Komatsu D155AX-6 Bull Dozer Operation and Maintenance Manual EEAM025000

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: EEAM025000

- Format: PDF

- Size: 11.2MB

- Number of Pages: 312

-

Model List:

- D155AX-6 Bull Dozer

- 1. FOREWORD

- 1.1. FOREWORD

- 1.2. SAFETY INFORMATION

- 1.2.1. Noise emission levels

- 1.2.2. Vibration levels

- 1.2.2.1. Guide to Reduce Vibration Levels on Machine

- 1.3. INTRODUCTION

- 1.3.1. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 1.3.2. VISIBILITY FROM OPERATORS SEAT

- 1.3.2.1. PROXIMITY VISIBILITY

- 1.3.2.2. CIRCUMFERENCE VISIBILITY

- 1.3.3. BREAKING IN THE MACHINE

- 1.4. NECESSARY INFORMATION

- 1.4.1. PRODUCT IDENTIFICATION NUMBER (PIN), MACHINE SERIAL NO. PLATE

- 1.4.2. EPA REGULATIONS, ENGINE NUMBER PLATE

- 1.4.3. BLADE SERIAL NO. PLATE POSITION

- 1.4.4. RIPPER SERIAL NO. PLATE POSITION

- 1.4.5. ROPS, FOPS NO. PLATE POSITION

- 1.4.6. POSITION OF SERVICE METER

- 1.4.7. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 1.4.8. MACHINE SERIAL NUMBER PLATE

- 1.4.9. ATTACHMENTS, OPTIONS

- 1.4.10. POSITIONS OF SAFETY PICTOGRAMS

- 1.4.11. SAFETY LABELS

- 1.5. GENERAL PRECAUTIONS

- 1.6. PRECAUTIONS FOR OPERATION

- 1.6.1. BEFORE STARTING ENGINE

- 1.6.2. OPERATION

- 1.6.3. TRANSPORTATION

- 1.6.4. BATTERY

- 1.6.5. TOWING

- 1.7. PRECAUTIONS FOR MAINTENANCE

- 2. OPERATION

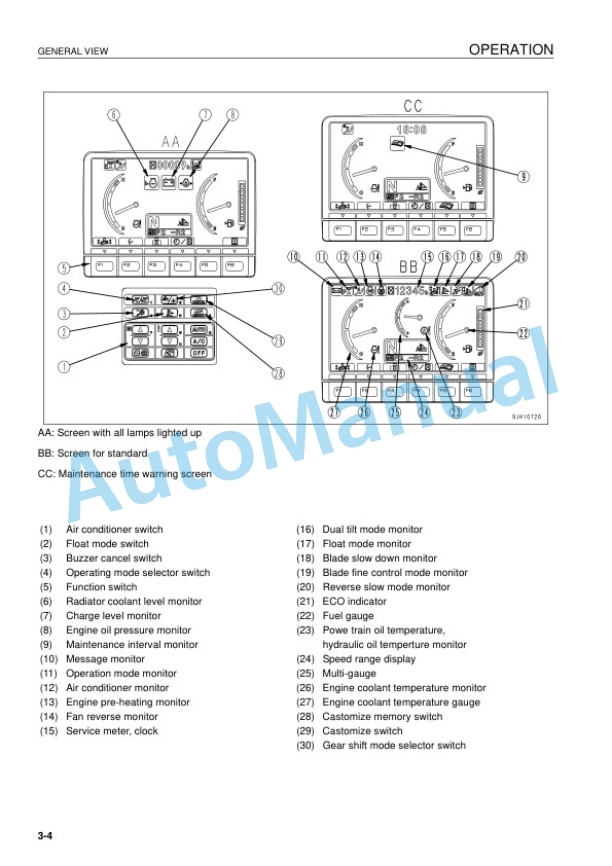

- 2.1. GENERAL VIEW

- 2.1.1. GENERAL VIEW OF MACHINE

- 2.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 2.2. EXPLANATION OF COMPONENTS

- 2.2.1. MACHINE MONITOR

- 2.2.1.1. BASIC OPERATION OF MACHINE MONITOR

- 2.2.1.2. BASIC CHECK MONITORS

- 2.2.1.3. CAUTION MONITORS

- 2.2.1.4. EMERGENCY MONITORS

- 2.2.1.5. METER DISPLAY PORTION

- 2.2.1.6. MONITOR SWITCHES PORTION

- 2.2.1.7. HANDLING FUNCTION SWITCHES

- 2.2.1.8. SPEED RANGE DISPLAY

- 2.2.2. SWITCHES

- 2.2.3. CONTROL LEVERS, PEDALS

- 2.2.4. DUST INDICATOR

- 2.2.5. FUSE BOX

- 2.2.5.1. CIRCUIT BREAKER

- 2.2.5.2. CIRCUIT BREAKER FOR MAIN POWER SUPPLY

- 2.2.5.3. FUSE CAPACITY AND NAME OF CIRCUIT

- 2.2.6. DOOR POCKET

- 2.2.7. ASHTRAY

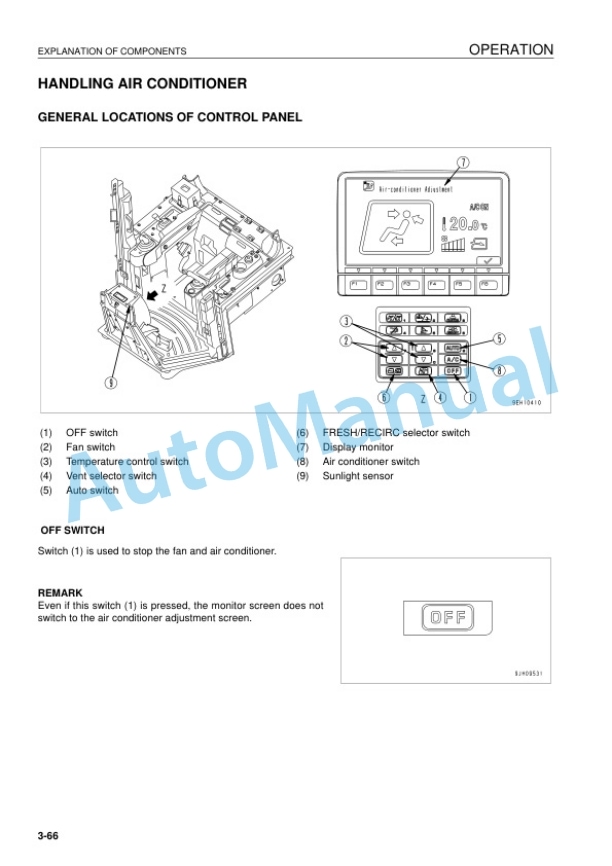

- 2.2.8. HANDLING AIR CONDITIONER

- 2.2.8.1. GENERAL LOCATIONS OF CONTROL PANEL

- 2.2.8.2. METHOD OF OPERATION

- 2.2.8.3. PRECAUTIONS WHEN USING AIR CONDITIONER

- 2.2.8.4. INSPECTION AND MAINTENANCE OF AIR CONDITIONER EQUIPPED MACHINE

- 2.3. OPERATION

- 2.3.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 2.3.1.1. WALKAROUND CHECK

- 2.3.1.2. CHECK BEFORE STARTING

- 2.3.1.3. ADJUSTMENT

- 2.3.1.4. OPERATIONS AND CHECKS BEFORE STARTING ENGINE

- 2.3.2. STARTING ENGINE

- 2.3.2.1. NORMAL STARTING

- 2.3.2.2. STARTING IN COLD WEATHER

- 2.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 2.3.3.1. WARMING UP OPERATIONS

- 2.3.3.2. IN COLD AREAS

- 2.3.4. STOPPING ENGINE

- 2.3.5. MOVING MACHINE

- 2.3.6. STOPPING MACHINE

- 2.3.7. SHIFTING GEAR

- 2.3.8. SHIFTING BETWEEN FORWARD AND REVERSE

- 2.3.9. STEERING MACHINE

- 2.3.9.1. NORMAL TURNING

- 2.3.9.2. TURNING WHILE DESCENDING A SLOPE

- 2.3.10. PRECAUTIONS FOR OPERATION

- 2.3.10.1. PAY ATTENTION TO GAUGES

- 2.3.10.2. PERMISSIBLE WATER DEPTH

- 2.3.10.3. PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS

- 2.3.10.4. PRECAUTIONS ON SLOPE

- 2.3.10.5. METHOD OF USING BRAKES

- 2.3.10.6. PROHIBITED TO KEEP THE DOOR OPEN DURING OPERATIONS

- 2.3.10.7. IT IS PROHIBITED TO MODIFY THE CAB GLASS IN ANY WAY THAT WILL OBSTRUCT THE VIEW

- 2.3.11. PARKING MACHINE

- 2.3.12. CHECK AFTER STOPPING ENGINE

- 2.3.13. CHECK AFTER FINISHING WORK

- 2.3.14. LOCKING

- 2.3.15. RIPPER OPERATION

- 2.3.15.1. EFFECTIVE METHOD OF USE

- 2.3.15.2. DIGGING UP BOULDERS OR ROCKBED

- 2.3.15.3. OPERATING ON SLOPES

- 2.3.15.4. METHOD OF OPERATING PIN PULLER

- 2.3.16. OPERATING METHOD FOR RIPPING OPERATIONS

- 2.3.16.1. BASIC OPERATING METHOD

- 2.3.16.2. RIPPING BY CLIFFS

- 2.3.16.3. RIPPING BY SLOPE FACES

- 2.3.16.4. DIGGING UP BOULDERS

- 2.3.16.5. PRECAUTIONS WHEN RIPPING

- 2.3.17. WORK POSSIBLE USING BULLDOZER

- 2.3.17.1. DOZING

- 2.3.17.2. SMOOTHING

- 2.3.17.3. CUTTING INTO HARD OR FROZEN GROUND OR DITCHING

- 2.3.17.4. FELLING TREES, REMOVING STUMPS

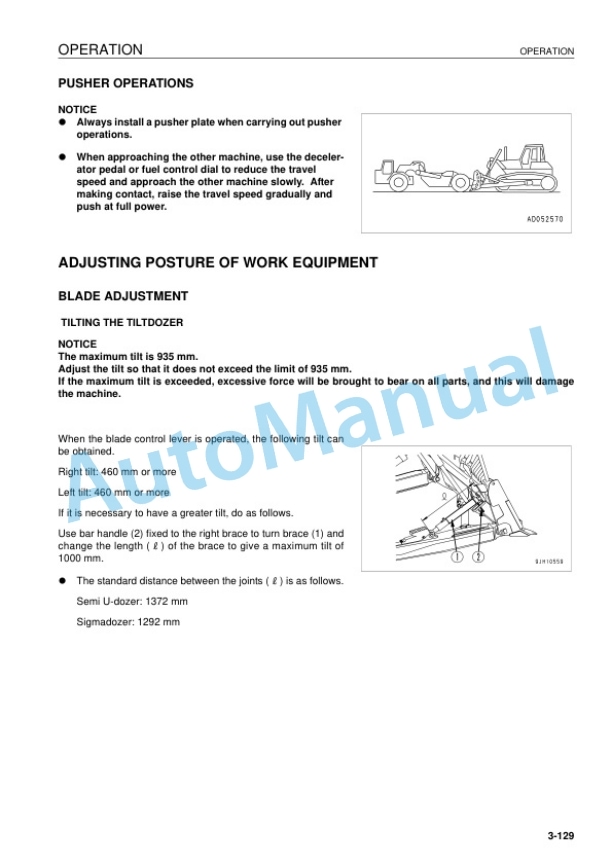

- 2.3.17.5. PUSHER OPERATIONS

- 2.3.18. ADJUSTING POSTURE OF WORK EQUIPMENT

- 2.3.18.1. BLADE ADJUSTMENT

- 2.3.18.2. METHOD OF ANGLING BLADE

- 2.3.18.3. ADJUSTING TILT AMOUNT

- 2.3.18.4. ADJUSTING RIPPER

- 2.3.18.5. ADJUST ANGLE OF BLADE EDGE

- 2.3.19. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 2.3.19.1. OPERATION METHOD

- 2.3.19.2. INSPECTION AND ADJUSTING

- 2.3.19.3. INSPECTION AND REPAIR

- 2.4. TRANSPORTATION

- 2.4.1. LOADING, UNLOADING WORK

- 2.4.1.1. LOADING

- 2.4.1.2. SECURING MACHINE

- 2.4.1.3. UNLOADING

- 2.4.2. METHOD OF LIFTING MACHINE

- 2.4.3. PRECAUTIONS FOR TRANSPORTATION

- 2.4.4. TRAVELING ON ROADS

- 2.4.5. REMOVAL OF CAB

- 2.5. COLD WEATHER OPERATION

- 2.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 2.5.1.1. FUEL AND LUBRICANTS

- 2.5.1.2. COOLANT

- 2.5.1.3. BATTERY

- 2.5.2. AFTER COMPLETION OF WORK

- 2.5.3. AFTER COLD WEATHER

- 2.6. LONGTERM STORAGE

- 2.6.1. BEFORE STORAGE

- 2.6.2. DURING STORAGE

- 2.6.3. AFTER STORAGE

- 2.7. TROUBLESHOOTING

- 2.7.1. AFTER RUNNING OUT OF FUEL

- 2.7.1.1. PROCEDURE FOR BLEEDING AIR

- 2.7.2. METHOD OF TOWING MACHINE

- 2.7.3. IF BATTERY IS DISCHARGED

- 2.7.3.1. REMOVAL AND INSTALLATION OF BATTERY

- 2.7.3.2. PRECAUTIONS WHEN CHARGING BATTERY

- 2.7.3.3. STARTING ENGINE WITH BOOSTER CABLE

- 2.7.4. OTHER TROUBLE

- 2.7.4.1. ELECTRICAL SYSTEM

- 2.7.4.2. ELECTRONIC CONTROL SYSTEM

- 2.7.4.3. CHASSIS

- 2.7.4.4. ENGINE

- 2.7.4.5. POINT OF CONTACT TO TELEPHONE WHEN ERROR OCCURS

- 3. MAINTENANCE

- 3.1. GUIDES TO MAINTENANCE

- 3.2. OUTLINES OF SERVICE

- 3.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 3.2.1.2. FUEL

- 3.2.1.3. COOLANT AND WATER FOR DILUTION

- 3.2.1.4. GREASE

- 3.2.1.5. CARRYING OUT KOWA (Komatsu Oil Wear Analysis)

- 3.2.1.6. STORING OIL AND FUEL

- 3.2.1.7. FILTERS

- 3.2.2. OUTLINE OF ELECTRIC SYSTEM

- 3.3. WEAR PARTS LIST

- 3.3.1. WEAR PARTS LIST

- 3.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 3.4.1. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 3.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 3.5.1. TORQUE LIST

- 3.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 3.6.1. SAFETY CRITICAL PARTS

- 3.7. MAINTENANCE SCHEDULE CHART

- 3.7.1. MAINTENANCE SCHEDULE CHART

- 3.7.1.1. INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)

- 3.7.1.2. WHEN REQUIRED

- 3.7.1.3. CHECK BEFORE STARTING

- 3.7.1.4. EVERY 250 HOURS SERVICE

- 3.7.1.5. EVERY 500 HOURS SERVICE

- 3.7.1.6. EVERY 1000 HOURS SERVICE

- 3.7.1.7. EVERY 2000 HOURS SERVICE

- 3.7.1.8. EVERY 4000 HOURS SERVICE

- 3.7.1.9. EVERY 8000 HOURS SERVICE

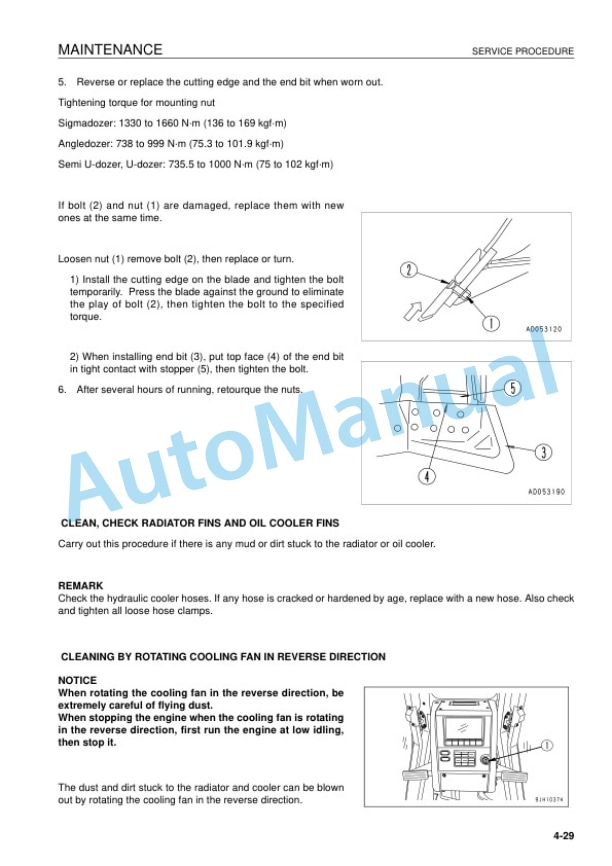

- 3.8. SERVICE PROCEDURE

- 3.8.1. INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)

- 3.8.2. WHEN REQUIRED

- 3.8.3. CHECK BEFORE STARTING

- 3.8.4. EVERY 250 HOURS SERVICE

- 3.8.5. EVERY 500 HOURS SERVICE

- 3.8.6. EVERY 1000 HOURS SERVICE

- 3.8.7. EVERY 2000 HOURS SERVICE

- 3.8.8. EVERY 4000 HOURS SERVICE

- 3.8.9. EVERY 8000 HOURS SERVICE

- 4. SPECIFICATIONS

- 4.1. SPECIFICATIONS

- 5. ATTACHMENTS, OPTIONS

- 5.1. GENERAL PRECAUTIONS

- 5.1.1. PRECAUTIONS RELATED TO SAFETY

- 5.2. INTRODUCTION OF ATTACHMENTS AND OPTIONS

- 5.2.1. INTRODUCTION OF ATTACHMENTS AND OPTIONS

- 5.3. HEADREST, HANDLING

- 5.4. CAP WITH LOCK, HANDLING

- 5.4.1. METHOD OF OPENING AND CLOSING CAP WITH LOCK

- 5.5. PROCEDURE FOR SELECTING RIPPER POINT

- 5.5.1. PROCEDURE FOR SELECTING RIPPER POINT

- 5.6. HANDLING MACHINES EQUIPPED WITH KOMTRAX

- 5.6.1. BASIC PRECAUTIONS

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800