Komatsu D155AX-6 Bull Dozer Field Assembly Instruction GEN00255-00

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: GEN00255-00

- Format: PDF

- Size: 14.7MB

- Number of Pages: 132

-

Model List:

- D155AX-6 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. SPECIFICATIONS

- 4. PRECAUTIONS FOR FIELD ASSEMBLY

- 5. ASSEMBLY PROCEDURE, NECESSARY EQUIPMENT, AND SCHEDULE

- 6. LAYOUT OF KIT

- 7. STYLE FOR TRANSPORTATION

- 8. LIST OF TOOLS FOR FIELD ASSEMBLING

- 9. TIGHTENING TORQUE

- 10. COATING MATERIALS LIST

- 11. Selection of wire ropes used for assembly

- 12. Assembly

- 12.1. A1 Unloading and installing tractor

- 12.2. A2 Installing track shoes

- 12.3. A3 Installation of blade lift cylinder (1/2)

- 12.4. A3 Installation of blade lift cylinder (2/2)

- 12.5. A4 Assembly of blade (1/6)

- 12.6. A4 Assembly of blade (2/6)

- 12.7. A4 Assembly of blade (3/6)

- 12.8. A4 Assembly of blade (4/6)

- 12.9. A4 Assembly of blade (5/6)

- 12.10. A4 Assembly of blade (6/6)

- 12.11. A5 Installation of full roller guard (1/4)

- 12.12. A5 Installation of full roller guard (2/4)

- 12.13. A5 Installation of full roller guard (3/4)

- 12.14. A5 Installation of full roller guard (4/4)

- 12.15. A6 Installation of blade (1/3)

- 12.16. A6 Installation of blade (2/3)

- 12.17. A6 Installation of blade (3/3)

- 12.18. A7 Installation of ripper assembly (1/12)

- 12.19. A7 Installation of ripper assembly (2/12)

- 12.20. A7 Installation of ripper assembly (3/12)

- 12.21. A7 Installation of ripper assembly (4/12)

- 12.22. A7 Installation of ripper assembly (5/12)

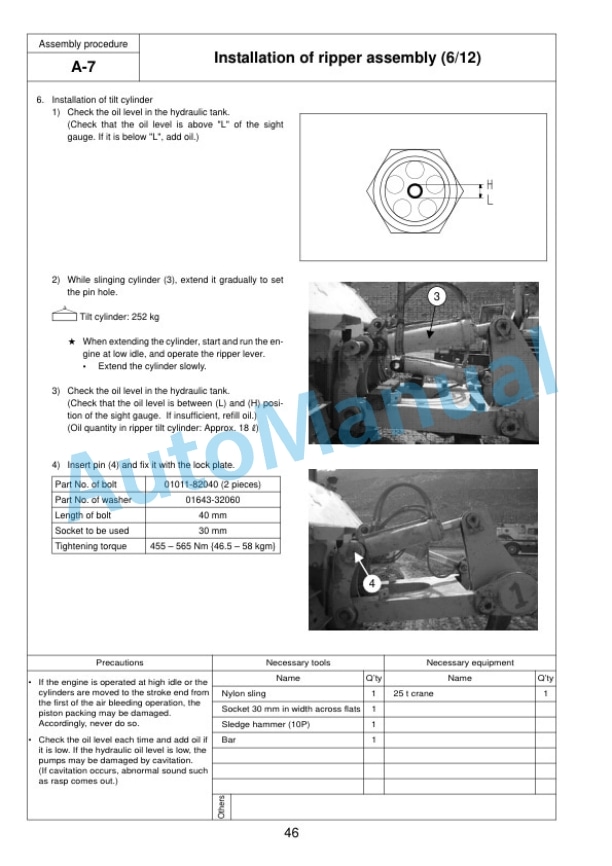

- 12.23. A7 Installation of ripper assembly (6/12)

- 12.24. A7 Installation of ripper assembly (7/12)

- 12.25. A7 Installation of ripper assembly (8/12)

- 12.26. A7 Installation of ripper assembly (9/12)

- 12.27. A7 Installation of ripper assembly (10/12)

- 12.28. A7 Installation of ripper assembly (11/12)

- 12.29. A7 Installation of ripper assembly (12/12)

- 12.30. A8 Installation of operators cab (1/17)

- 12.31. A8 Installation of operators cab (2/17)

- 12.32. A8 Installation of operators cab (3/17)

- 12.33. A8 Installation of operators cab (4/17)

- 12.34. A8 Installation of operators cab (5/17)

- 12.35. A8 Installation of operators cab (6/17)

- 12.36. A8 Installation of operators cab (7/17)

- 12.37. A8 Installation of operators cab (8/17)

- 12.38. A8 Installation of operators cab (9/17)

- 12.39. A8 Installation of operators cab (10/17)

- 12.40. A8 Installation of operators cab (11/17)

- 12.41. A8 Installation of operators cab (12/17)

- 12.42. A8 Installation of operators cab (13/17)

- 12.43. A8 Installation of operators cab (14/17)

- 12.44. A8 Installation of operators cab (15/17)

- 12.45. A8 Installation of operators cab (16/17)

- 12.46. A8 Installation of operators cab (17/17)

- 12.47. A9 Check track tension (1/2)

- 12.48. A9 Check track tension (2/2)

- 12.49. A10 Check of oil and coolant levels (1/2)

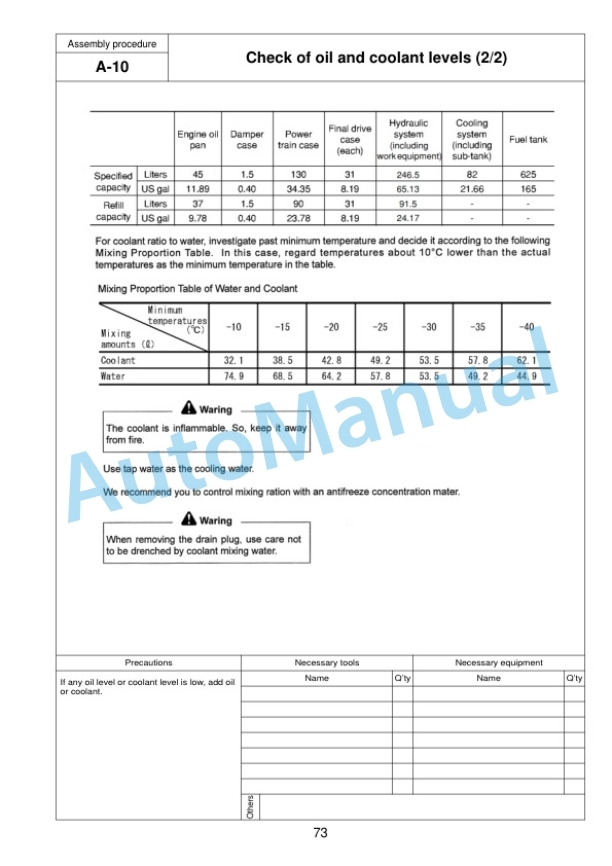

- 12.50. A10 Check of oil and coolant levels (2/2)

- 12.51. A11 Lubricating (1/3)

- 12.52. A11 Lubricating (2/3)

- 12.53. A11 Lubricating (3/3)

- 12.54. A12 Bleeding air from hydraulic cylinders (1/2)

- 12.55. A12 Bleeding air from hydraulic cylinders (2/2)

- 12.56. A13 Installation of additional working lamps (1/3)

- 12.57. A13 Installation of additional working lamps (2/3)

- 12.58. A13 Installation of additional working lamps (3/3)

- 12.59. A14 Installation of revolving warning lamp

- 12.60. A15 Installation of KOMTRAX parts (1/6)

- 12.61. A15 Installation of KOMTRAX parts (2/6)

- 12.62. A15 Installation of KOMTRAX parts (3/6)

- 12.63. A15 Installation of KOMTRAX parts (4/6)

- 12.64. A15 Installation of KOMTRAX parts (5/6)

- 12.65. A15 Installation of KOMTRAX parts (6/6)

- 12.66. A16 Installation of KOMTRAX antenna

- 12.67. A17 Installation of fire extinguisher (1/2)

- 12.68. A17 Installation of fire extinguisher (2/2)

- 12.69. A18 Installation of exhaust pipe

- 13. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

- 13.1. M1 Testing and adjusting operators cab (1/10)

- 13.2. M1 Testing and adjusting operators cab (2/10)

- 13.3. M1 Testing and adjusting operators cab (3/10)

- 13.4. M1 Testing and adjusting operators cab (4/10)

- 13.5. M1 Testing and adjusting operators cab (5/10)

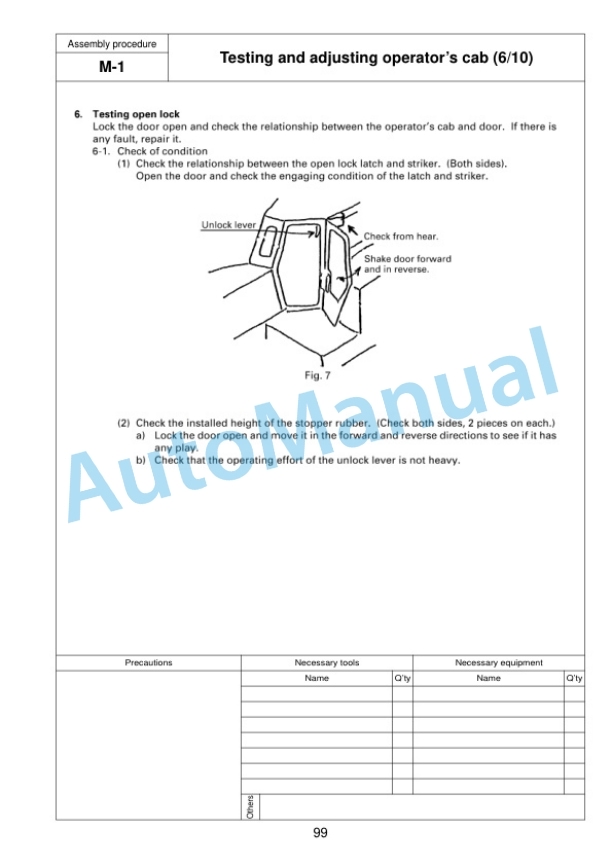

- 13.6. M1 Testing and adjusting operators cab (6/10)

- 13.7. M1 Testing and adjusting operators cab (7/10)

- 13.8. M1 Testing and adjusting operators cab (8/10)

- 13.9. M1 Testing and adjusting operators cab (9/10)

- 13.10. M1 Testing and adjusting operators cab (10/10)

- 13.11. M2 Replacement of return filter (Standard filter to flushing filter) (1/2)

- 13.12. M2 Replacement of return filter (Standard filter to flushing filter) (2/2)

- 13.13. M3 Flushing of hydraulic circuit, and bleeding air from hydraulic cylinders (Part 1)

- 13.14. M4 Replacement of return filter (Flushing filter to standard filter) (1/2)

- 13.15. M4 Replacement of return filter (Flushing filter to standard filter) (2/2)

- 13.16. M5 Bleeding air from hydraulic cylinders (Part 2)

- 14. FIELD ASSEMBLY INSPECTION REPORT

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF