Claas Medion 340 (934) Combines Technical System ES

$300.00

- Model: Medion 340 (934) Combines

- Type Of Manual: Technical System

- Language: ES

- Format: PDF(s)

- Size: 13.6 MB

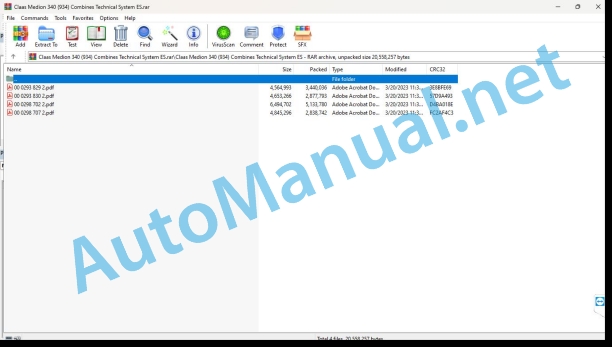

File List:

00 0293 829 2.pdf

00 0293 830 2.pdf

00 0298 702 2.pdf

00 0298 707 2.pdf

00 0293 829 2.pdf:

MEDION 340 – 310 from machine no. 934 00610, 932 02724 – Technical systems, Hydraulic installation

Chapter 1 General hydraulic system

1.1 General hydraulic system connection diagram

1.2 Oil tank, oil type, filling quantities, oil change, oil filter, oil pressure

1.3 Hydraulic pumps

Chapter 2 Hydraulic steering installation

2.1 Connection diagram of the hydraulic steering installation without AUTOPILOT

2.2 Connection diagram of the hydraulic steering system with AUTOPILOT

2.3 Steering valve unit

2.4 Steering function – neutral

2.5 Steering control

2.6 AUTOPILOT electromagnetic valve left/right

2.7 AUTOPILOT system control

Chapter 3 Hydraulic system operations

3.1 Connection diagram of the operating hydraulic system

3.2 Main valve with circulation shut-off valve, pressure limitation, raise/lower head

3.3 Regulation of the speed of the shelling cylinder

3.4 Rotate the discharge tube

3.5 Invert the head

3.6 Vertical adjustment of the reel

3.7 Horizontal adjustment of the reel

3.8 AUTO-CONTOUR transversal adjustment of the cutting mechanism

Chapter 4 Low pressure hydraulic installation

4.1 Connection diagram of the low pressure hydraulic installation

4.2 Pressure limiting valve

4.3 Electromagnetic valves of the low-pressure hydraulic system 3/2-way valves, threshing unit clutch, grain tank discharge, header clutch

4.4 Operation of the 3-D screen box Oscillating housing with 4/3-way valve and hydraulic cylinder

4.5 Front implement drive Hydraulic cylinder with rotary connection

Chapter 5 Front implements

5.1 Connection diagram, folding the cutting mechanism

5.2 Connection diagram, folding the corn header / adjustment of the starting plates

5.3 Folding the cutting mechanism 6/2-way solenoid valve with locking valve block

5.4 Folding the corn header / adjusting the starter plates Valve unit

5.5 Rake-up connection diagram – Hydraulic drive system

Chapter 6 Propulsion Hydraulic System

6.1 Connection diagram, LINDE propulsion hydraulic system

6.2 HPV 105 pump unit

6.3 Servo regulation valve

6.4 Multifunctional propulsion valve

6.5 Constant propulsion motor HMF 105 motor unit

6.6 Traction 4-Trac Valve Unit

6.7 Maintenance

Chapter 7 Cleaning the radiator rotary screen

7.1 Radiator rotary screen connection diagram

7.2 Drive of the radiator rotary screen

Alphabetical index

0293 829.2

00 0293 830 2.pdf:

MEDION 340 – 310 From machine no. 934 00610, 932 02724. Technical systems, Electrical installation

central electrical system

Module occupancy

A6 automatic air conditioning system module:

Cabin fan module, A7 revolution regulator:

AUTOCONTOUR (CAC) A8 module: Ref.-Nr. 011 015.x

Contour A8 Module: Ref.-Nr. 011 026.x

AUTOPILOT A9 module:

A12 revolution controller module:

A15 engine electronic operation module:

Engine adaptation module (ADM) A17:

A21 quantimeter module:

Spreader plate regulation module A26:

A52 multifunctional control module:

Fuse summary table:

Connection diagrams 01a – 50a

1st Main voltage system supply, diesel engine starter motor

2a Start the diesel engine, adjust the diesel engine revolutions

3a Diesel engine control

4a Gear change on road trips, circulation blocking valve

5a On-board reporter

7th Start-up of the threshing equipment

8a Sheller cylinder variator

10a Fan variator

12a Regulation of the spreader plate, control of grain passage

14a Rotate the grain tank discharge tube

15th Grain tank unloading

17a Head drive

19a Reel variator

19b Rake-up – Speed adjustment, hydraulic oil temperature control

20a Raise/lower the head, transversal adjustment

21a Reel adjustment

23a Fold the cutting mechanism

24th AUTOCONTOUR (CAC)

24b CONTOUR

25a Revolution control

26a Machine control

27a Quanmeter

28a AUTOPILOT

29a 4 wheel drive

30a Full grain tank indicator / rotating ligh31ashing light equipment

32a Main light connection, position light

33a Low beam, headlight switching

34a Work lighting

35a Lighting of the grain tank, – of the sieve box, – of the return horn, brake light

36a Interior lighting, instrument lighting

37a Windshield wipers

38a Cooling system compressor, cabin fan

38b Automatic air conditioning installation (Climatic)

39a Air seat compressor

40a Additional sockets

50a Electrical adjustment of the mirrors

Component Grid

Alphabetical index

0293 830.2

00 0298 702 2.pdf:

Technical systems – MEDION 340 – 310 hydraulic system, up to machine no. 934 00609, 932 02723

Chapter 1 General hydraulic system

1.1 Connection diagram of the general hydraulic system – up to machine no. 932 02028, 934 00534

1.2 Oil tank, oil type, filling quantities, oil change, oil filter, oil pressure

1.3 Hydraulic pumps

Chapter 2 Hydraulic steering installation

2.1 Connection diagram of the hydraulic steering installation without AUTOPILOT

2.2 Connection diagram of the hydraulic steering system with AUTOPILOT

2.3 Steering valve unit

2.4 Steering function – neutral

2.5 Steering control

2.6 AUTOPILOT electromagnetic valve left/right

2.7 AUTOPILOT system control

Chapter 3 Hydraulic system operations

3.1 Connection diagram of the operating hydraulic system

3.2 Pressure limiting valve, operating hydraulic system

3.3 Raise/lower the head

3.4 Unfold/fold the grain tank discharge tube

3.5 Vertical adjustment of the reel

3.6 Reverse the head (hydraulically)

3.7 AUTO-CONTOUR transversal adjustment of the cutting mechanism

3.8 Horizontal adjustment of the reel

3.9 Regulation of the speed of the shelling cylinder

3.10 Checking the operating hydraulic system

Chapter 4 Low pressure hydraulic installation

4.1 Connection diagram of the low pressure hydraulic installation

4.2 Pressure limiting valve

4.3 Electromagnetic valves of the low pressure hydraulic installation

4.4 Handling of the 3-D sieve box

4.5 Front implement drive

4.6 Regulation of the diesel engine revolutions (Perkins engines only)

Chapter 5 Front implements

5.1 Connection diagram, folding the cutting mechanism

5.2 Connection diagram, folding the corn header / adjustment of the starting plates

5.3 Folding the cutting mechanism

5.4 Folding the corn header / adjusting the starting plates

Chapter 6 Propulsion Hydraulic System

6.1 Connection diagram, LINDE propulsion hydraulic system

6.2 HPV 105 pump unit

6.3 Servo regulation valve

6.4 Multifunctional propulsion valve

6.5 Motor constant propulsion

6.6 Traction 4-Trac

6.7 Maintenance

Chapter 7 Cleaning the radiator rotary screen

7.1 Radiator rotary screen connection diagram

7.2 Radiator rotary screen drive

Location of components

Component Grid

Alphabetical index

0298 702.2

00 0298 707 2.pdf:

Technical systems Electrical installation MEDION 340 – 310

Structure of the connection diagrams

central electrical system

Module occupancy

A6 automatic air conditioning system module:

Cabin fan module, A7 revolution regulator:

AUTOCONTOUR (CAC) A8 module: Ref.-N° 011 015.x

Contour A8 Module: Ref.-N° 011 026.x

AUTOPILOT A9 module:

A12 revolution controller module:

A15 engine electronic operation module:

Engine adaptation module (ADM) A17:

A21 quantimeter module:

Spreader plate regulation module A26:

Connection diagrams 01a – 50a

1st Main voltage system supply, diesel engine starter motor

2a Start the diesel engine, regulation of the diesel engine revolutions – with mechanical engine regulation (Perkins)

2b Starting the diesel engine, diesel engine speed regulation – with electronic engine regulation (Daimler-Chrysler)

3a Diesel engine control – with mechanical engine regulation (Perkins)

3b Diesel engine control – with electronic engine regulation (Daimler-Chrysler)

4a Gear change on road trips

5a On-board reporter

7a Commissioning of the threshing units up to machine number 932 02028, 934 00534

7b Commiioning of the threshing units from machine number 932 02029, 934 00535

10a Fan variator

12a Regulation of the spreader plate, control of grain passage

14a Rotate the grain tank discharge tube

15th Grain tank unloading

17a Spindle drive, reversing process drive (electric)

17b Spindle drive, reversing process drive (hydraulic) up to machine number 932 02028, 934 00534

17c Spindle drive, reversing process drive (hydraulic) from machine number 932 02029, 934 00535

19a Reel variator

20a Raise/lower the head, transversal adjustment

21a Reel adjustment

21b Folding the corn header / adjusting the starting plates

23a Fold the cutting mechanism

24th AUTOCONTOUR (CAC)

24b CONTOUR

25a Revolution control

26a Machine control up to machine number 932 02028, 934 00534

26b Machine control from machine number 932 02029, 934 00535

27a Quanmeter

28a AUTOPILOT

29a 4 wheel drive

30a Full grain tank indicator / rotating light

31a Flashing light equipment

32a Main light connection, position light

33a Low beam, headlight switching

34a Work lighting up to machine number 932 02028, 934 00534

34b Work lighting from machine number 932 02029, 934 00535

35a Lighting of the grain tank, – of the sieve box, – of the return horn, brake light

36a Interior lighting, instrument lighting

37a Windshield wipers

38a Cooling system compressor, cabin fan

38b Automatic air conditioning installation

39a Air seat compressor

40a Additional sockets

50a Electrical adjustment of the mirrors

Component Grid

Alphabetical index

0298 707.2

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF