Final drive housing oil Level make up

- 7.5.4. Brake fluid Level make up

- 7.5.5. Windshield washer fluid Level make up

- 7.5.6. Fuel filter water separator Drain fluid

- 7.5.7. Cab recirculation air filter Clean

- 7.5.8. Cab air filter Clean

- 7.5.9. Wheel hardware Check

- 7.5.10. Grease points Grease

- 7.5.11. Clutch pedal Adjust

- 7.6. Every 300 hours

- 7.6.1. FourWheel Drive (4WD) front axle differential oil Level make up

- 7.6.2. FourWheel Drive (4WD) front axle hub oil Level make up

- 7.6.3. Transmission and hydraulic oil filter Replace

- 7.6.4. Cab and safety frame mounting hardware torque Check

- 7.6.5. Parking brake Adjust

- 7.6.6. Brake pedal Adjust

- 7.6.7. Alternator drive belt Check

- 7.6.8. Air conditioning compressor belt Check

- 7.6.9. Battery cables Check

- 7.7. Every 600 hours

- 7.7.1. Diesel Exhaust Fluid (DEF)/AdBlue supply module prefilter Clean

- 7.7.2. Engine oil Change fluid

- 7.7.3. Engine air filter (outer element) Replace

- 7.7.4. Fuel filter water separator Replace

- 7.8. Every 1200 hours or annually

- 7.8.1. Diesel Exhaust Fluid (DEF)/AdBlue supply module prefilter Replace

- 7.8.2. Transmission, rear axle, and hydraulic system oil Change fluid

- 7.8.3. Final drive housing oil Change fluid

- 7.8.4. FourWheel Drive (4WD) front axle differential oil Change fluid

- 7.8.5. FourWheel Drive (4WD) front axle hub oil Change fluid

- 7.9. Every 3600 hours or two years

- 7.9.1. Diesel Exhaust Fluid (DEF)/AdBlue supply module main filter Replace

- 7.10. Every 4000 hours or four years

- 7.10.1. Engine coolant Change fluid

- 7.11. As required

- 7.11.1. Diesel Exhaust Fluid (DEF)/AdBlue supply module inlet filter Replace

- 7.11.2. Diesel Exhaust Fluid (DEF)/AdBlue tank inlet filter Replace

- 7.11.3. Diesel Exhaust Fluid (DEF)/AdBlue supply module backflow filter Replace

- 7.11.4. Headlights Adjust

- 7.11.5. Headlight bulb Replace

- 7.11.6. Work light bulb Replace

- 7.11.7. Rear light bulb Replace

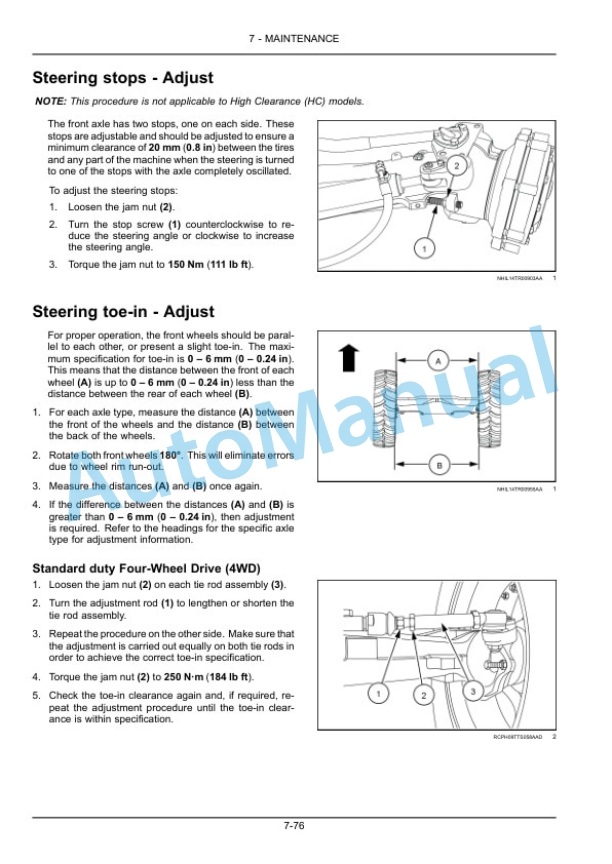

- 7.11.8. Steering stops Adjust

- 7.11.9. Steering toein Adjust

- 7.11.10. Roof hatch Cleaning

- 7.11.11. Parking brake Adjust

- 7.12. Fuse and relay locations

- 7.12.1. Chassis fuse box

- 7.12.2. Engine fuse box

- 7.12.3. Other fuses and relays

- 7.13. Storage

- 7.13.1. Preparing for storage

- 7.13.2. Removing from storage

- 8. TROUBLESHOOTING

- 8.1. Symptom(s)

- 8.1.1. Engine

- 8.1.2. Transmission

- 8.1.3. Electrical system

- 8.1.4. Hydraulic system

- 8.1.5. Hydraulic remote control valves

- 8.1.6. Threepoint hitch

- 8.1.7. Brakes

- 9. SPECIFICATIONS

- 9.1. Length and height

- 9.2. Width

- 9.3. Ground clearance

- 9.4. Maximum side slope operation

- 9.5. Power TakeOff (PTO)

- 9.6. Hydraulic system

- 9.7. Threepoint linkage

- 9.8. Brake system

- 9.9. Steering system

- 9.10. Electrical system

- 9.11. Lubrication system Capacities

- 10. ACCESSORIES

- 10.1. Engine

- 10.2. Chassis

- 10.4. Roll Over Protective Structure (ROPS)

- 10.5. Safety

- 10.6. Hydraulics

- 10.7. Hitch

- 11. FORMS AND DECLARATIONS

- 11.1. Delivery report Owner copy

- 11.2. Delivery report Dealer copy

New Holland Operator Manual PDF

New Holland 26 Rotary Tiller Attachment Operation Manual and Part List 42002611

New Holland Operator Manual PDF

New Holland 105LC For Boomer 25 Compact Front Loader Operation and Maintenance Manual 51562809

New Holland Operator Manual PDF

New Holland 230TL Loader Operation and Maintenance Manual 87541767

New Holland Operator Manual PDF

New Holland 25 Compact Boomer Stage V Compact Tractor Operation and Maintenance Manual 51558622

New Holland Operator Manual PDF

New Holland 160GMS For Boomer 25 Compact Mower Deck Operation and Maintenance Manual 51567834

New Holland Operator Manual PDF

New Holland 1720 Tractor Operation and Maintenance Manual 42172010

New Holland Operator Manual PDF

New Holland 16LA, 17LA Loader Operation and Maintenance Manual 87571253

New Holland Operator Manual PDF

New Holland 1030, 230GM Boomer Operation and Maintenance Manual 87487351

New Holland Operator Manual PDF

New Holland 160GMS Mower Deck Operation and Maintenance Manual 51410112

New Holland Operator Manual PDF

New Holland 200LC Loader Operation and Maintenance Manual 51421058