- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

New Holland W90 Wheel Loader Service Manual 6040234100EN

$30.00

- Type Of Manual: Service Manual

- Manual ID: 6040234100EN

- Format: PDF

- Size: 8.7MB

- Number of Pages: 321

- Serial Number:

6040234100EN

Category: New Holland Service Manual PDF

-

Model List:

- W90 Wheel Loader

- 1. Introduction

- 2. Summary

- 2.1. Specifications

- 2.2. Capacities and Fluid Types

- 2.3. Safety Rules

- 2.4. Units of Measure Used in the Manual

- 2.5. Tightening Torques

- 2.6. Section 1 Engine

- 2.6.1. General Description

- 2.6.2. General Characteristics

- 2.6.3. Specifications and Assembly Clearances

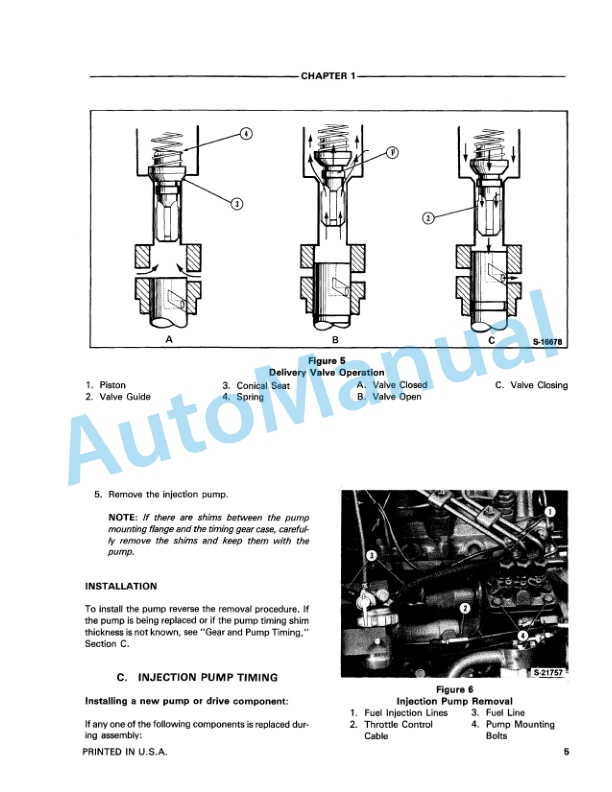

- 2.6.4. Fuel Injection Pump Specifications

- 2.6.5. External Views

- 2.6.6. Engine Supports

- 2.6.7. Main Tightening Torques and Pressure Ports

- 2.6.8. Lubrication System

- 2.6.9. Cooling System

- 2.6.9.1. General Description

- 2.6.9.2. Radiator

- 2.6.10. Fuel System

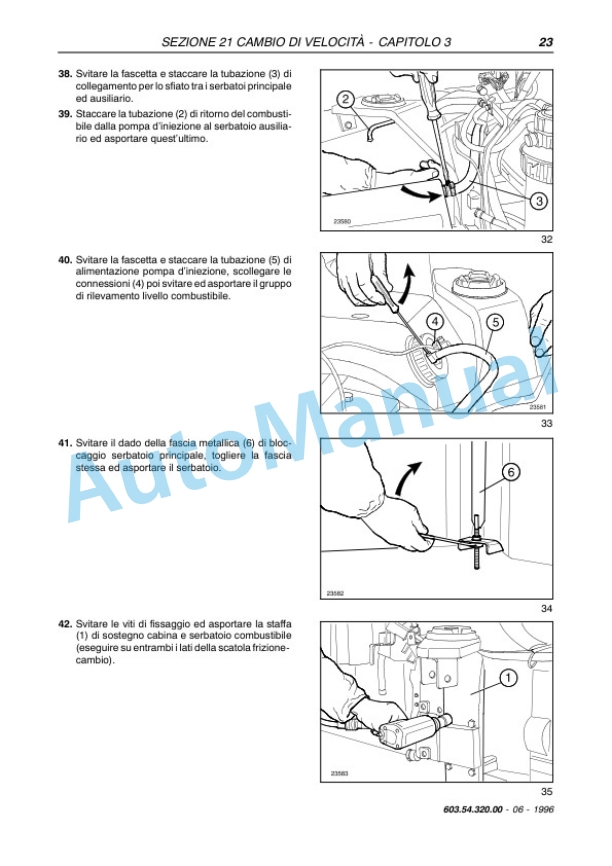

- 2.6.10.1. Fuel Tank

- 2.6.11. Air Intake and Exhaust System

- 2.6.11.1. General Description

- 2.6.11.2. Turbocharger

- 2.6.11.3. Air Filter

- 2.6.12. Electrical System

- 2.6.12.1. Batteries

- 2.6.12.2. Start Switch

- 2.6.12.3. Cold Engine Start

- 2.6.12.4. Engine ShutDown Solenoid Valve

- 2.6.12.5. Engine PreHeating Sequence

- 2.6.12.6. PreHeating Malfunction Warning Lamp Modes

- 2.6.12.7. Throttle Control Linkage

- 2.7. Section 2 Transmission

- 2.7.1. General Description

- 2.7.2. Torque Convertor Transmission

- 2.7.3. Torque Convertor

- 2.7.4. Transmission Convertor Pump

- 2.7.5. Transmission

- 2.7.5.1. Directional Clutch Shaft

- 2.7.5.2. Power Transfer Schematic

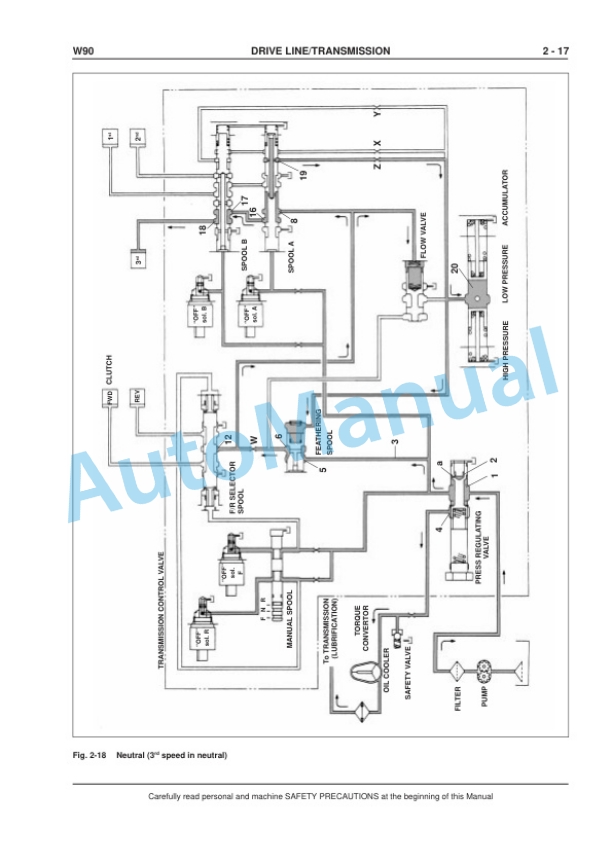

- 2.7.5.3. Transmission Control Valve

- 2.7.5.4. Transmission Control System

- 2.7.6. Transmission Disassembly/ReAssembly

- 2.7.6.1. Disassembly

- 2.7.6.2. ReAssembly

- 2.7.6.3. Troubleshooting

- 2.7.6.4. Standard Values for Manteinance

- 2.7.6.5. Tightening Torques for Main Bolts

- 2.7.7. Oil Circuits

- 2.7.8. Drive Shafts

- 2.7.9. Axles (Front and Rear)

- 2.7.9.1. Axle

- 2.7.9.2. Differential Assembly

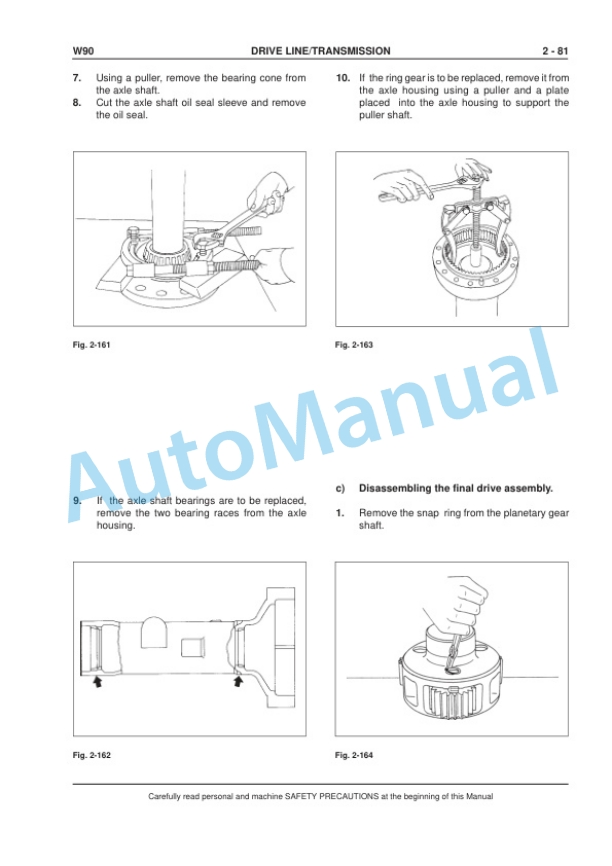

- 2.7.9.3. Final Drives

- 2.7.9.4. Axles

- 2.7.10. Wheels

- 2.7.10.1. Tyres

- 2.8. Section 3 Braking System

- 2.8.1. General Description

- 2.8.2. Operation

- 2.8.2.1. Operating Conditions

- 2.8.3. Disc Brake

- 2.8.4. Brake Pedal Valve

- 2.8.4.1. Circuit Separation Valve Operation Inside the Braking System

- 2.8.5. Parking Brake Control Valve

- 2.8.6. Parking Brake

- 2.8.6.1. Manual Release Procedure

- 2.8.6.2. Disc Parking Brake Operation

- 2.8.6.3. Brake Disengagement

- 2.8.7. Other Components

- 2.8.7.1. Brake Accumulator

- 2.8.7.2. Check Valve

- 2.8.8. Brake Pedal Valve Hydraulic Connections

- 2.8.9. Diagnostics and Testing

- 2.8.9.1. Brake Control Pressure Testing Test

- 2.8.9.2. Min and Max Accumulator Recharge Pressure Adjustment

- 2.8.9.3. Parking Brake Engagement Test

- 2.8.9.4. Accumulator PreCharge Test

- 2.8.9.5. Accumulator PreCharge Reset Instruction

- 2.8.9.6. Bleeding the Brake System

- 2.8.9.7. Brake Disc Wear Check

- 2.9. Section 4 Steering System

- 2.9.1. General Description

- 2.9.2. Principles of Operation of Nain Priority Valve

- 2.9.3. Steering Valve (Orbitrol)

- 2.9.3.1. Removal

- 2.9.3.2. Main Priority Valve

- 2.9.3.3. Secondary Priority Valve (Optional)

- 2.9.3.4. Cushion Valve

- 2.9.3.5. Steering Cylinders

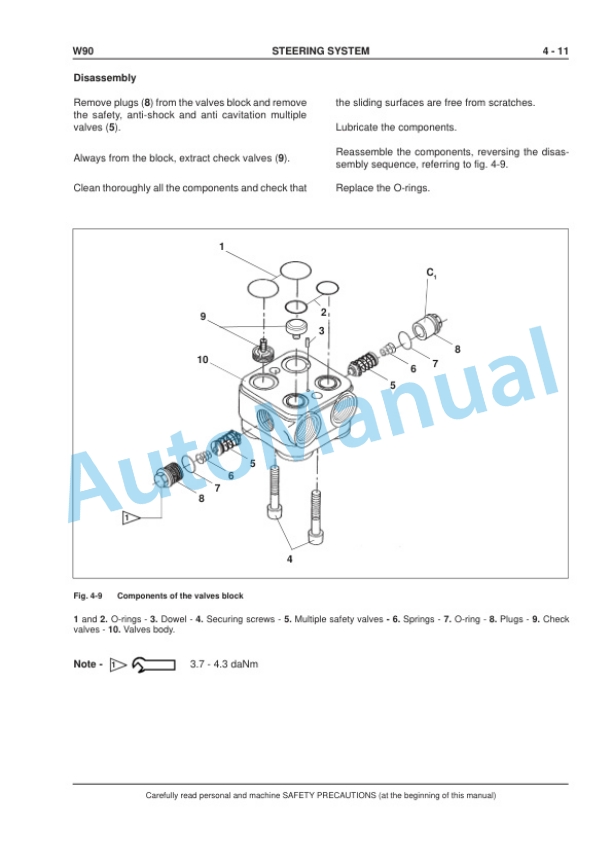

- 2.9.3.6. Multiple Check Valve

- 2.10. Section 5 Bucket Booms and Frame

- 2.10.1. Load Handling System

- 2.10.2. Boom, Bellcrank and Bucket

- 2.10.2.1. eneral Description

- 2.10.2.2. Bucket

- 2.10.2.3. Bucket Automatic Leveller

- 2.10.2.4. Boom Kickout (Optional)

- 2.10.3. Frame Pivot Pins

- 2.11. Section 6 Attachment Hydraulic System

- 2.11.1. General Description

- 2.11.2. Oil Circuit

- 2.11.2.1. Attachment Hydraulic Circuit

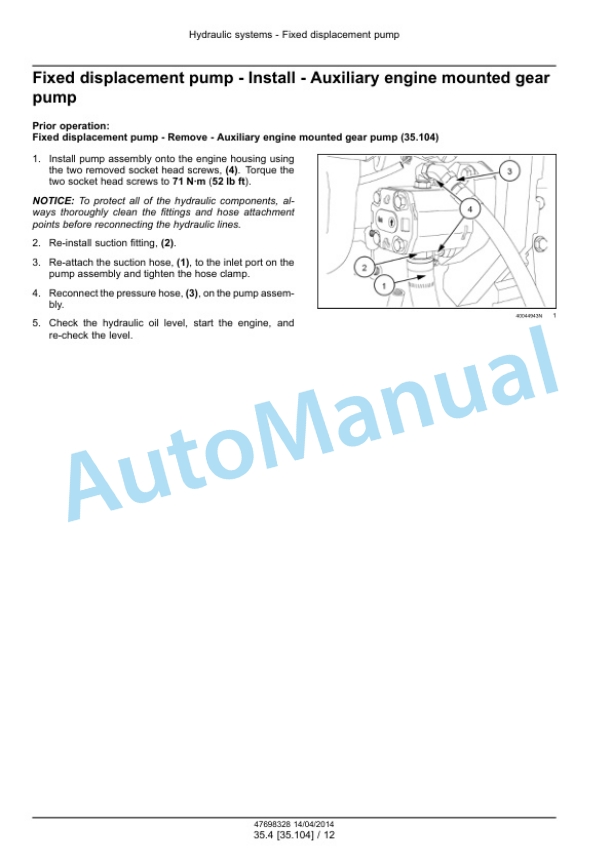

- 2.11.3. Hydraulic System Pump

- 2.11.3.1. Attachment/Steering Pump Testing and Repair

- 2.11.4. Attachment Control Valve

- 2.11.4.1. General Description

- 2.11.4.2. Control Valve Operation

- 2.11.4.3. Pressure Relief Valve

- 2.11.5. Control Valve Controls

- 2.11.6. Hydraulic Oil Reservoir

- 2.11.7. Cylinders

- 2.11.7.1. Boom Raise Cylinders

- 2.11.7.2. Bucket Roll Cylinder

- 2.11.8. AntiPitch System (Option)

- 2.11.8.1. Description

- 2.11.8.2. Accumulator Discharge

- 2.11.8.3. Hydraulic Diagram

- 2.11.8.4. System Operating Tests

- 2.11.8.5. Accumulator PreCharge Check

- 2.11.8.6. Accumulator PreCharge Reset Instructions

- 2.11.9. Auxiliary Hydraulics Operation (Option)

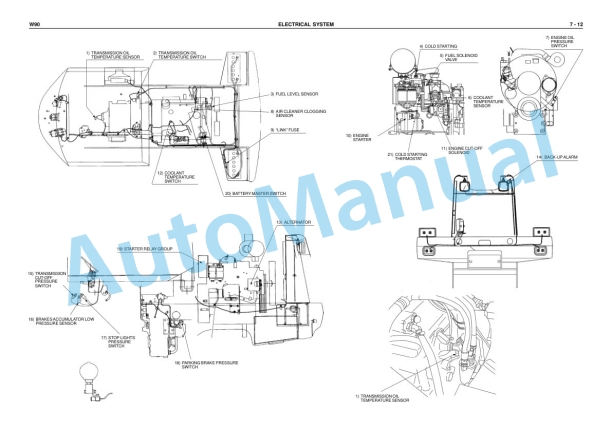

- 2.12. SECTION 7 ELECTRICAL SYSTEM

- 2.12.1. SAFETY RULES

- 2.12.2. GENERAL LAYOUT OF ELECTRICAL SYSTEM

- 2.12.3. LOGIC BOARD AND CAB CONNECTIONS

- 2.12.4. FUSES

- 2.12.5. CONNECTORS

- 2.12.6. INDICATORS ON INSTRUMENT PANEL

- 2.12.7. SWITCH PANEL

- 2.12.8. TRANSMISSION CONTROL SELECTOR

- 2.12.9. STARTER SWITCH

- 2.12.10. MACHINE GROUPS ELECTRIC DIAGRAMS

- 2.13. SECTION 8 CAB

- 2.13.1. GENERAL DESCRIPTION

- 2.13.2. WINDSCREEN WIPERS AND WASHERS

- 2.13.3. HEATER

- 2.13.4. GLASSES

- 2.13.5. REPAIR

- 2.13.6. AIR CONDITIONING UNIT

- 2.13.7. TROUBLESHOOTING

Rate this product

You may also like

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

New Holland 100, 115, 135, 160 HP Tractor Repair Manual 6035432100

$30.00

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

New Holland 1400, 1500 Combine Tractor Service Manual 40481300

$30.00

New Holland Service Manual PDF

New Holland 100, 115, 135, 160 CV Tractor Repair Manual 6035432000 ITA

$30.00

New Holland Service Manual PDF

New Holland 12.9L Turbo Compound Engine Repair Manual 87737594

$30.00

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

New Holland 130 Speedrower Self-Propelled Windrower Service Manual 47698328

$30.00

New Holland Service Manual PDF

$20.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF