- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Claas Dominator 150 140 (200) Combines Operator Manual EN

$50.00

- Model: Dominator 150 140 (200) Combines

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 97.1 MB

File List:

00 0293 210 2.pdf

00 0294 840 0.pdf

00 0301 051 0.pdf

00 0303 482 0.pdf

00 0303 846 1.pdf

00 0293 210 2.pdf:

1 Introduction

1.1 General Information

1.1.1 How to use this manual

1.1.2 Validity of instructions

1.1.3 Specifications

1.1.4 Road traffic regulations

1.1.5 Note on electronic engine management

1.2 Various components / Machine body

1.2.1 Spare parts and technical questions

1.2.2 Machine identification plate

1.2.3 Identification plate of CATERPILLAR 3056 E engine

1.2.4 Identification plate of PERKINS 1006-6T engine

1.2.5 Identification plate of CATERPILLAR C6.6 engine

1.2.6 Drive axle identification plate

1.2.7 Rear axle identification plate

1.2.8 Trailer hitch identification plate

1.2.9 Hitch block identification plate

1.2.10 Cab identification plate

1.2.11 Straw chopper identification plate

2 Sectional view of machine

2.1 Attachment parts / machine body

2.1.1 Machine overview

2.1.2 Access to the workplace and maintenance areas

3.1 General Information

3.1.1 General information

3.1.2 Important information

3.1.3 Intended use

3.1.4 Reasonable foreseeable misuse

3.1.5 Safety and accident prevention regulations

3.1.6 General safety and accident prevention regulations for combine harvesters

3.1.7 Prior to operation, general

3.1.8 Additional weights

3.1.9 Transporting passengers

3.1.10 General driving operations

3.1.11 Automotive operation of combine harvester

3.1.12 Driving operations on slopes

3.1.13 Leaving the machine

3.1.14 Front attachments and trailers

3.1.15 Crop receptacle / straw receptacle

3.1.16 Grain delivery

3.1.17 Air conditioner

3.1.18 Adjustment and maintenance work

3.1.19 Accumulators

3.1.20 Antifreeze

3.1.21 First aid measures

3.1.22 Decommissioning and disposal

3.1.23 Applying the feeder housing safety lock

3.1.24 Moving out the feed rake conveyor safety lock

3.1.25 Secure the machine with wheel chocks so it will not roll away

3.1.26 Securing the straw guide apron in raised position

3.1.27 Jack up the machine

3.1.28 Fire extinguisher

3.1.29 Battery isolating switch

3.1.30 Danger of injury due to escaping hydraulic liquid

3.1.31 Loading and tying down the machine

3.1.32 Removing the lift eyes

3.2 Safety rules

3.2.1 Identification of warning and danger signs

3.3 Safety decals

3.3.1 General information on safety decals

3.3.2 Engine

3.3.3 Chassis

3.3.4 Cab / Operator’s platform

3.3.5 Feeder unit

3.3.6 Threshing mechanism

3.3.7 Separation

3.3.8 Crop receptacle / straw receptacle

3.3.9 Grain delivery

3.3.10 Various components / Machine body

3.4 Safety decals

3.4.1 General instructions on safety decals

3.4.2 Chassis

4 Specifications

4.1 DOMINATOR 150 / 140 / 130

4.1.1 General information

4.1.2 CATERPILLAR C6.6 engine

4.1.3 CATERPILLAR 3056E engine

4.1.4 Perkins 1006-T6 engine

4.1.5 Chassis

4.1.6 Tyre pressures

4.1.7 Chassis track width

4.1.8 Brake

4.1.9 Steering

4.1.10 Electric system / Electronics

4.1.11 Cab / Operator’s platform

4.1.12 Intake

4.1.13 Threshing mechanism

4.1.14 Separation

4.1.15 Cleaning unit

4.1.16 Grain delivery

4.1.17 Attachment parts / machine body dimensions

4.1.18 Attachment parts / machine body weights

5 Prior to initial operation

5.1 General Information

5.1.1 General warnings Prior to initial operation

5.1.2 Initial operation check list

5.2 Chassis

5.2.1 Removing / installing the wheels

5.2.2 Overview of rear axle

5.2.3 Converting the rear axle from transport to working position

5.2.4 Rear axle 00 0649 950 1 – Adjusting the track width

5.3.1 Installing the trailer hitch (accessories)

5.4 Electrical / electronic equipment

5.4.1 Installing the fan / air conditioner fuse

5.5 Feeder unit

5.5.1 Fitting / adjusting the mounting plates

5.5.2 Aligning the coupling pin

5.5.3 Checking the front attachment cylinders

5.5.4 Checking the cutterbar float springs

5.6 Grain delivery

5.6.1 Closing the service aperture on the grain tank unloading tube

5.6.2 Installing the grain tank safety device

6 Prior to each operation

6.1 General Information

6.1.1 General warnings Prior to operation

6.1.2 Check list for daily operation

7 Overview of controls

7.1 General Information

7.1.1 General warnings – Overview of controls

7.2 Cab / Operator’s platform

7.2.1 Overview of operator’s platform (DOMINATOR 130)

7.2.2 Overview of operator’s platform (DOMINATOR 150/140)

7.2.3 Hydraulic system control unit (DOMINATOR 130 lift hydraulic system)

7.2.4 Multifunction handle (DOMINATOR 150 / 140)

7.2.5 Switch console (DOMINATOR 130)

7.2.6 Diesel engine speed adjustment rotary switch (DOMINATOR 130, CATERPILLAR C-6.6, 3056 E)

7.2.7 Diesel engine speed lever (DOMINATOR 130, Perkins 1006-T6)

7.2.8 Function of warning lights 7 and 8 (DOMINATOR 130)

7.2.9 Switch console (DOMINATOR 150 / 140)

7.2.10 Diesel engine speed rotary switch (DOMINATOR 150 / 140)

7.2.11 Function of warning lights 15 and 18 (DOMINATOR 150 / 140)

7.2.12 Overview of steering column

7.2.13 Cab roof controls

7.2.14 Cab with fan

7.2.15 Cab with air conditioner (with York compressor)

7.2.16 Cab with air conditioner (with Sanden compressor)

7.2.17 Cab with fan and heater

7.2.18 Control levers

7.2.19 Functions monitor

7.3 Attachment parts / machine body

7.3.1 Worklights

7.3.3 Sun roof

7.3.4 Tool box

8 Mounting/removing front attachment

8.1 General Information

8.1.1 General warnings Installing / removing the front attachment

8.2 Installing the front attachment

8.2.1 Suspending front attachment

8.2.2 Interlocking the front attachment

8.2.3 Installing universal drive shaft

8.2.4 Connecting the hydraulic system

8.2.5 Connecting the electric equipment (accessory)

8.2.6 Removing the stands

8.3 Removing the front attachment

8.3.1 Fitting the stands

8.3.2 Disconnecting the hydraulic system

8.3.3 Disconnecting the electric equipment (accessory)

8.3.4 Removing universal drive shaft

8.3.5 Unlocking the front attachment

8.3.6 Unhitching front attachment

9 Driving and transportation

9.1 General Information

9.1.1 General warnings – Driving and transportation

9.1.2 Preparing road travel

9.1.3 Preparing fieldwork

9.2 Engine

9.2.1 Adjusting the diesel engine speed (DOMINATOR 150 / 140)

9.2.2 Starting the diesel engine (DOMINATOR 150 / 140)

9.2.3 Stopping the diesel engine (DOMINATOR 150 / 140)

9.2.4 Adjusting the diesel engine speed (DOMINATOR 130)

9.2.5 Starting the diesel engine (DOMINATOR 130)

9.2.6 Stopping the diesel engine (DOMINATOR 130)

9.3 Chassis

9.3.1 Ground speed control lever (DOMINATOR 150 / 140)

9.3.2 Shifting a gear (DOMINATOR 150 / 140)

9.3.3 Ground speed control lever (DOMINATOR 130)

9.3.4 Shifting a gear (DOMINATOR 130)

9.3.5 Adjusting the ground speed control lever actuating resistance (DOMINATOR 150 / 140)

9.3.6 Driving behaviour

9.3.7 Towing the machine

9.3.8 Forward towing

9.3.9 Reverse towing

9.4.1 Applying the parking brake

9.4.2 Releasing the parking brake

9.4.3 Foot brake

9.4.4 Braking / stopping the machine (DOMINATOR 150 / 140)

9.4.5 Braking / stopping the machine (DOMINATOR 130)

9.4.6 Parking the machine

9.5 Steering

9.5.1 Steering

9.5.2 Adjusting the steering column

9.6.1 Hitching the trailer

9.6.2 Unhitching the trailer

9.7 Cab / Operator’s platform

9.7.1 Adjusting the driver’s seat with mechanical suspension (standard version)

9.7.2 Adjusting the driver’s seat with mechanical suspension (standard version)

9.7.3 Adjusting the mechanically suspended driver’s seat (option)

9.8 Various components / Machine body

9.8.1 Rotating the front ladder (standard)

9.8.2 Adjusting the rear ladder

10 Fieldwork settings

10.1 General Information

10.1.1 General warnings – Fieldwork settings

10.2 Feeder unit

10.2.1 Adjusting the cutting height indicator

10.2.2 Adjusting the scraper profiles

10.2.3 Adjusting the height of the feeder chain

10.2.4 Adjusting the front attachment drop rate (DOMINATOR 150)

10.3 Threshing mechanism

10.3.1 Removing / installing threshing concave segments (Multicrop concave)

10.3.2 Adjusting the basic concave adjustment

10.4 Separation

10.4.1 Adjusting the separation performance monitor sensors

10.5 Cleaning unit

10.5.1 Checking / adjusting the fan speed display

10.5.2 Adjusting the cleaning performance monitor sensors

10.5.3 Removing the sieves

10.5.4 Installing the sieves

10.6 Crop receptacle / straw receptacle

10.6.1 Removing the straw guide plate (straw chopper with standard spreader)

10.6.2 Installing the straw guide plate (straw chopper with standard spreader)

10.6.3 Unscrewing the free-swinging knives

10.6.4 Bolting down the free-swinging knives

10.6.5 Straw chopper sieves installation position

10.7 Grain delivery

10.7.1 Adjusting the grain tank full indicator DOMINATOR 150

11 Fieldwork

11.1 General Information

11.1.1 General warnings Fieldwork

11.2 Description and function

11.2.1 Cutterbar

11.2.2 Threshing mechanism

11.2.3 Straw walker

11.2.4 Cleaning unit

11.2.5 Disawning

11.3 Considerations before combining

11.3.1 When combining, remember:

11.4 Front attachment

11.4.1 Adjusting the reel horizontally (mechanically)

11.4.2 Adjusting the reel horizontally (hydraulically)

11.4.3 Adjusting the reel circumferential speed

11.5 Feeder unit

11.5.1 Reading the ground pressure

11.5.2 Reading the cutting height

11.5.3 Reversing the front attachment / feeder unit

11.5.4 Switching on the front attachment

11.5.5 Disengaging the front attachment

11.6 Threshing mechanism

11.6.1 Engaging the threshing mechanism

11.6.2 Disengaging the threshing mechanism

11.6.3 Adjusting the concave

11.6.4 Installing / removing the disawner bars (accessory)

11.6.5 Unslugging the threshing drum

11.6.6 Adjusting the threshing drum speed

11.6.7 Threshing drum two-step variable- speed drive (chain drive)

11.7 Separation

11.7.1 Adjusting the deflector curtain

11.7.2 Observe the straw blockage warning downstream of the separation stage

11.7.3 Adjusting the separation performance monitor display

11.7.4 Installing / removing the straw walker fishback

11.8 Cleaning unit

11.8.1 Adjusting the fan speed

11.8.2 Adjusting the wind board

11.8.3 Adjusting the sieves manually

11.8.4 Adjusting the cleaning performance monitor display

11.9 Crop receptacle / straw receptacle

11.9.1 Putting the straw chopper into operation (swinging the standard spreader to chopping position)

11.9.2 Putting the straw chopper out of operation (swinging the standard spreader to swathing position)

11.9.3 Swinging the standard distributor into the transport trolley transport position

11.9.4 Adjusting the stationary knives (standard straw chopper)

11.10 Grain delivery

11.10.1 Inspecting the returns

11.10.2 Opening / closing the grain tank cover

11.10.3 Swinging the grain tank unloading tube out / in (DOMINATOR 150 / 140)

11.10.4 Swinging the grain tank unloading tube out / in (DOMINATOR 130)

11.10.5 Engaging / disengaging the grain tank unloading

11.10.6 Removing / installing the grain tank auger cover plates

11.10.7 Clean machine for bulk seed change

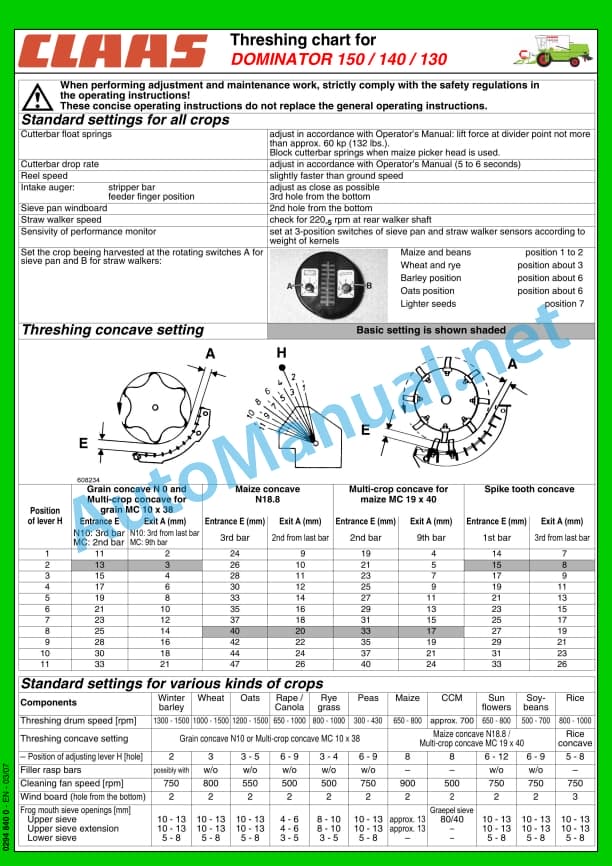

11.11 Sieve charts / threshing charts

11.11.1 Sieve table

11.11.2 Threshing table

11.12 Disawning

11.12.1 Disawner bars

12 Faults and remedies

12.1 General Information

12.1.1 General warnings Faults and remedy

12.2 Cab / Operator’s platform

12.2.1 Central terminal compartment

12.2.2 Air conditioner faults and remedies

12.3 Front attachment

12.3.1 Front attachment

12.4 Feeder unit

12.4.1 Feeder unit problem and remedy

12.5 Threshing mechanism

12.5.1 Threshing mechanism problem and remedy

12.5.2 Threshing drum

12.6 Separation

12.6.1 Separation problem and remedy

12.7 Cleaning unit

12.7.1 Cleaning problem and remedy

12.8 Crop receptacle / straw receptacle

12.8.1 Crop / straw discharge problems and remedies

12.9 Grain delivery

12.9.1 Grain delivery problems and remedies

12.9.2 Installing the grain tank unloading shear bolt

13 Maintenance

13.1 General Information

13.1.1 General warnings Maintenance

13.2 General Information

13.2.1 Front attachment

13.2.2 Cleaning the engine compartment and hazard areas

13.2.3 Belts

13.2.4 Variable-speed drives

13.2.5 Bolts

13.2.6 Lubrication

13.2.7 Cleanliness of lubricants

13.2.8 Brakes

13.2.9 Wheels / tyres

13.2.10 Hydraulic system

13.2.11 Electrical system

13.2.12 Air conditioner

13.2.13 Protective guards

13.2.14 Spare parts

13.2.15 Unbalance

13.2.16 Welding work on combine harvester

13.2.17 Putting the machine out of action

13.2.18 Cleaning of surfaces with decals applied

13.2.19 Winter storage instructions for combines

13.2.20 Coolant

13.3 Maintenance schedule

13.3.1 Service intervals

13.4 Lubricants chart

13.4.1 Lubricants

13.5 Engine

13.5.1 Overview of engine CATERPILLAR C-6.6

13.5.2 Overview of engine CATERPILLAR 3056 E

13.5.3 Overview of engine PERKINS 1006-6T

13.5.4 Overview of cooling units

13.5.5 Cleaning the diesel engine surroundings

13.5.6 Draining fuel from the fuel tank

13.5.7 Fill up the machine’s fuel tank

13.5.8 Cleaning the fuel tank filler screen

13.5.9 Closing / opening the fuel system shut- off tap

13.5.10 Bleed fuel system

13.5.11 Cleaning the fuel sediment bowl filter

13.5.12 Draining condensation at the fuel prefilter (standard equipment)

13.5.13 Changing the fuel prefilter (standard equipment)

13.5.14 Draining condensation at the fuel prefilter (additional equipment)

13.5.15 Changing the fuel pre-filter (accessory)

13.5.16 Changing the fuel filter CATERPILLAR C-6.6 / 3056 E

13.5.17 Changing the fuel filter PERKINS 1006-6T

13.5.18 Checking the diesel engine oil level

13.5.19 Changing the diesel engine oil / oil filter

13.5.20 Adjusting the diesel engine valves

13.5.21 Checking the radiator coolant level

13.5.22 Checking the coolant mixing ratio

13.5.23 Changing the radiator coolant

13.5.24 Draining the radiator coolant

13.5.25 Topping up coolant

13.5.26 Cleaning the rotary chaff screen

13.5.27 Cleaning the cooling unit

13.5.28 Changing the coolant hoses

13.5.29 Cleaning / changing the diesel engine air cleaner with plastic housing

13.5.30 Changing the diesel engine air cleaner safety cartridge with plastic housing

13.5.31 Cleaning the air filter intake screen

13.5.32 Changing the air intake hoses

13.5.33 Retightening the air intake tube clamps

13.6 Chassis

13.6.1 Wheels / tyres

13.6.2 Checking the tightening torque of wheel nuts / wheel bolts

13.6.3 Cleaning the surroundings of the drive axle manual gearbox

13.6.4 Checking the final drive oil level DOMINATOR 150 / 140

13.6.5 Draining the final drive oil DOMINATOR 150 / 140

13.6.6 Topping up the final drive oil DOMINATOR 150 / 140

13.6.7 Checking the final drive oil level DOMINATOR 130

13.6.8 Draining the final drive oil DOMINATOR 130

13.6.9 Topping up the final drive oil DOMINATOR 130

13.6.10 Checking the drive axle gearbox oil level

13.6.11 Draining the oil from the drive axle gearbox

13.6.12 Topping up oil in the drive axle gearbox

13.6.13 Adjusting the chassis clutch DOMINATOR 130

13.6.14 Adjusting the short-circuit valve DOMINATOR 130

13.7 Brake

13.7.1 Checking / refilling brake fluid

13.7.2 Adjusting the parking brake

13.7.3 Adjusting the foot brake

13.8 Drive belts / drive chains

13.8.1 General warnings

13.8.2 Drive diagram, left side DOMINATOR 150 / 140 / 130

13.8.3 Drive diagram, right side DOMINATOR 150 / 140 / 130

13.8.4 Adjusting belt (R1)

13.8.5 Adjusting belt (R2)

13.8.6 Adjusting belt (R3)

13.8.7 Adjusting belt (R4)

13.8.8 Adjusting belt (R5)

13.8.9 Adjusting belt (R8)

13.8.10 Adjusting belt (R9)

13.8.11 Adjusting belt (R10)

13.8.12 Removing belt (R7)

13.8.13 Installing belt (R7)

13.8.14 Adjusting belt (R12)

13.8.15 Adjusting belt (R13)

13.8.16 Removing belt (R14)

13.8.17 Installing belt (R14)

13.8.18 Adjusting belt (R14)

13.8.19 Removing belt (R42)

13.8.20 Installing belt (R42)

13.9 Hydraulic system

13.9.1 Checking the hydraulic system oil level

13.9.2 Changing the hydraulic system oil / oil filter / fresh air filter element DOMINATOR 150 / 140

13.9.3 Changing the hydraulic system oil / oil filter / fresh air filter element DOMINATOR 130

13.10 Electric system / Electronics

13.10.1 Checking the battery electrolyte level

13.11 Cab / Operator’s platform

13.11.1 Cleaning / changing the cab air filter

13.11.2 Cleaning the cab recirculation air filter

13.11.3 Cleaning the cab roof units

13.11.4 Putting the air conditioner into operation

13.11.5 Precautions for protecting the air conditioner during extended standstill periods – DOMINATOR 130 with York compressor

13.11.6 Checking the air conditioner refrigerant moisture saturation

13.11.7 Changing the air conditioner refrigerant

13.12 Feeder unit

13.12.1 Cleaning the feed rake conveyor retainers

13.12.2 Adjusting the feeder chains

13.12.3 Adjusting the feeder chain slip clutch

13.12.4 Checking the rasp plates on the feed rake conveyor

13.13 Threshing mechanism

13.13.1 Cleaning the stone trap

13.13.2 Cleaning the threshing mechanism

13.14 Separation

13.14.1 Cleaning the straw walker

13.14.2 Checking the deflector curtain

13.14.3 Cleaning the separation throughput monitor sensor

13.15 Cleaning unit

13.15.1 Cleaning the cleaning throughput monitor sensor

13.15.2 Cleaning the fan

13.15.3 Setting the fan speed gauge

13.15.4 Cleaning the stepped preparation floors

13.15.5 Cleaning the sieves

13.16 Grain delivery

13.16.1 Adjusting the returns elevator chain

13.16.2 Adjusting the grain elevator chain

13.16.3 Cleaning the auger troughs

13.16.4 Cleaning the grain tank

13.16.5 Adjusting the grain tank unloading tube support transport position

13.17 Various components / Machine body

13.17.1 Checking the fire extinguisher

14 Lubrication chart

14.1 Lubrication points

14.1.1 General warnings Lubrication chart

14.1.2 Lubricants

14.1.3 Greasing cycles

14.1.4 Lubrication points – 10 h on the left

14.1.5 Lubrication points – 10 h on the right

14.1.6 Lubrication points – 50 h on the left

14.1.7 Lubrication points – 50 h on the right

14.1.8 Lubrication points – 100 h on the left

14.1.9 Lubrication points – 100 h on the right

14.1.10 Lubrication points – 500 h on the left

14.1.11 Lubrication points – 500 h on the right

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0303 482 0.pdf:

PROFI CAM 4

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Structural changes

2.2.3 Optional equipment and spare parts

2.2.4 Operation only following proper putting into operation

2.2.5 Technical status

2.2.6 Respecting technical limit values

Respecting technical limit values

2.2.7 Hazards when driving on roads and fields

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Identification plates

3.3 Information on the product

3.3.1 CE marking

4 Operating and display elements

4.1 Camera system

4.1.1 Camera system monitor

4.1.2 CEBIS

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

6 Preparing the product

6.1 Switching off and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to putting into operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electric and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Putting out of operation and disposal

10.1 General information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0303 846 1.pdf:

DOMINATOR 40 WHEEL

Table of contents

1 To this Operator’s Manual

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Notes on the Operator’s Manual

1.1.3 Symbols and notices

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Notes on maintenance

1.1.7 Notes on warranty

1.1.8 Technical specifications

1.1.9 Spare parts and technical questions

2.1 Intended use

2.1.1 Intended use

2.1.2 Reasonably foreseeable misuse

2.2 Safety rules

2.2.1 Operator’s Manual and other sources of information

Meaning of Operator’s Manual

2.2.2 Personnel qualification and organization

Requirements made on all persons working with the machine

2.2.3 Hazard for children

Children in danger

2.2.4 Modifications on the machine

Structural modifications

2.2.5 Additional equipment and spare parts

Additional equipment and spare parts

2.2.6 Workplace and persons travelling on the machine

Control of running machine

2.2.7 Technically flawless condition

Operation only following proper pre-delivery inspection

Operation only following proper putting into operation

Technically flawless condition of machine

Danger from damage on the machine

Respecting technical limit values

2.2.8 Hazard areas

Hazard areas

Standing between machine and front attachment

Objects flying away

Hazard while drive is engaged

Risk of injury on the universal drive shaft

Hazard from machine parts that continue rotating

2.2.9 Safety devices

Keeping the safety devices functional

2.2.10 Personal protective equipment

Personal protective equipment

Wearing suitable clothing

2.2.11 Safety markings

Keeping safety decals legible

2.2.12 Road safety

Hazards when driving on the road and on the field

Danger of tipping

Preparing the machine for road travel

Parking the machine safely

Unsupervised parking

Keeping the machine free of foreign objects

2.2.13 Operating utilities

Unsuitable operating utilities

Safe handling of operating and auxiliary utilities

Fuel is hazardous to your health

Environmental protection and disposal

2.2.14 Hazards caused by the field environment

Fire hazard

Possibly lethal electrocution from overhead lines

Behaviour in case of voltage flash-over of overhead lines and in case of lightning strike

2.2.15 Hazard sources on the machine

Electrocution from electric system

Noise may cause health problems

Vibrations may cause health problems

Liquids under pressure

Toxic exhaust gas

Hot surfaces

2.2.16 Hazard when climbing on and leaving the machine

Safe climbing on and leaving the machine

2.2.17 Hazards when working on the machine

Working on machine only after shutting it down

Maintenance and repair work

Lifted machine parts and loads

Danger from welding work

2.2.18 Checking the battery

Checking and charging the battery

2.3 Safety instructions in this manual

2.3.1 Identification of warning and danger signs

2.4 Safety decals on the machine

2.4.1 Front attachment

2.4.2 Notes on safety decals

2.4.3 Safety decals of engine

2.4.4 Safety decals of chassis

2.4.5 Safety decals of hydraulic system

2.4.6 Safety decals on operator’s platform

2.4.7 Safety decals of feed rake conveyor

2.4.8 Safety decals of crop discharge and straw discharge

2.4.9 Safety decals of grain delivery

2.4.10 Drives

2.5 Safety devices

2.5.1 Applying the feed rake conveyor safety lock

2.5.2 Releasing the feed rake conveyor safety lock

2.5.3 Securing the machine against rolling away

2.5.4 Switching the battery isolating switch on and off

2.5.5 Checking the fire extinguisher

3 Machine description

3.1 Overview and method of operation

3.1.1 Overview of DOMINATOR 40 Wheel, front and left

3.1.2 Overview of rear and right side of machine

3.1.3 Overview of front attachment

3.1.4 Working mode of the machine

3.1.5 Function of machine

3.1.6 Engine overview Ashok Leyland H3C4E7422

3.1.7 Overview of cooling units

3.2 Identification plates and vehicle identification number

3.2.1 Machine identification plate

Identification plate

4 Operating and control elements

4.1 Operator’s platform

4.1.1 Operator’s platform

4.1.2 Switch console and display panel

4.1.3 Drive lights, work lights, mirrors

4.1.4 Control levers

4.1.5 Lever for adjusting the diesel engine speed

4.1.6 Ignition switch

4.1.7 Steering column controls

4.1.8 Driver���s seat

5 Technical specifications

5.1 DOMINATOR 40 Wheel – type 551

5.1.1 Ashok Leyland H3C4E7422 diesel engine

5.1.2 Chassis

5.1.3 Chassis wheel tread

5.1.4 Tyre Pressure

5.1.5 Clearance circle diameter

5.1.6 Turning circle diameter

5.1.7 Brake

5.1.8 Steering

5.1.9 Electric and electronic equipment

5.1.10 Sound pressure level and vibrations

5.1.11 Feed rake conveyor

5.1.12 Threshing mechanism

5.1.13 Separation unit

5.1.14 Cleaning unit

5.1.15 Grain tank capacity

5.1.16 Dimensions of grain tank unloading tube in working position

5.1.17achine dimensions

5.1.18 Weights

6 Machine preparation

6.1 Switching off and securing the machine

6.1.1 Switch off and secure the machine

6.2 Accerkplaces and maintenance places

6.2.1 Remove the front ladder

6.2.2 Adjusting the rear ladder

ccess to the workplace and maintenance areas

6.3 Prior to putting into operation

6.3.1 Prior to initial operation

6.4 Setting of the machine for the operation

6.4.1 Setting the machine to grain harvest

6.4.2 Sieve chart

6.4.3 Threshing chart

6.4.4 Clean the machine for harvesting seeds

6.5 Diesel engine

6.5.1 Refuelling

6.6 Chassis

6.6.1 Removing and installing the wheels

6.6.2 Jacking up the machine

6.7.1 Checking the parking brake

6.7.2 Checking the foot brake

6.8 Hydraulic system

6.8.1 Identifying the hydraulic oil

6.9 Operator’s platform

6.9.1 Installing rear view mirrors

6.10 Feeder unit

6.10.1 Adjusting the feeder chain height

6.11 Threshing mechanism

6.11.1 Opening and closing the stone trap

6.11.2 Opening and closing the drum inspection cover

6.11.3 Checking the basic threshing concave setting

6.11.4 Installing or removing the disawner bars*

6.12 Separation

6.12.1 Removing and installing the deflector curtain

6.12.2 Installing and removing side risers

6.12.3 Installing and removing centre risers

6.13 Cleaning system

6.13.1 Removing the sieves

6.13.2 Installing the sieves

6.13.3 Assembly of Straw Walker

6.14 Grain delivery

6.14.1 Entering and leaving the grain tank

Entering and leaving the straw walker compartment

6.14.2 Adjusting the grain tank auger cover plates

6.14.3 Closing the service flap on the grain tank unloading tube

6.15 Assembly parts and bodywork

6.15.1 Opening / closing the side panels

6.15.2 Checking the reverse warning horn

7 Operation

7.1 Driving the machine

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF